Printing with ABS.. Questions

Posted by jdebuhr

|

Printing with ABS.. Questions April 20, 2020 11:02PM |

Registered: 4 years ago Posts: 77 |

|

Re: Printing with ABS.. Questions April 20, 2020 11:30PM |

Registered: 7 years ago Posts: 363 |

|

Re: Printing with ABS.. Questions April 20, 2020 11:32PM |

Registered: 4 years ago Posts: 77 |

|

Re: Printing with ABS.. Questions April 20, 2020 11:33PM |

Registered: 11 years ago Posts: 5,780 |

ABS likes to stick to PEI at 100C.

If you're serious about printing ABS, there's a little more to it. See: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you're serious about printing ABS, there's a little more to it. See: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printing with ABS.. Questions April 20, 2020 11:47PM |

Registered: 4 years ago Posts: 77 |

|

Re: Printing with ABS.. Questions April 20, 2020 11:58PM |

Registered: 11 years ago Posts: 5,780 |

If the part isn't too bulky, you can get away without heating the enclosure- just put a box over the printer to prevent drafts from cooling the print too suddenly.

A lot of people print a lot of PLA because they have open printers. But if you're printing things that you want to last a long time, PLA is not a great choice because it melts at a very low temperature. Can you guarantee that your print will never be left sitting in a sunny window or in a hot car, or near any other source of heat? If you build/modify your printer to print ABS reliably, there's (almost) no reason to ever print PLA.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A lot of people print a lot of PLA because they have open printers. But if you're printing things that you want to last a long time, PLA is not a great choice because it melts at a very low temperature. Can you guarantee that your print will never be left sitting in a sunny window or in a hot car, or near any other source of heat? If you build/modify your printer to print ABS reliably, there's (almost) no reason to ever print PLA.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printing with ABS.. Questions April 21, 2020 12:27AM |

Registered: 4 years ago Posts: 77 |

Quote

the_digital_dentist

If the part isn't too bulky, you can get away without heating the enclosure- just put a box over the printer to prevent drafts from cooling the print too suddenly.

A lot of people print a lot of PLA because they have open printers. But if you're printing things that you want to last a long time, PLA is not a great choice because it melts at a very low temperature. Can you guarantee that your print will never be left sitting in a sunny window or in a hot car, or near any other source of heat? If you build/modify your printer to print ABS reliably, there's (almost) no reason to ever print PLA.

Printer sits in my basement which is around 68 degrees.. basement is finished and the printer is in my office/smaller room. it is an open frame printer. I have been printing the test piece I want to make out of PLA. going by what I am reading I need to upgrade my hotend to be all metal ( V6 clone is there now) and I think a e3d V6 would be a direct swap.

I am building a small LCD bezel for a 5" screen, not very thick or tall. but it will live in a car interior when complete

|

Re: Printing with ABS.. Questions April 21, 2020 07:47AM |

Registered: 7 years ago Posts: 363 |

If you anneal PLA it's temperature performance can exceed that of ABS. But there is a trade-off. The annealing process can warp your part. It also causes shrinkage that means you'd probably not want to go that route for anything requiring precise measurements. PETG is a more temperature tolerant material that is easier to print with an open printer although ABS is the better choice if you're able to print with it effectively.

Edited 1 time(s). Last edit at 04/21/2020 07:47AM by obelisk79.

Edited 1 time(s). Last edit at 04/21/2020 07:47AM by obelisk79.

|

Re: Printing with ABS.. Questions April 21, 2020 08:23AM |

Registered: 4 years ago Posts: 77 |

I am all for using PLA if I can.. But here is why I am looking at ABS.

this part I am making will potentially need to attach to an ABS part in my car. to do that I use Acetone along with ABS pellets. this part also needs to be painted along with my ABS part in the car

attached is a picture overall rough size is 140mm x 80mm X 8mm

Thanks!!

this part I am making will potentially need to attach to an ABS part in my car. to do that I use Acetone along with ABS pellets. this part also needs to be painted along with my ABS part in the car

attached is a picture overall rough size is 140mm x 80mm X 8mm

Thanks!!

|

Re: Printing with ABS.. Questions April 21, 2020 09:03AM |

Registered: 11 years ago Posts: 5,780 |

Yes, annealing PLA is great... as long as the finished shape and dimensions of the part don't matter - Yoda heads, tugboats, and other throw-away stuff like that. But what's the point of annealing throw-aways?

If your print is for use in a car, then PLA is out. I don't know about using PETG in a hot car.

The E3D V6 is the go-to hot-end and I used them for years, but they have problems. The heatsink has no flat surface on the mount, so it can rotate unless the extruder clamps it tightly- some do and some don't. I found the E3D Titan didn't clamp it very tightly, the Bondtech BMG does. The fan is mounted on a little plastic piece that clips onto the heatsink fins and can rotate easily. Sooner or later it hits the heater block and melts. The worst part is that the heatbreak that screws into the heatsink has no way to be tightened securely, and it can and will come loose while printing. The throat of the heatbreak is very thin which makes for good thermal isolation but also makes it very weak. Crashing the nozzle into the bed can easily bend it.

