Is there any one here?

Posted by gadman58

|

Is there any one here? February 27, 2012 10:28AM |

Registered: 12 years ago Posts: 27 |

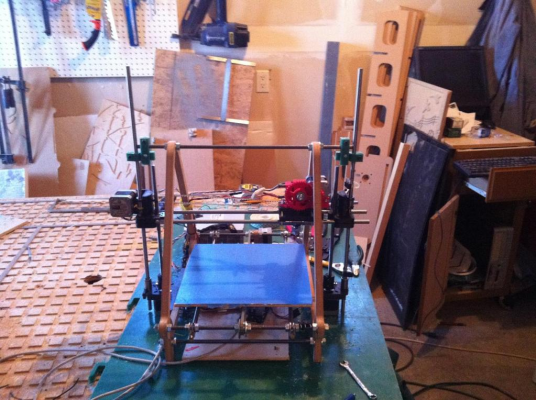

I just finished mine. I guess it is technically a RepStrap.

It is built with MDF, UHMW not sure what the green plastic is and then the standard Prusa Mendal vitamins.

I patterned the frame after the RonThomp Mendel because it was easy to cut out on my DIY router.

For electronics it has a PC power supply sadly only 10 amps so no heated table yet. Arduino 2560 connected to a Xylotex stepper driver board. I had the Xylotex laying around after an upgrade on the router. I used a perf board for the heater components and used the Ramps 1.4 schematic to set it up.

The hot end is from LulzBot and is working well so far.

I am using Marlin as the firmware had to adjust the pin numbers to work better with my layout.

I am using Slic3r as my slicing program pretty straight forward to use.

Glenn

It is built with MDF, UHMW not sure what the green plastic is and then the standard Prusa Mendal vitamins.

I patterned the frame after the RonThomp Mendel because it was easy to cut out on my DIY router.

For electronics it has a PC power supply sadly only 10 amps so no heated table yet. Arduino 2560 connected to a Xylotex stepper driver board. I had the Xylotex laying around after an upgrade on the router. I used a perf board for the heater components and used the Ramps 1.4 schematic to set it up.

The hot end is from LulzBot and is working well so far.

I am using Marlin as the firmware had to adjust the pin numbers to work better with my layout.

I am using Slic3r as my slicing program pretty straight forward to use.

Glenn

|

Re: Is there any one here? March 08, 2012 01:04PM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? March 14, 2012 06:05PM |

|

Re: Is there any one here? March 14, 2012 09:04PM |

Registered: 12 years ago Posts: 27 |

Thank you

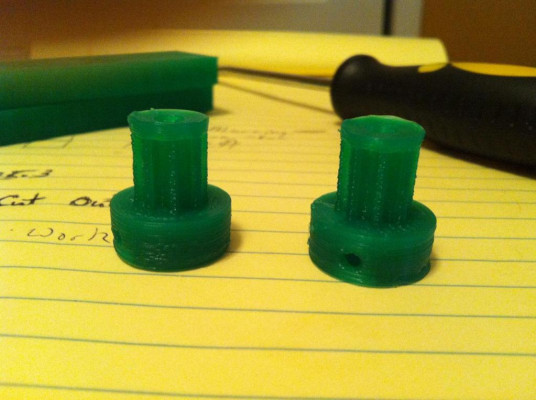

Minor things, mostly created by my use of non standard parts.

The Xylotex board extruder drive chip got fried. The Xylotex is setup for NEMA 23 motors so the stepper connections were pretty good size screw connectors. I suspect I pushed the small wires to far in and caught part of the insulation which let it come loose. One day I turned it on the motors jumped heard a pop and then nothing. So I replaced it with a ramps1.4 and the Pololu drives.

