Home

>

RepRap User Groups

>

United States

>

New Mexico, Albuquerque - RepRap User Group

>

Topic

>

Page 2

Is there any one here?

Posted by gadman58

|

Re: Is there any one here? May 10, 2012 09:54AM |

Registered: 12 years ago Posts: 27 |

I would guess your screws have a bow.

Try shimming up your motor so it wont fall and loosen the Z coupling and gently, by hand rotate, the screw once or twice maybe it will help center it better in the coupling.

I left my Z motors loose slightly so they can move as well. One side rocks some the other is quite still, it really is down to how straight the all thread is, i believe.

One more thing to look at is if the screw is parallel to the vertical rod, that might effect it as well.

Glenn

Try shimming up your motor so it wont fall and loosen the Z coupling and gently, by hand rotate, the screw once or twice maybe it will help center it better in the coupling.

I left my Z motors loose slightly so they can move as well. One side rocks some the other is quite still, it really is down to how straight the all thread is, i believe.

One more thing to look at is if the screw is parallel to the vertical rod, that might effect it as well.

Glenn

|

Re: Is there any one here? May 10, 2012 11:17AM |

Registered: 12 years ago Posts: 27 |

|

Re: Is there any one here? May 12, 2012 02:59PM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? June 08, 2012 11:00AM |

Registered: 12 years ago Posts: 53 |

I'm finally printing, after fixing two electrical problems. I had a bad solder joint on the X, Y, and E Enable pin of the microprocessor, and the USB connector case pins were not soldered to the PCB. After a few trial runs I printed out a set of parts New Extruder . Everything printed out real clean except the small gear. I will have to do that one over.

I still have a couple of problems. While I do a good eject before I start a print the first perimeter does not print. I increased the perimeter count to three and now at least the last perimeter layer always prints.

Second I think my bed thermister has become unglued from the PCB. I will take thing to pieces today and check.

My software is Repetier-Host for the PC GUI, Slic3r for slicing and Sprinter for the controller firmware. I'm using a sugar solution in place of ABS Juice on the glass top of my bed. Just paint in on when it gets to 100 deg C. The first layer sticks real well, and when the bed cools to 40 deg C the part comes off with a little tug of my hand.

I still have a couple of problems. While I do a good eject before I start a print the first perimeter does not print. I increased the perimeter count to three and now at least the last perimeter layer always prints.

Second I think my bed thermister has become unglued from the PCB. I will take thing to pieces today and check.

My software is Repetier-Host for the PC GUI, Slic3r for slicing and Sprinter for the controller firmware. I'm using a sugar solution in place of ABS Juice on the glass top of my bed. Just paint in on when it gets to 100 deg C. The first layer sticks real well, and when the bed cools to 40 deg C the part comes off with a little tug of my hand.

|

Re: Is there any one here? June 08, 2012 12:37PM |

Registered: 12 years ago Posts: 27 |

Sweet, I still haven't printed ABS finally got my bed to go over 100C I have 4ea 14g a. wire running to the PCB bed 2 for + and 2 for -.

But it takes quite a long time to get there. The head does not take that long to get to the 230 temp though.

What is the ratio for the sugar solution and how do you apply it?

Thanks

Glenn

But it takes quite a long time to get there. The head does not take that long to get to the 230 temp though.

What is the ratio for the sugar solution and how do you apply it?

Thanks

Glenn

|

Re: Is there any one here? June 08, 2012 11:02PM |

Registered: 12 years ago Posts: 53 |

I use one tablespoon sugar to one cup of water. I wait until the bed is near 100C then paint the print area. Then when the bed is happy and the Extruder starts to heat I wait until it is about 200C and put on a second coat. Not sure if all this is necessary but it works. If you let the bed cool to 40C the part comes away with a little tug of the hand. Clean up is just with a wet rag. You can also wash the sugar from the bottom of the part with hot tap water.

I solved my perimeter printing problem. After homing all three axis I did an Extrude 10 then an Extrude -1. Which was a retract of 11. The second extrude should have been 9, for a retract of one.

My bed takes about 10 mins to make 110C from room temperature. The extruder then takes about 4 mins.I have double wiring but 20AWG I measured 11.5V on the PCB pads, so I cranked up my powersupply to 12.5V to get 12V at the PCB

The 'New Extruder' parts look good but the do not fit together well. The head of my knurled screw did not fit into the hex in the big gear without a lot of scraping, and the hinged part did not fit to the main part until I cut over a 1/16" from the main part.

