Slic3r Bridging and Platforms Problems

Posted by KimBrown

|

Slic3r Bridging and Platforms Problems April 12, 2014 09:07AM |

Registered: 10 years ago Posts: 859 |

Hi, I'm using the latest version of Slic3r, and been fairly happy with it,

but I've noticed an annoying problem.

When making a bridge, when the HotEnd does the first pass, the HotEnd doesn't quite get to the otherwall or support, stopping 1 or 2mm short.

The filament being unsupported loops.... It is the same affect as if the Belt had skipped a tooth, but it hasn't....

The printer then continues around the walls and rest of the print, then comes back and does a perfect pass on the bridging area.

This only ever happends on the first pass at bridging, and the print remains perfectly aligned, so no missed steps or jumped teeth.

Has any one else noticed this? I can't seem to find a way to let the programmer know there might be a problem.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

but I've noticed an annoying problem.

When making a bridge, when the HotEnd does the first pass, the HotEnd doesn't quite get to the otherwall or support, stopping 1 or 2mm short.

The filament being unsupported loops.... It is the same affect as if the Belt had skipped a tooth, but it hasn't....

The printer then continues around the walls and rest of the print, then comes back and does a perfect pass on the bridging area.

This only ever happends on the first pass at bridging, and the print remains perfectly aligned, so no missed steps or jumped teeth.

Has any one else noticed this? I can't seem to find a way to let the programmer know there might be a problem.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Slic3r Bridging and Platforms Problems April 12, 2014 01:39PM |

Registered: 10 years ago Posts: 859 |

It seems that it might have been a machine problem....

A bearing fell out of the X-axis carriage carrying the HotEnd.

After replacing I was unable to print, then decided to change the Nozzle Mounting as it was broken.

Now the Nozzle is level to the bed it seems to be working ok......

Even on the first level bridging...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

A bearing fell out of the X-axis carriage carrying the HotEnd.

After replacing I was unable to print, then decided to change the Nozzle Mounting as it was broken.

Now the Nozzle is level to the bed it seems to be working ok......

Even on the first level bridging...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Slic3r Bridging and Platforms Problems April 14, 2014 06:31AM |

Registered: 10 years ago Posts: 69 |

I get a similar thing printing a 20mm hollow cube (calibration print) - it will print the bottom layer fine, then print the walls, but the top layer fails on the bridging. I've got no machine problems that I can tell (brand new E3d hotend, everything's levelled, thin wall calibration width is spot on, bearings are all sound, motion is good, no missed steps, belt tension is sound, no skipping teeth, extrusion is good) but that first layer seems to fail the bridge

|

Re: Slic3r Bridging and Platforms Problems April 29, 2014 09:02AM |

Registered: 13 years ago Posts: 228 |

Hi majic79, regarding the calibration cube please see [github.com]

|

Re: Slic3r Bridging and Platforms Problems April 29, 2014 05:49PM |

Registered: 11 years ago Posts: 1,592 |

Hey Sound, if you're still around....

When bridging between 2 pillars say, the extruder will print (for example), 3 perimeters by stretching across the gap - no problem there. But it then does a normal 'criss/cros's infill which is difficult at best to get a good result. My suggestion would be to treat the bridge as all perimeters so the filament is stretched nicely between the pillars i.e. the "extra" perimeters replaces the infill in the air gap. Or is there some setting that already achieves that?

_______________________________________

Waitaki 3D Printer

When bridging between 2 pillars say, the extruder will print (for example), 3 perimeters by stretching across the gap - no problem there. But it then does a normal 'criss/cros's infill which is difficult at best to get a good result. My suggestion would be to treat the bridge as all perimeters so the filament is stretched nicely between the pillars i.e. the "extra" perimeters replaces the infill in the air gap. Or is there some setting that already achieves that?

