VFA (vertical fine artefacts)

Posted by yet-another-average-joe

|

VFA (vertical fine artefacts) March 18, 2023 12:24PM |

Registered: 4 years ago Posts: 90 |

Hi,

I'm finalizing a bed slinger I built reusing a Tevo Tornado (bed slinger, CR10 knockoff) : I reused the frame and the bed, threw away most of the sheet metal parts, machined everything I could from 6 mm aluminium and more, reinforced everything, and replaced the BMG + V6 Bowden I've been using for years with a Stealthburner. It's built like a tank.

And now I have VFA on all walls. Pitch 2 mm. Exactly in sync with the belts.

It's a known issue on many printers. I did some readings, mainly about the Prusa MK3. Seems some solved the problem with 0.9° steppers. But I didn't find a real explanation...

The first that came to my mind is a polygon effect because of the timing belts / pulleys. And the problem is now more visible because of the huge increase in rigidity (it existed, but was negligible).

Some thoughts ? (the search engine gave zero answers...)

I'm more interested in explanations than solutions because it's not a big issue for the parts I'm printing : it's mainly cosmetic.

PS : idlers are thoothed when needed, as per Gates guidelines for smaller idlers - belts, pulleys and idlers are not Gates ones, but cheap components from Ali, some from Amazon) . Profiles not matching well ?

Edited 1 time(s). Last edit at 03/18/2023 01:10PM by yet-another-average-joe.

I'm finalizing a bed slinger I built reusing a Tevo Tornado (bed slinger, CR10 knockoff) : I reused the frame and the bed, threw away most of the sheet metal parts, machined everything I could from 6 mm aluminium and more, reinforced everything, and replaced the BMG + V6 Bowden I've been using for years with a Stealthburner. It's built like a tank.

And now I have VFA on all walls. Pitch 2 mm. Exactly in sync with the belts.

It's a known issue on many printers. I did some readings, mainly about the Prusa MK3. Seems some solved the problem with 0.9° steppers. But I didn't find a real explanation...

The first that came to my mind is a polygon effect because of the timing belts / pulleys. And the problem is now more visible because of the huge increase in rigidity (it existed, but was negligible).

Some thoughts ? (the search engine gave zero answers...)

I'm more interested in explanations than solutions because it's not a big issue for the parts I'm printing : it's mainly cosmetic.

PS : idlers are thoothed when needed, as per Gates guidelines for smaller idlers - belts, pulleys and idlers are not Gates ones, but cheap components from Ali, some from Amazon) . Profiles not matching well ?

Edited 1 time(s). Last edit at 03/18/2023 01:10PM by yet-another-average-joe.

|

Re: VFA (vertical fine artefacts) March 18, 2023 05:19PM |

Registered: 12 years ago Posts: 1,450 |

Assuming that this is not resonance, the first question is if there is any noise from the idler - or for that matter, from the drive gear.

My first printer, a Prusa Mendel, did show a 2.5mm pattern effect on T2.5 belt, but it turned out to be a substandard stepper motor - the pitch similarity was coincidental.

If it does turn out that it is caused by a poor tooth form on the idler, you could try having the smooth side of the belt on the idler - either by the old 1/2 twist or by having the half of the belt that is running over the idler reversed. Picture below from my Delta printer with reversed belt over idler.

The reason the belt is glued back to back instead of tooth to tooth is that the toothed side of the belt has a lubricant dispersed through the rubber which makes gluing unreliable.

Mike

My first printer, a Prusa Mendel, did show a 2.5mm pattern effect on T2.5 belt, but it turned out to be a substandard stepper motor - the pitch similarity was coincidental.

If it does turn out that it is caused by a poor tooth form on the idler, you could try having the smooth side of the belt on the idler - either by the old 1/2 twist or by having the half of the belt that is running over the idler reversed. Picture below from my Delta printer with reversed belt over idler.

