Help, internal size of part(s) too small...

Posted by Qsilver

|

Re: Help, internal size of part(s) too small... June 13, 2014 01:42PM |

Registered: 11 years ago Posts: 24 |

|

Re: Help, internal size of part(s) too small... June 17, 2014 05:20PM |

Registered: 13 years ago Posts: 228 |

Okay nophead, you have a point. You're talking about the shape that extrudate gets after nozzle has moved on. Viscosity of plastic rounds the sides until they become semicircles, even if they weren't such while each section was being extruded. That makes sense.

I'm open to testing the change in the upcoming experimental release. Both luckily and unluckily, I think that things won't change much anyway since the change is going to affect a limited set of situations (those where target width is smaller than nozzle diameter + layer height). Also, using a spreadsheet I calculated how thinner would extrusion width be in those cases, i.e. how much would the error be reduced by.

To do this, I calculated the cross-sectional area with current formula, and then divided using the new formula solving by width.

For a 0.35mm nozzle and 0.1mm layer height, the actual width (according to the new formula) will be -0.02mm over the current one. And -0.06mm for a 0.4mm layer height.

For the OP issue raised by Qsilver who started this thread, the difference according to his settings would be -0.05mm, which is way less than the errors he measured so not very useful for fixing his issues. (It's even less than the difference in error he measured between X and Y, 0.1mm, that he thinks might be caused by mechanical issues.)

So, luckily this change won't raise too many complaints since it will change very little. But unluckily, it's not the definitive solution for getting exact dimensions… and probably not the main cause to blame either.

I'm open to testing the change in the upcoming experimental release. Both luckily and unluckily, I think that things won't change much anyway since the change is going to affect a limited set of situations (those where target width is smaller than nozzle diameter + layer height). Also, using a spreadsheet I calculated how thinner would extrusion width be in those cases, i.e. how much would the error be reduced by.

To do this, I calculated the cross-sectional area with current formula, and then divided using the new formula solving by width.

For a 0.35mm nozzle and 0.1mm layer height, the actual width (according to the new formula) will be -0.02mm over the current one. And -0.06mm for a 0.4mm layer height.

For the OP issue raised by Qsilver who started this thread, the difference according to his settings would be -0.05mm, which is way less than the errors he measured so not very useful for fixing his issues. (It's even less than the difference in error he measured between X and Y, 0.1mm, that he thinks might be caused by mechanical issues.)

So, luckily this change won't raise too many complaints since it will change very little. But unluckily, it's not the definitive solution for getting exact dimensions… and probably not the main cause to blame either.

|

Re: Help, internal size of part(s) too small... June 17, 2014 11:00PM |

Registered: 14 years ago Posts: 142 |

Great, thanks. I've been quietly following this thread and was going to suggest this.Quote

Sound

I'm open to testing the change in the upcoming experimental release.

I value the contributions both you and Nophead make to the community.

As a software developer, I understand this problem, often things are affected by multiple elements, but this still means it is worth fixing everything we can.Quote

Sound

So, luckily this change won't raise too many complaints since it will change very little. But unluckily, it's not the definitive solution for getting exact dimensions… and probably not the main cause to blame either.

As a person who has bought plastic printed parts from Nophead (both for my original Sells Mendel back in about 2008 or so and last year for a friend's M90 (I printed my own, but he was in a hurry and my printer was broken), I can attest to the fact that nophead's parts have good dimensional accuracy. With the Sells parts I could see some evidence of cleanup/reaming of holes. With the latest M90 parts they look like they're straight off the printer, and they're perfect.

I guess a secondary element to this is the point made about slicing with the "outside perimeters first" setting when wanting dimensional accuracy. IIRC this is what Nophead also does. Could this combined with the above account or some of the OP's original issues? (Sorry on an iphone, so not rereading the entire thread although I have previously read every word and gone and re-read the relevant posts on nophead's blog and your manual and GitHub tickets/comments)

Edited 1 time(s). Last edit at 06/17/2014 11:02PM by CraigRK.

