Problems in fusing internal structure to thin walled skin

Posted by U400666

|

Problems in fusing internal structure to thin walled skin September 27, 2018 11:03AM |

Registered: 5 years ago Posts: 13 |

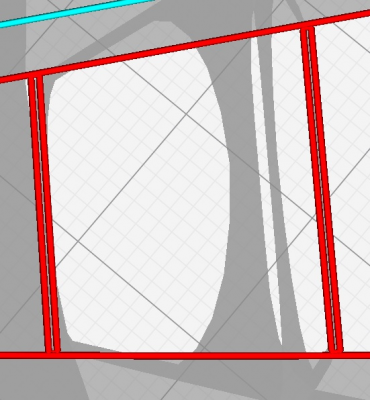

I am trying to create a wing section using a single perimeter skin and a lattice of ribs inside. The problem I have is getting the ribs to fuse to the inside of the skin, without being visible on the outside.

I have attached to screenshots showing a section of the wing. If I leave a gap of 0.1 mm between the ribs and the inner surface of the skin the ribs do not fuse well to the skin. If this gap is reduced to 0.05 mm the ribs fuse to the skin but create lines on the outer surface of the skin which affect the surface finish. I know that it is possible to have the ribs fuse with a smooth outer surface as 3dlabprints manage to do this, but I do not know the slic3r setting to get around my problem.

I would be grateful for any help you can give.

I am using a Prusa I3 MK2 printer and Slic3r Prusa edition Version 1.39.1 with a nozzle diameter of 0.4 mm.

I have attached to screenshots showing a section of the wing. If I leave a gap of 0.1 mm between the ribs and the inner surface of the skin the ribs do not fuse well to the skin. If this gap is reduced to 0.05 mm the ribs fuse to the skin but create lines on the outer surface of the skin which affect the surface finish. I know that it is possible to have the ribs fuse with a smooth outer surface as 3dlabprints manage to do this, but I do not know the slic3r setting to get around my problem.

I would be grateful for any help you can give.

I am using a Prusa I3 MK2 printer and Slic3r Prusa edition Version 1.39.1 with a nozzle diameter of 0.4 mm.

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 01:14PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 01:56PM |

Registered: 5 years ago Posts: 13 |

The native infill does not provide an acceptable strength / weight ratio. The wing has to be very light but with adequate resistance to bending and torsional loads.

If you check out 3dlabprints you can see that they have gone to a lot if effort to achieve this and that is what I am trying to emulate.

Edited 1 time(s). Last edit at 09/27/2018 01:57PM by U400666.

If you check out 3dlabprints you can see that they have gone to a lot if effort to achieve this and that is what I am trying to emulate.

Edited 1 time(s). Last edit at 09/27/2018 01:57PM by U400666.

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 02:53PM |

Registered: 11 years ago Posts: 5,780 |

I've never seen a single wall print that didn't show the internal fill. You usually have to use at least 3 perimeters to make the infill "disappear".

Molten plastic shrinks as it cools, and that cause single thin wall strands to pull the the infill verticals toward each other. Since they are less likely to move because of bulk, the thin wall tends to move instead. On a flat area it's less of a problem, but a curved single wall shell will tend to straighten as the plastic shrinks, and that will make the infill very visible.

You can try tweaking the overlap between the outer wall and the infill, but if you make it too small, you lose bond strength and end up with a wing that looks nice but isn't very strong.

Edited 1 time(s). Last edit at 09/27/2018 02:56PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Molten plastic shrinks as it cools, and that cause single thin wall strands to pull the the infill verticals toward each other. Since they are less likely to move because of bulk, the thin wall tends to move instead. On a flat area it's less of a problem, but a curved single wall shell will tend to straighten as the plastic shrinks, and that will make the infill very visible.

You can try tweaking the overlap between the outer wall and the infill, but if you make it too small, you lose bond strength and end up with a wing that looks nice but isn't very strong.

