What are the real advantages of Mach3?

Posted by bobc

|

What are the real advantages of Mach3? December 30, 2011 08:48AM |

Registered: 12 years ago Posts: 1,236 |

Clearly, the CNC model is a backward step for 3D printing. Obviously though, there is a market in CNC users who want off the shelf 3D printing without leaving their comfort zone. The CNC arena is about big, expensive and tried and trusted technology (read : "old"). If you have space for a CNC rig, you have space for an obsolete PC with a parallel port, and a large controller box. If you have spent $1000's on the CNC, an additional $200 for software is not much to worry about.

I can see the point of visualization for CNC machines, you don't really want to stick your head near to a live CNC, and anyway the workpiece may be obscured by coolant. If I want to see what my printer is doing... I look at the printer. I don't need an on screen display for my laser printer, why do I need one for my 3D printer?

So I can see this is a method to introduce 3D printing into the existing hobby CNC area, but it is never going to persuade existing Reprappers to start using CNC type kit for 3D printing.

If there are any real benefits from CNC techniques, such as 3D tool paths, these can easily be adopted.

I can see the point of visualization for CNC machines, you don't really want to stick your head near to a live CNC, and anyway the workpiece may be obscured by coolant. If I want to see what my printer is doing... I look at the printer. I don't need an on screen display for my laser printer, why do I need one for my 3D printer?

So I can see this is a method to introduce 3D printing into the existing hobby CNC area, but it is never going to persuade existing Reprappers to start using CNC type kit for 3D printing.

If there are any real benefits from CNC techniques, such as 3D tool paths, these can easily be adopted.

|

Re: What are the real advantages of Mach3? January 01, 2012 10:10AM |

Hi, For me as a newbie intending to try out a RepRap the advantage is that I am already very familiar with Mach3 having adapted a Cobra Lathe/Mill to 3D CNC with excellent results. So I already have the PC parallel port interfaces and microstep drives which could all be utilised for either machine.

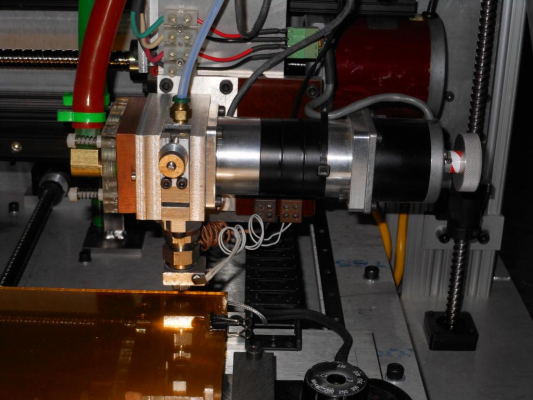

In fact I am thinking about mounting an extruder head in place of the milling head which will give me a working area about mm 70W 150L 40H, well suitable for trials if not for actual use as I am into modelling so parts will be quite small.

So can Skeinforge output a G code file that can be used without modification (or some simple seach and replaces) in Mach3 ? I presume coolant control could be used for the extruder control ?

Are there many RepRap users of Mach3 ??

Is there any sub group / forum w.h.y.

Many thanks in anticipation

In fact I am thinking about mounting an extruder head in place of the milling head which will give me a working area about mm 70W 150L 40H, well suitable for trials if not for actual use as I am into modelling so parts will be quite small.

So can Skeinforge output a G code file that can be used without modification (or some simple seach and replaces) in Mach3 ? I presume coolant control could be used for the extruder control ?

Are there many RepRap users of Mach3 ??

Is there any sub group / forum w.h.y.

Many thanks in anticipation

|

Re: What are the real advantages of Mach3? January 01, 2012 01:49PM |

Registered: 12 years ago Posts: 139 |

I had a reason to install mach3 into an obsolete PC a week ago. The computer was running XP and had a parallel port as built into the main board. No matter what I did I couldn't tune the output from at PC. The steppers moved, but not with a nice constant hum like my other machine. I dialed them back to 1/2 of the max speed and was able to demo something, but I wouldn't want to cut that way. I had the software rebuilt in my orginal machine, installed Mach3 and everything sounded great as it always did.

The point is that Mach3 requires a decent PC and a parallel port. I'm sure there are a bunch out there that run and won't run Mach3. I didn't try but I'll bet that that obsolete PC would drive an Arduino for a 3D printer. So if was have Mach3 you might want to add a smooth stepper card to the list if you plan to run either a laptop or an obsolete PC.