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

|

Re: Help, internal size of part(s) too small... July 27, 2014 02:38PM |

Registered: 13 years ago Posts: 228 |

Okay, I confirm I have now extended the usage of the rectangle model with semicircles even in those cases that were previously handled by very similar yet different formulas. The main reason I did this hypothetical "fix" is to stop discussing on a secondary factor that has very limited impact on dimensional issues, but was still attracting too much attention giving users the feeling that flow math was the main thing to blame. Release 1.2.0 will include this minor change (and will also include the XY Size Compensation option which is way more important for handling dimensions).

CraigRK, I bought parts from nophead as well in 2010 or 2011, and I confirm they were quite good. (Oh, my prints from these days are very good and precise as well, do you want to check? I can mail you one :-)). Saying that their quality was only caused by flow math is unfair, since nophead as a knowledgeable person has always been able to build very good machines, tune them, use good quality filament etc. Even in 2014, the average user can't do all of those. Nophead even invented the polyhole OpenSCAD function that addresses one of the main factors for hole errors lying at the CAD stage. I'm not sure all Slic3r users are aware of polyhole.

The "outside perimeters first" option was introduced in Slic3r about two years ago or something.

I keep saying that even with this hypothetical -0.05mm compensation, the OP issues are not fixed at all given the numbers he reported. So, my best effort for helping OP is this answer: [manual.slic3r.org]

CraigRK, I bought parts from nophead as well in 2010 or 2011, and I confirm they were quite good. (Oh, my prints from these days are very good and precise as well, do you want to check? I can mail you one :-)). Saying that their quality was only caused by flow math is unfair, since nophead as a knowledgeable person has always been able to build very good machines, tune them, use good quality filament etc. Even in 2014, the average user can't do all of those. Nophead even invented the polyhole OpenSCAD function that addresses one of the main factors for hole errors lying at the CAD stage. I'm not sure all Slic3r users are aware of polyhole.

The "outside perimeters first" option was introduced in Slic3r about two years ago or something.

I keep saying that even with this hypothetical -0.05mm compensation, the OP issues are not fixed at all given the numbers he reported. So, my best effort for helping OP is this answer: [manual.slic3r.org]

|

Re: Help, internal size of part(s) too small... July 29, 2014 02:19PM |

Registered: 14 years ago Posts: 142 |

Thanks for doing this. I am sure you are right, but often the easiest way to stop the debate on a point is to prove it by doing what people say and proving your point.Quote

Sound

Okay, I confirm I have now extended the usage of the rectangle model with semicircles even in those cases that were previously handled by very similar yet different formulas. The main reason I did this hypothetical "fix" is to stop discussing on a secondary factor that has very limited impact on dimensional issues, but was still attracting too much attention giving users the feeling that flow math was the main thing to blame. Release 1.2.0 will include this minor change (and will also include the XY Size Compensation option which is way more important for handling dimensions).

I've just re-read my post in case I got the tone wrong, I don't think I did. I didn't say you were not producing equally good stuff, or that their quality was only caused by flow math. I worked very hard to make sure I worded things evenly as I didn't want to offend either of you. This is why I said:Quote

Sound

CraigRK, I bought parts from nophead as well in 2010 or 2011, and I confirm they were quite good. (Oh, my prints from these days are very good and precise as well, do you want to check? I can mail you one :-)). Saying that their quality was only caused by flow math is unfair, since nophead as a knowledgeable person has always been able to build very good machines, tune them, use good quality filament etc. Even in 2014, the average user can't do all of those. Nophead even invented the polyhole OpenSCAD function that addresses one of the main factors for hole errors lying at the CAD stage. I'm not sure all Slic3r users are aware of polyhole.

Quote

CraigRK

I value the contributions both you and Nophead make to the community.

As I said, the issues are probably caused by multiple factors, and eliminating as many of them as possible will help

Quote

Sound

The "outside perimeters first" option was introduced in Slic3r about two years ago or something.

I keep saying that even with this hypothetical -0.05mm compensation, the OP issues are not fixed at all given the numbers he reported. So, my best effort for helping OP is this answer: [manual.slic3r.org]

Thanks again for all you are doing for the community.

Craig

Edited 1 time(s). Last edit at 07/29/2014 02:19PM by CraigRK.

