filled area problem

Posted by glyn

|

filled area problem June 18, 2012 10:12AM |

Registered: 12 years ago Posts: 82 |

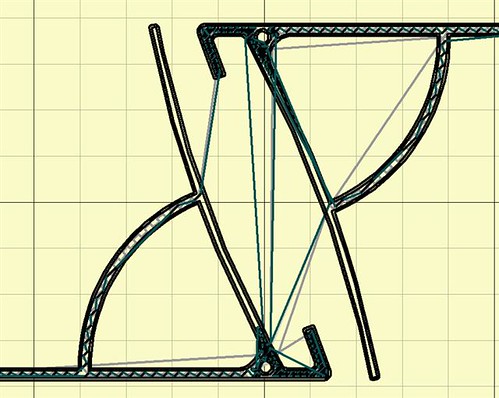

I'm trying to slice the attached stl and get either a solid fill or basically any fill but seem unable to achieve this, all I end up with is just the perimeters and not even the top layer completed. I've tried various combinations of layer height, number of perimeters, solid levels etc without success.

The only thing which gave me a solid section was to set perimeters to zero which worked but does not make for a very smooth item.

Tried this with 0.8.2 and 0.8.3.

Any thoughts?

The only thing which gave me a solid section was to set perimeters to zero which worked but does not make for a very smooth item.

Tried this with 0.8.2 and 0.8.3.

Any thoughts?

|

Re: filled area problem June 18, 2012 11:21AM |

Admin Registered: 12 years ago Posts: 2,569 |

I'd try and cheat slic3r to think your nozzle is tinier than what it actually is, and use a single perimeter.

Like, enter nozzle size 0.05 mm lower than your real aperture, slice and iterate until it can finally stick some infill between the walls.

Note that this may be a source of other problems in the print.

The alternative would be to redesign the part so that its thickness is whether precisely 2 times your nozzle aperture OR at least 4 times. Between those values, no slicer I've tried - that's Slic3r and skeinforge - are able to do something filled up nicely.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Like, enter nozzle size 0.05 mm lower than your real aperture, slice and iterate until it can finally stick some infill between the walls.

Note that this may be a source of other problems in the print.

The alternative would be to redesign the part so that its thickness is whether precisely 2 times your nozzle aperture OR at least 4 times. Between those values, no slicer I've tried - that's Slic3r and skeinforge - are able to do something filled up nicely.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: filled area problem June 18, 2012 11:39AM |

Admin Registered: 17 years ago Posts: 7,879 |

Exactly two times the filament width or anything more than three should get infill. Widths between those values leave a gap smaller than a filament width, so there is no room for infill.

A more intelligent slicer could extrude enough plastic to fill the gap and try to inject it down the thin slot but it would take a lot of pressure as the slot gets thinner. Then you need a very rigid machine or the nozzle would be lifted.

[www.hydraraptor.blogspot.com]

A more intelligent slicer could extrude enough plastic to fill the gap and try to inject it down the thin slot but it would take a lot of pressure as the slot gets thinner. Then you need a very rigid machine or the nozzle would be lifted.

[www.hydraraptor.blogspot.com]

|

Re: filled area problem June 18, 2012 02:56PM |

Registered: 12 years ago Posts: 82 |

Quote

Exactly two times the filament width or anything more than three should get infill.

Is the filament width the width of the extrudate in air?

Mine is about 0.75mm from a 0.5mm nozzle.

The width of the section is 2.6mm so you would think it ought to fill. i.e. 3*0.75=2.25

Another anomaly is that even though I alter the setting to 1 perimeter it is still coming out as 2.

Anyway I will alter the design to make that section a bit wider and await further updates.

Thanks for the comments.

|

Re: filled area problem June 18, 2012 03:23PM |

Admin Registered: 17 years ago Posts: 7,879 |

The filament width is whatever slic3r decides it should be from the nozzle size you give it. Not being able to force it to do one outline seems a major limitation. You have a lot more control with Skeinforge.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: filled area problem June 18, 2012 04:08PM |

Registered: 12 years ago Posts: 82 |

|

Re: filled area problem June 18, 2012 07:21PM |

Registered: 12 years ago Posts: 313 |

nophead Wrote:

-------------------------------------------------------

> The filament width is whatever slic3r decides it

> should be from the nozzle size you give it. Not

> being able to force it to do one outline seems a

> major limitation. You have a lot more control with

> Skeinforge.

The inability of forcing just one perimeter seems to be a regression (which reportedly is getting fixed) but I just noticed while reprinting an older design that the latest Slic3r version is finally able to print true single-walled objects. I have the W/T fixed to 200% of the layer height of 0.225 mm and the walls are very close to that. (The model's walls were 0.8 mm but that's another story...)

I have also been slicing the wall thickness test regularly and the latest versions of Slic3r have been getting much better with that. But even with Skeinforge, getting the best walls always required testing the current printing parameters with something like that and then adjusting the model's wall thicknesses based on the results. Otherwise you could end up with a gap between the tracks or infill which would vibrate the printer like crazy.

-------------------------------------------------------

> The filament width is whatever slic3r decides it

> should be from the nozzle size you give it. Not

> being able to force it to do one outline seems a

> major limitation. You have a lot more control with

> Skeinforge.

The inability of forcing just one perimeter seems to be a regression (which reportedly is getting fixed) but I just noticed while reprinting an older design that the latest Slic3r version is finally able to print true single-walled objects. I have the W/T fixed to 200% of the layer height of 0.225 mm and the walls are very close to that. (The model's walls were 0.8 mm but that's another story...)

I have also been slicing the wall thickness test regularly and the latest versions of Slic3r have been getting much better with that. But even with Skeinforge, getting the best walls always required testing the current printing parameters with something like that and then adjusting the model's wall thicknesses based on the results. Otherwise you could end up with a gap between the tracks or infill which would vibrate the printer like crazy.

|

Re: filled area problem June 19, 2012 04:20AM |

Admin Registered: 17 years ago Posts: 7,879 |

I suppose the slicer could make a special case when with walls that are one or two filaments wide and change the W/T ratio to match the model.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: filled area problem June 21, 2012 03:21PM |

Registered: 12 years ago Posts: 141 |

nophead Wrote:

-------------------------------------------------------

> I suppose the slicer could make a special case

> when with walls that are one or two filaments wide

> and change the W/T ratio to match the model.

or using 3 thin filament instead of 2 very wide (better aspect and strength)

or may be an interactive GUI who ask if there is situation which need a choice (always difficult to know in advance all the case) but it will need to rewrite all the slicer, some volunteer over there ? ;-)

-------------------------------------------------------

> I suppose the slicer could make a special case

> when with walls that are one or two filaments wide

> and change the W/T ratio to match the model.

or using 3 thin filament instead of 2 very wide (better aspect and strength)

or may be an interactive GUI who ask if there is situation which need a choice (always difficult to know in advance all the case) but it will need to rewrite all the slicer, some volunteer over there ? ;-)

Sorry, only registered users may post in this forum.