|

slic3r dimensional accuracy January 10, 2012 06:52AM |

Registered: 13 years ago Posts: 486 |

How exactly does slic3r calculate the extrusion width?

I have been doing experiments to try and work this out, but it has me a bit baffled.

When I slice with a nozzle size of 0.5 and a layer height of 0.5 (I realise this is not recommended), the perimiter is 0.263mm from the edge of the object. This suggests to me that it thinks the width of a single filament is 0.526mm.

The first loop and the infill are spaced by 0.515mm

This means an overlap of 0.011 mm is catered for. Given that the edge of the extrusion should be cylindrical, this is a very small overlap for a 1:1 w/t.

This will mean either the fill will be sparse, or if the flow rate compensates for this, the perimiter will spill over the edge of the object and the object will be too big.

When I slice with a nozzle size of 0.5 and a layer height of 0.05 (the other extreme), the perimiter is 0.350mm from the edge of the object. This suggests to me that it thinks the width of a single filament is 0.700mm. Why has it made the filament width wider for a smaller layer height?

The first loop and then infill are spaced by 0.695mm

This means an overlap of 0.005 mm is catered for. Again, this is pretty small being 1/10 the layer height.

I havent studied the flow that goes with these paths yet so im not sure what happens there. I want to understand the spacing first.

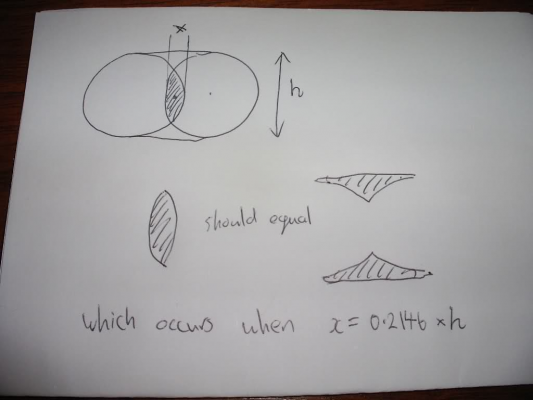

ahmetcemturan did some good work with SFACT and calculated that when you have 2 filaments adjacent to one another with rounded edges, they should overlap by a fixed fraction of the the diameter in order for the volume of the overlap to equal the space as a result of the curvature.

Is this sort of maths done in slic3r?

I have been doing experiments to try and work this out, but it has me a bit baffled.

When I slice with a nozzle size of 0.5 and a layer height of 0.5 (I realise this is not recommended), the perimiter is 0.263mm from the edge of the object. This suggests to me that it thinks the width of a single filament is 0.526mm.

The first loop and the infill are spaced by 0.515mm

This means an overlap of 0.011 mm is catered for. Given that the edge of the extrusion should be cylindrical, this is a very small overlap for a 1:1 w/t.

This will mean either the fill will be sparse, or if the flow rate compensates for this, the perimiter will spill over the edge of the object and the object will be too big.

When I slice with a nozzle size of 0.5 and a layer height of 0.05 (the other extreme), the perimiter is 0.350mm from the edge of the object. This suggests to me that it thinks the width of a single filament is 0.700mm. Why has it made the filament width wider for a smaller layer height?

The first loop and then infill are spaced by 0.695mm

This means an overlap of 0.005 mm is catered for. Again, this is pretty small being 1/10 the layer height.

I havent studied the flow that goes with these paths yet so im not sure what happens there. I want to understand the spacing first.

ahmetcemturan did some good work with SFACT and calculated that when you have 2 filaments adjacent to one another with rounded edges, they should overlap by a fixed fraction of the the diameter in order for the volume of the overlap to equal the space as a result of the curvature.

Is this sort of maths done in slic3r?

|

Re: slic3r dimensional accuracy January 10, 2012 11:49AM |

Registered: 13 years ago Posts: 228 |

Hello GregFrost!

Slic3r does indeed calculate overlap, but its math is different than Sfact's. It's been reported to be quite good, and for dimensional accuracy purposes too. The only known issue is with some poor overlap between perimeter and infill at the end of the infill lines (in other words, where infill is perpendicular to perimeter).

I'm sorry I'm very busy at the moment, and can't take the time to explain the math it uses in depth. I'll do it in the future.

However, the flow is tightly related to extrusion width and spacing in Slic3r's logic, so the analysis of the bare toolpaths without taking flow into account is not very meaningful. Also, Slic3r adjusts flow in some places to better fill tiny gaps.

Slic3r does indeed calculate overlap, but its math is different than Sfact's. It's been reported to be quite good, and for dimensional accuracy purposes too. The only known issue is with some poor overlap between perimeter and infill at the end of the infill lines (in other words, where infill is perpendicular to perimeter).

I'm sorry I'm very busy at the moment, and can't take the time to explain the math it uses in depth. I'll do it in the future.

However, the flow is tightly related to extrusion width and spacing in Slic3r's logic, so the analysis of the bare toolpaths without taking flow into account is not very meaningful. Also, Slic3r adjusts flow in some places to better fill tiny gaps.

|

Re: slic3r dimensional accuracy January 11, 2012 09:25PM |

Registered: 16 years ago Posts: 1,094 |

fwiw, I find slic3r's gcode to give me absolutely incredible dimensional accuracy.

I'm not sure if it's because I force a particular extrusion width or if the accuracy is as good when it chooses the width itself.

I can comfortably create holes in my model with a precision of 0.1mm and they come out perfectly in the resulting print, either horizontally or vertically. I can make about 0.05mm space between sections that must fit together, and indeed they fit snugly without requiring a lot of force.

Being able to specify a hole which is the perfect size to hold an M3 or M4 screw tightly is really handy!

-----------------------------------------------

Wooden Mendel

Teacup Firmware

I'm not sure if it's because I force a particular extrusion width or if the accuracy is as good when it chooses the width itself.

I can comfortably create holes in my model with a precision of 0.1mm and they come out perfectly in the resulting print, either horizontally or vertically. I can make about 0.05mm space between sections that must fit together, and indeed they fit snugly without requiring a lot of force.

Being able to specify a hole which is the perfect size to hold an M3 or M4 screw tightly is really handy!

-----------------------------------------------

Wooden Mendel

Teacup Firmware

|

Re: slic3r dimensional accuracy January 12, 2012 02:37PM |

Registered: 12 years ago Posts: 86 |

|

Re: slic3r dimensional accuracy January 12, 2012 05:48PM |

Registered: 16 years ago Posts: 1,094 |

> Triffid_Hunter, so are you saying you don't need

> to account for variation in your modelling to

> acheive correct hole sizing?

yes, however if I want things to not be a super tight fit I do need to leave some space, which is true of all manufacturing methods.

-----------------------------------------------

Wooden Mendel

Teacup Firmware

> to account for variation in your modelling to

> acheive correct hole sizing?

yes, however if I want things to not be a super tight fit I do need to leave some space, which is true of all manufacturing methods.

-----------------------------------------------

Wooden Mendel

Teacup Firmware

Sorry, only registered users may post in this forum.