Extruder woes (not extruding correct amount under pressure)

Posted by Ohmarinus

|

Extruder woes (not extruding correct amount under pressure) April 17, 2019 05:04AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi all, I am having the strangest issue!

My printer has been running quite well for years now but I haven't used it a lot. About 2 times per month. Never a single issue, always constant extrusion, no electronical noise, etc.

Lately my extrusion has become very problematic. I extrude for 100mm but the results are all over the chart, here a list of the extrusion results I got:

Anyway, I've also lubricated the bowden tube and it didn't make a difference.

So now I'm about to change out my extruder motor to see if that's the problem, I also checked all the bearings in my extruder and they do not seem to cause any issues. I did notice however that when printing, the motor sometimes couldn't push the filament through when printing infill and it would shoot back the extruder motor with force.

Edit:

Changed the motor, it didn't make a difference. So the issue is down to either the hotend OR the Ramps board. Extruding 100mm results in extrusion of 90.29mm of filament.

The issue is clearly happening when I extrude with pressure. It is missing about 10% of it's steps but I do not hear it missing any steps.

If changing out the extruder motor doesn't fix it, then I might have to change the hotend, but it's been running fine and upon inspection I have not found any issues such as a blockage, a break in the parts, or anything else.

If even changing the hotend doesn't work, I guess I'll have to ditch my Premium quality Ramps board and install a crappy Ramps board to see if there is maybe an electronic issue but I doubt that. All the systems seem to work fine individually, it's mainly causing issues when I am both extruding and pushing it through the hotend. Which is strange as I have made sure there are absolutely no blockages and the machine's hotend and electronics have been unaltered in years.

Is there anyone that's a better detective than me? And am I overseeing something here? I'm pretty much at rock bottom. I need to finish printing parts for my new 3rd machine because I need to print parts for my job...

Some technical data:

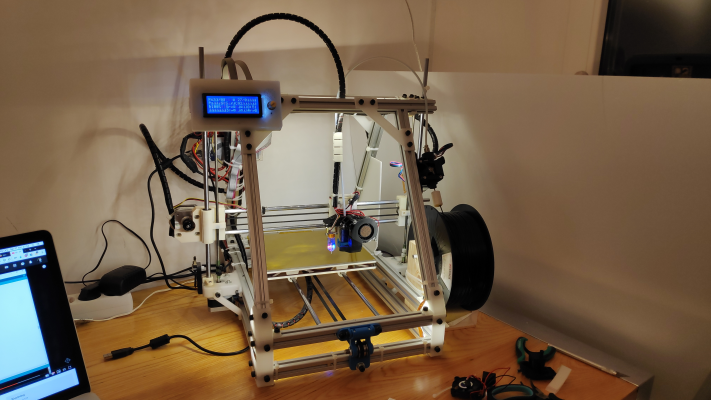

MendelMax 1.6 (self iterated)

G3D Ramps 1.4 [reprap.org] with stepper board cooling and fan breakout board

Merlin Hotend [www.reprapdiscount.com]

Extruder design: Airtrippers Bowden [www.thingiverse.com]

Time to work..

Edited 2 time(s). Last edit at 04/17/2019 05:51AM by Ohmarinus.

http://www.marinusdebeer.nl/

My printer has been running quite well for years now but I haven't used it a lot. About 2 times per month. Never a single issue, always constant extrusion, no electronical noise, etc.

Lately my extrusion has become very problematic. I extrude for 100mm but the results are all over the chart, here a list of the extrusion results I got:

100mm extrude WHITE ReForm FormFutura PLA 1.75mm 210ºC Old stepper driver: 93.73 98.65 96.10 Maybe the stepper driver is broken and it's missing steps? New stepper driver: 96.78 96.38 96.08 96.00 94.28 97.14 96.38 97.10 Results seem the same on both stepper drivers, varying equally. After removing the hotend's cooler airflow guide: 80.15 88.70 Maybe the filament plugs up in the hotend now? After hot & cold pulls to remove potential blockage in hotend, nothing was blocking it and I have 100% surely cleaned the entire hotend (multiple times): 66.99 97.42 No improvement. Without hotend connected, free extrusion in the air (I had previously set the steps/mm while extruding filament through the hotend, so I had to raise the steps/mm to get the correct extrusion length, but without any backpressure, suddenly it extrudes too much): 108.85 109.68 109.30 109.18 Adjusted steps/mm to correct value again After setting correct values in free extrusion: 100MM YES Now try extruding through hot hotend again to see if it still extrudes 100mm: 89.78 89.33 87.90 81.73 85.00 NOPE. Maybe try a different kind of filament? BLACK Premium FormFutura PLA 1.75mm 210ºC 89.32 88.81 Same results...