The reason the belt is glued back to back instead of tooth to tooth is that the toothed side of the belt has a lubricant dispersed through the rubber which makes gluing unreliable.

Mike

|

Re: VFA (vertical fine artefacts) March 18, 2023 10:30PM |

Registered: 4 years ago Posts: 90 |

Oh yes, the motors springyness : MRR ! Didn't think of that. Just found this page : [prorifi3d.com]

I don't think the motors are the only culprit, because the problem showed a lot more after rigidifying the printer (not Z-banding or wobbling, I straightened the leadscrews using a press and a surface plate, they are mounted with respect of isostatism, belt driven, on preloaded bearings pairs, hanging from top, with very rigid and precise machined carriages, and rollers not being in a cantilever configuration).

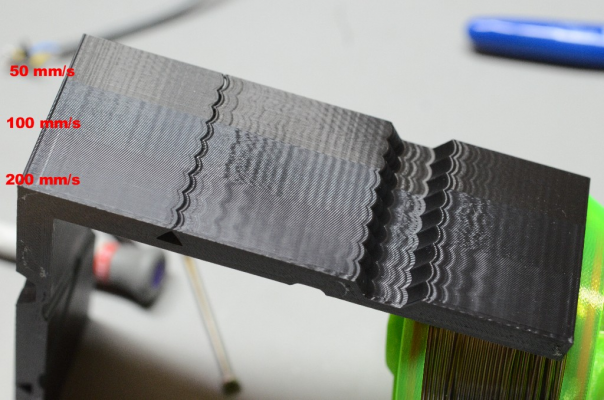

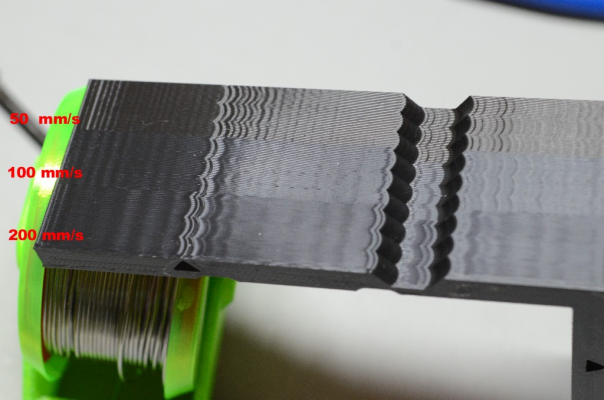

I printed the Klipper Input Shaper calibration model at different speeds. And guess what ? Worse results are at lower speeds, best ones at higher ones !

I pushed up to 200 mm/s / 15 mm/s, 2000 mm/s² in Marlin (20 mm/s -> layer shifting). Very agressive for such a printer AFAIK. The model looks much better at 200 mm/s than 50 !!! Even less ringing.

Have to do more testing, as it is counter intuitive.

This being said, I discovered my belts are falling apart ; 20 hours : shot !

5 single fiberglass strands only. The tooth pattern now can be seen on their back ! Will put the old ones back (5 fiberglass pairs, thousands of hours, in a much better shape). Could twist the Y, not the X.

Took a couple of pictures with the phone, but due to moiré, they are unreadable on screen. Will try with better cameras and macro lens later.

Was suspecting new things were about to happen with the super rigid structure + DD, wasn't wrong ! Thinking of cars (4WD for example) and the mix between suspension and chassis flex. Still have those motor dampers that had the hype years ago. Removed them immediately because they were producing bad prints, but I'm now wondering if they could help...

Edited 1 time(s). Last edit at 03/18/2023 10:31PM by yet-another-average-joe.

I don't think the motors are the only culprit, because the problem showed a lot more after rigidifying the printer (not Z-banding or wobbling, I straightened the leadscrews using a press and a surface plate, they are mounted with respect of isostatism, belt driven, on preloaded bearings pairs, hanging from top, with very rigid and precise machined carriages, and rollers not being in a cantilever configuration).

