speeding up print time 2 or 3 times by wallsubdivide

Posted by artbody

|

speeding up print time 2 or 3 times by wallsubdivide January 26, 2017 09:20AM |

Registered: 7 years ago Posts: 34 |

Behaviour

since today each layer is the same hight. Printing a fine structured surface needs a lot of time

this is a new feature request

this idea will speeding up print time 2 or 3 times

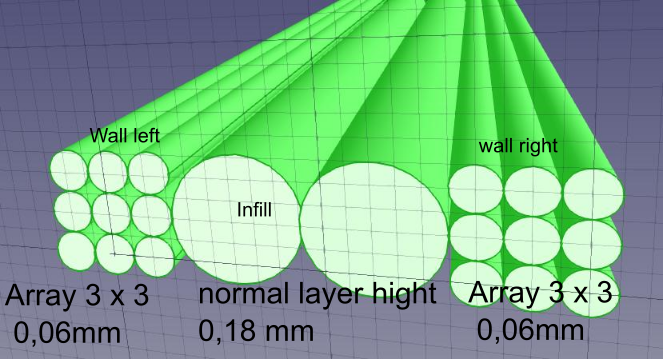

if we print with layer hight i.e. 0,06 mm this needs a lot of time but gives a nice surface

so my idea was to print the wall zone with 0,06 mm 3 Layers in hight and i.e. 3 lines width and then print one Layer with 0,18mm

ooo ------------------------- ooo

ooo ||||||||||||||||||||||||| ooo

ooo ------------------------- ooo

o = 0,06mm

| = 0,18mm

wallsubdivide by 2x2 3x3 up to 6x6

i'm building a printer (based on Prusa i3) with 90cm x 90cm x 40cm printing area.

so in this dimension such a feature will increase printing speed dramatically

Thanks and - make it - do it

anycubic delta linear plus ### Reprap Prusa i3 3D Printer

Samsung 245B 1920x1200 GeForce GT710

4.4.26-gentoo #1 SMP Fri Dec 16 20:40:58 CET 2016 x86_64 AMD F tm)-8350 Eight-Core Processor AuthenticAMD GNU/Linux

tm)-8350 Eight-Core Processor AuthenticAMD GNU/Linux

Eigenbau ist in Produktion

since today each layer is the same hight. Printing a fine structured surface needs a lot of time

this is a new feature request

this idea will speeding up print time 2 or 3 times

if we print with layer hight i.e. 0,06 mm this needs a lot of time but gives a nice surface

so my idea was to print the wall zone with 0,06 mm 3 Layers in hight and i.e. 3 lines width and then print one Layer with 0,18mm

ooo ------------------------- ooo

ooo ||||||||||||||||||||||||| ooo

ooo ------------------------- ooo

o = 0,06mm

| = 0,18mm

wallsubdivide by 2x2 3x3 up to 6x6

i'm building a printer (based on Prusa i3) with 90cm x 90cm x 40cm printing area.

so in this dimension such a feature will increase printing speed dramatically

Thanks and - make it - do it

anycubic delta linear plus ### Reprap Prusa i3 3D Printer

Samsung 245B 1920x1200 GeForce GT710

4.4.26-gentoo #1 SMP Fri Dec 16 20:40:58 CET 2016 x86_64 AMD F

tm)-8350 Eight-Core Processor AuthenticAMD GNU/Linux

tm)-8350 Eight-Core Processor AuthenticAMD GNU/LinuxEigenbau ist in Produktion

|

Re: speeding up print time 2 or 3 times by wallsubdivide January 26, 2017 09:27AM |

Admin Registered: 12 years ago Posts: 2,569 |

Do no reinvent the wheel : It has been done for quite some time, it was called the "skin" module in skeinforge for instance, and I believe all the serious slicers do it too, maybe under a different name.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: speeding up print time 2 or 3 times by wallsubdivide January 26, 2017 11:29PM |

Registered: 9 years ago Posts: 351 |

|

Re: speeding up print time 2 or 3 times by wallsubdivide January 27, 2017 07:36AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: speeding up print time 2 or 3 times by wallsubdivide January 27, 2017 08:16AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: speeding up print time 2 or 3 times by wallsubdivide January 27, 2017 02:00PM |

Registered: 7 years ago Posts: 34 |

|

Re: speeding up print time 2 or 3 times by wallsubdivide January 27, 2017 02:17PM |

Registered: 14 years ago Posts: 128 |

Rather than using Acetone to polish the surface, coat printed item with XTC-3D. Easy to use and you don't use much. Gives a really great finish.

A number of companies sell it around the world.

[forums.reprap.org]

Edited 1 time(s). Last edit at 01/27/2017 02:21PM by RepRot.

A number of companies sell it around the world.

[forums.reprap.org]

Edited 1 time(s). Last edit at 01/27/2017 02:21PM by RepRot.

|

Re: speeding up print time 2 or 3 times by wallsubdivide February 13, 2017 05:11PM |

Registered: 7 years ago Posts: 17 |

Quote

dmould

As others have said, Slic3r already does this. However you won't get good results if the infill height is greater than the nozzle diameter, so ensure that your layer height multiplied by number of layers between infill does not exceed your nozzle diameter.

Dave

So does Slic3r re-adjust the thickness of the in-fill to try to compensate for the skipped infill layers or does it just skip the infill for the set amount of layers? I have not used this feature but I would like to understand its capabilities better.

|

Re: speeding up print time 2 or 3 times by wallsubdivide February 14, 2017 07:08AM |

Registered: 10 years ago Posts: 2,472 |

Quote

doodady

So does Slic3r re-adjust the thickness of the in-fill to try to compensate for the skipped infill layers or does it just skip the infill for the set amount of layers? I have not used this feature but I would like to understand its capabilities better.

Yes, Slic3r calculates the correct extrusion rate to fill the missing layers.

Dave

Sorry, only registered users may post in this forum.