Anyway, I've also lubricated the bowden tube and it didn't make a difference.

So now I'm about to change out my extruder motor to see if that's the problem, I also checked all the bearings in my extruder and they do not seem to cause any issues. I did notice however that when printing, the motor sometimes couldn't push the filament through when printing infill and it would shoot back the extruder motor with force.

Edit:

Changed the motor, it didn't make a difference. So the issue is down to either the hotend OR the Ramps board. Extruding 100mm results in extrusion of 90.29mm of filament.

The issue is clearly happening when I extrude with pressure. It is missing about 10% of it's steps but I do not hear it missing any steps.

If changing out the extruder motor doesn't fix it, then I might have to change the hotend, but it's been running fine and upon inspection I have not found any issues such as a blockage, a break in the parts, or anything else.

If even changing the hotend doesn't work, I guess I'll have to ditch my Premium quality Ramps board and install a crappy Ramps board to see if there is maybe an electronic issue but I doubt that. All the systems seem to work fine individually, it's mainly causing issues when I am both extruding and pushing it through the hotend. Which is strange as I have made sure there are absolutely no blockages and the machine's hotend and electronics have been unaltered in years.

Is there anyone that's a better detective than me? And am I overseeing something here? I'm pretty much at rock bottom. I need to finish printing parts for my new 3rd machine because I need to print parts for my job...

Some technical data:

MendelMax 1.6 (self iterated)

G3D Ramps 1.4 [reprap.org] with stepper board cooling and fan breakout board

Merlin Hotend [www.reprapdiscount.com]

Extruder design: Airtrippers Bowden [www.thingiverse.com]

Time to work..

Edited 2 time(s). Last edit at 04/17/2019 05:51AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) April 17, 2019 06:07AM |

Registered: 9 years ago Posts: 752 |

Maybe the nozzle is partially blocked? Did you try heating up the hotend while pulling the filament out before it reaches the temperature? This will pull out all the filament including particles that may have collected in there. If you don't use your 3D printer for longer periods, it may collect dust on the filament spool and draw it into the nozzle. I had something similar with older filament. Also try new filament, maybe the softeners in the plastic have gone bad. Also check the filament where the hobbed bolt latches onto the filament. Does it show any tear out?

Is the temperature stable during printing, when it does infill is the temperature dropping? Do you use a part cooling fan, is it directed at the nozzle/heater block?

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

Is the temperature stable during printing, when it does infill is the temperature dropping? Do you use a part cooling fan, is it directed at the nozzle/heater block?

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Extruder woes (not extruding correct amount under pressure) April 17, 2019 01:34PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

imqqmi

Maybe the nozzle is partially blocked? Did you try heating up the hotend while pulling the filament out before it reaches the temperature? This will pull out all the filament including particles that may have collected in there. If you don't use your 3D printer for longer periods, it may collect dust on the filament spool and draw it into the nozzle. I had something similar with older filament. Also try new filament, maybe the softeners in the plastic have gone bad. Also check the filament where the hobbed bolt latches onto the filament. Does it show any tear out?

Is the temperature stable during printing, when it does infill is the temperature dropping? Do you use a part cooling fan, is it directed at the nozzle/heater block?

Yes, I can look through the nozzle, zero blockage. I also use a filament filter, so no dust can go into the system

I performed a 'warm pull' (self-invented), which means that when I do a filament pull to get debris out, I do this at 105ºC, which causes the filament to remove itself 100% from the nozzle. I can see the whole inside shape of the hotend and it pulls everything with it if there's anything inside.

I performed a 'warm pull' (self-invented), which means that when I do a filament pull to get debris out, I do this at 105ºC, which causes the filament to remove itself 100% from the nozzle. I can see the whole inside shape of the hotend and it pulls everything with it if there's anything inside.Part cooling fan, not directed at the nozzle. It is located on the back of the extruder carriage and there is a small nozzle directing the air over the printed part, doesn't hit the hotend, not even while printing. But this fan is off when doing a test-extrude.

