Print Stretched Vertically(height)

Posted by Abdul Mannan

|

Print Stretched Vertically(height) January 17, 2019 02:12PM |

Registered: 5 years ago Posts: 15 |

Hello. I had made prusa i3 and facing some problem. The lead screw diameter 8mm with 2mm pitch. I had A4988 stepper driver installed in all motor with 1/16 Microstepping . The AXIS_STEPS_PER_UNIT { X/80, Y/80, Z/1600, E/103.2 }. I had calculated it with prusa calculator.For calculating steps.. I had printed calibrated cube(20mm x 20mm x 20mm) and it turns out as seen in pictures. I think that the stretch increase the gap between each line. I have also upload Marlin Firmware. I hope if anyone can help me out. Thank you

Edited 1 time(s). Last edit at 01/17/2019 03:21PM by Abdul Mannan.

Edited 1 time(s). Last edit at 01/17/2019 03:21PM by Abdul Mannan.

|

Re: Print Stretched Vertically(height) January 17, 2019 04:56PM |

Registered: 9 years ago Posts: 465 |

1600 steps/mm is right for a 2mm pitch/lead screw, driven by a 1.8degree/step motor at 16X microstepping.

200 steps/revolution * 16x microstepping / 2mm = 1600 steps/mm These lead screws do exist, but aren't very common from what I've seen.

For my I3 printer, I had 0.8mm pitched screws (5mmx0.8mm pitch) which needed to be set up with:

200 steps/mm * 16x microstepping / 0.8mm = 4000steps/mm. If I tol those that they were 1600 steps/mm, prints would be squashed to less than 1/2 of their intended sizes.

For my other printers, the Z screw is 2mm pitch, 4 start for an 8mm lead. these are the most common lead screws that I've seen for printers. In that case:

200 steps/revolution * 16x microstepping / 8mm = 400 steps/mm. If these are your lead screws, your print would end up 4X as tall as it should be, except that the layers wouldn't sit right.

You've done something wrong with your Z steps/mm.

For your X/Y steps/mm, 80 is a bit of an oversimplification, based on the 20 tooth pulley having 20 teeth at 2mm each. Though the number of teeth SHOULD tell the story, it does not, because the belt radius itself adds some travel to the belt when it goes around the pulley. I found that my steps/mm were a little under the nominal to get the dimensions that I expected.

200 steps/revolution * 16x microstepping / 2mm = 1600 steps/mm These lead screws do exist, but aren't very common from what I've seen.

For my I3 printer, I had 0.8mm pitched screws (5mmx0.8mm pitch) which needed to be set up with:

200 steps/mm * 16x microstepping / 0.8mm = 4000steps/mm. If I tol those that they were 1600 steps/mm, prints would be squashed to less than 1/2 of their intended sizes.

For my other printers, the Z screw is 2mm pitch, 4 start for an 8mm lead. these are the most common lead screws that I've seen for printers. In that case:

200 steps/revolution * 16x microstepping / 8mm = 400 steps/mm. If these are your lead screws, your print would end up 4X as tall as it should be, except that the layers wouldn't sit right.

You've done something wrong with your Z steps/mm.

For your X/Y steps/mm, 80 is a bit of an oversimplification, based on the 20 tooth pulley having 20 teeth at 2mm each. Though the number of teeth SHOULD tell the story, it does not, because the belt radius itself adds some travel to the belt when it goes around the pulley. I found that my steps/mm were a little under the nominal to get the dimensions that I expected.

|

Re: Print Stretched Vertically(height) January 21, 2019 07:41PM |

Registered: 6 years ago Posts: 1,863 |

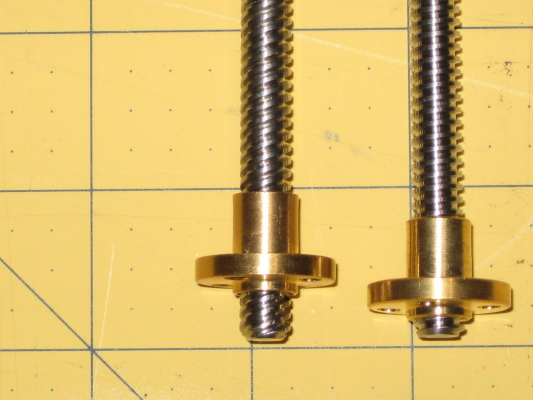

This is an easy way to see what lead screw you have.

Drop the Nozzle to the Bed. Mark the position of the Lead screw Coupler set screw. Rotate the coupler 360 degrees and measure the distance the nozzle traveled upward.

If the Nozzle traveled 2mm you have a T8-2. If the Nozzle traveled 8mm you have a T8-8.

Image of both styles lead screws nuts were both turned one complete revolution.

Left is a T8-8 4 Start - Right is a T8-2 Single Start.

Actually you can see the Pitch of both lead screws.

Edited 3 time(s). Last edit at 01/21/2019 07:43PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Drop the Nozzle to the Bed. Mark the position of the Lead screw Coupler set screw. Rotate the coupler 360 degrees and measure the distance the nozzle traveled upward.

If the Nozzle traveled 2mm you have a T8-2. If the Nozzle traveled 8mm you have a T8-8.

Image of both styles lead screws nuts were both turned one complete revolution.

Left is a T8-8 4 Start - Right is a T8-2 Single Start.

Actually you can see the Pitch of both lead screws.

Edited 3 time(s). Last edit at 01/21/2019 07:43PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Print Stretched Vertically(height) January 21, 2019 08:48PM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Print Stretched Vertically(height) January 22, 2019 02:27AM |

Registered: 6 years ago Posts: 1,007 |

NO !Quote

SupraGuy

..... Though the number of teeth SHOULD tell the story, it does not, because the belt radius itself adds some travel to the belt when it goes around the pulley. I found that my steps/mm were a little under the nominal to get the dimensions that I expected.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.