1st Failed ABS Model

Posted by Roberts_Clif

|

1st Failed ABS Model June 05, 2019 10:49AM |

Registered: 6 years ago Posts: 1,863 |

Today I had my first failed ABS print.

Although it was defiantly my fault, was still a my first failed ABS Print, now this was a simple error on my part.

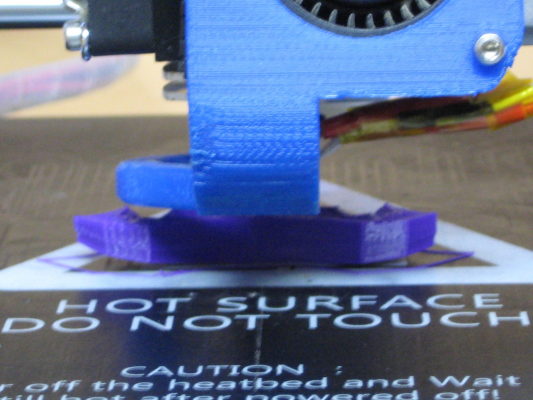

As I was in a hurry to print the model I forgot it was sliced for PLA an not for ABS, so I was printing an ABS model at PLA temperatures, below is the results of this error.

You can see very easily that the model had no intentions on staying flat on the hot-bed at 42C.

So in the future I will need to pay much more attention when selecting the 3D Models I want to Print.

It is quite simply an easy task to change from PLA to ABS, as all that is required is to change the Nozzle and Hot-bed temperatures, I do not even worry about the parts cooling fan speed, as when printing inside my homemade enclosure the heated air blowing on the model does not seen to disturb it in any way whatsoever.

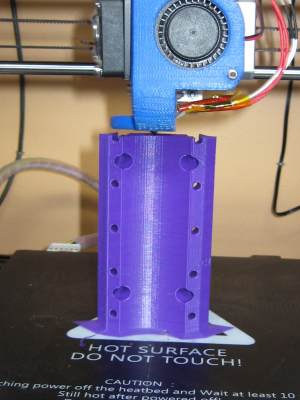

Here is the same model printed by changing the PLA temps to bed 96C an nozzle 228C.

Edited 2 time(s). Last edit at 06/05/2019 11:07AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Although it was defiantly my fault, was still a my first failed ABS Print, now this was a simple error on my part.

As I was in a hurry to print the model I forgot it was sliced for PLA an not for ABS, so I was printing an ABS model at PLA temperatures, below is the results of this error.

You can see very easily that the model had no intentions on staying flat on the hot-bed at 42C.

So in the future I will need to pay much more attention when selecting the 3D Models I want to Print.

It is quite simply an easy task to change from PLA to ABS, as all that is required is to change the Nozzle and Hot-bed temperatures, I do not even worry about the parts cooling fan speed, as when printing inside my homemade enclosure the heated air blowing on the model does not seen to disturb it in any way whatsoever.

Here is the same model printed by changing the PLA temps to bed 96C an nozzle 228C.

Edited 2 time(s). Last edit at 06/05/2019 11:07AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: 1st Failed ABS Model June 05, 2019 12:28PM |

Registered: 11 years ago Posts: 5,780 |

Shut off the print cooling fan. See the way the edges at the holes are lifting up at the top of the print? You'll get a little of that with ABS without a cooling fan. With the fan on it will be worse, and the layers are liable to start splitting apart.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 1st Failed ABS Model June 05, 2019 01:57PM |

Registered: 6 years ago Posts: 1,863 |

Thank you. I will Try on another Model.

Though what you are seeing is an optical illusion caused by the objects shape. the picture distorts the models true shape.

I watched this part very carefully while it was being printed because I wanted a really strong tool holder mount. Reason for using ABS.

I have seen the edges curl from what you are referring while printing many PLA models, an I assure you this did not happen while 3D Printing this model.

Thank you again

Computer Programmer / Electronics Technician

Though what you are seeing is an optical illusion caused by the objects shape. the picture distorts the models true shape.

I watched this part very carefully while it was being printed because I wanted a really strong tool holder mount. Reason for using ABS.

I have seen the edges curl from what you are referring while printing many PLA models, an I assure you this did not happen while 3D Printing this model.

Thank you again

Computer Programmer / Electronics Technician

|

Re: 1st Failed ABS Model June 05, 2019 04:42PM |

Registered: 10 years ago Posts: 14,672 |

I agree, it's annoying to have to re-slice for a different material. One of my aims is to have GCode that is independent of all machine parameters except a small number of essential ones such as nozzle size. All other configuration, including temperatures, will be done on the printer. I already print the same GCode files on my Cartesian, Delta and Scara printers.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: 1st Failed ABS Model June 05, 2019 07:03PM |

Registered: 6 years ago Posts: 1,863 |

Quote

dc42

I agree, it's annoying to have to re-slice for a different material. One of my aims is to have GCode that is independent of all machine parameters except a small number of essential ones such as nozzle size. All other configuration, including temperatures, will be done on the printer. I already print the same GCode files on my Cartesian, Delta and Scara printers.

OK I see, I can remove the Bed an Nozzle Temps slice and it will not be ABS or PLA dependent.

I like.

Computer Programmer / Electronics Technician

Sorry, only registered users may post in this forum.