Printer thinks file is 2x the size of the printer bed, need help.

Posted by Firefightergirl

|

Printer thinks file is 2x the size of the printer bed, need help. June 16, 2019 03:57PM |

Registered: 4 years ago Posts: 12 |

Dear printer guys, I talked my husband into building this printer from scratch and he’s been building for months and I have been helping a little, and when we finally got all the hardware issues ironed out, we went to print the xy practice cube from thingiverse and he downloaded it on Cura and sliced it, and it looked good, we thought all the settings we’re correct because the guy who designed this printer looked them over and said they looked fine. But when we went to print, it not only tried to print the cube at twice the size but it tried to print it all the way in the back corner like that was the center. It looked correct in Cura and we had it set to a 300mm x 300mm bed size, and when it printed like this the first time it did the same thing so we set the print bed size as 250mm to 250mm, (we measured it, it is 300mmx300mm) but it didn’t seem to make a difference. Please take a look at the video and tell me what we need to change because we’re so close to printing we can almost taste it and it’s taken so long to get to this point. Thanks in advance. I tried to attach a video by compressing it but it didn’t work even when I made it 6MB...so I put it up on YouTube. Please check it out. [youtu.be]

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 16, 2019 04:50PM |

Registered: 6 years ago Posts: 1,863 |

Watched your video.

If you have a Arduino with a Ramps, did you install the 3 jumpers under the stepper motor modules before installing the modules.

If not What controller are you using, What Firmware was loaded onto the controller or was it pre-flashed.

Computer Programmer / Electronics Technician

If you have a Arduino with a Ramps, did you install the 3 jumpers under the stepper motor modules before installing the modules.

If not What controller are you using, What Firmware was loaded onto the controller or was it pre-flashed.

Computer Programmer / Electronics Technician

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 16, 2019 08:25PM |

Registered: 4 years ago Posts: 12 |

The printer is on this GitHub link. the printer is based on a MKS maker base version 1.3, 32 bit with TFT screen. It is running Smoothieware. This is The GitHub site for configuration file information. [github.com]

I believe the controller was preflashed, but it was updated with a SD card with the appropriate updates.

Hope this is what your asking for as far as information

I believe the controller was preflashed, but it was updated with a SD card with the appropriate updates.

Hope this is what your asking for as far as information

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 17, 2019 12:54AM |

Admin Registered: 13 years ago Posts: 6,999 |

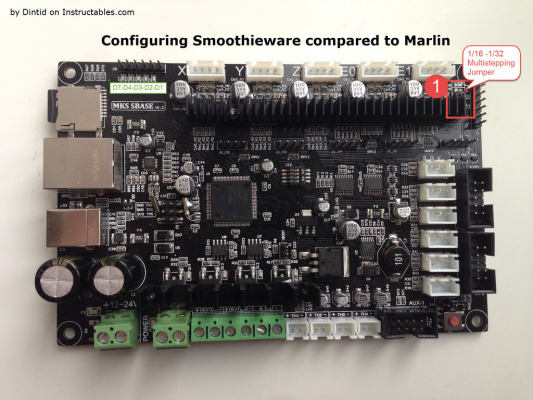

This control board also has micro stepping jumpers

if its on 1/16th change it to 1/32

if its on 1/16th change it to 1/32

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 17, 2019 03:52PM |

Registered: 4 years ago Posts: 12 |

It’s set on 1/16, the creator got back to us too, with a typo in the code, there’s a # where it’s not supposed to be, making it so when we home the X & Y were traveling together. Anyways my husband is going to fix that and then test that fix out then if that works correctly but still Doesn’t print right, which I think it won’t, then we’ll switch it over to 1/32, I do wonder though do we have to switch it to that as well in the gcode before we try and print? Thanks again for the help guys.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 17, 2019 04:28PM |

Registered: 11 years ago Posts: 5,780 |

IRIC, most slicers drop prints at the center of the bed, but Cura defaults to dropping the prints at the origin of the machine/bed. You can get Cura to drop prints on the bed center by using some custom g-code to force it to do so, but it might be easier to just set the printer's origin at the center of the bed- that should work with any slicer without having to use any custom gcode.

Example with custom gcode at the end of the post, here.

