Infill of narrow areas with 0.9.10b

Posted by BrentB

|

Infill of narrow areas with 0.9.10b September 23, 2013 02:08PM |

Registered: 11 years ago Posts: 33 |

I've noticed a difference in the infill with Slic3r 0.9.10b. This version actually fixed several problems relating to infill of small areas vs. single-wall configuration (like, to force a "small" object to be hollow), but it's also broken infill patterns around small areas.

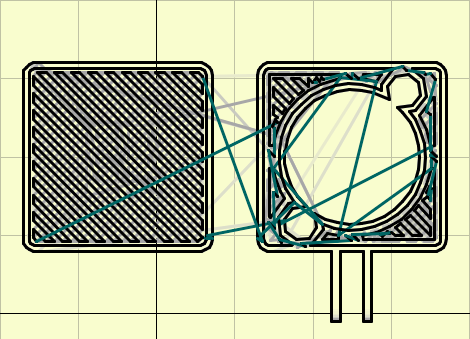

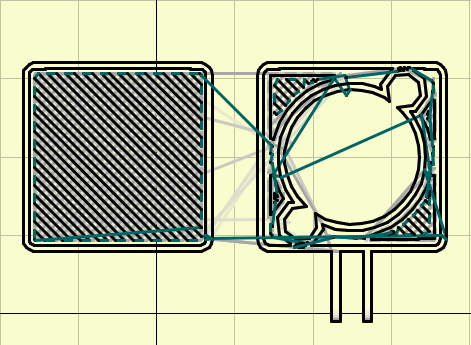

For example, I have a square bracket with a circular hole. As the distance between the hole and edge boundaries decreases, Slic3r just quits infilling it, leaving an ugly hole clear through the object. I sliced the object with 0.9.8 and 0.9.10b, and used macpronterface to show the infill in the top layer of the bracket. The two errors are at the top-center of the bracket, and the lower-left corner. Image is correct, is bad. I used the same configuration files for both slicings.

Anybody else noticed this?

For example, I have a square bracket with a circular hole. As the distance between the hole and edge boundaries decreases, Slic3r just quits infilling it, leaving an ugly hole clear through the object. I sliced the object with 0.9.8 and 0.9.10b, and used macpronterface to show the infill in the top layer of the bracket. The two errors are at the top-center of the bracket, and the lower-left corner. Image is correct, is bad. I used the same configuration files for both slicings.

Anybody else noticed this?

|

Re: Infill of narrow areas with 0.9.10b September 23, 2013 02:48PM |

Registered: 11 years ago Posts: 1,320 |

I have the same issue with 0.9.10b with narrow walls. My layer height is 0.254mm and my extrusion width is set at 220% which, if I understand things correctly results in an extrusion width of 0.254 * 2.2 = 0.559. If I print an object with a 2 millimeter thick wall, I just get the perimeters with nothing in between. Slicer puts something in there, but it appears on my host software as single dots and the print head moves very quickly over this area, laying down almost no material.

Using my extrusion width of 0.559 from above, the interior of a 2mm wall should be 2 - 2*0.559 = 0.882mm which is plenty wide enough for another bead of filament. As a test, I widened the wall to 2.25 mm, which is wide enough for 4 beads using the above logic, and sure enough, slic3r filled in the interior with two beads - so the wall ends up solid.

Why is it not giving me a single bead when it has the room to do so?

Using my extrusion width of 0.559 from above, the interior of a 2mm wall should be 2 - 2*0.559 = 0.882mm which is plenty wide enough for another bead of filament. As a test, I widened the wall to 2.25 mm, which is wide enough for 4 beads using the above logic, and sure enough, slic3r filled in the interior with two beads - so the wall ends up solid.

Why is it not giving me a single bead when it has the room to do so?

|

Re: Infill of narrow areas with 0.9.10b September 23, 2013 06:41PM |

Registered: 11 years ago Posts: 33 |

I've seen the dot effect in a few spots, and I think there are a couple of those useless points in the second image I attached.

I doubled the size of my bracket, and those areas were infilled as we would expect, so the issue is indeed the narrow gaps. I wonder how some of the other settings may affect the logic of the infill generator, things like auto-gen extra perimeters, solid-area-infill threshold, and infill density. May need to try some experiments, but I'll check the slic3r bug list first.

