|

Persistant bed level issues - new x-carriage May 16, 2021 10:45AM |

Registered: 3 years ago Posts: 55 |

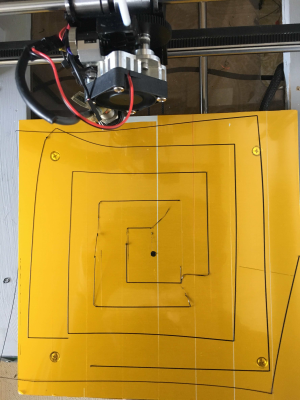

Got this 3mm aluminum plate with Titan Aero head you see in pics below. Using Marlin with bilevel bed leveling and 9 measurement points. I'd just re-done the whole carriage and X ends to what you see below so that it does not stick out so much, is stiffer, and has the probe closer to the nozzle. Now, I can get the probe to all points the nozzle can go and it probes at very edges nicely.

My bed level test works better but darned thing still could be better. The test has been disturbed in pic below, I'd lifted it a bit and measured the thickness at various points. The thickness on the left side is pretty goot at 0.22 mm thickness. The right side though, it varies from 0.16 mm down to 0.1mm at the far edge.

The bed level matrix looks OK, looks like this:

echo: G29 W I0 J0 Z-0.37250

echo: G29 W I1 J0 Z-0.33250

echo: G29 W I2 J0 Z-0.46000

echo: G29 W I0 J1 Z0.01250

echo: G29 W I1 J1 Z0.01500

echo: G29 W I2 J1 Z-0.15000

echo: G29 W I0 J2 Z0.42250

echo: G29 W I1 J2 Z0.22000

echo: G29 W I2 J2 Z-0.24000

I'd seen somebody mention checking the twist in your two z-bars, that for me is quite good. I'd tried even offsetting that to see if there was an effect, I'd have to say that it isn't significant even if it were off.

Gonna try mechanical leveling some more to get the above matrix more flat but .. have done this before, and I'm expecting there will still be this 0.1mm difference over the bed. I'd like to see it under 0.05mm as I usually print with ABS and it is very particular about bed level.

Edited 1 time(s). Last edit at 05/16/2021 12:31PM by NovaHuta.

My bed level test works better but darned thing still could be better. The test has been disturbed in pic below, I'd lifted it a bit and measured the thickness at various points. The thickness on the left side is pretty goot at 0.22 mm thickness. The right side though, it varies from 0.16 mm down to 0.1mm at the far edge.

The bed level matrix looks OK, looks like this:

echo: G29 W I0 J0 Z-0.37250

echo: G29 W I1 J0 Z-0.33250

echo: G29 W I2 J0 Z-0.46000

echo: G29 W I0 J1 Z0.01250

echo: G29 W I1 J1 Z0.01500

echo: G29 W I2 J1 Z-0.15000

echo: G29 W I0 J2 Z0.42250

echo: G29 W I1 J2 Z0.22000

echo: G29 W I2 J2 Z-0.24000

I'd seen somebody mention checking the twist in your two z-bars, that for me is quite good. I'd tried even offsetting that to see if there was an effect, I'd have to say that it isn't significant even if it were off.

Gonna try mechanical leveling some more to get the above matrix more flat but .. have done this before, and I'm expecting there will still be this 0.1mm difference over the bed. I'd like to see it under 0.05mm as I usually print with ABS and it is very particular about bed level.

Edited 1 time(s). Last edit at 05/16/2021 12:31PM by NovaHuta.

|

Re: Persistant bed level issues - new x-carriage May 19, 2021 08:31AM |

Registered: 3 years ago Posts: 55 |

So, replaced the end part and removed the spring from the tensioner, coo-incidental really but none the less, after re-calibrating there is still this 0.1mm difference between different areas of the bed on my test-print BUT it is now just a tad closer to the bed and you know, 0.1mm difference in the first layer is good enough for reliable printing. It is only that far off at the extreme edges so I'd call this problem solved.

I think the key was getting the probe close enough to the nozzle so that the probe can get to all edges of the build-plate and this helped the bilinear levelling to be more accurate for the entire build-plate and then just setting the height to that happy zone of acceptability with the given error.

I think the key was getting the probe close enough to the nozzle so that the probe can get to all edges of the build-plate and this helped the bilinear levelling to be more accurate for the entire build-plate and then just setting the height to that happy zone of acceptability with the given error.

Sorry, only registered users may post in this forum.