Hotend heatbreak fan, with a guide, so it doesn't cool down the heatblock.

Filament path is safe, no grindings or any filament between the teeth.

It's a mystery! Otherwise I wouldn't have posted here, between the 6+years of experience that I have with DIY 3D-printers

Edited 2 time(s). Last edit at 04/17/2019 03:25PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) April 17, 2019 03:50PM |

Registered: 6 years ago Posts: 23 |

I had a similar problem today. I replaced the nozzle (.4mm) Direct drive Mk8 Extruder. Pushing the filament through by hand I noticed slight puffing of the extruded filament. My experience tells me that puffing filament has some moisture in it. Slight moisture can cause steaming inside the nozzle and cause the pressure to build up and as the filament is pushed through, and the pressure is relieved randomly. (Puffs) excess nozzle pressure will cause the filament to slip on the drive sprocket thus giving random extrusion. I changed to another filament and now the extrusion rate is more consistent.

|

Re: Extruder woes (not extruding correct amount under pressure) April 17, 2019 04:01PM |

Registered: 9 years ago Posts: 752 |

Ok, it's just to rule out the basics since you didn't tell us (everything) what you tried/checked already  . So without feeding filament into the nozzle it extrudes the right amount, and with it feeding through the nozzle (under pressure) it will be 10% short?

. So without feeding filament into the nozzle it extrudes the right amount, and with it feeding through the nozzle (under pressure) it will be 10% short?

I love a mystery, so thanks for sharing

Did you check motor current? Replace the stepstick? Check voltage stability under load? Replace the ramps board? Does the extruder feedrate have any influence on the amount extruded? Is the hobbed bolt or gears slipping?

Do you use a bowden tube? Some pre tensioning is needed (extra length fed) before the requested length translates into extruded length.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

. So without feeding filament into the nozzle it extrudes the right amount, and with it feeding through the nozzle (under pressure) it will be 10% short?

. So without feeding filament into the nozzle it extrudes the right amount, and with it feeding through the nozzle (under pressure) it will be 10% short?I love a mystery, so thanks for sharing

Did you check motor current? Replace the stepstick? Check voltage stability under load? Replace the ramps board? Does the extruder feedrate have any influence on the amount extruded? Is the hobbed bolt or gears slipping?

Do you use a bowden tube? Some pre tensioning is needed (extra length fed) before the requested length translates into extruded length.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Extruder woes (not extruding correct amount under pressure) April 17, 2019 04:24PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

G3DBuilder

I had a similar problem today. I replaced the nozzle (.4mm) Direct drive Mk8 Extruder. Pushing the filament through by hand I noticed slight puffing of the extruded filament. My experience tells me that puffing filament has some moisture in it. Slight moisture can cause steaming inside the nozzle and cause the pressure to build up and as the filament is pushed through, and the pressure is relieved randomly. (Puffs) excess nozzle pressure will cause the filament to slip on the drive sprocket thus giving random extrusion. I changed to another filament and now the extrusion rate is more consistent.

Yes, I actually bought new filament because I thought maybe the filament was the issue

it is 100% brand new high quality filament without moisture. It also sits in a special drybox with a drying agent..

it is 100% brand new high quality filament without moisture. It also sits in a special drybox with a drying agent..Quote

imqqmi

Ok, it's just to rule out the basics since you didn't tell us (everything) what you tried/checked already. So without feeding filament into the nozzle it extrudes the right amount, and with it feeding through the nozzle (under pressure) it will be 10% short?

I love a mystery, so thanks for sharing

Did you check motor current? Replace the stepstick? Check voltage stability under load? Replace the ramps board? Does the extruder feedrate have any influence on the amount extruded? Is the hobbed bolt or gears slipping?

Do you use a bowden tube? Some pre tensioning is needed (extra length fed) before the requested length translates into extruded length.

Thanks, indeed, the next step will be to switch out the Ramps + Arduino Mega.. Sadly.

The feedrate was also checked within variation. So replacing the logic board would be my last straw after placing back the hotend. The only thing I can do is try to rearrange all the wires of the whole machine, in case all of a sudden there is some kind of digital noise or interference, but the machine remains unchanged for 5 years now so I find it hard to believe that it's going to develop an issue like this all of a sudden..

