Why is my surface finish comically bad?

Posted by mpk23

|

Why is my surface finish comically bad? July 21, 2015 04:23PM |

Registered: 8 years ago Posts: 2 |

Hello,

I'm printing with a Simple Metal fitted with an E3D v6, 0.4 nozzle. Been printing for seven months.

I've been mostly printing with Cura, but I saw the new version pop up, so I thought I'd see if I could get better results on some of the Make: shootout parts using Slic3r.

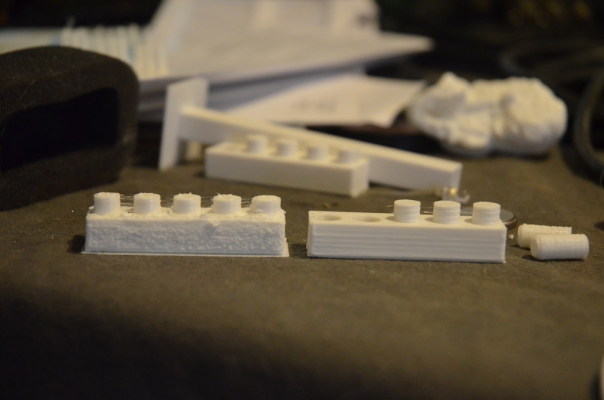

The results are more poor than I could have imagined - I'm using the same speeds, retraction, temps, and such in both slicers, so I was hoping someone could identify the culprit from the image attached. Slic3r is the left print, Cura on the right.

I used Slic3r when I first started for quite a while, and always got better results than this...

Unrelated, but 'Export .Gcode' doesn't seem to actually create a file in my target folder, even though I can see the 'ghost' of the exported file in the folder when I try to export again. Send to Octoprint printer works fine, so I could download the gcode to show the settings section:

Following is the relevant bits, I can post some code too if needed.

Thanks in advance for the knowledgable eyes! I'm looking forward to getting back into Slic3r! I hope I haven't violated too many forum rules and norms....

-Matt

; generated by Slic3r 1.2.9 on 2015-07-21 at 13:31:06

; external perimeters extrusion width = 0.40mm

; perimeters extrusion width = 0.67mm

; infill extrusion width = 0.67mm

; solid infill extrusion width = 0.67mm

; top infill extrusion width = 0.67mm

//Large amount of gcode

Edited 1 time(s). Last edit at 07/21/2015 04:24PM by mpk23.

I'm printing with a Simple Metal fitted with an E3D v6, 0.4 nozzle. Been printing for seven months.

I've been mostly printing with Cura, but I saw the new version pop up, so I thought I'd see if I could get better results on some of the Make: shootout parts using Slic3r.

The results are more poor than I could have imagined - I'm using the same speeds, retraction, temps, and such in both slicers, so I was hoping someone could identify the culprit from the image attached. Slic3r is the left print, Cura on the right.

I used Slic3r when I first started for quite a while, and always got better results than this...

Unrelated, but 'Export .Gcode' doesn't seem to actually create a file in my target folder, even though I can see the 'ghost' of the exported file in the folder when I try to export again. Send to Octoprint printer works fine, so I could download the gcode to show the settings section:

Following is the relevant bits, I can post some code too if needed.

Thanks in advance for the knowledgable eyes! I'm looking forward to getting back into Slic3r! I hope I haven't violated too many forum rules and norms....