I doubled the size of my bracket, and those areas were infilled as we would expect, so the issue is indeed the narrow gaps. I wonder how some of the other settings may affect the logic of the infill generator, things like auto-gen extra perimeters, solid-area-infill threshold, and infill density. May need to try some experiments, but I'll check the slic3r bug list first.

|

Re: Infill of narrow areas with 0.9.10b September 23, 2013 06:58PM |

Registered: 11 years ago Posts: 1,320 |

Another interesting observation - if I make the wall narrower it fills in a single bead. It's as if it doesn't know what to do if the wall is the in-between width. It's too wide for 1 bead, and not wide enough for two, so it does almost nothing. It sounds like a condition where the infill logic breaks down - this looks like a software bug to me. We may be able to work around it by changing settings or the object itself, but at some point it should be fixed in the slicer.

|

Re: Infill of narrow areas with 0.9.10b September 23, 2013 09:06PM |

Registered: 11 years ago Posts: 33 |

I've been digging through slic3r bugs and it's been mentioned in several ways that slic3r expects to extrude a bead of a certain width, x. Features less than x thick may or may not get printed, or may be missing layers, due to numerical rounding errors (normal with computer math). Features between x and 2x may be printed with 1 or 2 passes, again due to rounding. But you and I are seeing this in larger features, too.

My extrusion width is 0.85mm from a 0.5mm nozzle (and 0.2mm print layer height). It's calibrated very well, and so WYSIWYG when I design a part. It's just that inside those dimensions the infill is incomplete.

I think I'll file a bug on this. I didn't see anything directly similar to what we are seeing in the current bug list.

My extrusion width is 0.85mm from a 0.5mm nozzle (and 0.2mm print layer height). It's calibrated very well, and so WYSIWYG when I design a part. It's just that inside those dimensions the infill is incomplete.

I think I'll file a bug on this. I didn't see anything directly similar to what we are seeing in the current bug list.

|

Re: Infill of narrow areas with 0.9.10b September 24, 2013 10:07PM |

Registered: 11 years ago Posts: 33 |

My default extrusion width of 0.85mm is just plain large, but that is what Slic3r defaults to with my nozzle and 0.20mm layer height. In Slic3r's Print Settings->Advanced->Extrusion Width section, all my values were 0 which uses the calculated default.

I changed the first value to a more reasonable extrusion width, 0.6, and re-sliced my parts. The infill is much better, and on the vertical tabs with width 1.95mm, Slic3r is now using two walls plus a zig-zag infill. This makes sense, since going to a smaller extrusion width means you have more room to lay out the infill.

So, while there is certainly a difference in the way 0.9.10b chooses to infill things, it's not a bug. In my case it was caused by such a large extrusion width (which isn't too desireable anyway).

I changed the first value to a more reasonable extrusion width, 0.6, and re-sliced my parts. The infill is much better, and on the vertical tabs with width 1.95mm, Slic3r is now using two walls plus a zig-zag infill. This makes sense, since going to a smaller extrusion width means you have more room to lay out the infill.

So, while there is certainly a difference in the way 0.9.10b chooses to infill things, it's not a bug. In my case it was caused by such a large extrusion width (which isn't too desireable anyway).

|

Re: Infill of narrow areas with 0.9.10b September 25, 2013 10:48AM |

Registered: 11 years ago Posts: 1,320 |

I have mine set to 220%. I was going to suggest to you that 0.85 seemed very high for a 0.2 layer height, but you seemed otherwise happy with your results. Did you set it to 0.6 explicitly, or did you set it to 300%. If you set it to 0.6 explicitly, then you'll need to adjust it if you ever change your layer height. If you set it to 300% (0.2 layer height * 300% = 0.6 extrusion width) then it will track with layer height changes.

|

Re: Infill of narrow areas with 0.9.10b September 29, 2013 11:48PM |

Registered: 11 years ago Posts: 33 |

Using percentages makes sense, thanks. In the past I went through and tuned my printer for layer heights of 0.33, 0.25, 0.20, and finally, 0.125. But the extrusion width that Slic3r used to calculate always seemed reasonable, and I'd go with it. The 0.125mm layer height makes for an amazing print, but it essentially doubles the print time.

Since my last post I found a few other practices that people do, and some have just settled on 0.5mm extrusion width. Since setting it to that, I'm getting great results at 0.20 layers. I think this is the sweet spot, and even the slight overhangs in various parts are coming out well.

Since my last post I found a few other practices that people do, and some have just settled on 0.5mm extrusion width. Since setting it to that, I'm getting great results at 0.20 layers. I think this is the sweet spot, and even the slight overhangs in various parts are coming out well.

Sorry, only registered users may post in this forum.