I found this on calibration Calibration and got the STL files. I printed the 20mm cube and when cooled to room temperature it measured 19.5 x 19.5. So I tweaked my Sprinter settings and printed it again. 20.05 x 20.05 close enough for government work. So I'll print the New Extruder parts again.

John

I solved my perimeter printing problem. After homing all three axis I did an Extrude 10 then an Extrude -1. Which was a retract of 11. The second extrude should have been 9, for a retract of one.

My bed takes about 10 mins to make 110C from room temperature. The extruder then takes about 4 mins.I have double wiring but 20AWG I measured 11.5V on the PCB pads, so I cranked up my powersupply to 12.5V to get 12V at the PCB

The 'New Extruder' parts look good but the do not fit together well. The head of my knurled screw did not fit into the hex in the big gear without a lot of scraping, and the hinged part did not fit to the main part until I cut over a 1/16" from the main part.

I found this on calibration Calibration and got the STL files. I printed the 20mm cube and when cooled to room temperature it measured 19.5 x 19.5. So I tweaked my Sprinter settings and printed it again. 20.05 x 20.05 close enough for government work. So I'll print the New Extruder parts again.

John

|

Re: Is there any one here? June 17, 2012 05:42AM |

So my friend and I live in the valley area of ABQ and have already built Prusas, but have yet to get them up and printing due to the fact that we're still figuring out the electronics.

I will most likely forget about this forum for a bit since I quit lurking these forums a few months ago so I'll have to get back into the rhythm of it, but just figured you two might be interested to know that there are at least 2 other people in Burque building RepRaps.

Cheers

I will most likely forget about this forum for a bit since I quit lurking these forums a few months ago so I'll have to get back into the rhythm of it, but just figured you two might be interested to know that there are at least 2 other people in Burque building RepRaps.

Cheers

|

Re: Is there any one here? June 17, 2012 06:37AM |

Registered: 12 years ago Posts: 53 |

|

Re: Is there any one here? June 24, 2012 12:45AM |

gadman58 Wrote:

-------------------------------------------------------

> I just finished mine. I guess it is technically a

> RepStrap.

> It is built with MDF, UHMW not sure what the green

> plastic is and then the standard Prusa Mendal

> vitamins.

> I patterned the frame after the RonThomp Mendel

> because it was easy to cut out on my DIY router.

>

> For electronics it has a PC power supply sadly

> only 10 amps so no heated table yet. Arduino 2560

> connected to a Xylotex stepper driver board. I

> had the Xylotex laying around after an upgrade on

> the router. I used a perf board for the heater

> components and used the Ramps 1.4 schematic to set

> it up.

>

> The hot end is from LulzBot and is working well so

> far.

>

> I am using Marlin as the firmware had to adjust

> the pin numbers to work better with my layout.

> I am using Slic3r as my slicing program pretty

> straight forward to use.

>

> Glenn

> [i1081.photobucket.com]

> IMG_0111.jpg

> [i1081.photobucket.com]

> IMG_0122.jpg

> [i1081.photobucket.com]

> IMG_0135-1.jpg

> [i1081.photobucket.com]

> IMG_0131.jpg

Gadman58,

Any chance you can point me in the right direction?

I have a fully functional mini mill 4 axis (not getting any use) it has 269oz steppers with a 4 axis Xylotex controller.

Since you have been down this street. Could you advice what Im missing to convert my setup basically add a milstrap?

long enough for me to perhaps build my own separate machine? the software Im using is Mach3 currently. any help would be most appreciated.

Sam

-------------------------------------------------------

> I just finished mine. I guess it is technically a

> RepStrap.

> It is built with MDF, UHMW not sure what the green

> plastic is and then the standard Prusa Mendal

> vitamins.

> I patterned the frame after the RonThomp Mendel

> because it was easy to cut out on my DIY router.

>

> For electronics it has a PC power supply sadly

> only 10 amps so no heated table yet. Arduino 2560

> connected to a Xylotex stepper driver board. I

> had the Xylotex laying around after an upgrade on

> the router. I used a perf board for the heater

> components and used the Ramps 1.4 schematic to set

> it up.

>

> The hot end is from LulzBot and is working well so

> far.

>

> I am using Marlin as the firmware had to adjust

> the pin numbers to work better with my layout.

