Sub-layer slicing. Why is that?

Posted by barakori

|

Sub-layer slicing. Why is that? April 30, 2014 12:09PM |

Registered: 9 years ago Posts: 56 |

I tried to slice balcony2.stl from http://www.thingiverse.com/thing:215585/#files.

I'm using slic3r 0.9.9 because I only have config files for this version (tried 1.0.1 with the same config files, and result were not good).

My first layer is set to 0.35 height, and the rest to 0.25.

I used Pronterface to look at the result gcode, and I seem to be getting too many layers (think of it as sub-layers).

The 1st layer (z=0) is empty (as always).

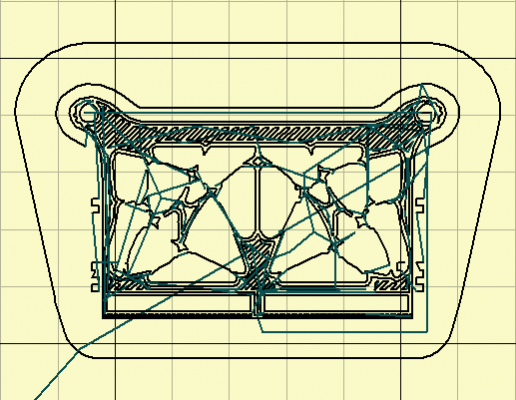

The 2nd layer (z= 0.35) looks fine:

The 3rd layer is at z=0.4, which is only 0.05 above the previous. Why is that? How is it possible? This layer only has a few pieces of

support material:

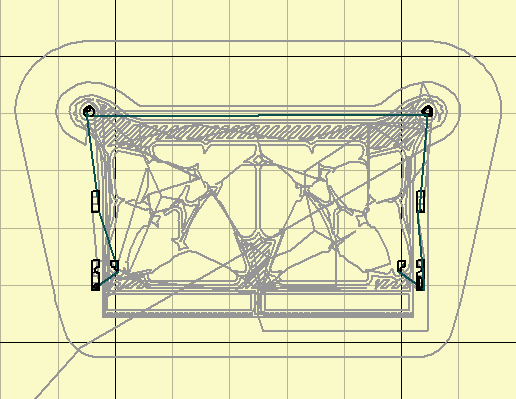

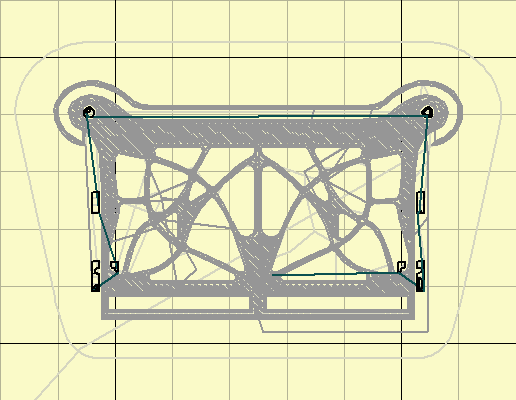

The 4th layer is at z=0.6, and seems fine. See:

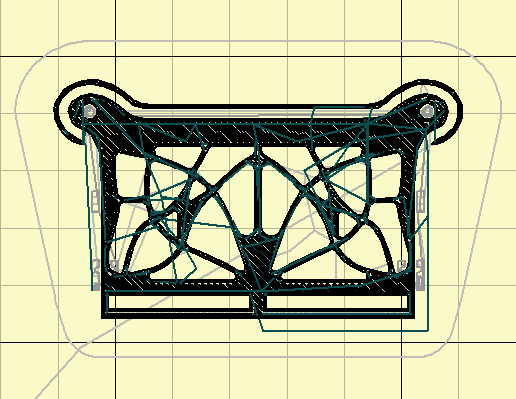

The 5th layer is at z=0.75, again, only 0.15mm above the previous one. See:

The 6th layer is fine, etc.

Why do I get these sub-layers? I printed the model and it came really bad, and I think it's mostly due to slicing.

I'd appreciate any advice.

I'm using slic3r 0.9.9 because I only have config files for this version (tried 1.0.1 with the same config files, and result were not good).

My first layer is set to 0.35 height, and the rest to 0.25.

I used Pronterface to look at the result gcode, and I seem to be getting too many layers (think of it as sub-layers).

The 1st layer (z=0) is empty (as always).

