1.3.0 dev 1590 - Brim width, skirt width, and upper surface issues

Posted by WesBrooks

|

1.3.0 dev 1590 - Brim width, skirt width, and upper surface issues January 25, 2018 09:44AM |

Registered: 9 years ago Posts: 383 |

I'm running 0.3|0.2 layer thickness, 2.8mm3/sec volumetric rate (auto speed - slow TPU), with volumetric extrusion and firmware retracts.

A few issues:

I'd been doing sample 20mm square single pass 0.7mm wall but seem unable to disable the slow down on the first layer? I'd set extrusion width to 0.7 and first layer speed to 100% but it still slowed down?

How are you supposed to control the width of the brim and skirt extrusions? These seem unaffected by forcing the perimeter/outer perimeter to 0.7mm.

I've a disc component with an array of holes in it that I'm building solid - 100% rectilinear infill. The holes are close enough to break the fill area into many tiny zones of extrusion which doesn't seem to suit this material. I decided to drop the vertical shells to 1. Even with this done on the final layer of the solid section before an array of square pillars Slic3r chucks 3 outer perimeters around the holes despite upper and lower solid layers being set to 0?

.

A few issues:

I'd been doing sample 20mm square single pass 0.7mm wall but seem unable to disable the slow down on the first layer? I'd set extrusion width to 0.7 and first layer speed to 100% but it still slowed down?

How are you supposed to control the width of the brim and skirt extrusions? These seem unaffected by forcing the perimeter/outer perimeter to 0.7mm.

I've a disc component with an array of holes in it that I'm building solid - 100% rectilinear infill. The holes are close enough to break the fill area into many tiny zones of extrusion which doesn't seem to suit this material. I decided to drop the vertical shells to 1. Even with this done on the final layer of the solid section before an array of square pillars Slic3r chucks 3 outer perimeters around the holes despite upper and lower solid layers being set to 0?

.

|

Re: 1.3.0 dev 1590 - Brim width, skirt width, and upper surface issues January 25, 2018 05:25PM |

Registered: 9 years ago Posts: 383 |

Slow first layer is because it is thicker! Daft me...

I think the extra perimeters may be something to do with the parameter that I've got in bold. Any idea why Slic3r may think they are needed? I'll check this in the morning when back at work.

Still confused about how to force the extrusion thickness for skirt and brim.

Here is a sample file:

BugCheck.stl

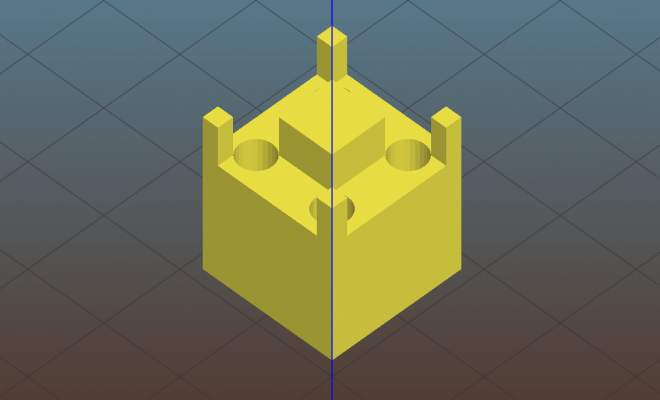

3D preview:

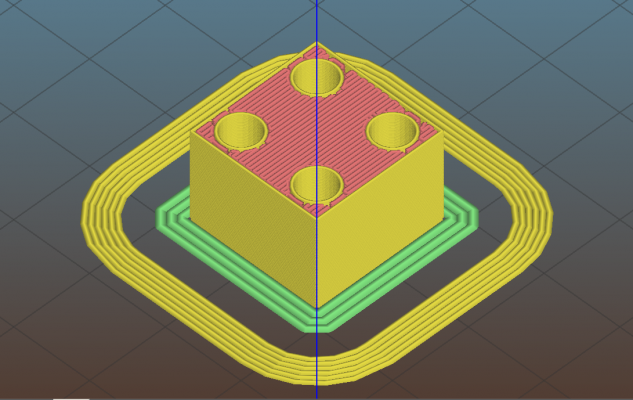

Here is the preview part way though (as I'd like it all the way):