I printed the Klipper Input Shaper calibration model at different speeds. And guess what ? Worse results are at lower speeds, best ones at higher ones !

I pushed up to 200 mm/s / 15 mm/s, 2000 mm/s² in Marlin (20 mm/s -> layer shifting). Very agressive for such a printer AFAIK. The model looks much better at 200 mm/s than 50 !!! Even less ringing.

Have to do more testing, as it is counter intuitive.

This being said, I discovered my belts are falling apart ; 20 hours : shot !

5 single fiberglass strands only. The tooth pattern now can be seen on their back ! Will put the old ones back (5 fiberglass pairs, thousands of hours, in a much better shape). Could twist the Y, not the X.

Took a couple of pictures with the phone, but due to moiré, they are unreadable on screen. Will try with better cameras and macro lens later.

Was suspecting new things were about to happen with the super rigid structure + DD, wasn't wrong ! Thinking of cars (4WD for example) and the mix between suspension and chassis flex. Still have those motor dampers that had the hype years ago. Removed them immediately because they were producing bad prints, but I'm now wondering if they could help...

Edited 1 time(s). Last edit at 03/18/2023 10:31PM by yet-another-average-joe.

|

Re: VFA (vertical fine artefacts) March 19, 2023 09:24AM |

Registered: 12 years ago Posts: 1,450 |

The article on the Profifi site that you linked to was very interesting and a number of there points were well taken.

Having said that, there are almost as many causes of ripples as printers - sometimes multiple causes. Below is from my own observations and your mileage may vary. I tend to divide ripples into three categories:-

There is of course a fourth type of ripple, one that a doctor would call idiopathic and an engineer may categorize as "buggeredifiknow". These appear, maybe only on one print, or only for a short time before disappearing again.

I have used both motor dampers of the type you mentioned, but also circular damping masses coupled to a drive shaft with a Rocol damping grease. This has proven very effective.

Mike

Having said that, there are almost as many causes of ripples as printers - sometimes multiple causes. Below is from my own observations and your mileage may vary. I tend to divide ripples into three categories:-

- Ripples that start at a corner or other sharp feature and die away are caused by system resonances. Recent developments in software solutions to these include Input Shaping and Pressure Advance (Linear Advance in Marlin).

- Ripples that persist and don't die away may be caused by resonance in the motor, drive shaft, or drive belt. These are likely to be at a higher frequency than whole system resonances. This again can be alleviated with Input Shaping on the software side while add-on circuits for the stepper wires or mechanical damping can also help.

- Ripples that persist but are either unchanged or minimally changed by speed are most likely to be a mechanical fault such as cogging on the toothed belt, a motor problem, or even a bearing problem on an idler.

There is of course a fourth type of ripple, one that a doctor would call idiopathic and an engineer may categorize as "buggeredifiknow". These appear, maybe only on one print, or only for a short time before disappearing again.

I have used both motor dampers of the type you mentioned, but also circular damping masses coupled to a drive shaft with a Rocol damping grease. This has proven very effective.

Mike

|

Re: VFA (vertical fine artefacts) March 19, 2023 10:09AM |

Registered: 4 years ago Posts: 90 |

Oh, forgot to say...

There's a flaw in the design. The printing head itself. It is too far from the X extrusion : I designed and printed an adapter for the Stealthburner, and there's a huge overhang. As a result, even if it feels rigid, I suspect it is doing some headbanging (what else could do a full metalhead ?). Have to design the adapter as a single part with the extruder back plate fully integrated, saving 8-10 mm. But is egg and chicken...

Currently on cable management before the printer goess into a active heated chamber (ready, tested good for 55°C)

Some prototypes to design/print for cable drag chains, and some photo shooting ASAP. The torture prints are really interesting, in relation with your last post.

Edited 1 time(s). Last edit at 03/19/2023 10:10AM by yet-another-average-joe.