Setting origin to center of bed here.

That appears to be a corexy printer. I wrote a post on setting up origin and endstops specifically for corexy here.

You are going to have to change the way the belts are clamped at the extruder carriage. The belts have to be kept parallel to the guide rails in X and Y or you'll have all sorts of problems. See: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Example with custom gcode at the end of the post, here.

Setting origin to center of bed here.

That appears to be a corexy printer. I wrote a post on setting up origin and endstops specifically for corexy here.

You are going to have to change the way the belts are clamped at the extruder carriage. The belts have to be kept parallel to the guide rails in X and Y or you'll have all sorts of problems. See: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 17, 2019 05:08PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

IRIC, most slicers drop prints at the center of the bed, but Cura defaults to dropping the prints at the origin of the machine/bed. You can get Cura to drop prints on the bed center by using some custom g-code to force it to do so, but it might be easier to just set the printer's origin at the center of the bed- that should work with any slicer without having to use any custom gcode.

Example with custom gcode at the end of the post, here.

Setting origin to center of bed here.

That appears to be a corexy printer. I wrote a post on setting up origin and endstops specifically for corexy here.

You are going to have to change the way the belts are clamped at the extruder carriage. The belts have to be kept parallel to the guide rails in X and Y or you'll have all sorts of problems. See: [drmrehorst.blogspot.com]

CURA defaults to dropping the model in the center of the bed, no matter the bed origin.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 18, 2019 11:50AM |

Registered: 4 years ago Posts: 12 |

Thanks so much for the replies guys, we’re currently switching it to 1/32, we will look at where Cura says its defaulting too, we changed the clamps we had on the printer head to zip ties so they interlock better, and he spent some time squaring everything up, making sure the printer head didn’t hit anything when going over all the stops again. He’s going to measure and see when he jogs the printer head 10mm if it actually moves 10mm, etc. I will get back with you all tomorrow and let ya know our progress.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 18, 2019 12:25PM |

Registered: 7 years ago Posts: 619 |

Quote

dlc60

Quote

the_digital_dentist

IRIC, most slicers drop prints at the center of the bed, but Cura defaults to dropping the prints at the origin of the machine/bed. You can get Cura to drop prints on the bed center by using some custom g-code to force it to do so, but it might be easier to just set the printer's origin at the center of the bed- that should work with any slicer without having to use any custom gcode.

Example with custom gcode at the end of the post, here.

Setting origin to center of bed here.

That appears to be a corexy printer. I wrote a post on setting up origin and endstops specifically for corexy here.

You are going to have to change the way the belts are clamped at the extruder carriage. The belts have to be kept parallel to the guide rails in X and Y or you'll have all sorts of problems. See: [drmrehorst.blogspot.com]

CURA defaults to dropping the model in the center of the bed, no matter the bed origin.

DLC

I realized that I need to qualify that statement...

In the "Printer Management", "Machine Settings" there is a box that you can check "Origin at center". When you enter a custom printer that is a Delta, you check this box. I am not sure what would happen if you set that on a Cartesian printer.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 19, 2019 10:25PM |

Registered: 4 years ago Posts: 12 |

Hi guys, we’ll the good news is after changing it to 1/32, and changing how it homes in the code, seemed to fix it, however now we have another problem. The extruder is heating, says so on the reprap tft screen, the voltage seems to go from 10.2 to 12.6, and is melting the PLA but the PTEF tubing popped out of the connector in the extruder cold end that pushes the PLA into the tube. My husband thinks it’s stopping extruding cause the hot end isn’t staying up to temperature, he’s relating to maybe it’s a voltage drop. I however think the Z axis isn’t moving enough, cause it didn’t seem to go up another layer it looked like it was ironing the layer...we just have no idea what’s going on. Hope you guys can help. I included a video of it to show you kinda what I mean. [youtu.be]

Edited 1 time(s). Last edit at 06/19/2019 10:27PM by Firefightergirl.

Edited 1 time(s). Last edit at 06/19/2019 10:27PM by Firefightergirl.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 19, 2019 11:18PM |

Registered: 6 years ago Posts: 1,863 |

Quote

Firefightergirl

the voltage seems to go from 10.2 to 12.6,

I would try again with the fan about half the speed for the 3nd layer, I do not believe you told what temperature or layer height you were printing at.