I'll update accordingly.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) April 18, 2019 03:53AM |

Admin Registered: 11 years ago Posts: 3,096 |

I don't get it, I have cleaned up the hotend, completely took away any possible problem and it still extrudes around 88mm (86 to 88mm at random) when telling the machine to extrude 100mm. Without extruding through the hotend it extrudes 100mm perfectly and there is no slippage, dirt, etc. I have absolutely 100% taken care of all the other factors. Even at superslow and superfast extrusion rates, it's always around 88mm that it feeds.

I changed everything but the ramps board, can it really be the problem?

Edited 2 time(s). Last edit at 04/18/2019 04:01AM by Ohmarinus.

http://www.marinusdebeer.nl/

I changed everything but the ramps board, can it really be the problem?

Edited 2 time(s). Last edit at 04/18/2019 04:01AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) April 18, 2019 08:46AM |

Registered: 9 years ago Posts: 752 |

Did you try feeding filament manually through the nozzle to see if it runs smoothly and doesn't take too much force to push it through? Did you check the nozzle temperature with an external thermocouple that's proven to be within about 2 degrees C accurate? Put it into the hot end all the way down.

If you use a Bowden the tube adds significant amount of springiness (though 1.75mm maybe less so than 2.85/3mm). It needs to build up back pressure. Did you try extruding some, then immediately extrude the set 100mm amount? This would account for the pre-tensioning of the filemant. Did you measure the filament going into the hobbed bolt vs the amount coming out of it, at the end or at the start of the bowden tube?

Did you try printing a test object to see if extrusion is correct? So far you only tried calibrating the e steps per mm (as far as I know).

For example, I need to extrude about 6mm before starting a print due to my 600mm 3mm diameter bowden tube to pre tension the filament or the first layer isn't going to start properly.

If you put pressure on the filament coming out of the cold end manually, does it show the same results of shorter than requested length of filament? Could you feel the motor slipping, skipping etc?

Is there any change in method when you extrude 100mm without nozzle and with nozzle on? If you use gcode scrips could there be a difference, maybe gcode that changes the extrusion rate that's not in the non nozzle script?

If none of the above, is there any way you could measure the number of step pulses on the step stick? If you've got an oscilloscope you could try to see if the actual amount of steps are sent to the step pin of the extruder stepstick.

Did you try a ramps firmware reset to factory defaults? Did you do any recent updates? Older versions?

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

If you use a Bowden the tube adds significant amount of springiness (though 1.75mm maybe less so than 2.85/3mm). It needs to build up back pressure. Did you try extruding some, then immediately extrude the set 100mm amount? This would account for the pre-tensioning of the filemant. Did you measure the filament going into the hobbed bolt vs the amount coming out of it, at the end or at the start of the bowden tube?

Did you try printing a test object to see if extrusion is correct? So far you only tried calibrating the e steps per mm (as far as I know).

For example, I need to extrude about 6mm before starting a print due to my 600mm 3mm diameter bowden tube to pre tension the filament or the first layer isn't going to start properly.

If you put pressure on the filament coming out of the cold end manually, does it show the same results of shorter than requested length of filament? Could you feel the motor slipping, skipping etc?

Is there any change in method when you extrude 100mm without nozzle and with nozzle on? If you use gcode scrips could there be a difference, maybe gcode that changes the extrusion rate that's not in the non nozzle script?

If none of the above, is there any way you could measure the number of step pulses on the step stick? If you've got an oscilloscope you could try to see if the actual amount of steps are sent to the step pin of the extruder stepstick.

Did you try a ramps firmware reset to factory defaults? Did you do any recent updates? Older versions?

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Extruder woes (not extruding correct amount under pressure) April 18, 2019 10:33AM |

Registered: 5 years ago Posts: 10 |

I would look at this another way before I started replacing electronics.

You say that the stepper extrudes 100mm when not under pressure (nozzle off) but only extrudes 90mm when under pressure.

I would check what the stepper thinks it has extruded by checking the exact number of revolutions of the stepper motor in both cases. Mark the end of the stepper motor shaft or something. I have seen little discs somewhere that you can attach to the end of the shaft.

If the measurements are the same in both cases then your electronics are OK and the filament is probably slipping on the hobbed bolt/gear (as IMQQMI mentioned above) or some other filament/heat/nozzle related problem.