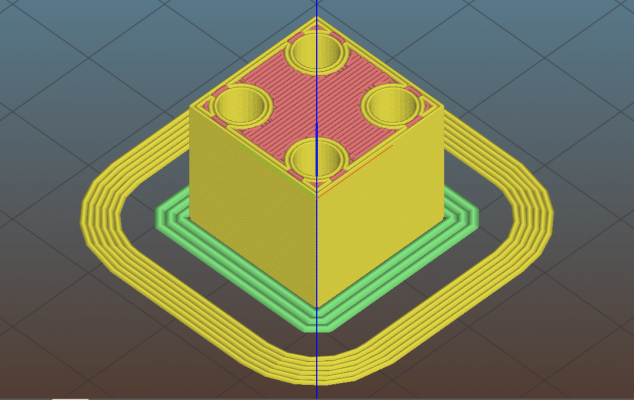

Here is the final slice of the bulk bit with a few extra perimeters that I don't want:

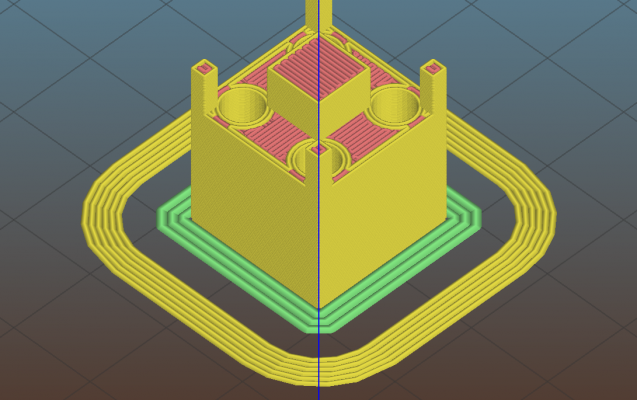

...and here is the full preview:

My settings were:

## Layers and Perimeters ##

Layer Height: 0.2

First Layer Height: 0.35

Use Adaptive slicing: False

Perimeters: 1

Spiral vase: False

Solid layers top: 0

Solid layers bottom: 0

Extra perimeters if needed: True

Avoid crossing perimeters: False

Detect thin walls: True

Detect bridging perimeters: True

Seam position: Aligned

External perimeters first: False

## Infill ##

Fill density: 100%

Fill pattern: Rectlinear

Combine infill every: 1

Only infill where needed: False

Fill gaps: True

Solid infill every: 0

Fill angle: 0

Solid infill threshold area 70mm2

Only retract when crossing perimeters: False.

I think the extra perimeters may be something to do with the parameter that I've got in bold. Any idea why Slic3r may think they are needed? I'll check this in the morning when back at work.

Still confused about how to force the extrusion thickness for skirt and brim.

Here is a sample file:

BugCheck.stl

3D preview:

Here is the preview part way though (as I'd like it all the way):

Here is the final slice of the bulk bit with a few extra perimeters that I don't want:

...and here is the full preview:

My settings were:

## Layers and Perimeters ##

Layer Height: 0.2

First Layer Height: 0.35

Use Adaptive slicing: False

Perimeters: 1

Spiral vase: False

Solid layers top: 0

Solid layers bottom: 0

Extra perimeters if needed: True

Avoid crossing perimeters: False

Detect thin walls: True

Detect bridging perimeters: True

Seam position: Aligned

External perimeters first: False

## Infill ##

Fill density: 100%

Fill pattern: Rectlinear

Combine infill every: 1

Only infill where needed: False

Fill gaps: True

Solid infill every: 0

Fill angle: 0

Solid infill threshold area 70mm2

Only retract when crossing perimeters: False.

|

Re: 1.3.0 dev 1590 - Brim width, skirt width, and upper surface issues January 26, 2018 01:39AM |

Registered: 9 years ago Posts: 383 |

Update:

Yes, unchecking extra perimeters if needed got rid of the additional perimeters on the last slice of the bulk section of the part.

So the remaining questions:

Edited 2 time(s). Last edit at 01/26/2018 01:45AM by WesBrooks.

Yes, unchecking extra perimeters if needed got rid of the additional perimeters on the last slice of the bulk section of the part.

So the remaining questions:

- Why did slic3r think they were needed (no gaps in previous layer)?

- Why was it treating this upper surface any different to the bulk when upper solid layers was set to 0?

- How is skirt / brim extrusion thickness controlled?

Edited 2 time(s). Last edit at 01/26/2018 01:45AM by WesBrooks.

|

Re: 1.3.0 dev 1590 - Brim width, skirt width, and upper surface issues January 29, 2018 07:29AM |

Registered: 9 years ago Posts: 383 |

Sorry, only registered users may post in this forum.