Ribbed banding | Delta Printer

Posted by StuartMoorhouse

|

Ribbed banding | Delta Printer April 16, 2020 07:21AM |

Registered: 7 years ago Posts: 15 |

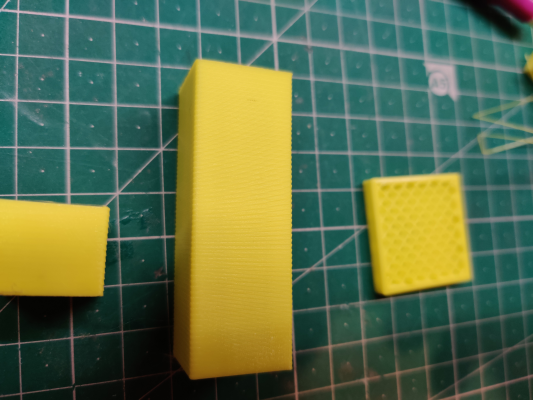

Im having an issue with ridges/banding being obvious on prints when printing in E3D Spoolworks' Edge filament.

I've always had good prints with PLA (60bed, 210nozzle) however with switching over to Edge i'm getting a consistent banding every couple of MM on the Z axis. Upon doing some research the general consensus is that theres a problem with my Z axis, however i'm running a delta.

Im running a kossel mini, with bed at 70oC and extruder at 240oC, sliced with Simplify 3D

I am inclined to say its not a printer issue, as mentioned PLA prints fine.

At first I though it might be a temperature thing. I created a tower and incremented the extruder temperature up from 230oC to 244oC in 5oC intervals, this didn't seem to make much difference.

I have checked the mechanical hardware for any obvious signs.

I've checked the filament thickness and adjusted.

I've checked the nozzle PID

Anyone had any experience of this or any suggestions?

I've always had good prints with PLA (60bed, 210nozzle) however with switching over to Edge i'm getting a consistent banding every couple of MM on the Z axis. Upon doing some research the general consensus is that theres a problem with my Z axis, however i'm running a delta.

Im running a kossel mini, with bed at 70oC and extruder at 240oC, sliced with Simplify 3D

I am inclined to say its not a printer issue, as mentioned PLA prints fine.

At first I though it might be a temperature thing. I created a tower and incremented the extruder temperature up from 230oC to 244oC in 5oC intervals, this didn't seem to make much difference.

I have checked the mechanical hardware for any obvious signs.

I've checked the filament thickness and adjusted.

I've checked the nozzle PID

Anyone had any experience of this or any suggestions?

|

Re: Ribbed banding | Delta Printer April 16, 2020 09:59AM |

Registered: 10 years ago Posts: 14,672 |

Are the side-to-side undulations on the left hand edge in phase with those on the right hand edge (i.e. layers are shifting sideways and back again), or out of phase (i.e. layers are expanding and contracting)?

If layers are expanding and contracting, check the following:

- Layer height is a whole number of full steps of the stepper motors

- Bed heat is using PID, not bang-bang

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If layers are expanding and contracting, check the following:

- Layer height is a whole number of full steps of the stepper motors

- Bed heat is using PID, not bang-bang

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ribbed banding | Delta Printer April 16, 2020 10:35AM |

Registered: 7 years ago Posts: 15 |

Apologies, I wasn't very clear. They're expanding and contracting over around every 6 layers or so i'd say.

Layer height is 0.25mm which is what I regularly print in and experience good results.

Excuse my ignorance, how do I check how the bed heater is controlled? Could this be something to do with both the extruder and bed being at higher temperatures and each time the bed kicks in we see a change in power to the extruder heater?

Layer height is 0.25mm which is what I regularly print in and experience good results.

Excuse my ignorance, how do I check how the bed heater is controlled? Could this be something to do with both the extruder and bed being at higher temperatures and each time the bed kicks in we see a change in power to the extruder heater?

|

Re: Ribbed banding | Delta Printer April 16, 2020 04:48PM |

Registered: 10 years ago Posts: 14,672 |

Quote

StuartMoorhouse

Could this be something to do with both the extruder and bed being at higher temperatures and each time the bed kicks in we see a change in power to the extruder heater?

