Cura setting for layer height.

Posted by dlw

|

Cura setting for layer height. June 04, 2019 04:17PM |

Registered: 6 years ago Posts: 127 |

Changed nozzle to 1mm. Not concerned with appearance so much as strength and faster printing time. Have many to print.

Problem now is the Z axis does not move.

Assuming layer height is the problem.

How is layer height changed in Cura 4?

And, is layer height really the problem?

Z axis worked with .04 nozzle.

Edited 1 time(s). Last edit at 06/04/2019 04:18PM by dlw.

Problem now is the Z axis does not move.

Assuming layer height is the problem.

How is layer height changed in Cura 4?

And, is layer height really the problem?

Z axis worked with .04 nozzle.

Edited 1 time(s). Last edit at 06/04/2019 04:18PM by dlw.

|

Re: Cura setting for layer height. June 04, 2019 04:59PM |

Admin Registered: 11 years ago Posts: 3,096 |

Can it be the axis speed/feedrate is too high? Maybe moving 0.3mm each time was doable but it skips steps with a 1mm movement? What layer height are you using anyway?

Did the layer height change at all?

http://www.marinusdebeer.nl/

Did the layer height change at all?

http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 05, 2019 06:13AM |

Registered: 9 years ago Posts: 752 |

You say 0.04 nozzle, I assume you mean 0.4? If you did the same with layer height, at 0.02 or something, I can understand why the z may not be moving...

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Cura setting for layer height. June 05, 2019 08:55PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 06, 2019 02:54AM |

Admin Registered: 11 years ago Posts: 3,096 |

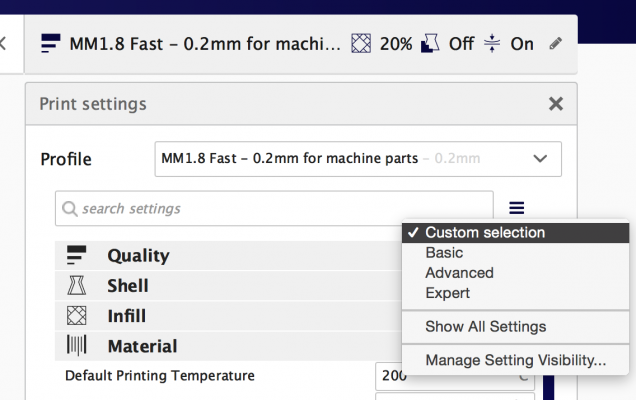

You're probably in 'Basic settings'. So....

Activate expert settings:

Edited 1 time(s). Last edit at 06/06/2019 02:55AM by Ohmarinus.

http://www.marinusdebeer.nl/

Activate expert settings:

Edited 1 time(s). Last edit at 06/06/2019 02:55AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 06, 2019 06:15PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 07, 2019 03:47AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

dlw

I simply do not understand how to make changes in the Settings menu.

The only change that can be made is in Materials.

How is the infill density changed?

Top and bottom thickness.

See attached.

You make the changes in the main window. On the top-right are the icons that you see in my screenshot. You click on the bar that says 'MM1.8 fast..' in my screenshot. It is there where you change everything, so you don't have to go into preferences

http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 07, 2019 09:34AM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 07, 2019 10:30AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

dlw

Thanks Ohmarinus.

The print is about to start.

I will let you know how it goes.

Thanks again,

dlw

Cool, so it worked? I'm curious to see the result!

Good luck!

Good luck!http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 13, 2019 10:03AM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 13, 2019 12:24PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 13, 2019 12:43PM |

Registered: 9 years ago Posts: 752 |

Check the device manager if the device is recognized or listed as unknown device. If the latter, try to find ender3 usb driver. If nothing is shown, see if you're supplying power to the 3d printer, check/replace usb cable or maybe the controller has died.

You probably try to use the liad gcode function in cura. You need to use load object or something to that effect. Many slicers use a + symbol for this.

As for the print, it looks like its under extruding. Try increasing the extrusion multiplier or reduce the filamend diameter.

The mess at the top usually means either the underextrusion layer by layer caused increasingly less support for the layers, or the nozzle got blocked or the heatbreak wasn't cooled.

If you want some more detailed feedback, please post some clearer pictures that show the extruded layers and infill in close up.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

You probably try to use the liad gcode function in cura. You need to use load object or something to that effect. Many slicers use a + symbol for this.

As for the print, it looks like its under extruding. Try increasing the extrusion multiplier or reduce the filamend diameter.