Edited 2 time(s). Last edit at 06/19/2019 11:24PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 19, 2019 11:23PM |

Registered: 4 years ago Posts: 12 |

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 19, 2019 11:24PM |

Registered: 6 years ago Posts: 1,863 |

The voltage drops over 2 volts, where on the controller or on the power supply terminals leads.

If the voltage remains 12 volt on the power supply an only drops on controller leads, I would wire with a larger power supply wire.

I use left over business radio power wires rated for 30amp, shown in link below.

[www.radioparts.com]

Edited 1 time(s). Last edit at 06/19/2019 11:24PM by Roberts_Clif.

Computer Programmer / Electronics Technician

If the voltage remains 12 volt on the power supply an only drops on controller leads, I would wire with a larger power supply wire.

I use left over business radio power wires rated for 30amp, shown in link below.

[www.radioparts.com]

Edited 1 time(s). Last edit at 06/19/2019 11:24PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 20, 2019 12:43PM |

Registered: 7 years ago Posts: 619 |

There are lots of things to look at here.

If you have a PSU that is at least 240 watts you have enough power. If you have less then a 12V/20A supply, you need to upgrade.

If however you are measuring the voltage applied to the hot end heater, you are fine. That voltage is "PWM'd", so 10V measured there means the heater is almost always on.

Popping the Bowden tube on the extruder means that either your tube coupler is not solidly installed or you have extreme back pressure on your filament.

If the Bowden tube is not connected you no longer can push filament through, which means no more layers will be laid down. So, best fix that first. Pushing filament through puts a lot of stress on that joint so you will have to find a way to get that better attached.

If that was well attached then you have an exceptional extruder gear! Also, you aren't heating your PLA hot enough. If this is a temperature thing then:

1- Check your TEMP_SENSOR_0 setting in configuration.h. Most generic hot-end sensors are either '5' or '1'. Start with 5. (This is Marlin Firmware)

2- Do a PID tune on your hot end - You will need to use Pronterface or similar such that you can issue g-code commands directly, specifically "M303 E0 S210 C8", is what I typically do for Marlin firmware. Your output will be Kp, Ki and Kd values that you can use to edit your configuration.h file under the PID settings for your hot end. I don't speak repetier, but I am sure that firmware has a similar PID tune process. Always PID tune with the hot end cold (room temperature).

Set your temperature for your PLA about the middle range of what the spool says, I generally start at 5Cbelow the max. I will then cycle up and down until I am happy.

While your printing, watch your Z screw. You will see it move a tiny bit. Don't bother to watch your print, most of us can't see a change of .2mm!

Good luck,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

If you have a PSU that is at least 240 watts you have enough power. If you have less then a 12V/20A supply, you need to upgrade.

If however you are measuring the voltage applied to the hot end heater, you are fine. That voltage is "PWM'd", so 10V measured there means the heater is almost always on.

Popping the Bowden tube on the extruder means that either your tube coupler is not solidly installed or you have extreme back pressure on your filament.

If the Bowden tube is not connected you no longer can push filament through, which means no more layers will be laid down. So, best fix that first. Pushing filament through puts a lot of stress on that joint so you will have to find a way to get that better attached.

If that was well attached then you have an exceptional extruder gear! Also, you aren't heating your PLA hot enough. If this is a temperature thing then:

1- Check your TEMP_SENSOR_0 setting in configuration.h. Most generic hot-end sensors are either '5' or '1'. Start with 5. (This is Marlin Firmware)

2- Do a PID tune on your hot end - You will need to use Pronterface or similar such that you can issue g-code commands directly, specifically "M303 E0 S210 C8", is what I typically do for Marlin firmware. Your output will be Kp, Ki and Kd values that you can use to edit your configuration.h file under the PID settings for your hot end. I don't speak repetier, but I am sure that firmware has a similar PID tune process. Always PID tune with the hot end cold (room temperature).

Set your temperature for your PLA about the middle range of what the spool says, I generally start at 5Cbelow the max. I will then cycle up and down until I am happy.

While your printing, watch your Z screw. You will see it move a tiny bit. Don't bother to watch your print, most of us can't see a change of .2mm!