Unless I am missing something.......

You say that the stepper extrudes 100mm when not under pressure (nozzle off) but only extrudes 90mm when under pressure.

I would check what the stepper thinks it has extruded by checking the exact number of revolutions of the stepper motor in both cases. Mark the end of the stepper motor shaft or something. I have seen little discs somewhere that you can attach to the end of the shaft.

If the measurements are the same in both cases then your electronics are OK and the filament is probably slipping on the hobbed bolt/gear (as IMQQMI mentioned above) or some other filament/heat/nozzle related problem.

Unless I am missing something.......

|

Re: Extruder woes (not extruding correct amount under pressure) April 18, 2019 10:42AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

imqqmi

Did you try feeding filament manually through the nozzle to see if it runs smoothly and doesn't take too much force to push it through? Did you check the nozzle temperature with an external thermocouple that's proven to be within about 2 degrees C accurate? Put it into the hot end all the way down.

If you use a Bowden the tube adds significant amount of springiness (though 1.75mm maybe less so than 2.85/3mm). It needs to build up back pressure. Did you try extruding some, then immediately extrude the set 100mm amount? This would account for the pre-tensioning of the filemant. Did you measure the filament going into the hobbed bolt vs the amount coming out of it, at the end or at the start of the bowden tube?

Did you try printing a test object to see if extrusion is correct? So far you only tried calibrating the e steps per mm (as far as I know).

For example, I need to extrude about 6mm before starting a print due to my 600mm 3mm diameter bowden tube to pre tension the filament or the first layer isn't going to start properly.

If you put pressure on the filament coming out of the cold end manually, does it show the same results of shorter than requested length of filament? Could you feel the motor slipping, skipping etc?

Is there any change in method when you extrude 100mm without nozzle and with nozzle on? If you use gcode scrips could there be a difference, maybe gcode that changes the extrusion rate that's not in the non nozzle script?

If none of the above, is there any way you could measure the number of step pulses on the step stick? If you've got an oscilloscope you could try to see if the actual amount of steps are sent to the step pin of the extruder stepstick.

Did you try a ramps firmware reset to factory defaults? Did you do any recent updates? Older versions?

I didn't think anyone would come up with such a detailed reaction, but I can assure you, that with all my years of experience, these were the first things I did

And yes, I just used manual gcode commands for extrusion with a set feedrate. I also tried feeding it manually, and yes I measured both incoming and outgoing amount of filament with the bowden system disconnected, so the extruder ran free while I had cold extrusion allowed through:

M302 S0 ; always allow extrusion (disable checking)

I do have an osc, but sadly it's not good enough to measure the pulses.. And I also tried out the older firmware, actually I updated the firmware because the issue suddenly happened without having done anything to the system. Then I went back to the old, still there, so now back to the new firmware again.

Have been printing multiple test objects, after the upgrade, one came out fine, some parts printed well partially, and others just printed completely messed up.

I'll replace the motherboard now and will see if anything improves!

Update:

So I replaced the motherboard completely and nothing has changed. Still around 88mm of extrusion when extruding through the hotend and exactly 100mm perfectly when the extruder runs freely.

Now I'm going to try a different hotend, but I cannot imagine this would fix it. Also went through the entire firmware to see if anything is off. Tried the old firmware again, nothing changed.

Maybe I should replace the PSU.. No clue. The only thing I can do is rearrange all the wiring. But as nothing has changed I cannot imagine this being the problem. The machine runs perfectly, it's only the extrusion that fails.

Edited 1 time(s). Last edit at 04/18/2019 04:01PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) April 19, 2019 05:51AM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay I've tried 3 different hotends (J-head, Merlin and E3D v6), 2 extruder motors (both new), rebuilt the extruder twice (no slippage, no filled up teeth, no loss of compression and consistent extrusion), completely changed the motherboard (replaced both Ramps 1.4 and the Arduino Mega), replaced the stepper driver 3 times on both Ramps, tried 3 versions of Marlin firmware (the first one I ran on for years from 2014, one from 2016 and the newest Marlin) and now I'm lost.

Lubricated the bowden cable, inspected every inch.