The mess at the top usually means either the underextrusion layer by layer caused increasingly less support for the layers, or the nozzle got blocked or the heatbreak wasn't cooled.

If you want some more detailed feedback, please post some clearer pictures that show the extruded layers and infill in close up.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Cura setting for layer height. June 14, 2019 08:13AM |

Admin Registered: 11 years ago Posts: 3,096 |

Are you printing in PLA? 250ºC is very high for PLA, I suggest printing at 220ºC max.

Also, looks like underextrusion to me, as imqqmi said. Did you correctly set the nozzle diameter in Cura?

I have noticed that my other software cannot connect to my 3D-printer as long as Cura is open, maybe that causes connectivity issues? Try connecting to the printer without Cura running. Cura hijacks the port on my computer.

http://www.marinusdebeer.nl/

Also, looks like underextrusion to me, as imqqmi said. Did you correctly set the nozzle diameter in Cura?

I have noticed that my other software cannot connect to my 3D-printer as long as Cura is open, maybe that causes connectivity issues? Try connecting to the printer without Cura running. Cura hijacks the port on my computer.

http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 14, 2019 04:52PM |

Registered: 7 years ago Posts: 619 |

It looks to me like you are printing:

under extruding

over temperature (250 is a little high even for some ABS)

Too fast.

Change one thing at a time.

As an aside, I keep reading that using 0.16 will give you better quality than 0.15 - something to do with stepper physics...

Have fun,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

under extruding

over temperature (250 is a little high even for some ABS)

Too fast.

Change one thing at a time.

As an aside, I keep reading that using 0.16 will give you better quality than 0.15 - something to do with stepper physics...

Have fun,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Cura setting for layer height. June 14, 2019 11:36PM |

Registered: 6 years ago Posts: 127 |

Thanks for the replies. Been busy building a woodworking shop.

The device manager does not show a com port. It appeared in the past as com1.

Nozzle is .04. Multiplier is 114%

Using PETG at 240. Tried to print a temp tower, no luck.

Will check nozzle for blockage.

Will try 1.6 at 230 and see what happens.

Thanks again for the suggestions,

dlw

The device manager does not show a com port. It appeared in the past as com1.

Nozzle is .04. Multiplier is 114%

Using PETG at 240. Tried to print a temp tower, no luck.

Will check nozzle for blockage.

Will try 1.6 at 230 and see what happens.

Thanks again for the suggestions,

dlw

|

Re: Cura setting for layer height. June 15, 2019 12:46PM |

Registered: 6 years ago Posts: 127 |

Here is the latest. See attached.

230, 60, .05 nozzle, speed 50mm, layer height .16.

The .04 is plugged. One problem is during warmup, the filament coils up on the nozzle.

Also, when nozzle hot, spring compressed, can not push filament through nozzle.

Have the feeling something is wrong with the extruder. Does not seem to feed the filament correctly.

Going to take it apart and see if anything is obvious.

Going out to the shop for the rest of today.

I'm not pissed yet, but getting there.

230, 60, .05 nozzle, speed 50mm, layer height .16.

The .04 is plugged. One problem is during warmup, the filament coils up on the nozzle.

Also, when nozzle hot, spring compressed, can not push filament through nozzle.

Have the feeling something is wrong with the extruder. Does not seem to feed the filament correctly.

Going to take it apart and see if anything is obvious.

Going out to the shop for the rest of today.

I'm not pissed yet, but getting there.

|

Re: Cura setting for layer height. June 16, 2019 12:38PM |

Registered: 9 years ago Posts: 752 |

If it doesn't appear in the device manager as COM1, it may be in unknown devices and requires a driver. If there's nothing there either you may have a damaged the Arduino. Also try a different usb port or a different laptop/PC.

You still use .04 and .05 instead of .4 and .5, if you've got that filled in in the slicer it will go wrong when slicing/printing. filament that's not going straight down from the nozzle can mean a partly blocked nozzle or a damaged one. If you've got spares, I'd try a new one.

If you leave the nozzle heated without extruding the filament will bake and loose viscosity, making it hard to impossible to extrude (and hard to clear the nozzle), especially at higher temperatures like 220 degrees and up. This usually happens when setting up or troubleshooting stuff on the printer, or changing filament (between ABS and PLA especially since ABS is a much higher temperature plastic. The residue of PLA will get caked if the nozzle is set for ABS temperatures). I usually extrude about 50mm at 220 degrees for ABS when PLA was loaded before that. Extrude slowly at 0.5 to 1mm/s. After that you can increase the nozzle temperature and clear some more. Turn off the nozzle heater as soon as possible or keep slowly extruding.