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

|

Re: Help, internal size of part(s) too small... November 05, 2015 12:59PM |

Registered: 10 years ago Posts: 13 |

@mikh3x4 have you figured out the answer? This is an old post, but I've carefully read all 6 pages and while there are lots of great improvements and insight, I feel like there's no comprehensive solution.

To sum up what we've learned: Slic3r incorrectly approximated the profile for EW<=nozzle diameter, but I personally think this was not far off enough to cause issues on the order of what most people see. Slic3r details many of the issues (http://manual.slic3r.org/troubleshooting/dimension-errors) including XYZ calibration, shrinkage, polygon approximation for circular holes, filament cutting corners, z wobble, inconsistent filament diameter, backlash, and dragging filament towards the center of a circle (there may be others).

I've made (thing:1113412) to test some of these issues and I'll post if I find a reasonable solution. I've set out to test the effect of a single perimeter, external perimeters first, number of perimeters, perimeter speed, and nozzle diameter.

@nophead, I agree with you that the nozzle diameter should have nothing to do with flow calculations (if extrusion width is constant) and I've found just that. With a constant EW of 0.5 and a nozzle of 0.25, 0.4, or 0.8, I get different filament usage!

@sound is this right? I thought it had something to do with the filament cross-section slic3r uses with a little more info here (http://forums.reprap.org/read.php?263,134103,137818#msg-137818)

Any one figure out an end-all be-all solution? I don't think XY compensation is it...

edit1: formatting

edit2: thing#

Edited 2 time(s). Last edit at 11/05/2015 01:06PM by nicksears.

To sum up what we've learned: Slic3r incorrectly approximated the profile for EW<=nozzle diameter, but I personally think this was not far off enough to cause issues on the order of what most people see. Slic3r details many of the issues (http://manual.slic3r.org/troubleshooting/dimension-errors) including XYZ calibration, shrinkage, polygon approximation for circular holes, filament cutting corners, z wobble, inconsistent filament diameter, backlash, and dragging filament towards the center of a circle (there may be others).

I've made (thing:1113412) to test some of these issues and I'll post if I find a reasonable solution. I've set out to test the effect of a single perimeter, external perimeters first, number of perimeters, perimeter speed, and nozzle diameter.

@nophead, I agree with you that the nozzle diameter should have nothing to do with flow calculations (if extrusion width is constant) and I've found just that. With a constant EW of 0.5 and a nozzle of 0.25, 0.4, or 0.8, I get different filament usage!

@sound is this right? I thought it had something to do with the filament cross-section slic3r uses with a little more info here (http://forums.reprap.org/read.php?263,134103,137818#msg-137818)

Any one figure out an end-all be-all solution? I don't think XY compensation is it...

edit1: formatting

edit2: thing#

Edited 2 time(s). Last edit at 11/05/2015 01:06PM by nicksears.

|

Re: Help, internal size of part(s) too small... November 06, 2015 07:18AM |

Registered: 10 years ago Posts: 2,472 |

Quote

justcurious

well, I think you have by far too big ambitions about accuracy with 3d printers. Think about again.

You have a nozzle that can make a line that is 0,40 wide or larger, never smaller. in layer height direction you can select a layer height smaller than nozzle width and by that get better resolution, but in x,y plane, accuracy is never better than extrusion width or at least half of it.

Why do you believe that? You are completely wrong. The extrusion width affects only the smallest feature that can be printed in XY, not the dimensional resolution of the part. On the contrary, it is the Z dimension that can only be made to the accuracy of your layer height, the XY accuracy can be a lot better - it is constrained only by the motor step size and the amount of backlash in your XY axis. Neither X nor Y have to be positioned on an exact multiple of the extrusion width, only an exact multiple of the distance moved by the stepper motor micro-step. When slicing therefore, choose a layer height that will divide exactly into the Z height of the part to achieve the greatest accuracy.

There are a few factors that affect the accuracy of printed circles, but probably the biggest is the fact that the inside circumference of a circle is smaller than the outside circumference. Most slicers will position the extruder to a position that is half the extrusion width away from the outside or inside perimeter, assuming that the centre of the nozzle will run along the centre of the extruded line. So (for example) if it "draws" a rectangle that the design file shows as being exactly 10mm in X using an extrusion width of 0.4mm, the extruder will move (in X) a distance of 9.6mm (from relative positions 0.2mm to 9.8mm) With straight lines and the correct extrusion factor that will give pretty good accuracy - 0.05mm or better IME. If however the extruder is describing a circular path, there is more plastic deposited in the inside of the circle than the outside, because it has a shorter circumference. This has the effect of displacing the centre of the extrusion toward the inside of the circle.

