Problems with top layer of print

Posted by ruggb

|

Problems with top layer of print July 17, 2015 02:23PM |

Registered: 9 years ago Posts: 294 |

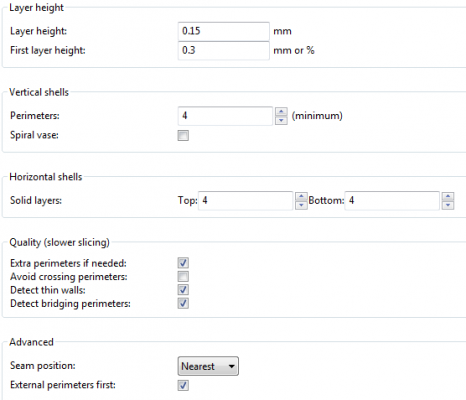

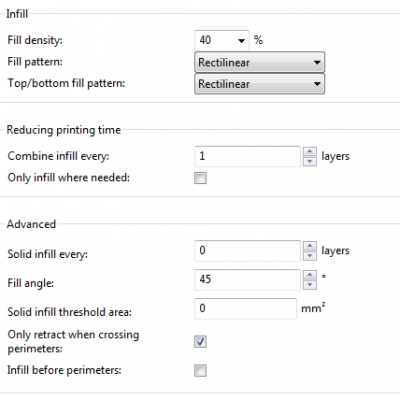

Using Repetier 1.5.3 and Slic3r 1.2.9

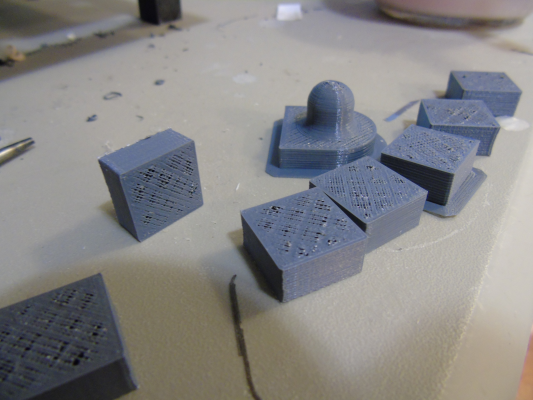

I printed this at 0.15mm layer and I have 2 problems.

The 1st one is the 1st layer of the top. (under the infill)

The 2nd one is the top layer of the top. (on top of infill)

The "top" is the part where u can see the infill and not the actual top of the print.

There is no support except for a few single threads Slic3r makes.

The settings: see attachments

I am assuming the model is OK.

If I print @ 100% infill that will eliminate any holes in the top (which is really the bottom).

The questions are:

Why am I getting spaces between the lines on the outside of these layers?

Can I improve the visible layers somehow with different settings?

OR is something else going on?

The outside of the cylinder looks very good but there r a few hickups.

thx

Edited 1 time(s). Last edit at 07/17/2015 02:25PM by ruggb.

I printed this at 0.15mm layer and I have 2 problems.

The 1st one is the 1st layer of the top. (under the infill)

The 2nd one is the top layer of the top. (on top of infill)

The "top" is the part where u can see the infill and not the actual top of the print.

There is no support except for a few single threads Slic3r makes.

The settings: see attachments

I am assuming the model is OK.

If I print @ 100% infill that will eliminate any holes in the top (which is really the bottom).

The questions are:

Why am I getting spaces between the lines on the outside of these layers?

Can I improve the visible layers somehow with different settings?

OR is something else going on?

The outside of the cylinder looks very good but there r a few hickups.

thx

Edited 1 time(s). Last edit at 07/17/2015 02:25PM by ruggb.

|

Re: Problems with top layer of print July 18, 2015 08:05AM |

Registered: 12 years ago Posts: 799 |

At "advanced", change the extrusion with values from Default "0" to your nozzlie size, i had similar problems which where solved through changing them.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Problems with top layer of print July 18, 2015 09:51AM |

Registered: 9 years ago Posts: 294 |

|

Re: Problems with top layer of print July 19, 2015 05:05AM |

Registered: 12 years ago Posts: 799 |

Yes by default its the best to change all them to your default nozzle size.

These fields are to change the extrusionwith of the correspondending parts.

For example if you want to have a smoother finer top layer and your default Nozzle is 0.5mm (so all set to 0.5) you can set the "top solid infill" to 0.4 then the infill will become nicer.

Or if you have very thin parts which are only some layers wide you can reduce the infill width a little bit then maybe slic3r does fill the holes.

Or if you need very brittle support, you also can reduce the width to your wanted minimum.

Best thing is to analyze the gcode before printing, this way i found out the problem for me (see here )

For doing so i recommend using Craftware, in my eye`s the best tool for gcode analyzing atm.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

These fields are to change the extrusionwith of the correspondending parts.

For example if you want to have a smoother finer top layer and your default Nozzle is 0.5mm (so all set to 0.5) you can set the "top solid infill" to 0.4 then the infill will become nicer.

Or if you have very thin parts which are only some layers wide you can reduce the infill width a little bit then maybe slic3r does fill the holes.

Or if you need very brittle support, you also can reduce the width to your wanted minimum.

Best thing is to analyze the gcode before printing, this way i found out the problem for me (see here )

For doing so i recommend using Craftware, in my eye`s the best tool for gcode analyzing atm.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Problems with top layer of print July 19, 2015 12:40PM |

Registered: 10 years ago Posts: 29 |

Sorry, only registered users may post in this forum.