I don't know if this also goes for PETG, I think it'll remain viscous longer but I'm not 100% sure.

It can be frustrating juggling, keeping all the balls in the air at times. The other day I forgot to remove the z steps I've lowered during a print as the nozzle was too far from the bed. I programmed the setting in the firmware and forgot to reset the GUI setting, basically doubling the z offset. It took out a fair chunk of the freshly placed 300x300mm buildtak surface :-S.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

You still use .04 and .05 instead of .4 and .5, if you've got that filled in in the slicer it will go wrong when slicing/printing. filament that's not going straight down from the nozzle can mean a partly blocked nozzle or a damaged one. If you've got spares, I'd try a new one.

If you leave the nozzle heated without extruding the filament will bake and loose viscosity, making it hard to impossible to extrude (and hard to clear the nozzle), especially at higher temperatures like 220 degrees and up. This usually happens when setting up or troubleshooting stuff on the printer, or changing filament (between ABS and PLA especially since ABS is a much higher temperature plastic. The residue of PLA will get caked if the nozzle is set for ABS temperatures). I usually extrude about 50mm at 220 degrees for ABS when PLA was loaded before that. Extrude slowly at 0.5 to 1mm/s. After that you can increase the nozzle temperature and clear some more. Turn off the nozzle heater as soon as possible or keep slowly extruding.

I don't know if this also goes for PETG, I think it'll remain viscous longer but I'm not 100% sure.

It can be frustrating juggling, keeping all the balls in the air at times. The other day I forgot to remove the z steps I've lowered during a print as the nozzle was too far from the bed. I programmed the setting in the firmware and forgot to reset the GUI setting, basically doubling the z offset. It took out a fair chunk of the freshly placed 300x300mm buildtak surface :-S.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Cura setting for layer height. June 16, 2019 04:00PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 16, 2019 07:40PM |

Registered: 7 years ago Posts: 619 |

Quote

dlw

The attached was printed with 230, 60, .05 nozzle, speed 50mm, layer height .16.

How is the feed rate changed in Cura 4?

You are confusing us. Are you or are you not setting your nozzle size to 0.05?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Cura setting for layer height. June 17, 2019 10:05AM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 17, 2019 10:26AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

dlw

Yes, the nozzle is set to .05.

As stated above: The attached was printed with 230, 60, .05 nozzle, speed 50mm, layer height .16.

I'm pretty sure your nozzle size should be 0.5 instead of 0.05 I might be wrong. But I wouldn't even know where to get a 0.05mm nozzle easily.

http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 17, 2019 12:33PM |

Admin Registered: 16 years ago Posts: 13,884 |

... if you really want a nozzle with 0.05mm or even smaller - I've tested with "laser-drilling" nozzles for dispensers - got 0.05mm without problems ... could reduce the bore down to 0.01mm.

But how to get the filament through?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But how to get the filament through?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Cura setting for layer height. June 17, 2019 05:06PM |

Registered: 7 years ago Posts: 619 |

Quote

dlw

Yes, the nozzle is set to .05.

As stated above: The attached was printed with 230, 60, .05 nozzle, speed 50mm, layer height .16.

If you have a 0.05mm nozzle then your print speed a way too high and your layer height is WAY too high. You will need to experiment, I would start at 10-20 mm/s with a .05mm nozzle. Your layers will have to be small too - call it 75% of your nozzle diameter for the layer, so your layers should be around .0375mm. With layers this thin you'll want to pay very close attention to your temperature as well so your print won't look like molten plastic...

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Cura setting for layer height. June 17, 2019 06:53PM |

Registered: 9 years ago Posts: 752 |

I'm not sure you understand what the nozzle setting is for. If your actual nozzle in the heater block is 0.4 or 0.5mm, you need to set the same value in the slicer for it to calculate the correct amount of filament to be extruded, together with the layer height and extrusion width (which is usually best left at default) filament diameter and multiplier. Any deviation is more likely to be a physical fault that needs fixing instead of a setting once you've got the basics down.

If you start changing these values to like 0.04 nozzle size things will start to make little sense quite quickly, and fail. And if you're using the tool in a way it wasn't designed for it'll be impossible for us to help you. We'll be talking a different language, as it were.

I recommend you go through the setup an calibration guide once more, use the known good default settings. If the extruder extrudes the commanded length of filament you can try an actual print. Set velocity for x and y at 30mm/s. Use a hollow test cube of 20x20x20mm with a single wall to home in on the correct extruder settings before trying larger prints.

