Painfull problem @ first layer

Posted by Carignan

|

Painfull problem @ first layer July 22, 2012 04:25PM |

Registered: 11 years ago Posts: 28 |

Not specifc to slic3r since sfact is doing the same thing.

it's hard to explain, i'll do my best.

in short, "The first layer is grinding awfully my filament!!!!!". Why I don't know!!!!

but all other layers, are just fine ??? this is driving me crazy. and since the filament is ginded, all the other layers do not print at all... So...

here is my painful workaround to come over that problem

1- I Print the first layer.

2- press "pause" then Home after first layer is done.

3- unjame manualy the filament, notice that the filament has been grinded ALOT!

4- press resume, and then everything become wonderfully fine for the rest of the print.... no grind at all!!!!!! at full speed!!!

Why only the first layer??? Is this possible that i print the first layer too close of the surface(glass) and then there is a pressure building up along the nozzle up to the barrel, and then this pressure getting too high preventing the filament from going down, creating the grind.....????

And yes! i'm using a wade's extruder

I can extrude up to 70 mm/s without any problem. my print speed is around 40mm/s, my first layer speed is 30% of that speed.

it's hard to explain, i'll do my best.

in short, "The first layer is grinding awfully my filament!!!!!". Why I don't know!!!!

but all other layers, are just fine ??? this is driving me crazy. and since the filament is ginded, all the other layers do not print at all... So...

here is my painful workaround to come over that problem

1- I Print the first layer.

2- press "pause" then Home after first layer is done.

3- unjame manualy the filament, notice that the filament has been grinded ALOT!

4- press resume, and then everything become wonderfully fine for the rest of the print.... no grind at all!!!!!! at full speed!!!

Why only the first layer??? Is this possible that i print the first layer too close of the surface(glass) and then there is a pressure building up along the nozzle up to the barrel, and then this pressure getting too high preventing the filament from going down, creating the grind.....????

And yes! i'm using a wade's extruder

I can extrude up to 70 mm/s without any problem. my print speed is around 40mm/s, my first layer speed is 30% of that speed.

|

Re: Painfull problem @ first layer July 22, 2012 05:07PM |

Registered: 11 years ago Posts: 939 |

|

Re: Painfull problem @ first layer July 22, 2012 05:56PM |

Admin Registered: 17 years ago Posts: 7,879 |

The height of the first layer should be the same as the normal layer height, If it is less then it will create more nozzle pressure, however it is normal to do the first layer more slowly so this the usual outcome of extruder problems is for the first layer to be fine and the second layer to fail.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Painfull problem @ first layer July 22, 2012 06:49PM |

Registered: 11 years ago Posts: 28 |

Yes I used to print very neer of the glass because otherwise, the abs does not stick to the glass i use a heat bed at 100C but as soon i use the Paper

height trick, i'm too high. so actualy i'm trying the "ABS juice method" to print the first layer farther from the bed.

as soon as i have news , i'll post my observation.

Edited 1 time(s). Last edit at 07/23/2012 12:33PM by Carignan.

height trick, i'm too high. so actualy i'm trying the "ABS juice method" to print the first layer farther from the bed.

as soon as i have news , i'll post my observation.

Edited 1 time(s). Last edit at 07/23/2012 12:33PM by Carignan.

|

Re: Painfull problem @ first layer July 22, 2012 07:16PM |

Registered: 11 years ago Posts: 28 |

|

Re: Painfull problem @ first layer July 22, 2012 08:57PM |

Registered: 11 years ago Posts: 2 |

kapton tape sicks very well to ABS to the point I have trouble getting the part of the bead afterwards some times. I use a 3x5 index card for my spacing. An index card is just shy of 0.2mm for my first layer. I've also had an extruder jam once, a few more turns on the idler fixed that issue.

|

Re: Painfull problem @ first layer July 22, 2012 11:12PM |

Registered: 11 years ago Posts: 28 |

I will try Sugar Water @ 8g per 100ml applied with a brush @ 100C on the glass, someone on the forum seems to have great result with that bond, i'll let you know if that work

So in short, my problem was not a Slic3r problem but:

1) a first layer that do not stick on the my glass

2) to stick,at the glass I needed to set the nozzle very near the bed ( soo near in fact, that it clog the nozzle hole, bottle necking the extrusion, creating a great pressure on the filament, that was causing a grinded filament, and a jammed extruder )

The Solution:

1)Set the nozzle height a little higher

2) use ABS juice so the bed get sticky

ABS Juice : Work great to make the glass sticky

Sugar Water: a more healthy solution without fume that seems to work great

Sandblasted Glass : according to this video http://www.youtube.com/watch?v=n_bgJ_lZNEc this is supposed to do the job without applying any coating

So in short, my problem was not a Slic3r problem but:

1) a first layer that do not stick on the my glass

2) to stick,at the glass I needed to set the nozzle very near the bed ( soo near in fact, that it clog the nozzle hole, bottle necking the extrusion, creating a great pressure on the filament, that was causing a grinded filament, and a jammed extruder )

The Solution:

1)Set the nozzle height a little higher

2) use ABS juice so the bed get sticky

ABS Juice : Work great to make the glass sticky

Sugar Water: a more healthy solution without fume that seems to work great

Sandblasted Glass : according to this video http://www.youtube.com/watch?v=n_bgJ_lZNEc this is supposed to do the job without applying any coating

|

Re: Painfull problem @ first layer July 23, 2012 04:06AM |

Registered: 12 years ago Posts: 300 |

I only have a small current power supply, so I modified my heating bed to have a higher resistor. So I only get 65°C.