Good luck,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 20, 2019 09:19PM |

Registered: 4 years ago Posts: 12 |

Thanks so much DLC, we tried a few things today, we bypassed the 12 volts off boost buck, and then disconnected it from the control board and provided our own clean bench power, at 12 volts, but it didn’t change anything the extruder stopped extruding PLA a little faster than last time. We are using smoothieware, not Marlin, so we weren’t sure what exactly you meant in your post about checking the code, he looked at the code but wasn’t sure what he was really looking for. We set it at 230 Centigrade which is max for our PLA that was listed on the box, and yes it’s 1.75mm filament in case you were gunna ask that. So far we’ve changed the hot end with nozzle 3x, he’s changed the cold end extruder to the red one in the video, the PTEF tube, and connectors, we keep getting the same result. It squirts out PLA really good right before it starts to print and then it prints good for about 1 minute then stops...we’re at our wits end, we get sooooo close then something else fails....we’re cursed. I really appreciate you guys taking the time to answer us and try and help. Thanks in advance.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 20, 2019 11:07PM |

Registered: 7 years ago Posts: 619 |

Oops. Sorry,I forgot you were using Smoothieware. There will be configuration settings somewhere that will allow you to do that tuning, but I don’t know them.

Those are still things to check though. As someone else mentioned,!if your part fan is too aggressive then you can cool the nozzle too much. However that usually causes a thermal runaway error. Is your Bowden tube too long or too tight for your filament?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Those are still things to check though. As someone else mentioned,!if your part fan is too aggressive then you can cool the nozzle too much. However that usually causes a thermal runaway error. Is your Bowden tube too long or too tight for your filament?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 20, 2019 11:14PM |

Registered: 4 years ago Posts: 12 |

The fan is running on code that the guy who designed the build for our core XYZ printer, so we don’t think it’s the fan, we’re gunna watch it closer tomorrow...the Bowden tube is the right length, and moves smoothly through it we checked that. My husband just said he will try running it without the fan running for a few minutes just to see if that makes a difference for some reason, and see if that lets us continue to print without the stopping it from extruding ...we are just out of ideas...also what tuning are we looking for in smoothieware? I’m kinda lost, maybe my husband understood your post earlier better than I have. Thanks again for replying

Edited 1 time(s). Last edit at 06/20/2019 11:14PM by Firefightergirl.

Edited 1 time(s). Last edit at 06/20/2019 11:14PM by Firefightergirl.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 21, 2019 12:40AM |

Registered: 7 years ago Posts: 619 |

I have to admit, I do not have a Smoothieware system so I do not know what kind of tuning is required. If you go to the main forums page and go _way_ down the list, under Electronics you will find a "Smoothie" forum that will help you out perhaps more than we are here. That group may better understand the problem since they are way more familiar with the firmware. The creators of the boards and firmware hang out there.

Sorry I can't be more helpful,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Sorry I can't be more helpful,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Printer head not extruding? June 21, 2019 05:01PM |

Registered: 4 years ago Posts: 17 |

ADMIN NOTE : Please Bernie create a separate thread for this different topic. It's considered rude to hijack other people thread - even if it's somewhat related.

I just completed a reprap cartesian style printer. Trying to print my first item. The test xyz cube from Thingiverse. The printer preheats fine. Bed just right and hot end so the tft screen says. I choose the cura sliced test print and the head/carriage goes through its pre print ritual. Even extruding a few mm of filament. The head then moves to the center of my heated bed and starts to print. It’s ok for 3-4 layers then the filament stops flowing and I end up stopping the print. It has done this exact same thing 3 times now. I have pulled the hot end each time making sure nothing is physically impeding the flow. The extruder is exceptional with a fine gear that grips the filament strongly enough to pop the tubing out of the compression connector at the cold end of the extruder when the filament stops flowing. I’m thinking it has to be cooling down for some reason unknown. It has an exchanger fan that turns on/off at 50c. It also has two side fans blowing through small funnels on the extruded filament when actually printing. The head says it’s maintaining 220c. The system is an MKS v1.3 32 bit with a tft screen, running Smoothieware. The primary power is a 24vdc supply split to heat the bed at 24vdc and goes through a buck boost to feed the MKS board at 12vdc. All steppers fans and hot end operate at the 12vdc. Hot end thermistor is accurate. I’m thinking either the fans are efficient enough to be cooling the head so the filament stops flowing(but the tft temp gauge says it’s maintaining at 220c) or the power/voltage is somehow an issue? Maybe even the configuration code is the issue? Attached is the website showing the printer design and electrical and mechanical components as well as the GitHub site location of the configuration file I’m running. I have 4 months in this build from scratch, parts sourcing and the like after work one on weekends. Any ideas?? THANKS IN ADVANCE. [repalmakershop.com] [github.com]