Dave

|

Re: Help, internal size of part(s) too small... November 08, 2015 03:51AM |

Registered: 9 years ago Posts: 125 |

|

Re: Help, internal size of part(s) too small... November 09, 2015 07:25AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Mikk36

Extrusion width does affect the corner radius in XY plane, so you could say that you can get better resolution in that sense with smaller extrusion width.

Yes, true, though having a very small radius instead of a sharp corner is seldom a problem - and IME the shape of most corners are affected far more by "blobbing" and other artefacts than by extrusion radius (at least when using a Bowden extruder).

Dave

|

Re: Help, internal size of part(s) too small... November 09, 2015 07:30AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think extrusion width and nozzle diameter also affect how much round holes shrink.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Help, internal size of part(s) too small... December 08, 2015 06:36PM |

Registered: 10 years ago Posts: 10 |

I revisited this issue, because I want to migrate from KISSlicer to Slic3r. (KISSlicer is closed, and the author tends to dissapear from time to time)

I see something that KISSlicer does with additional perimeters that Slic3r nor any other slicer does: The outer perimeter geometry is nominal, right? and the rest of the additional perimeters are just context coherent scaling of each of the features of the perimeter, but KISSlicer does more than this... KISSlicer rounds the perimeter more and more with each internal iteration, so the inner perimeters don't do much pressure upon the original geometry's features.

I'm sorry for writing this in such a heavy-reading way... It's a bit late.

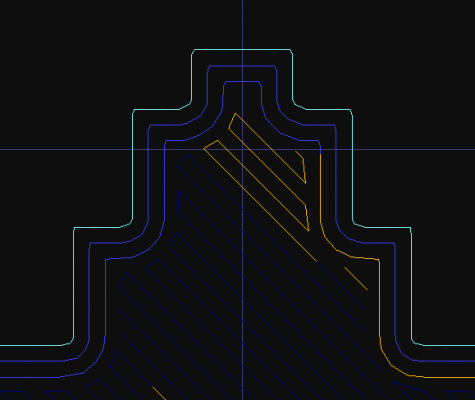

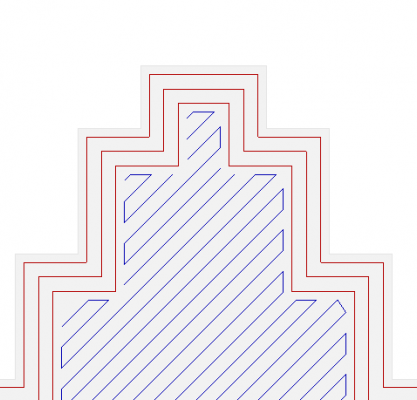

For TL;DR, and clarification, I attach the output of the two, so you can see the effect:

This could also be part of why KISSlicer gets such an even finish! My homemade prusa i2 is a cranky old printer that shakes and breaks and de-adjusts continously, but with KISSlicer gcodes it still makes better prints that many high specs printers. With astonishing accuracy.

I see something that KISSlicer does with additional perimeters that Slic3r nor any other slicer does: The outer perimeter geometry is nominal, right? and the rest of the additional perimeters are just context coherent scaling of each of the features of the perimeter, but KISSlicer does more than this... KISSlicer rounds the perimeter more and more with each internal iteration, so the inner perimeters don't do much pressure upon the original geometry's features.

I'm sorry for writing this in such a heavy-reading way... It's a bit late.

For TL;DR, and clarification, I attach the output of the two, so you can see the effect:

This could also be part of why KISSlicer gets such an even finish! My homemade prusa i2 is a cranky old printer that shakes and breaks and de-adjusts continously, but with KISSlicer gcodes it still makes better prints that many high specs printers. With astonishing accuracy.

|

Re: Help, internal size of part(s) too small... December 08, 2015 07:42PM |

Admin Registered: 17 years ago Posts: 7,879 |

I think the inner rounding is just a progression of the outer rounding when you offset inwards by the filament width. The difference comes from the outer perimeter. KISSlicer seems to round the corners where the model has sharp corners. To some extent that makes sense because you can't actually print a sharp corner. It will have a minimum radius of half the filament width. However KISSlicer seems to round it more than that.