The point is that Mach3 requires a decent PC and a parallel port. I'm sure there are a bunch out there that run and won't run Mach3. I didn't try but I'll bet that that obsolete PC would drive an Arduino for a 3D printer. So if was have Mach3 you might want to add a smooth stepper card to the list if you plan to run either a laptop or an obsolete PC.

|

Re: What are the real advantages of Mach3? January 01, 2012 10:35PM |

Registered: 12 years ago Posts: 216 |

Geoff, john here from SeeMeCNC

I have modified replicatorG and skeinforge to work with mach3. These programs are easily modified to output whatever you want to use for extruder control. We arr usimg M3/M5 for extruder on/off just like a spindle. If you want to know more, just ask. As for a forum, we have a rather large yahoo grouo started already by a user. Search yahoo groups for seemecnc and youll find it.

Thanks

John "oly"

I have modified replicatorG and skeinforge to work with mach3. These programs are easily modified to output whatever you want to use for extruder control. We arr usimg M3/M5 for extruder on/off just like a spindle. If you want to know more, just ask. As for a forum, we have a rather large yahoo grouo started already by a user. Search yahoo groups for seemecnc and youll find it.

Thanks

John "oly"

|

Re: What are the real advantages of Mach3? January 02, 2012 06:13AM |

Thanks johnoly99

That is comforting - I have done more research since my post and am now confident to go ahead with building an extruder head to fit on my mill head and experiment. My PC is an old Dell on XP, having removed as muany sources of interupts as I could then it runs very smoothly on 1/16 microstepping which is plenty good enough - so no worries there.

Only problem I have is when I jog say X whilst Y is already jogging then X drops out - I think that must be a bug in Mach3 as it does not happen with comparable moves under program control.

Thanks again

Geoff

That is comforting - I have done more research since my post and am now confident to go ahead with building an extruder head to fit on my mill head and experiment. My PC is an old Dell on XP, having removed as muany sources of interupts as I could then it runs very smoothly on 1/16 microstepping which is plenty good enough - so no worries there.

Only problem I have is when I jog say X whilst Y is already jogging then X drops out - I think that must be a bug in Mach3 as it does not happen with comparable moves under program control.

Thanks again

Geoff

|

Re: What are the real advantages of Mach3? January 02, 2012 10:31AM |

Hi All,

And don't forget Mach3 is free up to some quite high line (or character) limit (any one knows what it is ?) which I have yet to reach even with some complex part programs which I have written in Gcode to 3D CNC machine alu parts for a miniature engine.

[www.youtube.com]

I suspect that part path generation programs do not efficiently use sub routines and so will be very long but as others have said reprap is really multiple 2D and most parts I have seen exampled would actually need only quite short programs using nesting / sub routines and incrementing.

Geoff

And don't forget Mach3 is free up to some quite high line (or character) limit (any one knows what it is ?) which I have yet to reach even with some complex part programs which I have written in Gcode to 3D CNC machine alu parts for a miniature engine.

[www.youtube.com]

I suspect that part path generation programs do not efficiently use sub routines and so will be very long but as others have said reprap is really multiple 2D and most parts I have seen exampled would actually need only quite short programs using nesting / sub routines and incrementing.

Geoff

|

Re: What are the real advantages of Mach3? January 02, 2012 06:57PM |

Registered: 12 years ago Posts: 139 |

Mach3 will run up to 500 lines without a liscense.

My Mach3 files for wood cutting are between a few hundred and a couple thousand lines.

My printer files are often above 75K lines.

Keep in mind that a printer is all straight cuts because the mesh is all triangles. Depending on you CAM processor Mach3 relys on arc cuts which cuts the code down considerably. Using G03/G02 cuts very smooth curves resutling in a smooth surface.

If you ever break up a curved cut and post it out as a series of point to point moves you will notice that Mach3 tends to chop around the curve.

Printing straight surfaces will be fine but I think printing curved surfaces will drive a cnc machine (designed to cut) wood crazy.

I just looked at a printer file, and in 18K lines, cutting a very curvy part, the only move code it uses is G01 (G1).

My Mach3 files for wood cutting are between a few hundred and a couple thousand lines.

My printer files are often above 75K lines.

Keep in mind that a printer is all straight cuts because the mesh is all triangles. Depending on you CAM processor Mach3 relys on arc cuts which cuts the code down considerably. Using G03/G02 cuts very smooth curves resutling in a smooth surface.

If you ever break up a curved cut and post it out as a series of point to point moves you will notice that Mach3 tends to chop around the curve.

Printing straight surfaces will be fine but I think printing curved surfaces will drive a cnc machine (designed to cut) wood crazy.

