Starting ormerod print/setup

Posted by KTM80

|

Starting ormerod print/setup March 18, 2020 04:35PM |

Registered: 4 years ago Posts: 7 |

Hi people,

I’m using a ormerod printer at work (with a ramps board), so I’m using some gcode and the config file.

The bed level is really good along with nozzle height for printing. I used the filament (marked ) and extruded/reversed to get the correct steps.

I’ve attempted to print 2 items, first observation, the flow from the nozzle does not seem high enough (temp around 210c) the lay down of filament is very bitty with gaps on the first part of print (with head and bed up to temp).

2ndly I tried the axis correction and when it got on to the Z part the print is all over the place - ideas why? Print is fairly tidy down one side but not the other.

3rdly I tried a box, I was not with the machine but it seems like it’s jumped the y axis several times...! Thoughts, speed?

Pointers would be great, I’m just starting to get it to print (got new filament on order) so what’s the best way to tweak this.

Thanks

Phil

I’m using a ormerod printer at work (with a ramps board), so I’m using some gcode and the config file.

The bed level is really good along with nozzle height for printing. I used the filament (marked ) and extruded/reversed to get the correct steps.

I’ve attempted to print 2 items, first observation, the flow from the nozzle does not seem high enough (temp around 210c) the lay down of filament is very bitty with gaps on the first part of print (with head and bed up to temp).

2ndly I tried the axis correction and when it got on to the Z part the print is all over the place - ideas why? Print is fairly tidy down one side but not the other.

3rdly I tried a box, I was not with the machine but it seems like it’s jumped the y axis several times...! Thoughts, speed?

Pointers would be great, I’m just starting to get it to print (got new filament on order) so what’s the best way to tweak this.

Thanks

Phil

|

Re: Starting ormerod print/setup March 18, 2020 04:54PM |

Registered: 11 years ago Posts: 5,780 |

1) over extrusion. Steps/mm should be set based on the printed line width- i.e. plastic coming out of the extruder, not plastic going in. See: [reprap.org]

2) layer shifting is usually due to acceleration and/or jerk being set too high, though a sloppy loose belt could cause it, too.

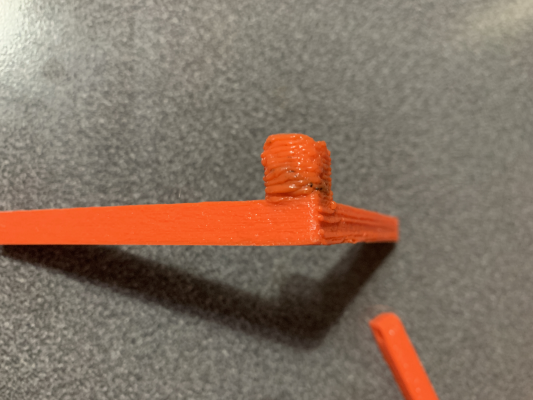

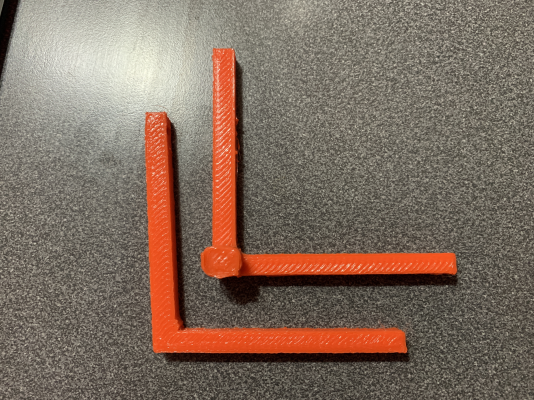

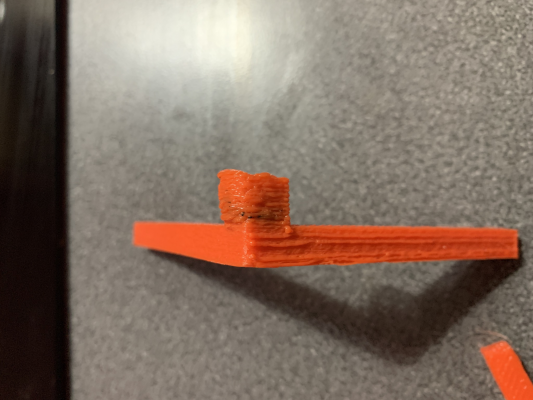

3) the blobby vertical post is because it is very small and the plastic doesn't have time to cool before the nozzle comes back and dumps more molten plastic on top of it. That "calibration" part is a poor design for that reason. You need to give the extruder something else to do while the plastic cools. Add a part (or 2 or 3) to the print that is the same height as the post and put it a few cm away on the bed. Turn on print cooling fan if you're printing PLA.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

2) layer shifting is usually due to acceleration and/or jerk being set too high, though a sloppy loose belt could cause it, too.