Objects with rounded corners always come out nicer because it lowers the acceleration which reduces ringing, etc, and also allows the filament flow to be more constant. Probably better to model that way rather than have a slicer that doesn't follow the model.

[www.hydraraptor.blogspot.com]

Objects with rounded corners always come out nicer because it lowers the acceleration which reduces ringing, etc, and also allows the filament flow to be more constant. Probably better to model that way rather than have a slicer that doesn't follow the model.

[www.hydraraptor.blogspot.com]

|

Re: Help, internal size of part(s) too small... December 09, 2015 11:05AM |

Registered: 10 years ago Posts: 10 |

If I could, I would include that as an option. Skeinforge included the option "Fillet corners with X radius". After all, attempting to make a sharp corner in an FFF machine is an unrealistic approach.

Like any other fabrication process, modifications must be made to the model in order to get the final product right, but I consider modifying the original geometry a bad practice, so those modifications must be made in the slicer, in my opinion.

XY Compensation parameter is wonderful for it, and the closest thing to "inset calibration" we have in the open source ecosystem, but I still don't get things to fit...

Layer evenness may be a thing here, it also happens that KISSlicer gets layers to be absolutely even, and Slic3r don't, but gcodes are almost the same!!! What's happening here?

I'll make more experiments when I have more time. I think that open source 3D printing is developed enough to overcome these kind of problems.

I made a repo sharing the slic3r settings I use, to keep track of why I changed each one of the parameters: [github.com]

Tests are to be documented but right now I can't because I really really should be studying.

Like any other fabrication process, modifications must be made to the model in order to get the final product right, but I consider modifying the original geometry a bad practice, so those modifications must be made in the slicer, in my opinion.

XY Compensation parameter is wonderful for it, and the closest thing to "inset calibration" we have in the open source ecosystem, but I still don't get things to fit...

Layer evenness may be a thing here, it also happens that KISSlicer gets layers to be absolutely even, and Slic3r don't, but gcodes are almost the same!!! What's happening here?

I'll make more experiments when I have more time. I think that open source 3D printing is developed enough to overcome these kind of problems.

I made a repo sharing the slic3r settings I use, to keep track of why I changed each one of the parameters: [github.com]

Tests are to be documented but right now I can't because I really really should be studying.

|

Re: Help, internal size of part(s) too small... December 09, 2015 11:16AM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Help, internal size of part(s) too small... December 09, 2015 01:42PM |

Registered: 10 years ago Posts: 10 |

By layer eveness, I mean that every external perimeter is exactly in place, when you look at the layers from the side. For example, in a vertical wall, every perimeter is exactly on top of the previous one, and looks exactly like the previous one. The idea can be expressed with a photo but I'm not at home right now.

With Slic3r, layers look displaced from each other, while in KISSlicer the layers look like in the gcode renderer.

Fine tuning of Slic3r can decrease this effect, but I haven got it just yet. Richrap's "Slic3r is nicer" tutorials have a lot of photos of what I call "even layers"

I hope I explained. When I get home, I'll post two examples I have lying on my desktop.

With Slic3r, layers look displaced from each other, while in KISSlicer the layers look like in the gcode renderer.

Fine tuning of Slic3r can decrease this effect, but I haven got it just yet. Richrap's "Slic3r is nicer" tutorials have a lot of photos of what I call "even layers"

I hope I explained. When I get home, I'll post two examples I have lying on my desktop.

|

Re: Help, internal size of part(s) too small... December 09, 2015 02:36PM |

Admin Registered: 17 years ago Posts: 7,879 |

Poor layer alignment is normally a mechanical problem. I am not sure how the slicer would affect it, other than if you only have rounded corners you don't have as much stress on the mechanics.

If you have backlash then the order and direction of the outlines can make a difference. If you always approach the start of an outline from the same direction the outline will be in the same place but if sometimes it is approached from the other side, starts in another place or goes in the opposite direction it will be displaced.