I just looked at a printer file, and in 18K lines, cutting a very curvy part, the only move code it uses is G01 (G1).

|

Re: What are the real advantages of Mach3? January 04, 2012 10:21AM |

|

Re: What are the real advantages of Mach3? January 05, 2012 02:22AM |

Registered: 12 years ago Posts: 18 |

|

Re: What are the real advantages of Mach3? January 05, 2012 12:39PM |

Registered: 12 years ago Posts: 216 |

Legion, want me to show you how? Check out seemecnc.com and some of the youtube videos on our channel. We have over 100 kiys "in the wild" with most being mach3 based. Its really not that hard to do. We have a yahoo group with over 100 members now, they all pitch in too, as were all mach guys, it was more prominent there than here we figured?

|

Re: What are the real advantages of Mach3? January 05, 2012 02:08PM |

Registered: 12 years ago Posts: 1,236 |

I guess I underestimated the depth of the existing hobby CNC market, it seems there are a *lot* of users and experience out there. A good idea to tap into that with a "CNC" friendly printer.

A 3D printer for a few hundred bucks can only be a good thing, so it is a positive contribution, even if doesn't quite fit with current Reprap type of design. Although, a 3D printer should perhaps be closer to a "standard" CNC type machine than it is. I think there are probably design techniques that could be applied both ways.

For example, doing floating point calcs makes more sense on a 3GHz PC than an 16 Mhz 8 bit micro. Perhaps the PC software should be doing more of the GCode processing, leaving the 8 bit micro to handle the steppers.

A 3D printer for a few hundred bucks can only be a good thing, so it is a positive contribution, even if doesn't quite fit with current Reprap type of design. Although, a 3D printer should perhaps be closer to a "standard" CNC type machine than it is. I think there are probably design techniques that could be applied both ways.

For example, doing floating point calcs makes more sense on a 3GHz PC than an 16 Mhz 8 bit micro. Perhaps the PC software should be doing more of the GCode processing, leaving the 8 bit micro to handle the steppers.

|

Re: What are the real advantages of Mach3? January 05, 2012 08:48PM |

Registered: 12 years ago Posts: 139 |

John Oly, I finally got a chance to take a look at about three videos posted on partdaddy.com the other day. Is that your goup or someone else? They were shots of a printer working on a raft. The unit had a triple gear extruder all in plastic.

What I couldn't help notice in the video was the pausing. When looking at streaming video you never know if pausing is from the video or not. I noticed was the extruder paused as well. I also noticed that the extruder had no retract on motion.

Was that the video or does Mach3 cause the machine to pause randomly (it seemed to me to be random) all the time during the print?

For those who arn't following why this might be an issue,,,it is because you are pushing a cold peice of plastic into a hot chamber. There are considerable pressures in that chamber. That pressure causes the plastic to come out a very small nozzle so the forces must be pretty high. When a machine pauses or doesn't retract at the ends of the path the plastic will just keep coming resulting in excess buildup thats not part of your design. You can find many posts on this issue.

What I couldn't help notice in the video was the pausing. When looking at streaming video you never know if pausing is from the video or not. I noticed was the extruder paused as well. I also noticed that the extruder had no retract on motion.

Was that the video or does Mach3 cause the machine to pause randomly (it seemed to me to be random) all the time during the print?

For those who arn't following why this might be an issue,,,it is because you are pushing a cold peice of plastic into a hot chamber. There are considerable pressures in that chamber. That pressure causes the plastic to come out a very small nozzle so the forces must be pretty high. When a machine pauses or doesn't retract at the ends of the path the plastic will just keep coming resulting in excess buildup thats not part of your design. You can find many posts on this issue.

|

Re: What are the real advantages of Mach3? January 06, 2012 06:50AM |

Registered: 12 years ago Posts: 216 |

|

Re: What are the real advantages of Mach3? January 13, 2012 02:22PM |

Registered: 15 years ago Posts: 84 |

|

Re: What are the real advantages of Mach3? April 14, 2012 03:49AM |

Registered: 12 years ago Posts: 6 |

Mach3 will run on a new PC with Win7 using a parallel port card, so there is no need to use an outdated computer.

I think one of the main reasons, is that Mach3 is very easy to interface and has been well established with handling motion commands,

a cnc machine running Mach3 can 3D print and mill critical areas of a part perfect in one shot as seen here (video somewhere in there ) not sure anyone would need to, but it's being done and possible.