> I am using Slic3r as my slicing program pretty

> straight forward to use.

>

> Glenn

> [i1081.photobucket.com]

> IMG_0111.jpg

> [i1081.photobucket.com]

> IMG_0122.jpg

> [i1081.photobucket.com]

> IMG_0135-1.jpg

> [i1081.photobucket.com]

> IMG_0131.jpg

Gadman58,

Any chance you can point me in the right direction?

I have a fully functional mini mill 4 axis (not getting any use) it has 269oz steppers with a 4 axis Xylotex controller.

Since you have been down this street. Could you advice what Im missing to convert my setup basically add a milstrap?

long enough for me to perhaps build my own separate machine? the software Im using is Mach3 currently. any help would be most appreciated.

Sam

|

Re: Is there any one here? June 24, 2012 01:28PM |

Registered: 12 years ago Posts: 27 |

I used a Arduino Mega to drive the Xylotex.

The issue with going through the parallel port with the Xylotex is there are not enough inputs.

By using the Mega I was able to have it think it had a Ramps board attached.

If your current machine is 3 axis and you don't mind making a stand alone controller for the extruder heat you could get away with it.

I see in Slic3r they have Mach3 output. I don't know much about it hough. i am assuming they are treading the extruder as the A axis.

Glenn

The issue with going through the parallel port with the Xylotex is there are not enough inputs.

By using the Mega I was able to have it think it had a Ramps board attached.

If your current machine is 3 axis and you don't mind making a stand alone controller for the extruder heat you could get away with it.

I see in Slic3r they have Mach3 output. I don't know much about it hough. i am assuming they are treading the extruder as the A axis.

Glenn

|

Re: Is there any one here? July 04, 2012 04:43PM |

Registered: 11 years ago Posts: 182 |

|

Re: Is there any one here? July 08, 2012 01:40AM |

Registered: 12 years ago Posts: 53 |

The quality of my printed parts has been steadily going down hill over the weeks, and this is because the machine has been steadily going out of calibration due to several reasons. As an example of how bad things have gotten look at this image:

Note the bearing holder lifting off the bearing on the left. The bow in the Extruder Base and the bow in the X Carriage. Also note the "leaning Tower of Pisa" effect on the part being printed.

The first thing I found was that every screw in the machine was loose by at least 1/2 a turn and some by two turns. This included the screws closing the clamps on the X and Y belts, also the thumb nuts holding the Top Y Plate to the Y carriage.

As a first pass I went round and tightened every screw, and Thumb Nut. Also on a tip from Ron Thompson, who told me "There is provision for Tie-Wraps at each end of the bearing holders", I installed Tie-Wraps on the outer end of the X and Y bearing holders.

I tried to print a new X Carriage by Jonas Skuehling, and lost the "Leaning Tower" effect and the extruder seemed much more stable; however alter this one print some of the M3 screws had loosened up by at least 1/2 turn.

I have ordered M3 lock-nuts 90576A102 from McMaster ($3.09/100) and plan to retrofit every M3 nut. I can get 6-32 lock-nuts from my local hardware store, and I will either use these or use a double jam nut arrangement. For the four Thumb Nuts I will add 6-32 Wing Nuts.

This I hope will give me a more stable machine.

Have you had similar problems?

John

Note the bearing holder lifting off the bearing on the left. The bow in the Extruder Base and the bow in the X Carriage. Also note the "leaning Tower of Pisa" effect on the part being printed.

The first thing I found was that every screw in the machine was loose by at least 1/2 a turn and some by two turns. This included the screws closing the clamps on the X and Y belts, also the thumb nuts holding the Top Y Plate to the Y carriage.

As a first pass I went round and tightened every screw, and Thumb Nut. Also on a tip from Ron Thompson, who told me "There is provision for Tie-Wraps at each end of the bearing holders", I installed Tie-Wraps on the outer end of the X and Y bearing holders.

I tried to print a new X Carriage by Jonas Skuehling, and lost the "Leaning Tower" effect and the extruder seemed much more stable; however alter this one print some of the M3 screws had loosened up by at least 1/2 turn.

I have ordered M3 lock-nuts 90576A102 from McMaster ($3.09/100) and plan to retrofit every M3 nut. I can get 6-32 lock-nuts from my local hardware store, and I will either use these or use a double jam nut arrangement. For the four Thumb Nuts I will add 6-32 Wing Nuts.

This I hope will give me a more stable machine.