Yes, that's one mechanism that causes extrusion to depend on whether the bed is on or off, although in RepRapFirmware that is compensated if the extruder heater has been tuned. The other mechanism is buckling of the bed heater or bed plate due to the temperature differential between its faces when the heater is on.

How you switch the bed heater control between bang-bang and PID depends on what firmware your printer is running, which you haven't told us.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ribbed banding | Delta Printer April 16, 2020 05:56PM |

Registered: 7 years ago Posts: 15 |

|

Re: Ribbed banding | Delta Printer April 17, 2020 04:40PM |

Registered: 10 years ago Posts: 14,672 |

If you really are running version 1.10 firmware, that's several years old. If you want to upgrade it, I suggest you seek advice at [forum.duet3d.com] for a faster response.

I think changing the bed heater to PID control may solve the problem.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I think changing the bed heater to PID control may solve the problem.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ribbed banding | Delta Printer April 18, 2020 07:42AM |

Registered: 7 years ago Posts: 15 |

Thanks, i'll head over there as i'm struggling to find documentation on how to update firmware on the older model of the duet that I have (Duet 0.8.5) I can only find firmware update instructions for duet2 or later.

Should I still be able to autotune the bed with the firmware that i'm running however? [edit] It doesn't look like I can [/edit]

Edited 1 time(s). Last edit at 04/18/2020 07:57AM by StuartMoorhouse.

Should I still be able to autotune the bed with the firmware that i'm running however? [edit] It doesn't look like I can [/edit]

Edited 1 time(s). Last edit at 04/18/2020 07:57AM by StuartMoorhouse.

|

Re: Ribbed banding | Delta Printer April 18, 2020 06:34PM |

Registered: 7 years ago Posts: 15 |

|

Re: Ribbed banding | Delta Printer April 26, 2020 07:20AM |

Registered: 7 years ago Posts: 15 |

Still having some troubles so i'm wandering if anyone has any more advice on things to try.

It looks as though the banding / ribbing of layers is occurring at the start of the outer perimeter and then eases off as the perimeter goes round. I think the reason I was seeing it on all 4 sides of the cube was due to each perimeter starting at a different corner and working round.

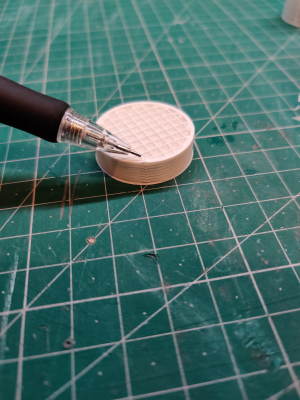

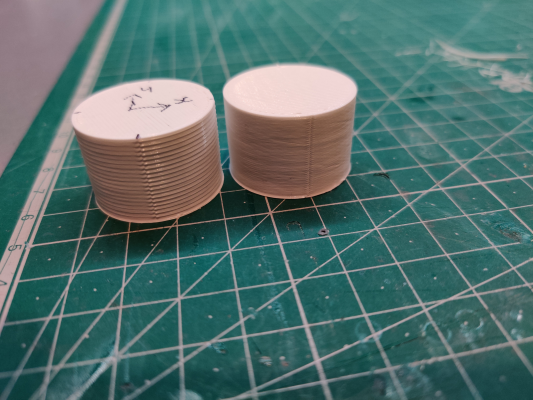

With the cylindrical print image i've uploaded, when watching this print, you can see the obvious zipper of where the layer starts and the banding continues in the direction of travel, almost like there is some over extrusion at the start of travel.

This was printed with:

extruder temp: 210 degrees

bed temp: 60 degrees

0.25mm layer height

3 bottom layers, 3 top layers 3 perimeters,

45mm/s default print speed

part cooling fan at full for every layer above the first

Sliced with S3D

@dc could you please point me in the right direction for being able to calculate correct layer height with regards to stepper motor steps - i've previously not though this could be the case due to having nearly always printed at 0.25mm

So far i've tried / have done:

-Update the firmware to 1.26.1

-Ran PID autotune for the bed and extruder

-Changing nozzle temperature, both up and down - this didn't make much difference at all.

