Horrible top layer on prints

Posted by Twitchity

|

Horrible top layer on prints January 15, 2016 01:00PM |

Registered: 8 years ago Posts: 3 |

I'm not really sure where to begin as I'm still fairly new to 3D printing so I'll try my best. I have a Printrbot 1405 that I converted into my own designed larger printer (180x180x180). Essentially the only parts I reused from the Printrbot are the stepper motors, X/Y stop switches, z-probe, and Printrboard. My printer is still setup to perform the 3 point z-probe for autolevel of the print bed. Layer height is set to 0.32mm due to the use of my 8mm thread pitch acme rods. I got the layer height from the RepRap calculator and it has been working great. For what I'm using the printer for the 0.32mm layer height is just fine.

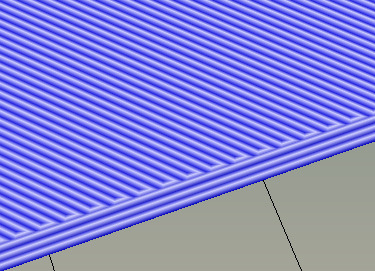

I've printed with ABS, PLA, and PETG filament and all three give the same results. I've calibrated the extruder so extrusion width matches the nozzle width of 0.4, and the 20mm calibration cube I printed out was within .05mm of actual size. The printer works great on everything except the very last top layer. This first picture was printed at 0.32mm layer height, 3 bottom solid layers, 3 top solid layers. As you can see in the center part where I tore the bad top layer away the print quality is in my opinion extremely nice, and then the top layer gets all messed up. I use Repetier Host with Slic3r for all of my printing. In the preview layer 4 appears to have a wider extruded line width than layer 5 (top layer). You'll also see the preview for layer 4 and 5 from Repetier Host below. The extrusion width is noticeable just by looking at it. I don't know if this is what's causing the problem or not.

To me it looks like the g-code isn't telling the extruder to move over far enough so the nozzle is dragging back over what was just extruded causing these ridges in the top layer. It's only real noticeable on large flat areas, but It does happen on smaller areas too. Here's a companion cube I printed with the exact same settings and the print came out great compared to above. But the top most layer still has a little bit of an issue. Is there a setting somewhere I'm missing? Any help in getting this sorted out is greatly appreciated. I tried searching but most everything I found was about calibrating the extruder which has already been done. If every solid layer did this I would agree, I just find it odd it only affects the top most solid layer and all subsequent layers print out nice and smooth.

I've printed with ABS, PLA, and PETG filament and all three give the same results. I've calibrated the extruder so extrusion width matches the nozzle width of 0.4, and the 20mm calibration cube I printed out was within .05mm of actual size. The printer works great on everything except the very last top layer. This first picture was printed at 0.32mm layer height, 3 bottom solid layers, 3 top solid layers. As you can see in the center part where I tore the bad top layer away the print quality is in my opinion extremely nice, and then the top layer gets all messed up. I use Repetier Host with Slic3r for all of my printing. In the preview layer 4 appears to have a wider extruded line width than layer 5 (top layer). You'll also see the preview for layer 4 and 5 from Repetier Host below. The extrusion width is noticeable just by looking at it. I don't know if this is what's causing the problem or not.

To me it looks like the g-code isn't telling the extruder to move over far enough so the nozzle is dragging back over what was just extruded causing these ridges in the top layer. It's only real noticeable on large flat areas, but It does happen on smaller areas too. Here's a companion cube I printed with the exact same settings and the print came out great compared to above. But the top most layer still has a little bit of an issue. Is there a setting somewhere I'm missing? Any help in getting this sorted out is greatly appreciated. I tried searching but most everything I found was about calibrating the extruder which has already been done. If every solid layer did this I would agree, I just find it odd it only affects the top most solid layer and all subsequent layers print out nice and smooth.

|

Re: Horrible top layer on prints January 15, 2016 02:54PM |

Registered: 10 years ago Posts: 580 |

Twitchity,

Good photos and info.

The only things missing are: the kind of filament, temperatures, and speeds.

I don't see over extrusion, as near the upper corner it is perfectly smooth.

It looks to me like one issue is with layer bonding. You shouldn't be able to peel the layer off, and perhaps they are not quite staying put when the top layer is going down.

The rule of thumb for layer height is: layer height < 80% of nozzle diameter.

The rule of thumb for extrusion width is: extrusion width > nozzle diameter * 1.05, < nozzle diameter * 1.7. These are the recommendations from the author of Slic3r.

So your max layer height would be .32, and minimum extrusion width would be .42. Your extrusion is right at the max layer height, and below the recommended minimum width.

The reason the extrusion width is important is that if you print at the nozzle diameter or below the filament is laid down in a nearly round bead and may even be stretched.

Too much layer height for the width is an issue - the plastic isn't squished into the previous layers as much, low contact = low bond.

So for better adhesion you want a lower layer height, and use wider extrusion width (more in the middle of the sane possibilities) so there is a bit of spread when the filament is laid down.

Slic3r on auto will use a lower width for outside perimeters to for better resolution.

Note that increasing the extrusion temperature will also help with adhesion.

Does that make sense?

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Good photos and info.

The only things missing are: the kind of filament, temperatures, and speeds.

I don't see over extrusion, as near the upper corner it is perfectly smooth.

It looks to me like one issue is with layer bonding. You shouldn't be able to peel the layer off, and perhaps they are not quite staying put when the top layer is going down.

The rule of thumb for layer height is: layer height < 80% of nozzle diameter.

The rule of thumb for extrusion width is: extrusion width > nozzle diameter * 1.05, < nozzle diameter * 1.7. These are the recommendations from the author of Slic3r.

So your max layer height would be .32, and minimum extrusion width would be .42. Your extrusion is right at the max layer height, and below the recommended minimum width.