Have you had similar problems?

John

|

Re: Is there any one here? July 08, 2012 07:25PM |

Registered: 12 years ago Posts: 27 |

John

I keep playing with mine, have had the table apart 3 times in the last month. I don't use it that much so I am not having the issues with bolts loosening yet , but do try to keep an eye on it. You can also use finger nail polish, it acts a lot like the blue thread lock. Just use a color that the misses doesn't like much or get your own.

I started using the glue mixture(Tite Bond II), on the glass and what a difference it made for parts lifting.

Stuck down pretty good now. Having a hard time getting it of the glass even after cool down.

Looks like your extruder drive is getting quite a bow too.

I am still printing with PLA so I don't have the heat going on that ABS printing would cause.

Did you print the parts for a second extruder drive yet?

I do have zip ties holding all of my bearings in place. Look at some of the first photos I posted for the X carriage.

Glenn

I keep playing with mine, have had the table apart 3 times in the last month. I don't use it that much so I am not having the issues with bolts loosening yet , but do try to keep an eye on it. You can also use finger nail polish, it acts a lot like the blue thread lock. Just use a color that the misses doesn't like much or get your own.

I started using the glue mixture(Tite Bond II), on the glass and what a difference it made for parts lifting.

Stuck down pretty good now. Having a hard time getting it of the glass even after cool down.

Looks like your extruder drive is getting quite a bow too.

I am still printing with PLA so I don't have the heat going on that ABS printing would cause.

Did you print the parts for a second extruder drive yet?

I do have zip ties holding all of my bearings in place. Look at some of the first photos I posted for the X carriage.

Glenn

|

Re: Is there any one here? July 08, 2012 10:52PM |

Registered: 12 years ago Posts: 53 |

Hi Glen,

I really like the way Jonas Kuehling's 'Gregg's Wade Reloaded' extruder is put together. (Got the first link from you), and have for the last few weeks have been trying to get my existing extruder to print the parts. The gears came out Ok but the main body always beat me. last week I gave up and ordered a kit of plastic parts from LulzBot in Colorado for $23. They and the lock-nuts from McMaster should be here by Wednesday, so I'm hoping for great things.

This weekend I'm remaking my bed top plate. From a model shop I got a piece of 'Aircraft Grade' plywood. Even though it is only 1/8" thick there are 8 ply layers. It works almost like metal. This go of making the plate, I will move the clip locations so that I will not have a clip blocking me from zeroing all the axis at once. Also I have positioned the holes more precisely so the new top plate will mate more closely with my aluminium Y Carriage.

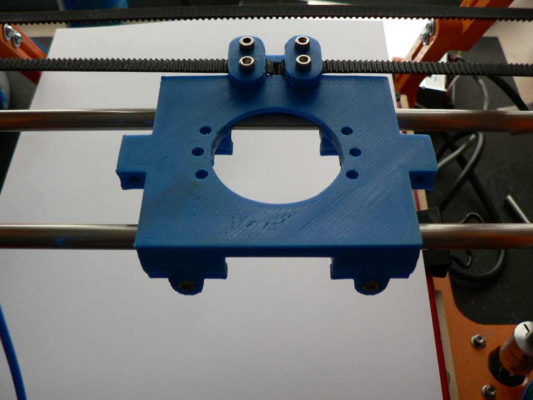

When I have the new extruder installed the next job will be to print a new X Carriage. Again I turn to Jonas Kuehling for his design:

X Carriage

Apart from having the bearing holders all part of the carriage, to make a much stiffer structure, there is provision for mounting the extruder at an angle so that the motor will not be rubbing the X belt.

Onward and upward

John

I really like the way Jonas Kuehling's 'Gregg's Wade Reloaded' extruder is put together. (Got the first link from you), and have for the last few weeks have been trying to get my existing extruder to print the parts. The gears came out Ok but the main body always beat me. last week I gave up and ordered a kit of plastic parts from LulzBot in Colorado for $23. They and the lock-nuts from McMaster should be here by Wednesday, so I'm hoping for great things.

This weekend I'm remaking my bed top plate. From a model shop I got a piece of 'Aircraft Grade' plywood. Even though it is only 1/8" thick there are 8 ply layers. It works almost like metal. This go of making the plate, I will move the clip locations so that I will not have a clip blocking me from zeroing all the axis at once. Also I have positioned the holes more precisely so the new top plate will mate more closely with my aluminium Y Carriage.