Edited 1 time(s). Last edit at 09/27/2018 02:56PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 03:25PM |

Registered: 5 years ago Posts: 13 |

Check out the 3dlabprints examples on their website. The ribs are visible when you hold the wing up to light, but the exterior surfaces are smooth, I have printed examples. They are single perimeter and they are strong.

I have been playing with the gap see examples I posted. 3dlabprints use simplify 3d and I wonder if this is more tunable in terms of the overlap. With slic3r I either have a gap and little fusion or the ribs visible and feelable on the extrenal surface.

I have been playing with the gap see examples I posted. 3dlabprints use simplify 3d and I wonder if this is more tunable in terms of the overlap. With slic3r I either have a gap and little fusion or the ribs visible and feelable on the extrenal surface.

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 04:14PM |

Registered: 5 years ago Posts: 13 |

To date I have beem controlling the gap in my CAD program. The gap that comes out in Slic3r seems to be more of an on / off thing. I wonder if there is a setting to allow a bit more extrusion at the top and bottom of the ribs to fill the gap.

Edited 1 time(s). Last edit at 09/27/2018 04:15PM by U400666.

Edited 1 time(s). Last edit at 09/27/2018 04:15PM by U400666.

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 04:21PM |

Registered: 7 years ago Posts: 759 |

I have printed several of the 3dlabprint planes,i never managed to get slic3r to slice the internal structure correctly

You get muchh better results using cura 3.4.1

Draw the ribs as a closed rectangle and the skin around the outside, see example

You get muchh better results using cura 3.4.1

Draw the ribs as a closed rectangle and the skin around the outside, see example

|

Re: Problems in fusing internal structure to thin walled skin September 27, 2018 05:25PM |

Registered: 5 years ago Posts: 13 |

|

Re: Problems in fusing internal structure to thin walled skin September 28, 2018 06:09AM |

Registered: 7 years ago Posts: 759 |

|

Re: Problems in fusing internal structure to thin walled skin September 28, 2018 06:48AM |

Registered: 5 years ago Posts: 13 |

|

Re: Problems in fusing internal structure to thin walled skin September 28, 2018 08:05AM |

Registered: 7 years ago Posts: 759 |

|

Re: Problems in fusing internal structure to thin walled skin September 28, 2018 09:47AM |

Registered: 5 years ago Posts: 13 |

|

Re: Problems in fusing internal structure to thin walled skin September 28, 2018 05:00PM |

Registered: 7 years ago Posts: 759 |

|

Re: Problems in fusing internal structure to thin walled skin September 29, 2018 05:19AM |

Registered: 5 years ago Posts: 13 |

Thanks for the settings file obewan, I will give this a try.

I had an initial go with cura and found that I got better results with the ribs bonding but some of the skin had gaps in it when printed. With Silc3r I would fix this with thin wall detection, not sure what the cura version is but hopefully your settings file will capture this.

I had an initial go with cura and found that I got better results with the ribs bonding but some of the skin had gaps in it when printed. With Silc3r I would fix this with thin wall detection, not sure what the cura version is but hopefully your settings file will capture this.

|

Re: Problems in fusing internal structure to thin walled skin September 30, 2018 02:41PM |

Registered: 5 years ago Posts: 13 |

Hi obewan,

The Cura profile almost does what I need, the print quality is very good but the skin is being printed double thickness at 0.8 mm whereas my model has 0.4 mm.

Bit surprised as you have the wall line count set to 1 and the nozzle on my Prusa is 0.4 mm.

Any help would be very welcome.

The Cura profile almost does what I need, the print quality is very good but the skin is being printed double thickness at 0.8 mm whereas my model has 0.4 mm.

Bit surprised as you have the wall line count set to 1 and the nozzle on my Prusa is 0.4 mm.