-Decreasing the extrusion multiplier - made some slight difference but the top and bottom layers suffered massively.

-Changing perimeter print order from 'out to in' to 'in to out' - this exaggerated the issue.

-Slowing the speed down - no noticeable change

-Checking extruder step calibration

-Re-tensioned the belts

Things that i'm thinking it could be and have yet to try:

-Changing the nozzle, could there be a small blockage thats reducing the flow rate?

-There looks to be a small amount of play between the gears of the extruder - this maybe a possibility, I'll try printing new gears but might struggle with the current print quality.

-Re-building the motion system to see if that makes any difference

Thanks

Edited 1 time(s). Last edit at 04/26/2020 06:28PM by StuartMoorhouse.

It looks as though the banding / ribbing of layers is occurring at the start of the outer perimeter and then eases off as the perimeter goes round. I think the reason I was seeing it on all 4 sides of the cube was due to each perimeter starting at a different corner and working round.

With the cylindrical print image i've uploaded, when watching this print, you can see the obvious zipper of where the layer starts and the banding continues in the direction of travel, almost like there is some over extrusion at the start of travel.

This was printed with:

extruder temp: 210 degrees

bed temp: 60 degrees

0.25mm layer height

3 bottom layers, 3 top layers 3 perimeters,

45mm/s default print speed

part cooling fan at full for every layer above the first

Sliced with S3D

@dc could you please point me in the right direction for being able to calculate correct layer height with regards to stepper motor steps - i've previously not though this could be the case due to having nearly always printed at 0.25mm

So far i've tried / have done:

-Update the firmware to 1.26.1

-Ran PID autotune for the bed and extruder

-Changing nozzle temperature, both up and down - this didn't make much difference at all.

-Decreasing the extrusion multiplier - made some slight difference but the top and bottom layers suffered massively.

-Changing perimeter print order from 'out to in' to 'in to out' - this exaggerated the issue.

-Slowing the speed down - no noticeable change

-Checking extruder step calibration

-Re-tensioned the belts

Things that i'm thinking it could be and have yet to try:

-Changing the nozzle, could there be a small blockage thats reducing the flow rate?

-There looks to be a small amount of play between the gears of the extruder - this maybe a possibility, I'll try printing new gears but might struggle with the current print quality.

-Re-building the motion system to see if that makes any difference

Thanks

Edited 1 time(s). Last edit at 04/26/2020 06:28PM by StuartMoorhouse.

|

Re: Ribbed banding | Delta Printer April 26, 2020 06:02PM |

Registered: 7 years ago Posts: 15 |

Update...

After watching several prints for a while i've made the following observations:

The issue always occurs at the start of a new layer after the printing of adjacent infill. (Image 1)

With the test cylinders i've been printing, the infill finishes at the perimeter, filament retracts, Z height is increased and then the perimeter of the next layer starts.

I tried doubling my retraction from 5mm to 10mm but this didn't seem to do much.

However, turning extraction off completely pretty much got rid of the problem (Image 2)

Still none the wiser as I cant get my head round whats going on, I still need extraction on to prevent stringing.

After watching several prints for a while i've made the following observations:

The issue always occurs at the start of a new layer after the printing of adjacent infill. (Image 1)

With the test cylinders i've been printing, the infill finishes at the perimeter, filament retracts, Z height is increased and then the perimeter of the next layer starts.

I tried doubling my retraction from 5mm to 10mm but this didn't seem to do much.

However, turning extraction off completely pretty much got rid of the problem (Image 2)

Still none the wiser as I cant get my head round whats going on, I still need extraction on to prevent stringing.

|

Re: Ribbed banding | Delta Printer April 28, 2020 03:34AM |

Registered: 10 years ago Posts: 14,672 |

Have you tried pressure advance? It's normal to get under-extrusion immediately after a travel move and over-extrusion immediately before one unless you take precautions to avoid it, of which pressure advance is usually the most effective.

Edited 2 time(s). Last edit at 04/28/2020 03:39AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 04/28/2020 03:39AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.