Right now I have put on the E3D V6 hotend that was supposed to be for my new printer, still no reliable extrusion. I have no clue what's wrong. It now extrudes a little more than 88mm, around 91~92mm but still not the 100mm I get when I run the extruder freely.

I have used 2 pieces of software to give the extrusion command, tried two different computers with USB, tried to put the extrusion command on an SD card in a gcode file.. I can't find the issue.

Can it be the PSU? I have tried two differens PSU's, no difference. I think the machine is haunted.

Oh and 3 different types of filament, different brands, etc. All stored in a good way, low humidity, no offgassing when extruding.

Edited 2 time(s). Last edit at 04/19/2019 06:05AM by Ohmarinus.

http://www.marinusdebeer.nl/

Lubricated the bowden cable, inspected every inch.

Right now I have put on the E3D V6 hotend that was supposed to be for my new printer, still no reliable extrusion. I have no clue what's wrong. It now extrudes a little more than 88mm, around 91~92mm but still not the 100mm I get when I run the extruder freely.

I have used 2 pieces of software to give the extrusion command, tried two different computers with USB, tried to put the extrusion command on an SD card in a gcode file.. I can't find the issue.

Can it be the PSU? I have tried two differens PSU's, no difference. I think the machine is haunted.

Oh and 3 different types of filament, different brands, etc. All stored in a good way, low humidity, no offgassing when extruding.

Edited 2 time(s). Last edit at 04/19/2019 06:05AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) April 19, 2019 10:24AM |

Registered: 7 years ago Posts: 619 |

Quote

Ohmarinus

Okay I've tried 3 different hotends (J-head, Merlin and E3D v6), 2 extruder motors (both new), rebuilt the extruder twice (no slippage, no filled up teeth, no loss of compression and consistent extrusion), completely changed the motherboard (replaced both Ramps 1.4 and the Arduino Mega), replaced the stepper driver 3 times on both Ramps, tried 3 versions of Marlin firmware (the first one I ran on for years from 2014, one from 2016 and the newest Marlin) and now I'm lost.

Lubricated the bowden cable, inspected every inch.

Right now I have put on the E3D V6 hotend that was supposed to be for my new printer, still no reliable extrusion. I have no clue what's wrong. It now extrudes a little more than 88mm, around 91~92mm but still not the 100mm I get when I run the extruder freely.

I have used 2 pieces of software to give the extrusion command, tried two different computers with USB, tried to put the extrusion command on an SD card in a gcode file.. I can't find the issue.

Can it be the PSU? I have tried two differens PSU's, no difference. I think the machine is haunted.

Oh and 3 different types of filament, different brands, etc. All stored in a good way, low humidity, no offgassing when extruding.

Sigh. I have a heavily modified Anet A8 that was absolutely perfect for about a year. Then (poof!) I have the same problems you have. Irregular extrusions, weird first layer, poor quality prints. I have tried all that you have too. Still, my perfect printer will not do well anymore. I am down to looking at bearings to see if the movements are putting the hot end in a bad place. It has gotten so bad that I am considering scrapping the whole printer and starting over. I work in the tech industry and over the years have seen several "possessed" devices that will not work even after replacing everything in the box. They become the home of Maxwell's Demon and cannot be reclaimed...

I feel your pain, I really liked this printer.

I think that I'll tear mine down into its component pieces and rebuild from the bottom up. Maybe "Max" will move on if left homeless for a while.

I think that I'll tear mine down into its component pieces and rebuild from the bottom up. Maybe "Max" will move on if left homeless for a while.DLC

Edited 1 time(s). Last edit at 04/19/2019 10:25AM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Extruder woes (not extruding correct amount under pressure) April 20, 2019 03:09AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

dlc60

Quote

Ohmarinus

Okay I've tried 3 different hotends (J-head, Merlin and E3D v6), 2 extruder motors (both new), rebuilt the extruder twice (no slippage, no filled up teeth, no loss of compression and consistent extrusion), completely changed the motherboard (replaced both Ramps 1.4 and the Arduino Mega), replaced the stepper driver 3 times on both Ramps, tried 3 versions of Marlin firmware (the first one I ran on for years from 2014, one from 2016 and the newest Marlin) and now I'm lost.

Lubricated the bowden cable, inspected every inch.

Right now I have put on the E3D V6 hotend that was supposed to be for my new printer, still no reliable extrusion. I have no clue what's wrong. It now extrudes a little more than 88mm, around 91~92mm but still not the 100mm I get when I run the extruder freely.