The reason the extrusion width is important is that if you print at the nozzle diameter or below the filament is laid down in a nearly round bead and may even be stretched.

Too much layer height for the width is an issue - the plastic isn't squished into the previous layers as much, low contact = low bond.

So for better adhesion you want a lower layer height, and use wider extrusion width (more in the middle of the sane possibilities) so there is a bit of spread when the filament is laid down.

Slic3r on auto will use a lower width for outside perimeters to for better resolution.

Note that increasing the extrusion temperature will also help with adhesion.

Does that make sense?

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Horrible top layer on prints January 15, 2016 05:20PM |

Registered: 8 years ago Posts: 3 |

Paul,

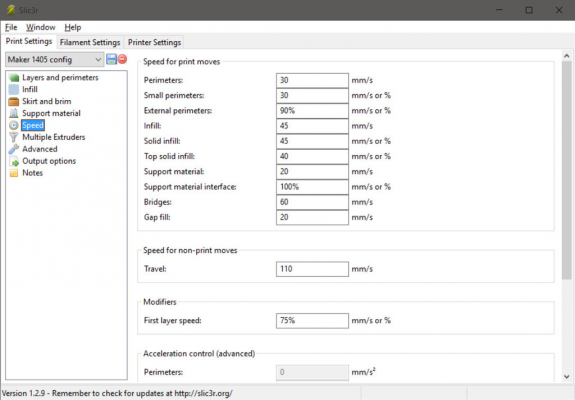

Thank you for the help. Please see below for print speeds. The part in the picture above was printed in eSun PETG 1.75mm at 250*C with the bed at 90*C.

I tried adjusting the nozzle width in the software to .42 (.40x1.05) and I got the exact same results. Around the boarder where the infill begins and ends it has a nice surface and adhesion to the previous layer. It's only in the middle where it all goes wrong. I see that you mentioned Slic3r will use a lower width for the outside perimeters, and I'm not having any issues with that. It looks like Slic3r is applying that same method to my top most layer which is causing the problem. I'm going to give a nozzle with of .50 a shot and see if I have any better results shortly.

Filament comes out nice and straight when I feed it through the extruder so I don't think it's clogged, and every other part of the print comes out great. I'm wondering if a different slicer will give me better results. I just really like the interface Repetier/Slic3r has so that's why I've been sticking with it.

Thank you for the help. Please see below for print speeds. The part in the picture above was printed in eSun PETG 1.75mm at 250*C with the bed at 90*C.

I tried adjusting the nozzle width in the software to .42 (.40x1.05) and I got the exact same results. Around the boarder where the infill begins and ends it has a nice surface and adhesion to the previous layer. It's only in the middle where it all goes wrong. I see that you mentioned Slic3r will use a lower width for the outside perimeters, and I'm not having any issues with that. It looks like Slic3r is applying that same method to my top most layer which is causing the problem. I'm going to give a nozzle with of .50 a shot and see if I have any better results shortly.

Filament comes out nice and straight when I feed it through the extruder so I don't think it's clogged, and every other part of the print comes out great. I'm wondering if a different slicer will give me better results. I just really like the interface Repetier/Slic3r has so that's why I've been sticking with it.

|

Re: Horrible top layer on prints January 15, 2016 07:23PM |

Registered: 10 years ago Posts: 580 |

|

Re: Horrible top layer on prints January 17, 2016 11:45AM |

Registered: 10 years ago Posts: 444 |

|

Re: Horrible top layer on prints January 17, 2016 11:52AM |

Registered: 11 years ago Posts: 5,780 |

Don't screw around with the nozzle diameter setting. That should match the nozzle on the extruder. The problem is not the top layer, it's the infill layers below- they are too thin. You need to increase the extrusion width of the infill. If you have a 0.4mm nozzle, I'd use 0.4mm infill width as a minimum.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Horrible top layer on prints January 18, 2016 09:49AM |

Registered: 8 years ago Posts: 3 |

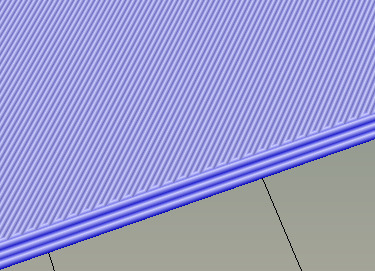

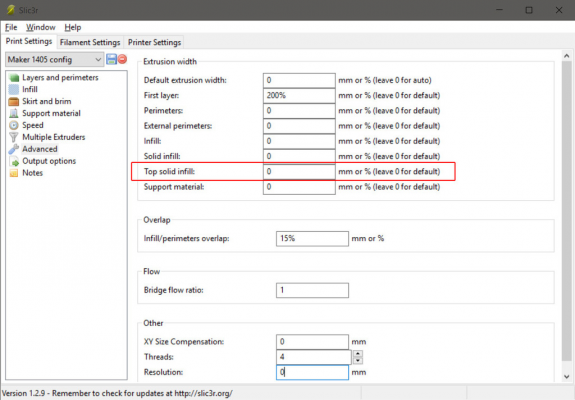

Thank you everyone for the help is getting this sorted out. While digging through the settings in Slic3r I came to the Advanced option under Print Settings and the "Top solid infill" option was set to 90%. I changed it to 0 for default and the printer is working great now. Here's a picture of it printing the last top solid layer and a picture of the setting I changed.

How that option got set to 90% is beyond me, but even in the rendered view I can see the extrusion width is the same for the top layer as all of the other layers. Prints back this up as well as it looks fantastic.

How that option got set to 90% is beyond me, but even in the rendered view I can see the extrusion width is the same for the top layer as all of the other layers. Prints back this up as well as it looks fantastic.

Sorry, only registered users may post in this forum.