There's a flaw in the design. The printing head itself. It is too far from the X extrusion : I designed and printed an adapter for the Stealthburner, and there's a huge overhang. As a result, even if it feels rigid, I suspect it is doing some headbanging (what else could do a full metalhead ?). Have to design the adapter as a single part with the extruder back plate fully integrated, saving 8-10 mm. But is egg and chicken...

Currently on cable management before the printer goess into a active heated chamber (ready, tested good for 55°C)

Some prototypes to design/print for cable drag chains, and some photo shooting ASAP. The torture prints are really interesting, in relation with your last post.

Edited 1 time(s). Last edit at 03/19/2023 10:10AM by yet-another-average-joe.

|

Re: VFA (vertical fine artefacts) March 19, 2023 05:12PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: VFA (vertical fine artefacts) March 20, 2023 11:07AM |

Registered: 4 years ago Posts: 90 |

Yep !

But I think that before I see this on my prints, I'll have to improve my crappy design !!!

I think the toolhead is a jackhammer.

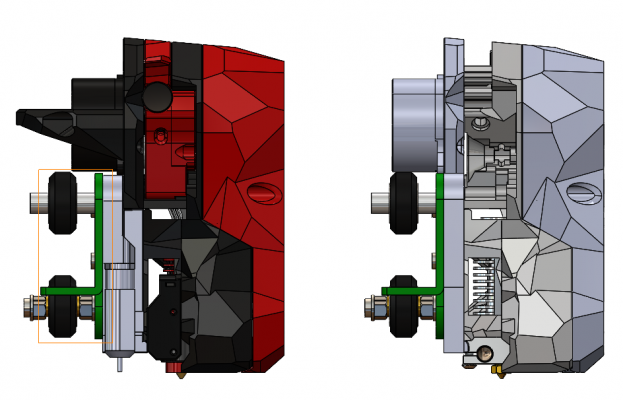

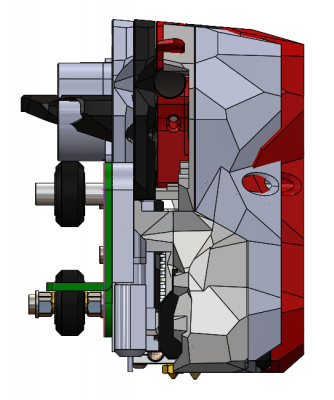

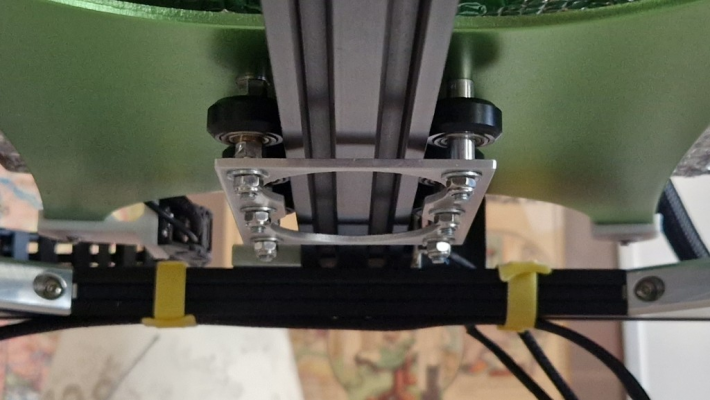

Along the X axis :

Along the Y axis :

The toolhead has a huge overhang ; on the left, le current design I'm printing with, on the right : the new one I'm working on ; difference = 8.3 mm ; redesiging a larger the motor plate so it is bolted to the cariage without the need for a thick adapter plate ; the motor plate is too complex to be machined in the carriage, would require a 5 axis CNC !

Will also add a backplate, like I did for the Y axis (massive improvement in rigidity) :

Will come back after I do my homework ! ( still can't print ABS)

Edited 2 time(s). Last edit at 03/20/2023 11:09AM by yet-another-average-joe.