I put a cheap XCR3D hotend on my printer about 2 years ago and it has worked perfectly except for the supplied fan which is a piece of crap. I replaced it with a $7 Sunon fan. About $22 total for the hot-end and the fan. The XCR3D hotend still has the round mount of the E3D V6, but similarities end there. The fan is mounted on a metal bracket that is screwed to the heatsink and never comes loose or melts, the heatbreak is held in the heatsink using set screws so it never comes loose, The throat of the heatbreak is thicker than the E3D part and won't bend if you happen to bang the nozzle into the bed. I print about 80% ABS, 18% PETG, and 2% PLA and I've never had any trouble with it. Oh, yeah, it comes with a 50W heater that gets it hot fast. It is longer than the E3D V6 so you lose a few mm of vertical print capacity. It uses E3D nozzles. More here: [drmrehorst.blogspot.com]

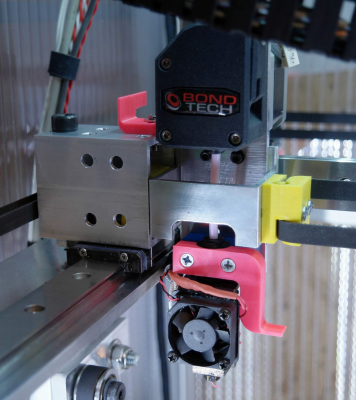

I no longer use the Titan extruder- switched to Bondtech BMG, and I don't use the hot-end mounted in the extruder- the two are separated by by about 75 mm of teflon tubing (world's shortest Bowden tube?), and the hot-end is mounted on a 5mm aluminum plate using printed ABS mounts:

Edited 1 time(s). Last edit at 04/21/2020 09:04AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If your print is for use in a car, then PLA is out. I don't know about using PETG in a hot car.

The E3D V6 is the go-to hot-end and I used them for years, but they have problems. The heatsink has no flat surface on the mount, so it can rotate unless the extruder clamps it tightly- some do and some don't. I found the E3D Titan didn't clamp it very tightly, the Bondtech BMG does. The fan is mounted on a little plastic piece that clips onto the heatsink fins and can rotate easily. Sooner or later it hits the heater block and melts. The worst part is that the heatbreak that screws into the heatsink has no way to be tightened securely, and it can and will come loose while printing. The throat of the heatbreak is very thin which makes for good thermal isolation but also makes it very weak. Crashing the nozzle into the bed can easily bend it.

I put a cheap XCR3D hotend on my printer about 2 years ago and it has worked perfectly except for the supplied fan which is a piece of crap. I replaced it with a $7 Sunon fan. About $22 total for the hot-end and the fan. The XCR3D hotend still has the round mount of the E3D V6, but similarities end there. The fan is mounted on a metal bracket that is screwed to the heatsink and never comes loose or melts, the heatbreak is held in the heatsink using set screws so it never comes loose, The throat of the heatbreak is thicker than the E3D part and won't bend if you happen to bang the nozzle into the bed. I print about 80% ABS, 18% PETG, and 2% PLA and I've never had any trouble with it. Oh, yeah, it comes with a 50W heater that gets it hot fast. It is longer than the E3D V6 so you lose a few mm of vertical print capacity. It uses E3D nozzles. More here: [drmrehorst.blogspot.com]

I no longer use the Titan extruder- switched to Bondtech BMG, and I don't use the hot-end mounted in the extruder- the two are separated by by about 75 mm of teflon tubing (world's shortest Bowden tube?), and the hot-end is mounted on a 5mm aluminum plate using printed ABS mounts:

Edited 1 time(s). Last edit at 04/21/2020 09:04AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Printing with ABS.. Questions April 21, 2020 10:40AM |

Registered: 4 years ago Posts: 77 |

Wow thanks for the info.. I like that setup with the fan mount. the kit printer I got as a gift from my wife, has this setup for the fan (heat sink is hidden in the picture as it is behind the fan. it is a direct mount and I would like to find a better solution, any suggestions?

I like the idea of the heatbreak being set and not turning as well

The auto bed level is mounted but I have not hooked it up yet.

I like the idea of the heatbreak being set and not turning as well

The auto bed level is mounted but I have not hooked it up yet.

|

Re: Printing with ABS.. Questions June 14, 2020 11:11AM |

Registered: 9 years ago Posts: 294 |

I have a very open frame coreXY printer and the only issue I have had with printing ABS is setting the hotend temp. What I found after many warped prints was that the temp 240-245 was too high. Lowering the temp 230-240 causes better adhesion to the PEI bed @ 110°C.

The higher temps I was using with PETG and PLA also affected those filaments the same way. I could not make PLA stick to the PEI at any bed temp until I lowered the hotend temp to under 200°.

The higher temps I was using with PETG and PLA also affected those filaments the same way. I could not make PLA stick to the PEI at any bed temp until I lowered the hotend temp to under 200°.

Sorry, only registered users may post in this forum.