The 2nd layer (z= 0.35) looks fine:

The 3rd layer is at z=0.4, which is only 0.05 above the previous. Why is that? How is it possible? This layer only has a few pieces of

support material:

The 4th layer is at z=0.6, and seems fine. See:

The 5th layer is at z=0.75, again, only 0.15mm above the previous one. See:

The 6th layer is fine, etc.

Why do I get these sub-layers? I printed the model and it came really bad, and I think it's mostly due to slicing.

I'd appreciate any advice.

|

Re: Sub-layer slicing. Why is that? April 30, 2014 07:34PM |

Registered: 11 years ago Posts: 1,171 |

It has to do with support / infill. I don't remember the exact numbers but support does not need such fine layer height so the support is printing thicker than the rest.

Here I found this explanation on the Slic3r Blog and the image attached.

A well-known feature introduced by Slic3r is Microlayering (aka Infill every 'n' layers, aka Combine infill). With this option, a different layer height is used for infill and for perimeters: this way you can do, say, 0.1mm thick perimeters while still printing infill at 0.3mm. You save time while still getting high resolutions on the surfaces. Note that this is very different from the "Skin" option that was introduced in Skeinforge: that one just duplicated perimeters several times, so you'd still get the infill resolution even on the outside. A former microlayering concept and implementation was actually introduced by Adrian Bowyer, so this is not entirely new in Slic3r.

So in the end, yes it's suppose to do what you are seeing. It's hard to wrap your head around but that's how it does support now.

Edited 1 time(s). Last edit at 04/30/2014 07:36PM by tmorris9.

Here I found this explanation on the Slic3r Blog and the image attached.

A well-known feature introduced by Slic3r is Microlayering (aka Infill every 'n' layers, aka Combine infill). With this option, a different layer height is used for infill and for perimeters: this way you can do, say, 0.1mm thick perimeters while still printing infill at 0.3mm. You save time while still getting high resolutions on the surfaces. Note that this is very different from the "Skin" option that was introduced in Skeinforge: that one just duplicated perimeters several times, so you'd still get the infill resolution even on the outside. A former microlayering concept and implementation was actually introduced by Adrian Bowyer, so this is not entirely new in Slic3r.

So in the end, yes it's suppose to do what you are seeing. It's hard to wrap your head around but that's how it does support now.

Edited 1 time(s). Last edit at 04/30/2014 07:36PM by tmorris9.

|

Re: Sub-layer slicing. Why is that? May 01, 2014 02:21PM |

Registered: 13 years ago Posts: 228 |

barakori, support material uses distinct layers than object in order to leave a small gap between support and object. They are just alternated with object's layer. It doesn't mean they are actually so thin. They're just interlaced with object's layers.

I really wish you could upgrade to a recent release. If you tell me what problems did you find I'll be glad to help you.

I really wish you could upgrade to a recent release. If you tell me what problems did you find I'll be glad to help you.

|

Re: Sub-layer slicing. Why is that? May 02, 2014 12:28AM |

Registered: 11 years ago Posts: 1,592 |

|

Re: Sub-layer slicing. Why is that? May 02, 2014 01:40PM |

Registered: 9 years ago Posts: 56 |

Thanks for the information. Now this all makes sense.

Sadly, now I need to look for another reason why the print for this model came out really bad.

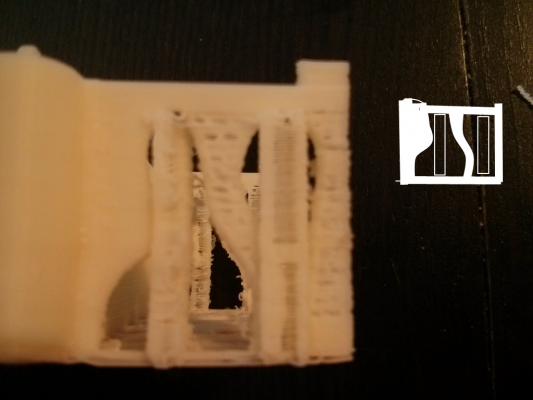

I saw two main things. First, in this picture which is a bit out of focus:

Some printed stuff is as sparse as the support (I drew a sketch of what should have been printed, and what's support on the right hand side).

Second, the front of the porch, which is the bottom few layers of the print came out, again, very sparse:

Can anyone suggest what might be causing this? Any other forum where I should ask this?

Thanks.

Sadly, now I need to look for another reason why the print for this model came out really bad.