But I think that before I see this on my prints, I'll have to improve my crappy design !!!

I think the toolhead is a jackhammer.

Along the X axis :

Along the Y axis :

The toolhead has a huge overhang ; on the left, le current design I'm printing with, on the right : the new one I'm working on ; difference = 8.3 mm ; redesiging a larger the motor plate so it is bolted to the cariage without the need for a thick adapter plate ; the motor plate is too complex to be machined in the carriage, would require a 5 axis CNC !

Will also add a backplate, like I did for the Y axis (massive improvement in rigidity) :

Will come back after I do my homework ! ( still can't print ABS)

Edited 2 time(s). Last edit at 03/20/2023 11:09AM by yet-another-average-joe.

|

Re: VFA (vertical fine artefacts) March 22, 2023 12:05AM |

Registered: 7 years ago Posts: 363 |

Just catching up, but I've experienced similar VFA artifacts from improperly tensioned belts (too tight). I resolved most of my artifacts using a Mersenne's equation and methodology as explained here: Belt Tension Article

Edited 1 time(s). Last edit at 03/22/2023 12:06AM by obelisk79.

Edited 1 time(s). Last edit at 03/22/2023 12:06AM by obelisk79.

|

Re: VFA (vertical fine artefacts) March 22, 2023 05:51PM |

Registered: 4 years ago Posts: 90 |

The belt is certainly part of the problem. But still redesigning the X carriage based on a modded Stealthburner.

Also, could be a bit picky. While drawing, tested a sub 30 mn (28 mn) benchy (Cura, 200 mm/s, 2000 mm/s², 20 mm/s everywhere - walls and infill - no pressure advance, no input shaping, PETG, massively underextruded of course : peek flow > 20 mm²/s with a genuine E3D V6 and a 40W heater ; probably does not reach those speeds, but it really shakes !)

Also, could be a bit picky. While drawing, tested a sub 30 mn (28 mn) benchy (Cura, 200 mm/s, 2000 mm/s², 20 mm/s everywhere - walls and infill - no pressure advance, no input shaping, PETG, massively underextruded of course : peek flow > 20 mm²/s with a genuine E3D V6 and a 40W heater ; probably does not reach those speeds, but it really shakes !)

|

Re: VFA (vertical fine artefacts) March 24, 2023 10:34AM |

Registered: 4 years ago Posts: 90 |

STUTID ME !!!!!

At high speeds, the head was *really* acting as a wood pecker.

Just forgot to properly tighten the bolt that holds the X czriage lower wheel after adjusting it : the eccentric was nearly turning free. Shaking the head while printing was making it turn... This explains why quality was degrading while reducing speed on the first test.

Lost hours designing a new X cariage.

VFA are negligible, at least from my POV. This benchy is gorgeous. (tuned for quality : 40 / 500 / 8). The Stealthburner prints a decent one at 200 / 2000 / 20 (need speed for quick iterations while modelling). Part cooling is absolutely perfect. The Voron team did an amazing job on this print head !

Edited 3 time(s). Last edit at 03/24/2023 11:00AM by yet-another-average-joe.

At high speeds, the head was *really* acting as a wood pecker.

Just forgot to properly tighten the bolt that holds the X czriage lower wheel after adjusting it : the eccentric was nearly turning free. Shaking the head while printing was making it turn... This explains why quality was degrading while reducing speed on the first test.

Lost hours designing a new X cariage.

VFA are negligible, at least from my POV. This benchy is gorgeous. (tuned for quality : 40 / 500 / 8). The Stealthburner prints a decent one at 200 / 2000 / 20 (need speed for quick iterations while modelling). Part cooling is absolutely perfect. The Voron team did an amazing job on this print head !

Edited 3 time(s). Last edit at 03/24/2023 11:00AM by yet-another-average-joe.

|

Re: VFA (vertical fine artefacts) April 02, 2023 01:10PM |

Registered: 4 years ago Posts: 90 |

Currently printing a new version of the print head...

