Slic3r Help (Slicing problem.)

Posted by Blake Redwine

|

Slic3r Help (Slicing problem.) November 18, 2013 09:12PM |

Registered: 10 years ago Posts: 1 |

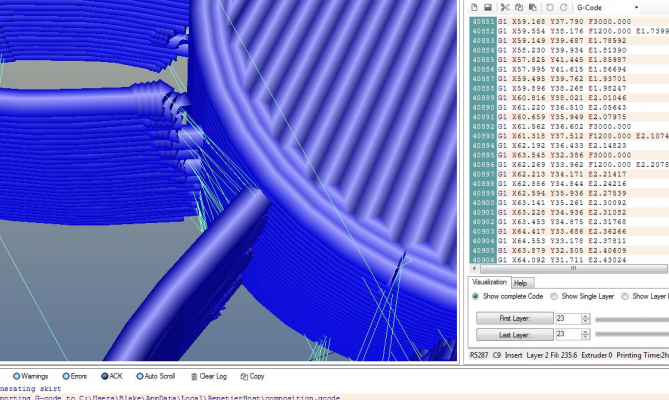

Attached is an STL of a file I made in SolidWorks. I've tinkered with it a ton, trying to find different ways to fix this but to no avail. In the picture, looking at the center circle, the curves that come to intersect the circle seem to just give up. It won't even try to intersect it looks like. So here's what I've done. I went back in to the file itself and made those curves extend past into the center circle to that it might think they go farther, but nothing. It does the same thing. Then I messed with the extrusion widths to see if that would do something. It worked to a degree. I changed my perimeter width from 0 to .15, and that fixed it in slic3r, but I don't think my .3 nozzle can handle it. Any ideas?!

Thanks guys!

|

Re: Slic3r Help (Slicing problem.) November 20, 2013 03:26AM |

Registered: 12 years ago Posts: 141 |

how could you think it is possible to print thin wall 0.1 mm wide with a 0.3 nozzle ? there is no way you coud print it !

your wall need to be at least as wide as your nozzle (and twice large is better ! then you have to specify 0.299 wide for the perimeters to cheat on slice and get consistent 2 perimeters)

your wall need to be at least as wide as your nozzle (and twice large is better ! then you have to specify 0.299 wide for the perimeters to cheat on slice and get consistent 2 perimeters)

|

Re: Slic3r Help (Slicing problem.) November 20, 2013 10:23AM |

Registered: 10 years ago Posts: 17 |

I've had a look at your STL file. The problem is actually in the design, not in the slicing of it. The reason that the curves seem to "give up" is because they become thinner than one single line of extrusion, so Slic3r faithfully obeys your design (less than one line obviously equals no lines).

As a general rule of thumb no part of your model should ever be thinner than 2x your extrusion width.

As a general rule of thumb no part of your model should ever be thinner than 2x your extrusion width.

|

Re: Slic3r Help (Slicing problem.) January 05, 2014 12:41AM |

Registered: 10 years ago Posts: 1 |

I have a similar problem, using a design with square tubing. Slic3r picked up some of the walls and made some spaghetti that shaped somewhat like the part. However, when I took out the shell command and made the tubing solid, Slic3r didn't like that either, so it ignored the tubes altogether if there was any interference in the model. I would like some kind of slicer program that makes any perimeter into at least a minimum perimeter, instead of saying anything less than one extrusion thickness is equal to zero.

Any help would be appreciated. I make a lot of stuff from tubing, and models would be helpful for show and tell.

Thanks

Dan

Any help would be appreciated. I make a lot of stuff from tubing, and models would be helpful for show and tell.

Thanks

Dan

Sorry, only registered users may post in this forum.