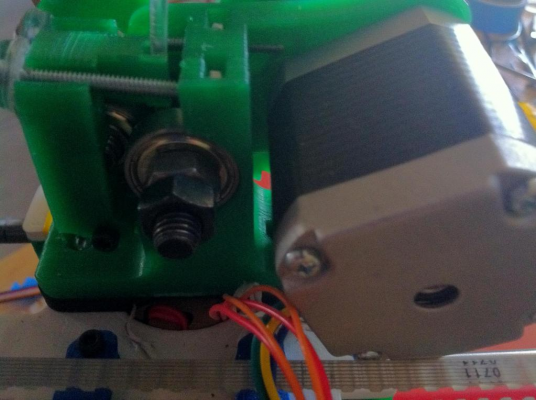

Here is what it looks like now.

I think I have printed a little over 30 hrs so far replacing most of the parts of issue with more standard Mendel parts.

As well as making the blocks you see on the table printing.

Next project is a heated bed then wiring clean up.

Glenn

Minor things, mostly created by my use of non standard parts.

The Xylotex board extruder drive chip got fried. The Xylotex is setup for NEMA 23 motors so the stepper connections were pretty good size screw connectors. I suspect I pushed the small wires to far in and caught part of the insulation which let it come loose. One day I turned it on the motors jumped heard a pop and then nothing. So I replaced it with a ramps1.4 and the Pololu drives.

Here is what it looks like now.

I think I have printed a little over 30 hrs so far replacing most of the parts of issue with more standard Mendel parts.

As well as making the blocks you see on the table printing.

Next project is a heated bed then wiring clean up.

Glenn

|

Re: Is there any one here? March 22, 2012 11:03PM |

Registered: 12 years ago Posts: 53 |

I'm just starting the assembly of my Ronthrop Mendel machine. I ordered a set of printed parts from Ron Thompson, and they arrived today. I'm very impressed with the quality of the parts he made. Very little clean up required. Someone is cutting the rods and shaft to length for me over the weekend, so things should move along fairly quickly next week.

For the electronics I ordered a Sanguinolulo PCB from the UK and a kit of parts from Mouser. Still waiting on the PCB. I've not done anything about the top print bed or the heater scheme except check out everything I can find on the internet.

John

For the electronics I ordered a Sanguinolulo PCB from the UK and a kit of parts from Mouser. Still waiting on the PCB. I've not done anything about the top print bed or the heater scheme except check out everything I can find on the internet.

John

|

Re: Is there any one here? March 23, 2012 09:56AM |

Registered: 12 years ago Posts: 27 |

|

John's Thompson Mendel April 11, 2012 12:12PM |

Registered: 12 years ago Posts: 53 |

Other activities have left little time for this project, but I have made some progress. While waiting for Ron Thompson to print my parts, I ordered most of the non-printed parts and had the 5/16" threaded rod, and 8-mm shafts cut to length as per Mendel. When the printed parts arrived, I laid them out on a table and took a picture. With some help from Ron I was able to edit the image and number the parts to match the numbering on Ron's list.

Here is the result

Edited 1 time(s). Last edit at 04/11/2012 03:36PM by JohnDH.

Here is the result

Edited 1 time(s). Last edit at 04/11/2012 03:36PM by JohnDH.

|

Re: Is there any one here? April 14, 2012 05:41PM |

Registered: 12 years ago Posts: 53 |

Early in the week I got the frame assembled. Seemed to spend forever adjusting nuts to make dimensions equal, with my calipers. On Friday I built and installed the 'Y' assembly. Lots more time adjusting nuts.

I'm not happy with the action of the bearings on the shafts. They feel gritty. Ron had a problem when he first tried these bearings on 5/16" (0.3125") shafts, but found them OK when he switched to 8-mm (0.3150") shafts. Only 0.0025" bigger but he said it made a world of difference. Did you have any problem with the bearings?

This is the frame assembly

I'm not happy with the action of the bearings on the shafts. They feel gritty. Ron had a problem when he first tried these bearings on 5/16" (0.3125") shafts, but found them OK when he switched to 8-mm (0.3150") shafts. Only 0.0025" bigger but he said it made a world of difference. Did you have any problem with the bearings?