3) the blobby vertical post is because it is very small and the plastic doesn't have time to cool before the nozzle comes back and dumps more molten plastic on top of it. That "calibration" part is a poor design for that reason. You need to give the extruder something else to do while the plastic cools. Add a part (or 2 or 3) to the print that is the same height as the post and put it a few cm away on the bed. Turn on print cooling fan if you're printing PLA.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Starting ormerod print/setup March 19, 2020 01:15AM |

Registered: 4 years ago Posts: 7 |

Quote

the_digital_dentist

1) over extrusion. Steps/mm should be set based on the printed line width- i.e. plastic coming out of the extruder, not plastic going in. See: [reprap.org]

2) layer shifting is usually due to acceleration and/or jerk being set too high, though a sloppy loose belt could cause it, too.

3) the blobby vertical post is because it is very small and the plastic doesn't have time to cool before the nozzle comes back and dumps more molten plastic on top of it. That "calibration" part is a poor design for that reason. You need to give the extruder something else to do while the plastic cools. Add a part (or 2 or 3) to the print that is the same height as the post and put it a few cm away on the bed. Turn on print cooling fan if you're printing PLA.

Hi digital dentist,

Point 1 - I used the rep rap calculator to initially get the values for extruder and others, I then done the measurement of filament, like in your link, do I need to be looking more at the line height and width, is that your thought?

Point 2 - I will slow all acceleration down, I’m new to this so jerk thing I’m not sure about, I don’t want to mess around with to many settings, unless I know what I’m doing - or help :-)

Point 3.- To be honest, I’m not sure the material I was using, loads of spools in a box with no label of pla or abs, it’s old and brittle so it could be a temp thing.

Is there anything good to try print that will give me an indication of what I need to adjust initially as this axis part was not good.

Thanks

Phil

|

Re: Starting ormerod print/setup March 19, 2020 07:34AM |

Registered: 11 years ago Posts: 5,780 |

First you need to know what sort of filament you're using. If the stuff is brittle don't use it- it will break in the hot-end and then you'll be cursing yourself while you try to extract it. That's an open printer, so you're going to be printing PLA, PETG, and TPU, but not much ABS.

Get the X and Y axes square then worry about Z. Print a large (100x100 mm) rectangle or square and measure the diagonals. If they are the same length the axes are square. if not, make adjustments to the X or Y axis.

Set acceleration to 500 and jerk to 5 and try again. You can start cranking those numbers up once it's printing without layer shifting.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Get the X and Y axes square then worry about Z. Print a large (100x100 mm) rectangle or square and measure the diagonals. If they are the same length the axes are square. if not, make adjustments to the X or Y axis.

Set acceleration to 500 and jerk to 5 and try again. You can start cranking those numbers up once it's printing without layer shifting.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Starting ormerod print/setup April 15, 2020 12:52PM |

Registered: 4 years ago Posts: 7 |

Back again, After finally getting round to altering the jerk and acceleration speeds I tried printing a small xyz calibration cube. The X is not well defined and the rear corners seem to then slope inwards,

The external perimeters is set to about 10mm/s, whilst perimeters is 35mm, PLA 200c

Any guidance here, slowing the perimeters seemed to have an effect on producing a better print finish.

The external perimeters is set to about 10mm/s, whilst perimeters is 35mm, PLA 200c

Any guidance here, slowing the perimeters seemed to have an effect on producing a better print finish.

|

Re: Starting ormerod print/setup April 16, 2020 03:52PM |

Registered: 6 years ago Posts: 23 |

Your Cube has some stringing, 200C seems a little hot for PLA. Try turning your extrusion temp down to 170 -180C. Some PLA's can print at 200C+ and some I have had to turn down to 160C.

If this is a Bowden setup you should have plenty of retraction, but not too much as you will pull the molten filament up into the cold zone where it will solidify and jam. For a direct drive Extruder I usually have ~1mm retraction, and yes I have used too much retraction and plugged the cold section myself.

Just my experience

If this is a Bowden setup you should have plenty of retraction, but not too much as you will pull the molten filament up into the cold zone where it will solidify and jam. For a direct drive Extruder I usually have ~1mm retraction, and yes I have used too much retraction and plugged the cold section myself.

Just my experience

|

Re: Starting ormerod print/setup April 16, 2020 04:42PM |

Registered: 10 years ago Posts: 14,672 |

On my Ormerod I used to print PLA at 195C for the first layer, 190C for subsequent layers, and 60 or 65C indicated bed temperature. Retraction was 4mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Starting ormerod print/setup April 17, 2020 07:55AM |

Registered: 4 years ago Posts: 7 |

Quote

G3DBuilder

Your Cube has some stringing, 200C seems a little hot for PLA. Try turning your extrusion temp down to 170 -180C. Some PLA's can print at 200C+ and some I have had to turn down to 160C.

If this is a Bowden setup you should have plenty of retraction, but not too much as you will pull the molten filament up into the cold zone where it will solidify and jam. For a direct drive Extruder I usually have ~1mm retraction, and yes I have used too much retraction and plugged the cold section myself.

Just my experience

Yes it’s a Bowden tube setup, I did print at a lower temp before but had trouble with the nozzle blocking (4mm retraction, 60mm/s) so I tried hotter, which seemed to stop the blocking of the nozzle.

I could try 180-190 with 2mm retraction, I also tried hotter too to enable better adhesion.

Bed is currently set at 65 1st layer 60 all others, I find I have to print a brim on parts otherwise corners may curl.

Sorry, only registered users may post in this forum.