Removed 8 mm overhang for the nozzle, relative to the X extrusion.

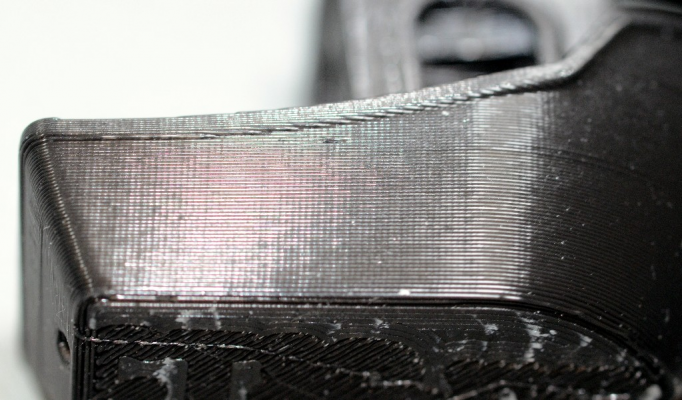

Just for now, with the 1st printhead iteration and bolts properly tightened, the quality is astounding. Easy to compare : I'm reprinting some of the Stealthburner parts I printed with the V6 Bowden a couple months back, with the same Cura profiles (same very conservative, quality oriented settings :40 mm/s, 500 mm/s², 10 mm/s, just reduced retraction, of course). VFA now are barely visible. No need for 0.9° steppers ! (see Prusa i3 Mk IV). The Voron team did an incredible job with this head. Cant see any artifacts related with the extruder wheels (Triangle Labs BMG knockoff parts).

Also slightly loosened the belts. Not that much : until now, I was tightening until I feel some resistance (bearings not happy), then back 1/4 turn with my homemade M4 tensioners ; now 1/2 turn... Being machined from aluminium (previous ones were printed), the printer now is probably much less tolerant to overtighting ! Sounded like a bass, now sounds like a djent guitar upper string.

Will try to shoot a few pictures (not easy, black being the most difficult colour). But it's night and day.

Removed 8 mm overhang for the nozzle, relative to the X extrusion.

Just for now, with the 1st printhead iteration and bolts properly tightened, the quality is astounding. Easy to compare : I'm reprinting some of the Stealthburner parts I printed with the V6 Bowden a couple months back, with the same Cura profiles (same very conservative, quality oriented settings :40 mm/s, 500 mm/s², 10 mm/s, just reduced retraction, of course). VFA now are barely visible. No need for 0.9° steppers ! (see Prusa i3 Mk IV). The Voron team did an incredible job with this head. Cant see any artifacts related with the extruder wheels (Triangle Labs BMG knockoff parts).

Also slightly loosened the belts. Not that much : until now, I was tightening until I feel some resistance (bearings not happy), then back 1/4 turn with my homemade M4 tensioners ; now 1/2 turn... Being machined from aluminium (previous ones were printed), the printer now is probably much less tolerant to overtighting ! Sounded like a bass, now sounds like a djent guitar upper string.

Will try to shoot a few pictures (not easy, black being the most difficult colour). But it's night and day.

|

Re: VFA (vertical fine artefacts) August 08, 2023 01:28PM |

Registered: 4 years ago Posts: 90 |

Follow up...

All VFA's are gone ! Couldn't believe it !

First, the noname belts were replaced with Gates ones. They were really falling apart. Have to retrieve them and post a picture. I didn't throw them away but can't remember where they are. It's an horror show.

Then : input shaping : tuned using accelerometers, stealthchop : deactivated, and microsteps : 64. Marlin/Octoprint definitely replaced with Klipper. Beautifull prints (ABS only) @ speed 75 to 120 mm/s, acceleration 1000 to 3000 mm/s². Nothing crazy : can't do more because of the V6 hotend/nozzle flow limitations, and anyway it's 3 to 4 times faster than what the printer was doing before). Voron Stealthburner : modded and optimized for the 3 wheel cariage, built with random BMG knockoff parts (the cheapest I found on Amazon, but with better bearings).

