First Layer Adhesion

Posted by Vagulus

|

First Layer Adhesion June 05, 2020 10:50PM |

Registered: 3 years ago Posts: 14 |

My Raise3D Pro2 printer has BuildTak on the Printing Platform. My filament is eSun PLA+ 1.75 mm. Platform Temperature is set to 50C. Nozzle clearance from Platform at 'Home' is 0.2 mm. My first layer does not stick to the BuildTak properly (even with 3DLac PVA spray). There is always some material swaying around in the breeze (so to speak). Download the gCode here.

How do I get my First Layer to stick?

Thanks

----------------------------------------------

"Some people

seem to misinterpret

complexity as sophistication."

(Nicklaus Wirth)

How do I get my First Layer to stick?

Thanks

----------------------------------------------

"Some people

seem to misinterpret

complexity as sophistication."

(Nicklaus Wirth)

|

Re: First Layer Adhesion June 06, 2020 04:26PM |

Registered: 4 years ago Posts: 285 |

My first thought is that your hot end is too high. The classic "paper" test for leveling is 0.004 inch, or 0.1 mm, no matter what the nozzle size is. Try baby stepping your nozzle down at the start of the print to get a good "squish" of the first layers, and you should be O.K.

I like to do about 5 circuits of the nozzle for a skirt (or brim), before the actual print starts. That gives me a chance to observe, and correct, the first layer squish before commiting to the print itself.

I like to do about 5 circuits of the nozzle for a skirt (or brim), before the actual print starts. That gives me a chance to observe, and correct, the first layer squish before commiting to the print itself.

|

Re: First Layer Adhesion June 06, 2020 08:49PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: First Layer Adhesion June 07, 2020 01:45AM |

Registered: 7 years ago Posts: 363 |

White vinegar also works well for cleaning build surfaces. I heat my bed to 50c and gently rub the plates several times to get any residue and oils off the surface. The heat ensures it evaporates quickly to avoid any risk of damage from letting the vinegar stay on the surface too long.

Edited 1 time(s). Last edit at 06/07/2020 01:45AM by obelisk79.

Edited 1 time(s). Last edit at 06/07/2020 01:45AM by obelisk79.

|

Re: First Layer Adhesion June 07, 2020 09:53AM |

Registered: 6 years ago Posts: 1,863 |

Quote

obelisk79

White vinegar also works well for cleaning build surfaces. I heat my bed to 50c and gently rub the plates several times to get any residue and oils off the surface. The heat ensures it evaporates quickly to avoid any risk of damage from letting the vinegar stay on the surface too long.

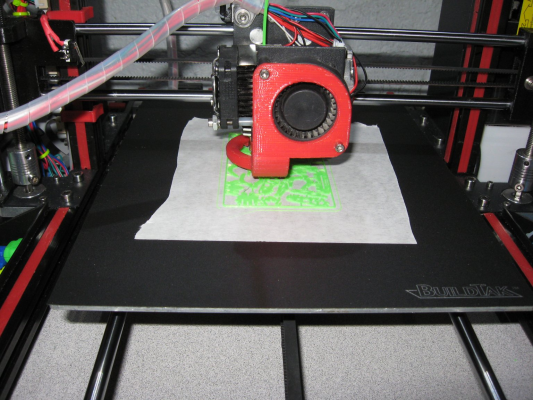

I had a BuildTak surface and cleaned it many times and never got good results, Posted here many times of my results.

I even had to cover the surface with Transfer paper to achieve good surface adhesion.

My personal BuildTak observations. I am adding this last comment. " with all fakes today who is to say that this was not a fake BuildTak Bed Surface "

I removed this brand new surface 2 years ago in attached post below and still use a cheap chinese surface today with perfect adhesion.

[reprap.org]

Edited 3 time(s). Last edit at 06/07/2020 09:57AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: First Layer Adhesion June 11, 2020 06:41PM |

Registered: 3 years ago Posts: 14 |

|

Re: First Layer Adhesion June 13, 2020 10:13PM |

Registered: 9 years ago Posts: 294 |

Sorry, only registered users may post in this forum.

.

.