I'm using kapton tape, and I clean it a little bit with acetone before each print, and I don't have any warping problems. As RustyPaint said, @100°C, it can be hard to remove the parts from the tape! But 65°C is fine.

Carignan, are you using kapton, or do you print on the glass, with the abs juice?

Frédéric

I'm using kapton tape, and I clean it a little bit with acetone before each print, and I don't have any warping problems. As RustyPaint said, @100°C, it can be hard to remove the parts from the tape! But 65°C is fine.

Carignan, are you using kapton, or do you print on the glass, with the abs juice?

Frédéric

|

Re: Painfull problem @ first layer July 23, 2012 09:46AM |

Registered: 11 years ago Posts: 28 |

|

Re: Painfull problem @ first layer July 23, 2012 10:41PM |

Registered: 11 years ago Posts: 28 |

Hi folks, I told you that I planed to test the sugar water Technic.... well I did, .... and it works pretty well, not as well as the ABS juice because I had to lower the speed of the First layer quiet a bit ( 30% of the normal speed ).

4 sugar cubes per 100 ml applied at 100°C, let it dry, applied 2 to 3 coats.

But I still prefer ABS juice, ,ore sticky = more first layer speed

4 sugar cubes per 100 ml applied at 100°C, let it dry, applied 2 to 3 coats.

But I still prefer ABS juice, ,ore sticky = more first layer speed

|

Re: Painfull problem @ first layer July 24, 2012 02:32AM |

Registered: 12 years ago Posts: 300 |

|

Re: Painfull problem @ first layer July 24, 2012 03:05PM |

Registered: 12 years ago Posts: 313 |

Set your extruder motor current low enough that the motor starts skipping steps before it chews the filament. Even with everything working normally, every now and then the extruder nozzle will end up trying to extrude somewhere where there is already plastic and the backpressure causes the bolt to chew the filament if the motor current is too high. It's much better to get some skipped steps instead.

|

Re: Painfull problem @ first layer July 24, 2012 08:14PM |

Registered: 11 years ago Posts: 28 |

fma Wrote:

-------------------------------------------------------

> I tried the ABS juice, yesterday: epic fail

>

> How do you put the juice on the glass? How much is

> needed?

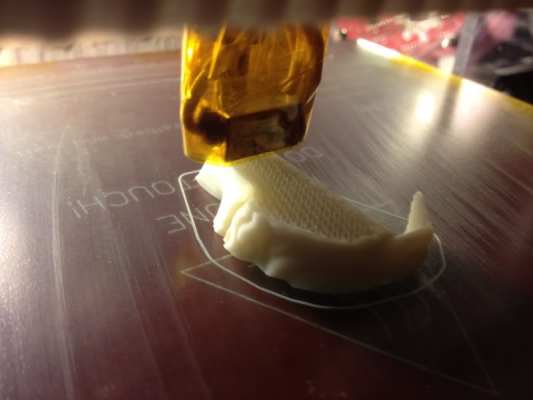

I apply the juice with a paint brush then let it dry for a minute or two, and it look like this

-------------------------------------------------------

> I tried the ABS juice, yesterday: epic fail

>

> How do you put the juice on the glass? How much is

> needed?

I apply the juice with a paint brush then let it dry for a minute or two, and it look like this

|

Re: Painfull problem @ first layer July 24, 2012 08:17PM |

Registered: 11 years ago Posts: 28 |

ttsalo Wrote:

-------------------------------------------------------

> Set your extruder motor current low enough that

> the motor starts skipping steps before it chews

> the filament. Even with everything working

> normally, every now and then the extruder nozzle

> will end up trying to extrude somewhere where

> there is already plastic and the backpressure

> causes the bolt to chew the filament if the motor

> current is too high. It's much better to get some

> skipped steps instead.

That's a good idea,but is this to the detriment of the high extruding speed?

And since this thread had nothing to do with slic3r are we not supposed to move this discussion elsewhere?

Edited 1 time(s). Last edit at 07/25/2012 12:56PM by Carignan.

-------------------------------------------------------

> Set your extruder motor current low enough that

> the motor starts skipping steps before it chews

> the filament. Even with everything working

> normally, every now and then the extruder nozzle

> will end up trying to extrude somewhere where

> there is already plastic and the backpressure

> causes the bolt to chew the filament if the motor

> current is too high. It's much better to get some

> skipped steps instead.

That's a good idea,but is this to the detriment of the high extruding speed?

And since this thread had nothing to do with slic3r are we not supposed to move this discussion elsewhere?

Edited 1 time(s). Last edit at 07/25/2012 12:56PM by Carignan.

|

Re: Painfull problem @ first layer July 25, 2012 02:19AM |

Registered: 12 years ago Posts: 300 |

Sorry, only registered users may post in this forum.