Edited 1 time(s). Last edit at 06/22/2019 06:13AM by DeuxVis.

I just completed a reprap cartesian style printer. Trying to print my first item. The test xyz cube from Thingiverse. The printer preheats fine. Bed just right and hot end so the tft screen says. I choose the cura sliced test print and the head/carriage goes through its pre print ritual. Even extruding a few mm of filament. The head then moves to the center of my heated bed and starts to print. It’s ok for 3-4 layers then the filament stops flowing and I end up stopping the print. It has done this exact same thing 3 times now. I have pulled the hot end each time making sure nothing is physically impeding the flow. The extruder is exceptional with a fine gear that grips the filament strongly enough to pop the tubing out of the compression connector at the cold end of the extruder when the filament stops flowing. I’m thinking it has to be cooling down for some reason unknown. It has an exchanger fan that turns on/off at 50c. It also has two side fans blowing through small funnels on the extruded filament when actually printing. The head says it’s maintaining 220c. The system is an MKS v1.3 32 bit with a tft screen, running Smoothieware. The primary power is a 24vdc supply split to heat the bed at 24vdc and goes through a buck boost to feed the MKS board at 12vdc. All steppers fans and hot end operate at the 12vdc. Hot end thermistor is accurate. I’m thinking either the fans are efficient enough to be cooling the head so the filament stops flowing(but the tft temp gauge says it’s maintaining at 220c) or the power/voltage is somehow an issue? Maybe even the configuration code is the issue? Attached is the website showing the printer design and electrical and mechanical components as well as the GitHub site location of the configuration file I’m running. I have 4 months in this build from scratch, parts sourcing and the like after work one on weekends. Any ideas?? THANKS IN ADVANCE. [repalmakershop.com] [github.com]

Edited 1 time(s). Last edit at 06/22/2019 06:13AM by DeuxVis.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 21, 2019 08:12PM |

Registered: 11 years ago Posts: 5,780 |

firefightergirl, the tube pops out of the extruder because the extruder is not extruding plastic. If the hot-end is failing to maintain the temperature, the plastic may solidify in the heaterblock/nozzle and that will stop it from extruding. If the Z axis is not dropping the bed, the nozzle will sit against the previously extruded plastic and the back pressure it creates will prevent extrusion. If the heater voltage is dropping when the heater turns on, there's probably a power supply problem. There should be a cooling fan blowing on the hot-end heatsink whenever the heater is on. I couldn't see one in the video. If there's no fan, heat will creep up the throat of the hot-end and the filament will soften and swell and jam things up (and you'll have to take the thing apart to clean it out). Make sure the print cooling fans don't blow against the heater block- turn them off and leave them off for initial testing.

Have you run the PID autotune on the hot-end? Do that before messing with anything else. Try a few basic tests- heat up the extruder and try to extrude filament into the air- make sure the hot end fan is on. Try a print file that will move the z axis in layer size steps- you can make a gcode file with a text editor- just stack a bunch of G01 Z0.2, G01 Z0.4, etc commands, and make sure the z axis moves as it should. If power supply voltage drops when the hot-end heater is on, that's a problem. The power supply is inadequate for the heater. Use a hot-end heater that is rated for the same voltage as the printer's power supply. Don't try to use a DC-DC converter to power the hot end heater. Heater cartridges are dirt cheap.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Have you run the PID autotune on the hot-end? Do that before messing with anything else. Try a few basic tests- heat up the extruder and try to extrude filament into the air- make sure the hot end fan is on. Try a print file that will move the z axis in layer size steps- you can make a gcode file with a text editor- just stack a bunch of G01 Z0.2, G01 Z0.4, etc commands, and make sure the z axis moves as it should. If power supply voltage drops when the hot-end heater is on, that's a problem. The power supply is inadequate for the heater. Use a hot-end heater that is rated for the same voltage as the printer's power supply. Don't try to use a DC-DC converter to power the hot end heater. Heater cartridges are dirt cheap.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 23, 2019 09:53PM |

