Layer features affecting layer width

Posted by drmaestro

|

Layer features affecting layer width April 10, 2021 10:29AM |

Registered: 9 years ago Posts: 330 |

Hi,

This is a topic that can be found on the Internet forums, but I still haevn't seen one where the exact reason is described and also how to correct it.

The problem: : If a layer contains features such as holes, the entire layer's width is changed. It doesn't align with the previous layer.

It sounds like a belt problem or loose idler but it probably isn't, as no one is able to correct it by tightening the belts.

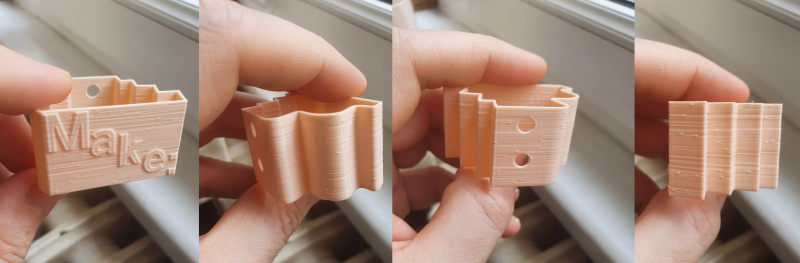

I've decide to print some test objects to demonstrate what I mean. I am using a calibration piece from the 2017 Make Magazine calibration test. Here's the object 'ıve used:

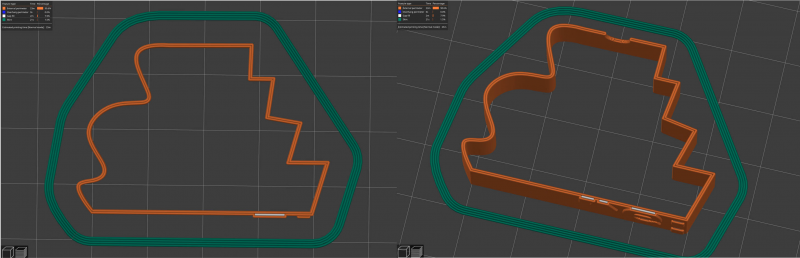

The object has 2 holes at different heights at its rear side. The wall thickness is 0.8 mm. My nozzle diemeter is 0.4 mm and layer height is 0.2 mm. Shell thickness is 2 layers. When sliced with Prusa Slicer (layer width is set to automatic), the layers with no hole elements on it print as 2 separate lines, while the layers with hole parts print as one single continous line that loops from the border of the hole:

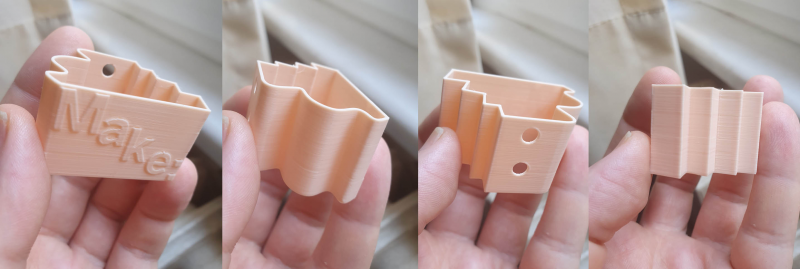

Here's how the printed object looks like when printed with internal perimeters first and aligned seams:

This is the print that has the best quality and the layer difference is the least visible. It can be seen best on the rightmost side on the picture, in front side (leftmost picture) and on the rear side's front wall (leftmost, rear side).

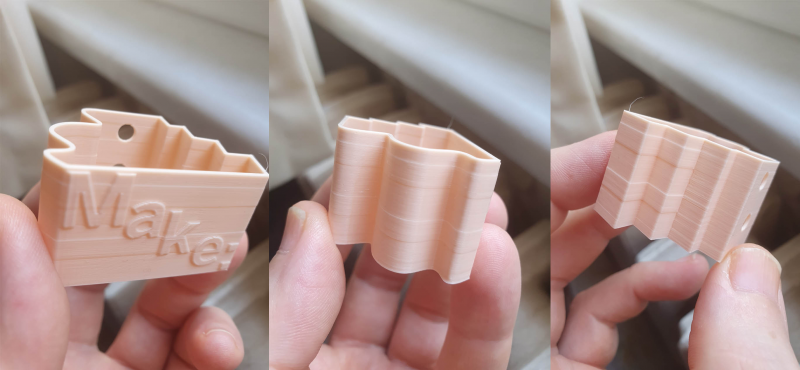

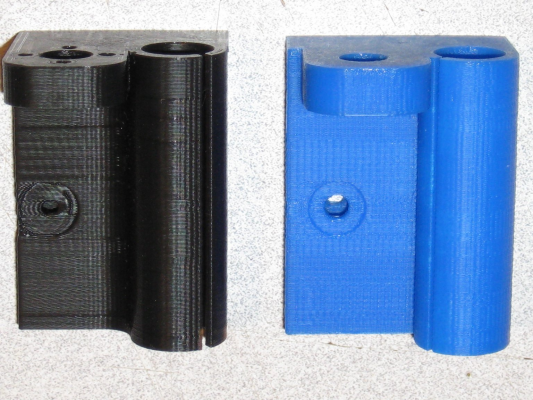

If I print the object with external perimeters first, here's what I get (all other settings are the same):

If I print the object with internal perimeters first but with random seams, here's what I get:

Why do I get those layer irregularities? Why do you think this difference exist between those settings?