This is the frame assembly

|

Re: Is there any one here? April 14, 2012 08:23PM |

Registered: 12 years ago Posts: 27 |

|

Re: Is there any one here? April 15, 2012 07:05PM |

Registered: 12 years ago Posts: 53 |

The shafts are 8mm but the surface is very finely rippled. Maybe drill rod is not up to the tasks. Where did you get your shafts, and do they look like they are centerless ground? I see that VXB sells a shaft and bearing kit for just under $60, but from the picture the bearings seem to be the 608 skate bearings. I'm going to press on with what I have, but think about a retrofit later if I know where to get good ones.

'Y' is finished, 'X' needs the bolt for the idler bearing, and the belt installed. I have the 'Z' motors and couplers installed. Not very impressed with the couplers. I can see a retrofit here.

Which version of Wades are you using? I'm looking for assembly instructions.

Here is my latest image

'Y' is finished, 'X' needs the bolt for the idler bearing, and the belt installed. I have the 'Z' motors and couplers installed. Not very impressed with the couplers. I can see a retrofit here.

Which version of Wades are you using? I'm looking for assembly instructions.

Here is my latest image

|

Re: Is there any one here? April 16, 2012 09:52AM |

Registered: 12 years ago Posts: 27 |

Looking good.

This is what I ordered from McMaster, 88625K67 O1 Tool Steel Tight-Tolerance Rod, 8 Millimeter Diameter, 3' Length. They have a semi dull finish so are not perfectly chrome plated smooth but seem to work ok.

This one here, pretty close to what you have I think.

I had planned on making those couplers but was looking for the tubing that goes over the shaft before I did. I have seen several people buy the AL or steel couplers and use those, but where is the fun in that....

This is what I ordered from McMaster, 88625K67 O1 Tool Steel Tight-Tolerance Rod, 8 Millimeter Diameter, 3' Length. They have a semi dull finish so are not perfectly chrome plated smooth but seem to work ok.

This one here, pretty close to what you have I think.

I had planned on making those couplers but was looking for the tubing that goes over the shaft before I did. I have seen several people buy the AL or steel couplers and use those, but where is the fun in that....

|

Re: Is there any one here? April 16, 2012 02:40PM |

Registered: 12 years ago Posts: 53 |

Extruder - Ron Thompson tells me that the printed extruder parts he supplied are for a 'Greg's Hinged Accessible Extruder'

Couplings - I commonly use the aluminum couplers that look like a solid piece of shafting, with a hole through the middle and a spiral groove cut through to the center hole to make into a one piece pair of hubs with an aluminum spring in between.

I'm thinking that something just like that can be printed with a 5/16" hub hole at one end and a 5mm hub hole at the other end. At the 5mm end I would add a nut slot to provide threads for the set screw. At the 5/16" end I was wondering if a 5/16" internal thread could be printed so that the 'Z' threaded rod could just screw into the coupling.

What do you think?

Couplings - I commonly use the aluminum couplers that look like a solid piece of shafting, with a hole through the middle and a spiral groove cut through to the center hole to make into a one piece pair of hubs with an aluminum spring in between.

I'm thinking that something just like that can be printed with a 5/16" hub hole at one end and a 5mm hub hole at the other end. At the 5mm end I would add a nut slot to provide threads for the set screw. At the 5/16" end I was wondering if a 5/16" internal thread could be printed so that the 'Z' threaded rod could just screw into the coupling.

What do you think?

|

Re: Is there any one here? April 16, 2012 04:05PM |

Registered: 12 years ago Posts: 27 |

So very close to the same on the extruders.

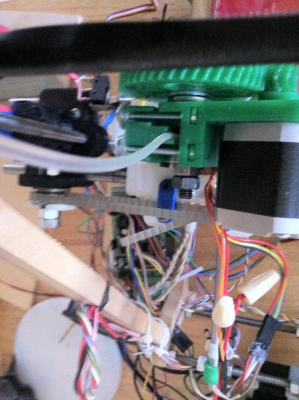

I have one like you are talking about in a cast plastic for a 1/4" to 1/2" for an encoder, sitting in my don't throw away box, but don't have any that worked so I use some printed ones from LulzBot.