Registered: 4 years ago Posts: 12 |

Dear ADMIN “Bernie” is my husband and the printer he’s mentioning is one and the same as mine, it’s his, lol, you couldn’t have known this when I realized he also had a query on here I told him to just post on mine, my bad if it looked like he was subject hopping.

Dear DLC 60 thanks for the reply and suggestions, sorry everyone for the slow reply, my hubby and I just took a few days off from working on it, it was making us kinda crazy.

Dear Digital Dentist thanks so much for the reply, Bernie said he’ll look into those possibilities, here’s what he requested I ask you. “When the MKS sBase Board v1.3 32 bit is running on 12vdc, generated by a buck boost unit fed by the printers main 24vdc 20amp power supply, how to turn on say a small mosfet feeding a new 24vdc hot end using the contacts on the MKS board currently running the troublesome 12vdc hot end. Also how do you set up a PID test in more detail, reminder I’m using Smoothieware.” He also wanted me to include a link of the code we’re using if you want to look at it. [github.com]

I feel that it’s a fan issue or Z axis thing, but he knows more than me, so I’ll wait to see what you guys say to his questions. I’m going to request he do some tests without the fans cooling the hot end. Thanks again everyone

Edited 1 time(s). Last edit at 06/23/2019 09:55PM by Firefightergirl.

Dear DLC 60 thanks for the reply and suggestions, sorry everyone for the slow reply, my hubby and I just took a few days off from working on it, it was making us kinda crazy.

Dear Digital Dentist thanks so much for the reply, Bernie said he’ll look into those possibilities, here’s what he requested I ask you. “When the MKS sBase Board v1.3 32 bit is running on 12vdc, generated by a buck boost unit fed by the printers main 24vdc 20amp power supply, how to turn on say a small mosfet feeding a new 24vdc hot end using the contacts on the MKS board currently running the troublesome 12vdc hot end. Also how do you set up a PID test in more detail, reminder I’m using Smoothieware.” He also wanted me to include a link of the code we’re using if you want to look at it. [github.com]

I feel that it’s a fan issue or Z axis thing, but he knows more than me, so I’ll wait to see what you guys say to his questions. I’m going to request he do some tests without the fans cooling the hot end. Thanks again everyone

Edited 1 time(s). Last edit at 06/23/2019 09:55PM by Firefightergirl.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 23, 2019 11:00PM |

Registered: 11 years ago Posts: 5,780 |

Why is the MKS board being powered by 12V if you have a 24V power supply? Or maybe I should ask why do you have a 24V power supply if you're running the controller from 12V? The hot end, bed heater, and fans all get power via the MKS board, which is running on 12V, so there will be problems if you try to use a 24V hot-end, fans, etc. How much current is the 12V buck converter rated for?

PID tuning is done using an M303 command that you send to the controller via a host program like pronterface via a USB cable. See [smoothieware.org]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

PID tuning is done using an M303 command that you send to the controller via a host program like pronterface via a USB cable. See [smoothieware.org]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 24, 2019 10:16PM |

Registered: 4 years ago Posts: 12 |

From my husband, “To answer your questions....

The printer design is here ( [repalmakershop.com] )