_______________________________________

Waitaki 3D Printer

|

Re: Slic3r Bridging and Platforms Problems April 30, 2014 05:43AM |

Registered: 13 years ago Posts: 228 |

|

Re: Slic3r Bridging and Platforms Problems April 30, 2014 06:21AM |

Registered: 11 years ago Posts: 1,592 |

Yes indeed!

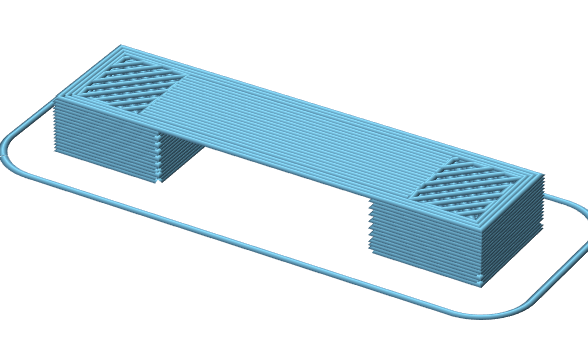

I noticed the problem on an "X end motor" where it prints the top "bridge" that links the motor bracket to the main body (see pic). On that occasion, it printed the bridging perimeters nicely but couldn't quite achieve the "cross fill" linking the two perimeter edges. The process eventually resulted in a reasonably finished bridge but it seemed to me that having all perimeters would be a nice way of bridging. However, after seeing your picture, I bet I've forgotten something setting here??

_______________________________________

Waitaki 3D Printer

I noticed the problem on an "X end motor" where it prints the top "bridge" that links the motor bracket to the main body (see pic). On that occasion, it printed the bridging perimeters nicely but couldn't quite achieve the "cross fill" linking the two perimeter edges. The process eventually resulted in a reasonably finished bridge but it seemed to me that having all perimeters would be a nice way of bridging. However, after seeing your picture, I bet I've forgotten something setting here??

_______________________________________

Waitaki 3D Printer

|

Re: Slic3r Bridging and Platforms Problems May 02, 2014 10:04AM |

Registered: 11 years ago Posts: 1,320 |

My issue with bridging is that often it prints a bridge as the very last thing on a layer, then it raises to the next layer and immediately starts printing on top of the just-laid-down bridge. I notice this especially when I am covering up hex nut traps with a bridge and then want to print circular bolt holes above it. If I have multiple of these, it will bridge all but the last one, do the infill for the remainder of the layer, and then come back to the last bridge and lay it down. Then it will lift up and put down the circular bolt hole perimeter directly on top of the bridge that hasn't has time to cool yet.

A simple way to avoid this is to make sure that bridges are not the last thing done on a layer (I know this probably sounds way easier that is is)

A simple way to avoid this is to make sure that bridges are not the last thing done on a layer (I know this probably sounds way easier that is is)

|

Re: Slic3r Bridging and Platforms Problems May 02, 2014 02:53PM |

Registered: 13 years ago Posts: 228 |

|

Re: Slic3r Bridging and Platforms Problems May 02, 2014 02:56PM |

Registered: 13 years ago Posts: 228 |

|

Re: Slic3r Bridging and Platforms Problems May 03, 2014 06:05AM |

Registered: 11 years ago Posts: 1,592 |

Sound,

Have a look at the pics (first bridging layer) - The first one was sliced in 0.99 - you can see what I mean there. However, I gave V1.1.2 a try with identical settings and got a different result - just what I wanted although I haven't tried a print yet to see how well the ends will anchor. The last pic is the model I'm referring to.

Edited 3 time(s). Last edit at 05/03/2014 06:10AM by waitaki.

_______________________________________

Waitaki 3D Printer

Have a look at the pics (first bridging layer) - The first one was sliced in 0.99 - you can see what I mean there. However, I gave V1.1.2 a try with identical settings and got a different result - just what I wanted although I haven't tried a print yet to see how well the ends will anchor. The last pic is the model I'm referring to.

Edited 3 time(s). Last edit at 05/03/2014 06:10AM by waitaki.

_______________________________________

Waitaki 3D Printer

Sorry, only registered users may post in this forum.