Any help would be very welcome.

|

Re: Problems in fusing internal structure to thin walled skin September 30, 2018 05:52PM |

Registered: 7 years ago Posts: 759 |

|

Re: Problems in fusing internal structure to thin walled skin September 30, 2018 06:10PM |

Registered: 5 years ago Posts: 13 |

Hi Obewan,

I have attached a couple of stl files which I have been using, these are just test pieces to try to get the method sorted out.

When I slice these in Cura and look in layer view it looks to me like a single perimeter skin, but it prints with 2 perimeters. I may be misreading the Cura images as I am new to this program.

I have attached a couple of stl files which I have been using, these are just test pieces to try to get the method sorted out.

When I slice these in Cura and look in layer view it looks to me like a single perimeter skin, but it prints with 2 perimeters. I may be misreading the Cura images as I am new to this program.

|

Re: Problems in fusing internal structure to thin walled skin October 01, 2018 07:41AM |

Registered: 7 years ago Posts: 759 |

|

Re: Problems in fusing internal structure to thin walled skin October 01, 2018 08:15AM |

Registered: 5 years ago Posts: 13 |

I am creating the skin in 3d CAD by importing an aerofoil, extruding it and creating a thickness of 0.4 mm. Not sure how to do this with zero thickness I am pretty new to CAD.

The skin came out well in Slic3r at 0.4 mm but my first attempts in Cura had missing patches where the nozzle did not seem to extrude well.

The skin came out well in Slic3r at 0.4 mm but my first attempts in Cura had missing patches where the nozzle did not seem to extrude well.

|

Re: Problems in fusing internal structure to thin walled skin October 01, 2018 09:17AM |

Registered: 5 years ago Posts: 13 |

|

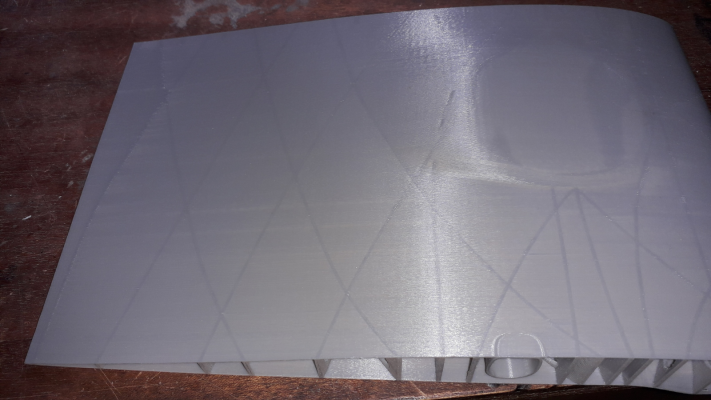

Re: Problems in fusing internal structure to thin walled skin October 03, 2018 01:05PM |

Registered: 5 years ago Posts: 13 |

I think that I am making some progress with getting Cura set up to produce a single perimeter aerofoil print, but I have one remaining problem.

I have attached a photo of the first layer which I stopped from printing before the ribs were printed. The aerofoil suction surface is printed first, nose to tail. When the pressure surface print is started, again nose to tail, the material does not flow for the first part and this is leaving gaps. I would like the whole aerofoil skin to be printed in one pass, but do not know the settings to force this to happen.

The skirt prints fine so it must be a problem with extrusion / retraction when the aerofoil print begins. I tried ticking the optimize wall printing order and the outer before inner walls boxes, but these had no effect.

Kelp would be much appreciated.

I have attached a photo of the first layer which I stopped from printing before the ribs were printed. The aerofoil suction surface is printed first, nose to tail. When the pressure surface print is started, again nose to tail, the material does not flow for the first part and this is leaving gaps. I would like the whole aerofoil skin to be printed in one pass, but do not know the settings to force this to happen.

The skirt prints fine so it must be a problem with extrusion / retraction when the aerofoil print begins. I tried ticking the optimize wall printing order and the outer before inner walls boxes, but these had no effect.

Kelp would be much appreciated.

Sorry, only registered users may post in this forum.