Obviously not of our making but a reputable online contributor. Our hot bed as per the design is running at 24vdc (the spec of our main operating power supply, capacity 20amps) switched by a power mosfet using the contacts on the MKS board that could be used for the hot bed in a different wiring design/scenario. The 24vdc is supposedly more efficient. The design we worked from then uses a buck boost unit to reduce the primary 24vdc to 12vdc to then operate/feed the MKS sbase 1.3 board. When the issue of the hot end not having filament flow appeared, toward the end with the hope we could print soon, we looked for answers. It was suggested a better choice for a hot end would be running at 24vdc. We are aware of the need to change out the fans too. (Loosing the buck boost unit). The stepper motors will be fine as is and the MKS tft32 v4.0 control screen will be fine as long as the sbase is powered within specs 12vdc-24vdc. To further answer your queries the buck boost is ratted for 10 amps. The 12vdc does drop a couple volts when the hot end heats but levels properly within a few tenths of a volt as soon as temp is reached and the PWM control keeps the power controlled to hold temp. (220c) It has been also suggested that improper cooling could allow a bit of swelling in the hot end heat exchanger if it is not cooled properly before it actually get to the hot end for full melting? Our hot end fan does run when the hot end reaches 40c and continues until if falls below 40c on cool down. We also have two print fans that kick in after approximately 4 layers have been laid down. Our no flow issue is right around that point in the process. We will disconnect the print fans to see if we can continue to get extruded filament in our next endeavor to get this thing printing. (Maybe too much cooling) As to PID test and the M303 instruction, we are aware but our lack of experience and literally step by step instructions, cause a bit of apprehension about trying that although for proper control that is a good idea. Pretty sure that with enough built up back pressure to pop the feed tube out of the connector at the extruder cold end, flow of melted filament is definitely our problem. Too much cooling? Not enough heating? Control problem? With our upgrade to a better extruder cold end, the power/traction to supply filament to the hot end is not the problem. Getting past/through the hot end is. (FYI in case it’s a question.... I have three complete new hot end assemblies, hot end plus exchanger plus connectors plus tubing plus thermistor, so all clean and checked before each of our tests). This is very frustrating. Thanks for your post return. Very kind of you.”

PS... Our configuration file we are using with Smoothieware is here: [github.com]

Update for today, we tried running it with no fans and it stopped again after like 2 layers, it just stops extruding....we’re so done with this thing, it’s a giant useless paperweight...

The printer design is here ( [repalmakershop.com] )

Obviously not of our making but a reputable online contributor. Our hot bed as per the design is running at 24vdc (the spec of our main operating power supply, capacity 20amps) switched by a power mosfet using the contacts on the MKS board that could be used for the hot bed in a different wiring design/scenario. The 24vdc is supposedly more efficient. The design we worked from then uses a buck boost unit to reduce the primary 24vdc to 12vdc to then operate/feed the MKS sbase 1.3 board. When the issue of the hot end not having filament flow appeared, toward the end with the hope we could print soon, we looked for answers. It was suggested a better choice for a hot end would be running at 24vdc. We are aware of the need to change out the fans too. (Loosing the buck boost unit). The stepper motors will be fine as is and the MKS tft32 v4.0 control screen will be fine as long as the sbase is powered within specs 12vdc-24vdc. To further answer your queries the buck boost is ratted for 10 amps. The 12vdc does drop a couple volts when the hot end heats but levels properly within a few tenths of a volt as soon as temp is reached and the PWM control keeps the power controlled to hold temp. (220c) It has been also suggested that improper cooling could allow a bit of swelling in the hot end heat exchanger if it is not cooled properly before it actually get to the hot end for full melting? Our hot end fan does run when the hot end reaches 40c and continues until if falls below 40c on cool down. We also have two print fans that kick in after approximately 4 layers have been laid down. Our no flow issue is right around that point in the process. We will disconnect the print fans to see if we can continue to get extruded filament in our next endeavor to get this thing printing. (Maybe too much cooling) As to PID test and the M303 instruction, we are aware but our lack of experience and literally step by step instructions, cause a bit of apprehension about trying that although for proper control that is a good idea. Pretty sure that with enough built up back pressure to pop the feed tube out of the connector at the extruder cold end, flow of melted filament is definitely our problem. Too much cooling? Not enough heating? Control problem? With our upgrade to a better extruder cold end, the power/traction to supply filament to the hot end is not the problem. Getting past/through the hot end is. (FYI in case it’s a question.... I have three complete new hot end assemblies, hot end plus exchanger plus connectors plus tubing plus thermistor, so all clean and checked before each of our tests). This is very frustrating. Thanks for your post return. Very kind of you.”

PS... Our configuration file we are using with Smoothieware is here: [github.com]

Update for today, we tried running it with no fans and it stopped again after like 2 layers, it just stops extruding....we’re so done with this thing, it’s a giant useless paperweight...