Make a square notch through and slide in a 5/16" nut. Shouldn't need internal threads that way. A second nut on top to keep everything from spinning, I would think you would be good.

I have some delrin ones, from Dumpster CNC, on my router that are just cut part way through pretty similar to what is on my printer.

The printing direction would make a huge difference for strength, I would think, with a greater chance to separate at each layer if printed standing up versus if it was printed laying down . So I think square/rectangular might be better. I probably should make a spare set, I might model something up tonight and see what I get..

I have one like you are talking about in a cast plastic for a 1/4" to 1/2" for an encoder, sitting in my don't throw away box, but don't have any that worked so I use some printed ones from LulzBot.

Make a square notch through and slide in a 5/16" nut. Shouldn't need internal threads that way. A second nut on top to keep everything from spinning, I would think you would be good.

I have some delrin ones, from Dumpster CNC, on my router that are just cut part way through pretty similar to what is on my printer.

The printing direction would make a huge difference for strength, I would think, with a greater chance to separate at each layer if printed standing up versus if it was printed laying down . So I think square/rectangular might be better. I probably should make a spare set, I might model something up tonight and see what I get..

|

Re: Is there any one here? April 16, 2012 10:22PM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? April 17, 2012 10:31AM |

Registered: 12 years ago Posts: 27 |

|

Re: Is there any one here? April 21, 2012 11:39PM |

Registered: 12 years ago Posts: 53 |

I have several problems with the Greg's Hinged version of the Wade's Extruder. Some of which go beck to the original Wades design. I think I have it fixed so it will work.

1. The hinged Idler Assembly din not sit square with the hobbed bolt.

2. The skate bearing farthermost from the big gear does not want to stay in place, but moves 1/16" plus towards the idler. You can see the problem on this picture that I stole from Greg's site. Do you have this problem. You need more than a 180 deg act to hold it in place.

3. The slots in top of the extruder body were way too small. Needed some dremel work, but then the nuts would rotate. So I copied a trick that Ron Thompson used. With the 6-32 screw threaded right through the nut, I melted some ABS over the top of the nut with a soldering iron.

4. The little gear had one misshapen tooth that was hard to fix because of the hub being in the way, but I did get it done

5. The screw holes in the hinged idler need to be slots to allow the hinge to work with the screw held rigidly. Dremel to the rescue.

I have the 'X' assembly installed and am working on getting the 'Z' smooth shafts to be verical. Hopefully Sunday will see that done.

I've ordered another set of smooth shafts from a Canadian outfit Roland Lock $25 for a set of six shafts cut to Prusa Mendel lengths. Hopefully the are better than the drill rod I got from McMaster

John

1. The hinged Idler Assembly din not sit square with the hobbed bolt.

2. The skate bearing farthermost from the big gear does not want to stay in place, but moves 1/16" plus towards the idler. You can see the problem on this picture that I stole from Greg's site. Do you have this problem. You need more than a 180 deg act to hold it in place.

3. The slots in top of the extruder body were way too small. Needed some dremel work, but then the nuts would rotate. So I copied a trick that Ron Thompson used. With the 6-32 screw threaded right through the nut, I melted some ABS over the top of the nut with a soldering iron.

4. The little gear had one misshapen tooth that was hard to fix because of the hub being in the way, but I did get it done

5. The screw holes in the hinged idler need to be slots to allow the hinge to work with the screw held rigidly. Dremel to the rescue.

I have the 'X' assembly installed and am working on getting the 'Z' smooth shafts to be verical. Hopefully Sunday will see that done.

I've ordered another set of smooth shafts from a Canadian outfit Roland Lock $25 for a set of six shafts cut to Prusa Mendel lengths. Hopefully the are better than the drill rod I got from McMaster

John

|

Re: Is there any one here? April 22, 2012 12:26PM |

Registered: 12 years ago Posts: 27 |

I printed this wades from Here.

It is printed in PLA. Sorry for the quality of the photos.

