Seams questions...

Posted by ampapa

|

Seams questions... January 31, 2018 09:05PM |

Registered: 7 years ago Posts: 128 |

Cross posting question since I think it fits better here...

In Slice3r there are 3 options for seams Random, Nearest and Aligned.

1- Nearest method, nearest to what?

2- Aligned, some of the seams are aligned but not all of them. In some of my prints the seams are inline for half the model then aligned somewhere else in the half of the model, what gives? Can I dictate where the seam is going to be placed? if not, why not and what determines its location meaning can I influence that by re positioning my models in space? Seams (get it) like we should be able to dictate where the seam is going to be in the model.

Since my prints are starting to look better with the exception of the seams I thought I might try and improve them.

ampapa,

In Slice3r there are 3 options for seams Random, Nearest and Aligned.

1- Nearest method, nearest to what?

2- Aligned, some of the seams are aligned but not all of them. In some of my prints the seams are inline for half the model then aligned somewhere else in the half of the model, what gives? Can I dictate where the seam is going to be placed? if not, why not and what determines its location meaning can I influence that by re positioning my models in space? Seams (get it) like we should be able to dictate where the seam is going to be in the model.

Since my prints are starting to look better with the exception of the seams I thought I might try and improve them.

ampapa,

|

Re: Seams questions... February 01, 2018 02:42AM |

Registered: 8 years ago Posts: 5,232 |

When your seams look bad, the position of it has no influence.

There are other ways to deal with it. Pressure advance or shorter/faster retraction settings may help. Also "wipe while retracting" or "external perimeters first" can change the result.

It's all about making sure, the nozzle doesn't stop too long at an outer perimeter position, while there is still pressure in the chamber.

There are other ways to deal with it. Pressure advance or shorter/faster retraction settings may help. Also "wipe while retracting" or "external perimeters first" can change the result.

It's all about making sure, the nozzle doesn't stop too long at an outer perimeter position, while there is still pressure in the chamber.

|

Re: Seams questions... February 01, 2018 07:37AM |

Registered: 11 years ago Posts: 5,780 |

Nearest: closest to other parts printed at the same time. I don't know what it means when you're printing a single part.

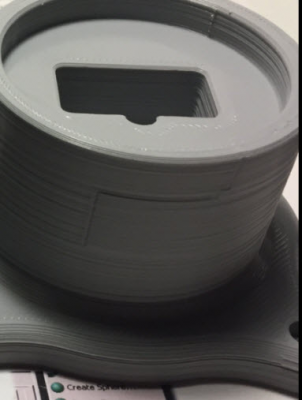

Aligned: the layers will start and stop at the same XY coordinates until the infill or shape of the part changes, then the seam will shift to a different location. If you print a cylinder or cube the seam will form a vertical line. If you print anything else, who knows?

Random: scatters the start stop XY coordinates all over the print and will leave small zits.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Aligned: the layers will start and stop at the same XY coordinates until the infill or shape of the part changes, then the seam will shift to a different location. If you print a cylinder or cube the seam will form a vertical line. If you print anything else, who knows?

Random: scatters the start stop XY coordinates all over the print and will leave small zits.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Seams questions... February 01, 2018 07:49AM |

Registered: 7 years ago Posts: 128 |

Do seams really disappear or do they just become less noticeable... I also assume that you may get better results with a direct vs bowden extruder.

I'll do some more research into the wiping and retraction settings. I'm unfamiliar with "wiping while retracting" how does this work?

So is there a way to dictate where the seam(s) will be placed? For some parts it would be great if it generated on the bottom but there is no setting for that, it there it just puts it where it wants. Maybe that should be a software feature for a future release...?

ampapa,

I'll do some more research into the wiping and retraction settings. I'm unfamiliar with "wiping while retracting" how does this work?

So is there a way to dictate where the seam(s) will be placed? For some parts it would be great if it generated on the bottom but there is no setting for that, it there it just puts it where it wants. Maybe that should be a software feature for a future release...?

ampapa,

|

Re: Seams questions... February 01, 2018 08:45AM |

Registered: 7 years ago Posts: 759 |

|

Re: Seams questions... February 01, 2018 10:20AM |

Registered: 11 years ago Posts: 5,780 |

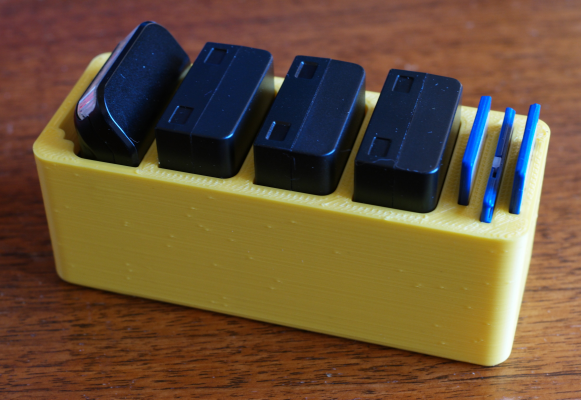

Here are "random" seam setting prints- the small bumps are the zits where the layers start and stop.

Cura gives you more control over location of the seam than Slic3r.

Wipe while retracting moves the nozzle during the retraction to prevent leaving a blob at the end of a line/layer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Cura gives you more control over location of the seam than Slic3r.

Wipe while retracting moves the nozzle during the retraction to prevent leaving a blob at the end of a line/layer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Seams questions... February 01, 2018 02:40PM |

Registered: 7 years ago Posts: 128 |

Thanks for the pics..

Looks like random is not exactly better than aligned... I have some banding, I think, to take care of first. Gotta go figure that out...

Hopefully Slic3r will add the feature for placing the seams.

I may take a look at Cura.

Thanks.

ampapa,

Looks like random is not exactly better than aligned... I have some banding, I think, to take care of first. Gotta go figure that out...

Hopefully Slic3r will add the feature for placing the seams.

I may take a look at Cura.

Thanks.

ampapa,

|

Re: Seams questions... February 01, 2018 04:18PM |

Registered: 11 years ago Posts: 5,780 |

Random is better if you have to do something like fit a bearing into a hole. If you use aligned, it tends to make a big lump that causes the bearing to sit off-center, but random alignment scatters the bumps everywhere so the bearing sits where intended.

It looks like you've got some z-wobble going on- that will make everything worse.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It looks like you've got some z-wobble going on- that will make everything worse.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Seams questions... February 02, 2018 07:28AM |

Registered: 7 years ago Posts: 128 |

Z wobble..?? I thought it was banding.

My Z axis is just plain sad... I thought I had improved it.. I'm currently gathering parts for a rebuild something similar to yours DD.

I think the belt drive on my XY axis works considerably better than my Z axis with 8mm ball screw and cheap linear bearings.

ampapa,

My Z axis is just plain sad... I thought I had improved it.. I'm currently gathering parts for a rebuild something similar to yours DD.

I think the belt drive on my XY axis works considerably better than my Z axis with 8mm ball screw and cheap linear bearings.

ampapa,

|

Re: Seams questions... February 03, 2018 02:40AM |

Registered: 8 years ago Posts: 5,232 |

It's hard to see from the picture. If it's wobble, the layers would be slightly shifted in a regular distance.

If it's under extrusion from failed retractions or "retract on layer change" it would be a thinner wall every time an unretract move failed. The extruder is strong enough to pull the filament back at xxx mm/s, but not to push it back with the same speed.

If it's under extrusion from failed retractions or "retract on layer change" it would be a thinner wall every time an unretract move failed. The extruder is strong enough to pull the filament back at xxx mm/s, but not to push it back with the same speed.

Sorry, only registered users may post in this forum.