When I have the new extruder installed the next job will be to print a new X Carriage. Again I turn to Jonas Kuehling for his design:

X Carriage

Apart from having the bearing holders all part of the carriage, to make a much stiffer structure, there is provision for mounting the extruder at an angle so that the motor will not be rubbing the X belt.

Onward and upward

John

|

Re: Is there any one here? July 15, 2012 06:41PM |

Registered: 12 years ago Posts: 53 |

Update Complete

1. 27 6-32 plain nuts, and 40 M3-0.5 plain nuts replaced with nylon insert lock-nuts. - No more loose screws

2. Added 16 tie-wraps (One per bearing on outside end) - No lifting bearings

3. New bed top plate (Model Aircraft 1/8" plywood) - Clips holding glass moved away from 'All-Home' position

4. New extruder plastic "Greg's Wade Reloaded Extruder" New Extruder from LutzBot Had to space the motor off by 3-mm from the plastic to get the gears to mesh ( 3 M4 nuts). Also the motor ran in the opposite direction to the old one.

5. Replaced MX belts and pulleys with GT2 belts and pulleys Wiki on GT2

Here are some pictures Update Pictures

Printed all day to get new X Carriage New Carriage and a spare set of Extruder plastic parts. No more mechanical problems; however I used the new Slic3r version 8.4 and tried the 'Support' feature. With Support On and the default settings the support was massive and the bottom hole for the bearing in the main extruder body was not full depth. I did a print with the 'Support' feature Off and got drooping strings on the bottom holes. See image 8. Maybe if I tweak the 'Support' settings I can get less support with an easy cleanup

John

1. 27 6-32 plain nuts, and 40 M3-0.5 plain nuts replaced with nylon insert lock-nuts. - No more loose screws

2. Added 16 tie-wraps (One per bearing on outside end) - No lifting bearings

3. New bed top plate (Model Aircraft 1/8" plywood) - Clips holding glass moved away from 'All-Home' position

4. New extruder plastic "Greg's Wade Reloaded Extruder" New Extruder from LutzBot Had to space the motor off by 3-mm from the plastic to get the gears to mesh ( 3 M4 nuts). Also the motor ran in the opposite direction to the old one.

5. Replaced MX belts and pulleys with GT2 belts and pulleys Wiki on GT2

Here are some pictures Update Pictures

Printed all day to get new X Carriage New Carriage and a spare set of Extruder plastic parts. No more mechanical problems; however I used the new Slic3r version 8.4 and tried the 'Support' feature. With Support On and the default settings the support was massive and the bottom hole for the bearing in the main extruder body was not full depth. I did a print with the 'Support' feature Off and got drooping strings on the bottom holes. See image 8. Maybe if I tweak the 'Support' settings I can get less support with an easy cleanup

John

|

Re: Is there any one here? July 16, 2012 10:02AM |

Registered: 12 years ago Posts: 27 |

On the spacing of the motor I have washers between my large pulley and the body to get where it fits. Fine tuning done on the motor shaft with the pulley.

Didn't have it quite right at first wore heaver on the one side of the gear for a bit. but could see it after a hour or so of printing and played with it some more.

I really need to reprint those gears now that I have it running better with the new wades and just a better set up.

Try tweaking your bridge speed first, I have mine set a 60mm/s and I get a couple of threads not make it all the way but very few. Second run usually is complete now.

Make yourself a test bridge piece to replicate the extruder body opening and try several settings.

Looking at RichRap sites he bridges pretty far without issues. I try to limit myself to the amount of extra plastic I use, so try to not do support structures when you can get away with it.

My son and a friend of his are Dr Who fans so worked on the Tardis , I followed the instruction that are further down on the same page of RichRap's blog. They turned out pretty good the top light was a bitch, the garage was close to 100 degF at the time. Had to use Repetier-host new real time speed bar to slow it way down so it would form the light on top.

Turned out ok although ran the code twice the second one was taller but done the next morning when the garage was cooler by oh 20 degrees F, might have made a difference not sure thought.

From looking at the pictures of the body, looks like you are getting extra plastic try double checking you filament dia. against what it is set in Slic3r.

My recent upgrades are a .35 nozzle form Lultzbot and now printing at .25 mm layer height.

Didn't have it quite right at first wore heaver on the one side of the gear for a bit. but could see it after a hour or so of printing and played with it some more.