[www.hydraraptor.blogspot.com]

If you have backlash then the order and direction of the outlines can make a difference. If you always approach the start of an outline from the same direction the outline will be in the same place but if sometimes it is approached from the other side, starts in another place or goes in the opposite direction it will be displaced.

[www.hydraraptor.blogspot.com]

|

Re: Help, internal size of part(s) too small... December 09, 2015 07:32PM |

Registered: 10 years ago Posts: 10 |

The two examples i had lying around turned out not to be that bad when it comes to layer evenness. It does when it comes to hiding the seam of a perimeter start. KISSlicer priorizes vertexes with narrower angle when Slic3r takes just the nearest one. This results in a much less camouflated seam... But I won't worry about that just yet because the constant pressure approach is interesting and I haven't had the opportunity to test it...

Back to the dimensioning problem. Last saturday I was tinkering with XYCompensation and found that it shrinks the inset as much as it shrinks the outset. When your printer makes the outset fine but the inset smaller, what do you do?

I'll tackle this problem this weekend, with a previous mechanical revision of the machine. I could believe that belts may have slept and produced backlash.

Back to the dimensioning problem. Last saturday I was tinkering with XYCompensation and found that it shrinks the inset as much as it shrinks the outset. When your printer makes the outset fine but the inset smaller, what do you do?

I'll tackle this problem this weekend, with a previous mechanical revision of the machine. I could believe that belts may have slept and produced backlash.

|

Re: Help, internal size of part(s) too small... December 13, 2015 06:33AM |

Registered: 10 years ago Posts: 10 |

I did what @nophead said. It came down to just retensioning the belts. The results are promising:

The file is the fit.stl attached in this message, scaled to 300%. When I tried to print it at 100%, it was too smalll and there were no use trying to fit the two halves.

Right now I'm printing the classic twisted bottle, and see what happens.

The file is the fit.stl attached in this message, scaled to 300%. When I tried to print it at 100%, it was too smalll and there were no use trying to fit the two halves.

Right now I'm printing the classic twisted bottle, and see what happens.

|

Re: Help, internal size of part(s) too small... December 20, 2015 12:04PM |

Registered: 10 years ago Posts: 10 |

After exams, I went back to this topic. This is what happened so far:

Printed the twisted bottle. Layers were so uneven, and of course it didn't fit. Then it came to my mind that maybe perimeters were being altered during the making of the infills, so I set that from 15% to 5% (I doubt this is even necessary, Slic3r makes infills fine). This resulted in a nice finish print test, but still needs more testing.

But then i came across another issue.... I suspect that my stepspermm are a bit low, but they are the standard 80 stepspermm for T2 pulleys. It's a well-known value, and widely used. However, with belts tensioned, and no hysteresis in my axes, the value that does the trick for me is 81.42steps. It doesn't fit any other clone of this printer but mine. How can this be?

I'll keep testing until I get a nice config file. This issue needs to be tackled once and for all.

Printed the twisted bottle. Layers were so uneven, and of course it didn't fit. Then it came to my mind that maybe perimeters were being altered during the making of the infills, so I set that from 15% to 5% (I doubt this is even necessary, Slic3r makes infills fine). This resulted in a nice finish print test, but still needs more testing.

But then i came across another issue.... I suspect that my stepspermm are a bit low, but they are the standard 80 stepspermm for T2 pulleys. It's a well-known value, and widely used. However, with belts tensioned, and no hysteresis in my axes, the value that does the trick for me is 81.42steps. It doesn't fit any other clone of this printer but mine. How can this be?

I'll keep testing until I get a nice config file. This issue needs to be tackled once and for all.

|

Re: Help, internal size of part(s) too small... December 21, 2015 07:18AM |

Admin Registered: 17 years ago Posts: 7,879 |

How are you measuring it? If it is by measuring a print some of the discrepancy will be plastic shrinkage. Perhaps your belts are inaccurate or not stretched tight enough to meet their spec. I don't know what tension belt pitch is quoted at or how much difference tension makes.

Edited 1 time(s). Last edit at 12/21/2015 07:19AM by nophead.

[www.hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 12/21/2015 07:19AM by nophead.

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.