Both Slic3r and Kisslicer now include output for Mach3 / EMC so I think your going to see a lot more of Mach3 and EMC 3D printers in the near future

I think one of the main reasons, is that Mach3 is very easy to interface and has been well established with handling motion commands,

a cnc machine running Mach3 can 3D print and mill critical areas of a part perfect in one shot as seen here (video somewhere in there ) not sure anyone would need to, but it's being done and possible.

Both Slic3r and Kisslicer now include output for Mach3 / EMC so I think your going to see a lot more of Mach3 and EMC 3D printers in the near future

|

Re: What are the real advantages of Mach3? May 23, 2012 08:28PM |

Registered: 12 years ago Posts: 139 |

I had to find out what Mach3 could do when running a printer so I built a second printer. Partly I was trying to not mess up my primary printer and I wanted to go much bigger then what a reprap could do. I have Mach3 powering a G540 which I'm borrowing from my router. Since the printer is sitting on the router it isn't missed.

I'm also running ABS where the primary printer is all PLA. I'll have to say that I'm impressed with the performance of Mach3. After solving the G92 (my other post on this site). I'm amazed with the control Mach3/G540 has over nema 17 steppers. My X axis is about 30" long and the Y axis drives the entire X axis including slide, stepper and extruder. Resolution is excellent. When looking at a gear tooth profile I see no difference between an ABS part and a PLA part and thats while moving more mass at the same speed. I'm sure thats mostly due the quality of the G540.

I'm probably using 5% of the features of Mach3: Home, jog directions, ect. The one thing that I can do in Mach3 that I couldn't do in the standard printer interfaces is pause. So if you want to stop and put something in the part that supports the print its easy to do in Mach3.

In all I think is a real sold way to go, especially if you have the hardware and software, which many folks do.

I'm also running ABS where the primary printer is all PLA. I'll have to say that I'm impressed with the performance of Mach3. After solving the G92 (my other post on this site). I'm amazed with the control Mach3/G540 has over nema 17 steppers. My X axis is about 30" long and the Y axis drives the entire X axis including slide, stepper and extruder. Resolution is excellent. When looking at a gear tooth profile I see no difference between an ABS part and a PLA part and thats while moving more mass at the same speed. I'm sure thats mostly due the quality of the G540.

I'm probably using 5% of the features of Mach3: Home, jog directions, ect. The one thing that I can do in Mach3 that I couldn't do in the standard printer interfaces is pause. So if you want to stop and put something in the part that supports the print its easy to do in Mach3.

In all I think is a real sold way to go, especially if you have the hardware and software, which many folks do.

|

Re: What are the real advantages of Mach3? May 27, 2012 02:17PM |

Registered: 12 years ago Posts: 216 |

Hey Dean, John here from SeeMeCNC again. Mach does have some advantages doesn't it? Now, that siad, the guys coding all the firmware/host software are catching up, AND FAST! I don't know if it's natural progression or what, but they have come a LONG way in the last 6 months or so I think.

We are starting to ship with the 4 axis toshiba boards now for our Mach3 setups, but are working out a deal to start shipping our kits with the RAMPS setup as well.

And yes, there are a LOT of people out there that have mach3, coming from the CNCzone or other DIY cnc adventures, so the ease of use and familiarity were one of our goals, as well as that one piece of software can run almost any type of machine you can build!

We are starting to ship with the 4 axis toshiba boards now for our Mach3 setups, but are working out a deal to start shipping our kits with the RAMPS setup as well.

And yes, there are a LOT of people out there that have mach3, coming from the CNCzone or other DIY cnc adventures, so the ease of use and familiarity were one of our goals, as well as that one piece of software can run almost any type of machine you can build!

|

Re: What are the real advantages of Mach3? May 27, 2012 11:16PM |

Registered: 12 years ago Posts: 139 |

John, I've been using Mach3 to print for a few weeks now and havn't found anything to complain about, at all. If you are use to Mach3 and have a license it seems like the best way to go.

There are a number of folks who might be tempted to try using their CNC wih lead screws and just swap out the spindle for an extruder. I'd love to hear if someone pulls this off. However I suspect that those machines will be too slow to print with. I'm running belt drive on this new printer with a 20 tooth pulley X, 20 driving a 40 tooth on Y and 20 driving a 5/16-18 on Z. This thing moves compared to my lead screw router.

So there is minimal investment requred for somone who has Mach3 and a drive is to get a machine with the Extruder, and no RAMPS. The machine you offer seems ideal because you can start out with machine only then when want to 'borrow' back the hardware from your router just invest in a Ramps or what ever. You just have to learn how to use the open souce code to get the controller to work. At least you understand and can support both worlds.