-Matt

; generated by Slic3r 1.2.9 on 2015-07-21 at 13:31:06

; external perimeters extrusion width = 0.40mm

; perimeters extrusion width = 0.67mm

; infill extrusion width = 0.67mm

; solid infill extrusion width = 0.67mm

; top infill extrusion width = 0.67mm

//Large amount of gcode

; filament used = 3976.1mm (9.1cm3) ; avoid_crossing_perimeters = 0 ; bed_shape = 0x0,150x0,150x150,0x150 ; bed_temperature = 55 ; before_layer_gcode = ; bridge_acceleration = 750 ; bridge_fan_speed = 100 ; brim_width = 2 ; complete_objects = 0 ; cooling = 1 ; default_acceleration = 600 ; disable_fan_first_layers = 2 ; duplicate_distance = 6 ; end_gcode = M104 S0 ; turn off temperature\nG28 X0 ; home X axis\nM84 ; disable motors\n ; extruder_clearance_height = 20 ; extruder_clearance_radius = 20 ; extruder_offset = 0x0 ; extrusion_axis = E ; extrusion_multiplier = 1 ; fan_always_on = 0 ; fan_below_layer_time = 100 ; filament_colour = #FFFFFF ; filament_diameter = 1.71 ; first_layer_acceleration = 450 ; first_layer_bed_temperature = 60 ; first_layer_extrusion_width = 105% ; first_layer_speed = 30 ; first_layer_temperature = 212 ; gcode_arcs = 0 ; gcode_comments = 1 ; gcode_flavor = reprap ; infill_acceleration = 750 ; infill_first = 0 ; layer_gcode = ; max_fan_speed = 100 ; max_print_speed = 80 ; max_volumetric_speed = 0 ; min_fan_speed = 95 ; min_print_speed = 10 ; min_skirt_length = 0 ; notes = ; nozzle_diameter = 0.4 ; only_retract_when_crossing_perimeters = 1 ; ooze_prevention = 0 ; output_filename_format = [input_filename_base].gcode ; perimeter_acceleration = 450 ; post_process = ; pressure_advance = 0 ; resolution = 0 ; retract_before_travel = 2 ; retract_layer_change = 0 ; retract_length = 2.5 ; retract_length_toolchange = 10 ; retract_lift = 1 ; retract_restart_extra = 0 ; retract_restart_extra_toolchange = 0 ; retract_speed = 40 ; skirt_distance = 6 ; skirt_height = 1 ; skirts = 2 ; slowdown_below_layer_time = 10 ; spiral_vase = 0 ; standby_temperature_delta = -5 ; start_gcode = G28 ; home all axes\nG29; Level Bed\nG1 Z5 F5000 ; lift nozzle\n ; temperature = 210 ; threads = 2 ; toolchange_gcode = ; travel_speed = 130 ; use_firmware_retraction = 0 ; use_relative_e_distances = 0 ; use_volumetric_e = 0 ; vibration_limit = 0 ; wipe = 1 ; z_offset = 0 ; dont_support_bridges = 1 ; extrusion_width = 0 ; first_layer_height = 0.35 ; infill_only_where_needed = 0 ; interface_shells = 0 ; layer_height = 0.2 ; raft_layers = 0 ; seam_position = aligned ; support_material = 0 ; support_material_angle = 0 ; support_material_contact_distance = 0.2 ; support_material_enforce_layers = 0 ; support_material_extruder = 1 ; support_material_extrusion_width = 0 ; support_material_interface_extruder = 1 ; support_material_interface_layers = 3 ; support_material_interface_spacing = 0 ; support_material_interface_speed = 100% ; support_material_pattern = rectilinear ; support_material_spacing = 2.5 ; support_material_speed = 60 ; support_material_threshold = 0 ; xy_size_compensation = 0 ; bottom_solid_layers = 3 ; bridge_flow_ratio = 1 ; bridge_speed = 60 ; external_fill_pattern = rectilinear ; external_perimeter_extrusion_width = 0 ; external_perimeter_speed = 70% ; external_perimeters_first = 0 ; extra_perimeters = 1 ; fill_angle = 45 ; fill_density = 10% ; fill_pattern = honeycomb ; gap_fill_speed = 20 ; infill_every_layers = 1 ; infill_extruder = 1 ; infill_extrusion_width = 0 ; infill_overlap = 15% ; infill_speed = 60 ; overhangs = 1 ; perimeter_extruder = 1 ; perimeter_extrusion_width = 0 ; perimeter_speed = 60 ; perimeters = 3 ; small_perimeter_speed = 15 ; solid_infill_below_area = 70 ; solid_infill_every_layers = 0 ; solid_infill_extruder = 1 ; solid_infill_extrusion_width = 0 ; solid_infill_speed = 30 ; thin_walls = 1 ; top_infill_extrusion_width = 0 ; top_solid_infill_speed = 15 ; top_solid_layers = 3

Edited 1 time(s). Last edit at 07/21/2015 04:24PM by mpk23.

|

Re: Why is my surface finish comically bad? July 21, 2015 04:54PM |

Registered: 8 years ago Posts: 2 |

Sorry, only registered users may post in this forum.