Once you've got the single wall to the correct thickness and printing consistently you can try optimizing settings to speed things up and print objects you actually need or want.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

If you start changing these values to like 0.04 nozzle size things will start to make little sense quite quickly, and fail. And if you're using the tool in a way it wasn't designed for it'll be impossible for us to help you. We'll be talking a different language, as it were.

I recommend you go through the setup an calibration guide once more, use the known good default settings. If the extruder extrudes the commanded length of filament you can try an actual print. Set velocity for x and y at 30mm/s. Use a hollow test cube of 20x20x20mm with a single wall to home in on the correct extruder settings before trying larger prints.

Once you've got the single wall to the correct thickness and printing consistently you can try optimizing settings to speed things up and print objects you actually need or want.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Cura setting for layer height. June 18, 2019 09:41PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 29, 2019 04:18PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 29, 2019 07:36PM |

Registered: 7 years ago Posts: 619 |

Quote

dlw

OK, back on line. Same problem.

How to change feed rate in Cura 4?

Also, what in the attached setting is causing a 5 hour print?

Lesson one: THINGS GO REALLY SLOW WHEN YOU USE A TINY NOZZLE AND/OR TINY LAYER HEIGHT.

So - unless your using terms that do not match how we use those terms:

You are using settings that would do credit to an SLA printer - This is an FFF printer, it is not reasonable to use these settings with an FFF printer.

Unless you are using a geared extruder I would not expect to even see your extruder motor even move.

To get your printer to work in a reasonable manner, until you get used to layer deposition printers start here:

0.4mm nozzle (not 0.04, 0.4)

layer height 0.2mm or for a finer surface, 0.16mm.

Anywhere from 40-80mm/s speeds (depends upon your printer), start with the CURA defaults and tweak the various speeds until you are happy.

When you get this working, then you can move to smaller nozzles (and slower speeds) to get finer detail. Your print times will go up A LOT as you go to smaller nozzles and smaller layers.

If you want to blow lots of plastic and print faster, move to .6 or .8mm nozzles and use layer heights of up to 75% of the nozzle diameter. However, you will hit the wall on speeds quickly because the standard hot-end will just not be able to heat the plastic fast enough to push it out the nozzle - You will need a "Volcano" type hot end to do stupid-fast high volume prints. You will have to experiment to see what layer heights do best with particular nozzles. As a rule, max layer height is 75% of nozzle diameter, minimum might work down to 25% of nozzle diameter, but that is iffy.

No matter what you do, do a PID TUNE on your hot end to get its best heating speed.

Have fun,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Cura setting for layer height. June 30, 2019 04:27AM |

Admin Registered: 11 years ago Posts: 3,096 |

A wall thickness of 0.08mm will cause huge issues. You should set the wall thickness to at least your extrusion width or a multiple of your extrusion width (= your nozzle size).

So the 0.08mm wall thickness setting is the cause of the 5 hour print.

http://www.marinusdebeer.nl/

So the 0.08mm wall thickness setting is the cause of the 5 hour print.

http://www.marinusdebeer.nl/

|

Re: Cura setting for layer height. June 30, 2019 02:52PM |

Registered: 6 years ago Posts: 127 |

|

Re: Cura setting for layer height. June 30, 2019 04:24PM |

Registered: 7 years ago Posts: 619 |

Quote

dlw

Changed to .4 nozzle because many of the attached are needed.

Tried layer heights from .16 to .6. No luck.

The printer tries to print layer 1 again and again.

Z axis does not move.

Firstly.

I am surprised that the slicer didn't barf, what version are you using? You should be reading the "tooltips" that CURA gives when you hover over an entry.

You have a .4mm nozzle, one standard "line" will then be .4mm wide.

You specify a wall thickness of 1mm, this is this is 2.5 lines wide - You should keep those to integer values to keep it simple (2 walls = .8mm), however this will typically still work.

Then you override the wall thickness by saying that the wall is 25 lines wide. 25x0.4=10mm wide walls.

I recommend that you either expose and set thickness, or wall/layer count, not both.

Secondly.

Because CURA marked youir height as "troublesome", this means that you machine setup will not like your settings. It will be difficult to achieve a .4mm layer if you have a .4mm nozzle. Like said before, your layer shouldn't be more than 75% of your nozzle diameter. 4mm nozzle means max height of 3mm.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Sorry, only registered users may post in this forum.