The problem clearly was the belts.

A lot of work, CAD, machining, but really was worth the effort.

Now ready for the Voron 0.2 and 2.4/350 projects starting next weekend if UPS doesn't mess up (LDO kits, gave up on sourcing).

The 2.4 will have a electrical drawer, the TDD way. Being 100mm wider than the 250, and the layout being the same, there's room for this feature.

@TDD : searched on your website, couldn't retrieve the printer you deigned this way. Link ?

Edited 2 time(s). Last edit at 08/08/2023 01:41PM by yet-another-average-joe.

All VFA's are gone ! Couldn't believe it !

First, the noname belts were replaced with Gates ones. They were really falling apart. Have to retrieve them and post a picture. I didn't throw them away but can't remember where they are. It's an horror show.

Then : input shaping : tuned using accelerometers, stealthchop : deactivated, and microsteps : 64. Marlin/Octoprint definitely replaced with Klipper. Beautifull prints (ABS only) @ speed 75 to 120 mm/s, acceleration 1000 to 3000 mm/s². Nothing crazy : can't do more because of the V6 hotend/nozzle flow limitations, and anyway it's 3 to 4 times faster than what the printer was doing before). Voron Stealthburner : modded and optimized for the 3 wheel cariage, built with random BMG knockoff parts (the cheapest I found on Amazon, but with better bearings).

The problem clearly was the belts.

A lot of work, CAD, machining, but really was worth the effort.

Now ready for the Voron 0.2 and 2.4/350 projects starting next weekend if UPS doesn't mess up (LDO kits, gave up on sourcing).

The 2.4 will have a electrical drawer, the TDD way. Being 100mm wider than the 250, and the layout being the same, there's room for this feature.

@TDD : searched on your website, couldn't retrieve the printer you deigned this way. Link ?

Edited 2 time(s). Last edit at 08/08/2023 01:41PM by yet-another-average-joe.

|

Re: VFA (vertical fine artefacts) August 08, 2023 05:21PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: VFA (vertical fine artefacts) August 09, 2023 05:35PM |

Registered: 4 years ago Posts: 90 |

Yep ! Was searching with "UMM" instead of "UMMD"

Found pics :

[milwaukeemakerspace.org]

[drmrehorst.blogspot.com]

Found pics :

[milwaukeemakerspace.org]

[drmrehorst.blogspot.com]

|

Re: VFA (vertical fine artefacts) August 11, 2023 09:08AM |

Registered: 11 years ago Posts: 5,780 |

That one is Son of MegaMax (SoM) not UMMD.

UMMD has the electronics enclosure at the top of the printer. That helps keep most cables short because the XY stage is also near the top of the printer. It is also easier to service/modify/maintain because I don't have to crawl on the floor to access the critical stuff. I had considered making the XY stage/electronics a drop-in module so I could use different sized Z axis assemblies- a short one to take to Maker Faires, etc., and a tall one to use at home, but decided I just needed the one printer.

UMMD has a 1mm nozzle right now which is great for printing large objects without too much detail. Now I'm considering building another printer with a smaller print envelope and small nozzle on the extruder for doing more detailed work.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

UMMD has the electronics enclosure at the top of the printer. That helps keep most cables short because the XY stage is also near the top of the printer. It is also easier to service/modify/maintain because I don't have to crawl on the floor to access the critical stuff. I had considered making the XY stage/electronics a drop-in module so I could use different sized Z axis assemblies- a short one to take to Maker Faires, etc., and a tall one to use at home, but decided I just needed the one printer.

UMMD has a 1mm nozzle right now which is great for printing large objects without too much detail. Now I'm considering building another printer with a smaller print envelope and small nozzle on the extruder for doing more detailed work.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.