Here is a picture of the gears, reprinted the small one this one did not turn out so well,

It went together pretty easily. I didn't think I had any of your issues. My drive bolt is different so I have more washers spacing the gear out.

It is printed in PLA. Sorry for the quality of the photos.

Here is a picture of the gears, reprinted the small one this one did not turn out so well,

It went together pretty easily. I didn't think I had any of your issues. My drive bolt is different so I have more washers spacing the gear out.

|

Re: Is there any one here? April 22, 2012 07:43PM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? April 22, 2012 10:00PM |

Registered: 12 years ago Posts: 27 |

Just used the STL's. Don't think I even ran them thru netfab

Yep that is what I have been doing us what I have make better if I can. Gives you something to learn on.

i am pretty proud of my prints now although have not printed anything since Easter. Honey do list has me hoping..

I just now got in some ABS, I need to give that a try. I really like printing with the PLA so far though.

Yep that is what I have been doing us what I have make better if I can. Gives you something to learn on.

i am pretty proud of my prints now although have not printed anything since Easter. Honey do list has me hoping..

I just now got in some ABS, I need to give that a try. I really like printing with the PLA so far though.

|

Re: Is there any one here? April 23, 2012 09:27PM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? April 24, 2012 01:14PM |

Registered: 12 years ago Posts: 27 |

|

Re: Is there any one here? April 24, 2012 07:58PM |

Registered: 12 years ago Posts: 53 |

Glen

I'll give Ultimachine a try.

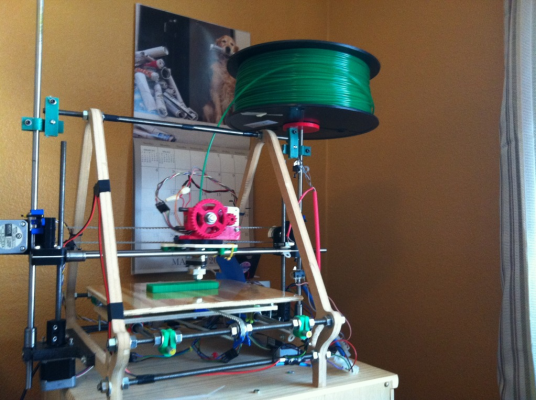

I have the basic assembly complete, and have moved the machine from my hot over-the-garage workshop to my 3rd bedroom office.

I'm starting on my MakerGear hot end kit

This week I should get the new set of smooth shafts from Roland Lock. Hopefully they will be without the rippled surface I have on the Mcmaster shafts

After Hot End and a shaft swap, the next thing is get the motors turning.

John

I'll give Ultimachine a try.

I have the basic assembly complete, and have moved the machine from my hot over-the-garage workshop to my 3rd bedroom office.

I'm starting on my MakerGear hot end kit

This week I should get the new set of smooth shafts from Roland Lock. Hopefully they will be without the rippled surface I have on the Mcmaster shafts

After Hot End and a shaft swap, the next thing is get the motors turning.

John

|

Re: Is there any one here? April 27, 2012 07:58PM |

Registered: 12 years ago Posts: 53 |

Finished my MakerGear hot end and have it installed on the extruder, after boring out the mounting hole to 5/8" diameter with a hole saw in a carpenter's brace.

Got my new sooth shaft set today. Found it easy to swap them out one at a time. Much better. That ripple on the McMaster drill rod has gone. Now without the 'Y' belt attached, the 'Y' carriage will slide from end to end under it's own weight when tilted 45 degrees.

Now to install the limit switches and to start wiring things up.

John

Got my new sooth shaft set today. Found it easy to swap them out one at a time. Much better. That ripple on the McMaster drill rod has gone. Now without the 'Y' belt attached, the 'Y' carriage will slide from end to end under it's own weight when tilted 45 degrees.

Now to install the limit switches and to start wiring things up.