I saw two main things. First, in this picture which is a bit out of focus:

Some printed stuff is as sparse as the support (I drew a sketch of what should have been printed, and what's support on the right hand side).

Second, the front of the porch, which is the bottom few layers of the print came out, again, very sparse:

Can anyone suggest what might be causing this? Any other forum where I should ask this?

Thanks.

|

Re: Sub-layer slicing. Why is that? May 02, 2014 02:55PM |

Registered: 13 years ago Posts: 228 |

I think you need to calibrate (i.e. increase) your flow, which is either influenced by E steps/mm in firmware or Extrusion Multiplier in Slic3r. Since your extrusion looks non regular I would also make sure there are no mechanical problems, like dirty hobbed bolt or loose extruder gears or too much friction caused by heat in extruder barrel etc. Also, make sure you have a recent Slic3r version (just in case...)

|

Re: Sub-layer slicing. Why is that? May 04, 2014 01:34PM |

Registered: 9 years ago Posts: 56 |

Thanks for all the information.

Are there good test shapes that can be used to check for flow and other calibrations?

I think that the flow is generally right (except maybe for the 1st layer multiplier). In 0002.jpg above, the big chunk

on the left came out well. It's only the small parts that don't come out well. Could it be that as long as the flow keeps

coming, everything is well, but just doing a small part isn't accurate?

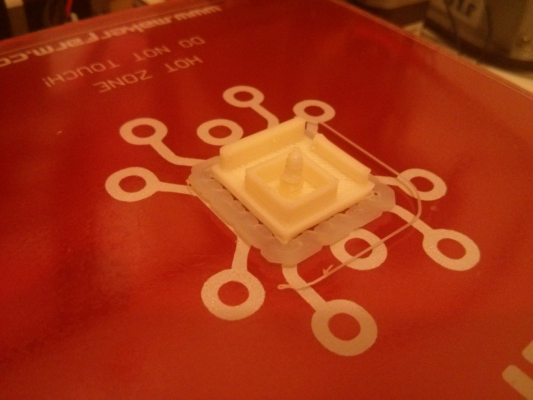

I tried printing a small test part 2 x 2 cm and it came out pretty well. Here's the printed output:

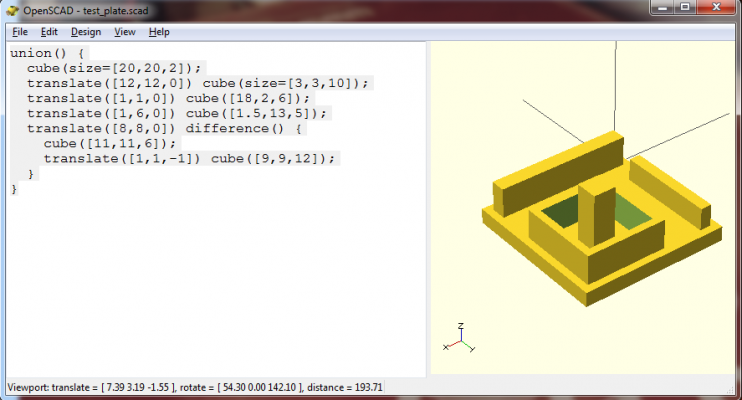

And here's the original model:

Everything came out quite accurate, except for the "tower" - this seems to have "melted" a bit since the layers were

drawn too fast. I remember there's an option for minimum layer time, but didn't find it (Slic3r 1.0.1) when briefly looking

at the settings.

So it seems that my problem is more with support or complex shapes, and not with general flow. Any suggestion

here?

Thanks.

Are there good test shapes that can be used to check for flow and other calibrations?

I think that the flow is generally right (except maybe for the 1st layer multiplier). In 0002.jpg above, the big chunk

on the left came out well. It's only the small parts that don't come out well. Could it be that as long as the flow keeps

coming, everything is well, but just doing a small part isn't accurate?

I tried printing a small test part 2 x 2 cm and it came out pretty well. Here's the printed output:

And here's the original model:

Everything came out quite accurate, except for the "tower" - this seems to have "melted" a bit since the layers were

drawn too fast. I remember there's an option for minimum layer time, but didn't find it (Slic3r 1.0.1) when briefly looking

at the settings.

So it seems that my problem is more with support or complex shapes, and not with general flow. Any suggestion

here?

Thanks.

|

Re: Sub-layer slicing. Why is that? May 04, 2014 06:23PM |

Registered: 11 years ago Posts: 1,171 |

Sorry, only registered users may post in this forum.