Yes I think you are correct in that many folks buiding things while wearing ear muffs in a subtractive process, like routing, can continue to build in the completely silent additive Reprap world.

There are a number of folks who might be tempted to try using their CNC wih lead screws and just swap out the spindle for an extruder. I'd love to hear if someone pulls this off. However I suspect that those machines will be too slow to print with. I'm running belt drive on this new printer with a 20 tooth pulley X, 20 driving a 40 tooth on Y and 20 driving a 5/16-18 on Z. This thing moves compared to my lead screw router.

So there is minimal investment requred for somone who has Mach3 and a drive is to get a machine with the Extruder, and no RAMPS. The machine you offer seems ideal because you can start out with machine only then when want to 'borrow' back the hardware from your router just invest in a Ramps or what ever. You just have to learn how to use the open souce code to get the controller to work. At least you understand and can support both worlds.

Yes I think you are correct in that many folks buiding things while wearing ear muffs in a subtractive process, like routing, can continue to build in the completely silent additive Reprap world.

|

Re: What are the real advantages of Mach3? July 04, 2012 04:22AM |

Registered: 11 years ago Posts: 32 |

|

Re: What are the real advantages of Mach3? November 22, 2013 06:32PM |

Registered: 10 years ago Posts: 7 |

I have a CNC router using Mach3. Recognizing that I had 3 moving axis, all I needed was an extruder plus a heated bed to create a 3D printer. So that's what I did and now I have a 3D printer that prints as good or better than anything I've seen. The main drawback is speed. Since CNC mills and routers have to be stiffer to withstand cutter forces, they are heavier, resulting is slower motion since you can't accelerate the mass as fast as lighter 3D printers. Many 3D printers boast speeds of 300+ mm/sec but whenever I see videos they don't actually print much faster than my router (30mm/sec) but they do have capability to rapid move for repositioning MUCH faster. Lately, I've been building a RichRap 3DR delta printer using a Rumba board. I can tell you this: the Arduino chip is working very hard to keep up wereas Mach3 running on a 10 year old PC is much faster and has look-ahead capabililty for over 500 lines of code - the motion is never hesitating because of lack of computational speed. None the less, I really like have all the control features of the Rumba but still haven't gotten the machine printing well enough to take advantage. As far as running overnight, I just plug my extruder and heated bed power supply into the spinder output so when Mach3 is finished printing the power is turned of and in the morning everything is cold.

The big advantage of Mach3 or any larger CNC type machine is they are built to handle larger forces and consequently use larger motors etc. I use Gecko drives that can output up to 7A so the motion system has lots of power. Conversely, 3D printer specific boards are limited to 1-2A and are only designed to drive small motors that don't produce much force. It's a trade off for sure but anyone who already has a moving 3 axis CNC machine if any size can easily create a 3D printer and it will be one that can produce print quality as high as any 3d printer specify control boards. There will be limits to some convenience items like turning fans on and off and it will be slower - otherwise it works great.

I wouldn't recommend builting a CNC router with Mach3 specifically as a 3D printer as it is an overkill and will cost more. Other than that Mach3 works quite well for 3d printing.

--Colin--

The big advantage of Mach3 or any larger CNC type machine is they are built to handle larger forces and consequently use larger motors etc. I use Gecko drives that can output up to 7A so the motion system has lots of power. Conversely, 3D printer specific boards are limited to 1-2A and are only designed to drive small motors that don't produce much force. It's a trade off for sure but anyone who already has a moving 3 axis CNC machine if any size can easily create a 3D printer and it will be one that can produce print quality as high as any 3d printer specify control boards. There will be limits to some convenience items like turning fans on and off and it will be slower - otherwise it works great.

I wouldn't recommend builting a CNC router with Mach3 specifically as a 3D printer as it is an overkill and will cost more. Other than that Mach3 works quite well for 3d printing.

--Colin--

|

Re: What are the real advantages of Mach3? December 25, 2013 08:16AM |

Registered: 10 years ago Posts: 474 |

colin I have built one with Mach 3 and fairly heavy-duty needed to be reliable and accurate I personally think it's the best short of buying a professional machine for 80,000 prints are much better on radius no segmentation like you see on the repraps here is a few pictures

|

Re: What are the real advantages of Mach3? January 14, 2014 02:16AM |

Registered: 12 years ago Posts: 1,236 |

Great! No thread is complete without image spam from the cnc_dick.

We can close this thread now, like anyone was still reading.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

We can close this thread now, like anyone was still reading.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Sorry, only registered users may post in this forum.