I have used 2 pieces of software to give the extrusion command, tried two different computers with USB, tried to put the extrusion command on an SD card in a gcode file.. I can't find the issue.

Can it be the PSU? I have tried two differens PSU's, no difference. I think the machine is haunted.

Oh and 3 different types of filament, different brands, etc. All stored in a good way, low humidity, no offgassing when extruding.

Sigh. I have a heavily modified Anet A8 that was absolutely perfect for about a year. Then (poof!) I have the same problems you have. Irregular extrusions, weird first layer, poor quality prints. I have tried all that you have too. Still, my perfect printer will not do well anymore. I am down to looking at bearings to see if the movements are putting the hot end in a bad place. It has gotten so bad that I am considering scrapping the whole printer and starting over. I work in the tech industry and over the years have seen several "possessed" devices that will not work even after replacing everything in the box. They become the home of Maxwell's Demon and cannot be reclaimed...

I feel your pain, I really liked this printer.I think that I'll tear mine down into its component pieces and rebuild from the bottom up. Maybe "Max" will move on if left homeless for a while.

DLC

Oh man.. I feel your pain. But... I can't give up! Haha, I need this one for work.. I still think cable management might play a role, maybe there is some unexplainable force field in my room. Maybe my neighbors have a new satellite dish receiver, I don't know. Something must have changed in my surroundings.

The only thing I can try is to move the PSU further away from the printer, not too far as it's DC. And try to manage the cables in different ways..

But first I will run the machine with only the extruder connected and leaving all the other parts off of the board.

Update #2:

After completely replacing every part in the machine that has to do with electronics and extrusion I can say that my 3D-printer has gotten a new name: Theseus.

It seems the only way to solve the extrusion issues, is by raising the E-steps/mm from the perfectly configured 151mm to 178mm. I do not think this is a healthy number and am doubting if my hotend is still okay. The only other thing I can think of, is that maybe the hotend's nozzle has gotten wider. So as a 'last act' I will, in my most desperate of times replace the nozzle which is a pain in the cunninglinguals and see if that fixes the issue.

I do not expect this to be the issue, since I have measured the thickness of the extruded plastic and have observed it to be a perfect 0.5mm this is completely perfect as the nozzle size is 0.5mm.

Update #3:

The nozzle broke when trying to detach it (while hot). The threads cannot be removed to the Merlin hotend is in the wastebin. Sadly now I have had to completely butcher myself a new hotend mount to accommodate the E3D v6 hotend I had laying around, waiting for the Prusa MK2.5 that I'm building.

This means I do not have a cooler yet, so I have to start from scratch and I'm forced to use the BLtouch I had laying around being all useless. This was a whole day of work with the primitive tools I have (since the 3D-printer doesn't work..).

Right now calibrating, suddenly the printer is losing steps. Does the nightmare ever end? The E3D hotend seems to do 'ok', especially with the mount that I butchered together. Been trying to print a fan holder so that I can cool down the prints but the bracket I designed keeps failing to print because somewhere it loses a few steps on the X-axis fml.

Update #4:

It's back to working condition, the Merlin hotend has been a total shit from the get-go and now that I use the E3D v6 I understand just how bad the old hotend was. The machine is working like a charm now. Using E-steps/mm for tuning as explained in Triffid Hunter's guide for volumetric tuning instead of using the slicing software to change parameters because the E-steps can be changed on the fly and it's way easier to control when changing filaments etc.

For more about my printer and how I 'fixed' it (for now) follow this IMGUR link to the album:

[imgur.com]

Last G29 after squaring the frame and leveling the bed:

Bilinear Leveling Grid:

0 1 2

0 +0.033 -0.045 -0.062

1 +0.014 +0.058 -0.013

2 +0.054 +0.068 -0.019

Edited 9 time(s). Last edit at 04/27/2019 04:47PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Extruder woes (not extruding correct amount under pressure) May 30, 2019 06:42AM |

Registered: 7 years ago Posts: 7 |

From the Ingenio Triana Association, we want to provide information on many problems related to 3D printing and in this case with extrusion through our blog.

[ingenio-triana.blogspot.com]

[ingenio-triana.blogspot.com]

Sorry, only registered users may post in this forum.