When the layers with the holes are printed, as they are looping from the edge of the holes, these layers are a continous single line, while the layers without a hole are 2 separate lines, where the head moves to another location to start printing. Do you think this can be a reason?

Thanks...

This is a topic that can be found on the Internet forums, but I still haevn't seen one where the exact reason is described and also how to correct it.

The problem: : If a layer contains features such as holes, the entire layer's width is changed. It doesn't align with the previous layer.

It sounds like a belt problem or loose idler but it probably isn't, as no one is able to correct it by tightening the belts.

I've decide to print some test objects to demonstrate what I mean. I am using a calibration piece from the 2017 Make Magazine calibration test. Here's the object 'ıve used:

The object has 2 holes at different heights at its rear side. The wall thickness is 0.8 mm. My nozzle diemeter is 0.4 mm and layer height is 0.2 mm. Shell thickness is 2 layers. When sliced with Prusa Slicer (layer width is set to automatic), the layers with no hole elements on it print as 2 separate lines, while the layers with hole parts print as one single continous line that loops from the border of the hole:

Here's how the printed object looks like when printed with internal perimeters first and aligned seams:

This is the print that has the best quality and the layer difference is the least visible. It can be seen best on the rightmost side on the picture, in front side (leftmost picture) and on the rear side's front wall (leftmost, rear side).

If I print the object with external perimeters first, here's what I get (all other settings are the same):

If I print the object with internal perimeters first but with random seams, here's what I get:

Why do I get those layer irregularities? Why do you think this difference exist between those settings?

When the layers with the holes are printed, as they are looping from the edge of the holes, these layers are a continous single line, while the layers without a hole are 2 separate lines, where the head moves to another location to start printing. Do you think this can be a reason?

Thanks...

|

Re: Layer features affecting layer width May 04, 2021 03:15AM |

Registered: 9 years ago Posts: 330 |

Some more observations:

I've printed the object in different orientations to see if it is a belt problem. The problem exists in all of the orientations (horizontal, vertical, 45 degrees) and it is always at the same location and at the same direction, so this should exclude a belt problem. I've also added another object roughly the same length but without holes and there is no layer shift at that object at the level of the holes (if it was a layer shift, then the layers at the other object should have shifted as well).

The thickness of the object matters. The object I've printed can be found at [www.thingiverse.com] It has 2 versions, one with 0.8 mm thick walls, and one with 1 mm thick walls. It is less visible in the object with 1 mm thick walls (printing with 0.4 mm nozzle and using default line widths provided by Prusa Slicer or Simplify 3D). The layer thickness changes when there is a hole (it is slightly - 0.1 mm maybe- thicker).

The thickness of the layer changes apparently on the layer itself. If you look at the second row of pictures on my original post, where I printed external layers first, the rightmost image demonstrates it the best. On the angular sides, the artifact becomes thinner.

I started to wonder if it is a limitation of the FDM printing itself an not my machine. Maybe it has something to do with cooling or a problem with the slicers miscalculating the amount of the deposited plastic. Could anyone also print the 0.8 mm thick version and see if you have similar artefacts there, espescially when printing with external perimeters first? Maybe it is something like the benchy line (that happens in almost all printers).

I've printed the object in different orientations to see if it is a belt problem. The problem exists in all of the orientations (horizontal, vertical, 45 degrees) and it is always at the same location and at the same direction, so this should exclude a belt problem. I've also added another object roughly the same length but without holes and there is no layer shift at that object at the level of the holes (if it was a layer shift, then the layers at the other object should have shifted as well).

The thickness of the object matters. The object I've printed can be found at [www.thingiverse.com] It has 2 versions, one with 0.8 mm thick walls, and one with 1 mm thick walls. It is less visible in the object with 1 mm thick walls (printing with 0.4 mm nozzle and using default line widths provided by Prusa Slicer or Simplify 3D). The layer thickness changes when there is a hole (it is slightly - 0.1 mm maybe- thicker).

The thickness of the layer changes apparently on the layer itself. If you look at the second row of pictures on my original post, where I printed external layers first, the rightmost image demonstrates it the best. On the angular sides, the artifact becomes thinner.

I started to wonder if it is a limitation of the FDM printing itself an not my machine. Maybe it has something to do with cooling or a problem with the slicers miscalculating the amount of the deposited plastic. Could anyone also print the 0.8 mm thick version and see if you have similar artefacts there, espescially when printing with external perimeters first? Maybe it is something like the benchy line (that happens in almost all printers).

|

Re: Layer features affecting layer width May 04, 2021 07:49AM |

Registered: 6 years ago Posts: 1,863 |

I have noted this for a long time until changing my slicer to PrusaSlicer 2.3.0

Computer Programmer / Electronics Technician

Computer Programmer / Electronics Technician

|

Re: Layer features affecting layer width May 04, 2021 11:00AM |

Registered: 9 years ago Posts: 330 |

I am not sure this is exactly the same problem. On the picture, I can see surface artefacts due to ringing and as the head has to move in opposite direction at the hole, it creates a different ringing pattern and they don't superimpose, so it gives the illusion of a displaced layer. Did you feel any difference in thickness?

I am already on Prusa Slicer and the parts are printed on it, but I had similar results with Simplify and Cura too.

Edited 1 time(s). Last edit at 05/04/2021 11:14AM by drmaestro.

I am already on Prusa Slicer and the parts are printed on it, but I had similar results with Simplify and Cura too.

Edited 1 time(s). Last edit at 05/04/2021 11:14AM by drmaestro.

Sorry, only registered users may post in this forum.