John

|

Re: Is there any one here? April 27, 2012 10:22PM |

Registered: 12 years ago Posts: 27 |

|

Re: Is there any one here? May 07, 2012 07:39PM |

Registered: 12 years ago Posts: 53 |

Glenn

Finished wiring this morning, except for installing fans. I have one 40mm square fan that came as part of the Hot End kit, and a 80mm square fan that I plan to use on my Sanguinololu board. I'm puzzling how to mount them. May just hang the on some wires until I can print some mounting brackets. What do you do in the way of fans?

My Heatbed arrived lunchtime (A Mk2 PCB Heatbed with 200mm square mirror), but not the top 'Thick Sheet'. I will have to round up some Masonite in the morning. I've seen some alternative ways of using the mirror or a glass plate.

1. Under the Heatbed PCB with cork spacers, with the idea that the glass will force the PCB to lay flat.

2. Clamped on top of the Heatbed PCB to ensure a flat surface to print on. Not sure about heat coupling with this idea

Do you have any recommendations?

John

Edited 1 time(s). Last edit at 05/08/2012 03:27PM by JohnDH.

Finished wiring this morning, except for installing fans. I have one 40mm square fan that came as part of the Hot End kit, and a 80mm square fan that I plan to use on my Sanguinololu board. I'm puzzling how to mount them. May just hang the on some wires until I can print some mounting brackets. What do you do in the way of fans?

My Heatbed arrived lunchtime (A Mk2 PCB Heatbed with 200mm square mirror), but not the top 'Thick Sheet'. I will have to round up some Masonite in the morning. I've seen some alternative ways of using the mirror or a glass plate.

1. Under the Heatbed PCB with cork spacers, with the idea that the glass will force the PCB to lay flat.

2. Clamped on top of the Heatbed PCB to ensure a flat surface to print on. Not sure about heat coupling with this idea

Do you have any recommendations?

John

Edited 1 time(s). Last edit at 05/08/2012 03:27PM by JohnDH.

|

Re: Is there any one here? May 08, 2012 02:21PM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? May 08, 2012 08:56PM |

Registered: 12 years ago Posts: 27 |

Followed pretty much what Joseph Prussa's method said. My table is different I don't have a second one any more.

Removed some mass that way. My I level the PCB corners and attach the glass on top with the clips. I do need to insulate the bottom of the PCB.

I am only getting to 105c even with 12.3 volts at the PCB. Using window glass from Lowes.

Removed some mass that way. My I level the PCB corners and attach the glass on top with the clips. I do need to insulate the bottom of the PCB.

I am only getting to 105c even with 12.3 volts at the PCB. Using window glass from Lowes.

|

Re: Is there any one here? May 09, 2012 10:46AM |

Registered: 12 years ago Posts: 53 |

Glenn

Where did you install the thermistor? I'm going to use one of Josif's suggestion and cement it to the underside of the PCB with two-part epoxy.

Also where and how are you measuring temperature? I have a EXTECH Mini IR Thermometer, that I will use. On my way out the door to get four 6-32 1.5" flat head screws to reduce the spacing between the top 'Thick Sheet' and the PCB to one or two washer thickness.

A $3 Clipboard from Office Depot was a better choice that a sheet of Masonite from Home Depot, to get material for the top Thick Sheet.

Mabe I can start calibration this evening.

John

Where did you install the thermistor? I'm going to use one of Josif's suggestion and cement it to the underside of the PCB with two-part epoxy.

Also where and how are you measuring temperature? I have a EXTECH Mini IR Thermometer, that I will use. On my way out the door to get four 6-32 1.5" flat head screws to reduce the spacing between the top 'Thick Sheet' and the PCB to one or two washer thickness.

A $3 Clipboard from Office Depot was a better choice that a sheet of Masonite from Home Depot, to get material for the top Thick Sheet.

Mabe I can start calibration this evening.

John

|

Re: Is there any one here? May 09, 2012 01:46PM |

Registered: 12 years ago Posts: 27 |

|

Re: Is there any one here? May 09, 2012 09:37PM |

Registered: 12 years ago Posts: 53 |

Sorry, only registered users may post in this forum.