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 25, 2019 09:45AM |

Registered: 11 years ago Posts: 5,780 |

Wow. I wonder what sequence of mistakes led to the design choice to use 24V for some of the critical stuff and not the whole thing... It's one thing to use a buck converter to run some LEDs, quite another to try to run the controller board.

If the 12V drops when the hot-end heater is turned on, the buck converter is under spec'd. You need one that can supply more current. Or switch the whole machine to 24V, if that's possible.

Doesn't the kit seller support their customers?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If the 12V drops when the hot-end heater is turned on, the buck converter is under spec'd. You need one that can supply more current. Or switch the whole machine to 24V, if that's possible.

Doesn't the kit seller support their customers?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printer thinks file is 2x the size of the printer bed, need help. June 27, 2019 12:27PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

Wow. I wonder what sequence of mistakes led to the design choice to use 24V for some of the critical stuff and not the whole thing... It's one thing to use a buck converter to run some LEDs, quite another to try to run the controller board.

If the 12V drops when the hot-end heater is turned on, the buck converter is under spec'd. You need one that can supply more current. Or switch the whole machine to 24V, if that's possible.

Doesn't the kit seller support their customers?

Wow, no kidding about support... I think that I would just go 24V all around - the MKS controller can certainly do that and you'd only need to get a 24V heater cartridge for your hot ends, your bed is already 24V. You will need to re-tune your steppers to get the correct current at 24V however. This should simplify your setup. Is there a support group that might have something to contribute?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. July 25, 2019 11:32AM |

Registered: 4 years ago Posts: 12 |

Hey guys, sorry I never got back with ya all, but it got close to the turtle race that I am manager for like 200 kids and didn’t have time to get back to this. So funny thing is I was right, it was squishing the prints, he didn’t calibrate the Z axis just the x, y, so the Z was only moving 2mm, when it was supposed to be 10mm, so he got that fixed but now when he went to print the z axis stepper motors like seize up, like the code isn’t telling them the right thing or something. So he could Home the z axis and it was working right but printing it didn’t work right. Someone told him that is was the feed rate and to try lower numbers but he told

Me the numbers are already low and that since he’s using smoothieware and not marlin they can’t help him to tell him where in the code to adjust what numbers. I’m just so sick of this large paperweight, and it won’t print. Maybe you can’t help, not sure. But anyway he did change everything over to 24 volts, then we figured out I was right, and it was the Z axis. You guys have no idea how exciting it is to be a women who’s not quite as versed and this and had the right answer, lol, I sure did get a kick outta that. Hope one of you can help us to finally get this thing running.

Me the numbers are already low and that since he’s using smoothieware and not marlin they can’t help him to tell him where in the code to adjust what numbers. I’m just so sick of this large paperweight, and it won’t print. Maybe you can’t help, not sure. But anyway he did change everything over to 24 volts, then we figured out I was right, and it was the Z axis. You guys have no idea how exciting it is to be a women who’s not quite as versed and this and had the right answer, lol, I sure did get a kick outta that. Hope one of you can help us to finally get this thing running.

|

Re: Printer thinks file is 2x the size of the printer bed, need help. July 25, 2019 10:36PM |

Admin Registered: 13 years ago Posts: 6,999 |

In smoothieware z_axis_max_speed 120 # mm/min

Should be a low number for Z

the number depends on your stepper drivers and what type of leadscrew Z has...

most printer are fine with a low value of 2mm/s so that is 120 mm/min so I would try that first.

If that works then you slowly increase it till you find your machines max (ie when it stops behaving) and set it to a lower value

Should be a low number for Z

the number depends on your stepper drivers and what type of leadscrew Z has...

most printer are fine with a low value of 2mm/s so that is 120 mm/min so I would try that first.

If that works then you slowly increase it till you find your machines max (ie when it stops behaving) and set it to a lower value

|

Re: Printer thinks file is 2x the size of the printer bed, need help. July 29, 2019 08:37PM |

Registered: 4 years ago Posts: 12 |

|

Re: Printer thinks file is 2x the size of the printer bed, need help. July 29, 2019 10:59PM |

Registered: 11 years ago Posts: 5,780 |

Sorry, only registered users may post in this forum.