I really need to reprint those gears now that I have it running better with the new wades and just a better set up.

Try tweaking your bridge speed first, I have mine set a 60mm/s and I get a couple of threads not make it all the way but very few. Second run usually is complete now.

Make yourself a test bridge piece to replicate the extruder body opening and try several settings.

Looking at RichRap sites he bridges pretty far without issues. I try to limit myself to the amount of extra plastic I use, so try to not do support structures when you can get away with it.

My son and a friend of his are Dr Who fans so worked on the Tardis , I followed the instruction that are further down on the same page of RichRap's blog. They turned out pretty good the top light was a bitch, the garage was close to 100 degF at the time. Had to use Repetier-host new real time speed bar to slow it way down so it would form the light on top.

Turned out ok although ran the code twice the second one was taller but done the next morning when the garage was cooler by oh 20 degrees F, might have made a difference not sure thought.

From looking at the pictures of the body, looks like you are getting extra plastic try double checking you filament dia. against what it is set in Slic3r.

My recent upgrades are a .35 nozzle form Lultzbot and now printing at .25 mm layer height.

|

Re: Is there any one here? July 16, 2012 09:47PM |

Registered: 12 years ago Posts: 53 |

Hi Glen,

On the motor spacing. I have a 1.3mm washer between the big wheel and the body to center the bolt hobbing. But with that in place I had to space the motor back 3mm from ins mounting surface to line up the little and big gears, and this with minimum clearance between the back of the small gear and the motor body.

My first print of the small gear came out with fuzzy teeth on one side. I think because the part was small the one layer had not hardened before the next layer was put down. I tried a second print at half speed using the Repetier-Host speed bar, but almost as bad. Then I made a third print, and after about ten layers, I turned on a desk fan to blow across the print surface, and got a good print.

I printed a 40-mm cube this morning and both X and Y were 39.85-mm. So I tweaked my Sprinter settings, and made a second cube. Y was 39.94-mm and X was 40.01-mm. I'll stick with those settings.

Checked my filament dia and that was good, but I had the extrusion multiplier set to 1.3. A leftover from a test on the old extruder. Set that back to 1 and tried another extruder body print. The ABS did not stick on the left hand end of the skirt print. Have to fiddle with getting my Z Zero working on all four corners of my bed. It was at least one layer high on the left side.

John

On the motor spacing. I have a 1.3mm washer between the big wheel and the body to center the bolt hobbing. But with that in place I had to space the motor back 3mm from ins mounting surface to line up the little and big gears, and this with minimum clearance between the back of the small gear and the motor body.

My first print of the small gear came out with fuzzy teeth on one side. I think because the part was small the one layer had not hardened before the next layer was put down. I tried a second print at half speed using the Repetier-Host speed bar, but almost as bad. Then I made a third print, and after about ten layers, I turned on a desk fan to blow across the print surface, and got a good print.

I printed a 40-mm cube this morning and both X and Y were 39.85-mm. So I tweaked my Sprinter settings, and made a second cube. Y was 39.94-mm and X was 40.01-mm. I'll stick with those settings.

Checked my filament dia and that was good, but I had the extrusion multiplier set to 1.3. A leftover from a test on the old extruder. Set that back to 1 and tried another extruder body print. The ABS did not stick on the left hand end of the skirt print. Have to fiddle with getting my Z Zero working on all four corners of my bed. It was at least one layer high on the left side.

John

|

Re: Is there any one here? July 16, 2012 10:14PM |

Registered: 12 years ago Posts: 27 |

I really need to try the ABS I have sitting in the corner.

I like PLA, but should see what else I can break.

Spent quite a bit of time leveling my table, I don't use the springs seemed too wobbly for me.

I have the plywood bolted directly to my bearings via zip ties was getting it as close to the the bearing as possible.

Had to notch the underside of the plywood to clear the rod holders so I could get full travel.

Then the PCB is bolted directly to that with a small space just enough for the clips to hold the glass on the PCB.

Was going for as much height as i can get out of the Z, I am close to 80 mm at a 195mm x 195mm working area.

I do have a 120mm fan siting at the back of the printer blowing across the table to help cool the parts as they are printed.

It is on a rheostat to slow it down if I can't get enough heat.

I like PLA, but should see what else I can break.

Spent quite a bit of time leveling my table, I don't use the springs seemed too wobbly for me.

I have the plywood bolted directly to my bearings via zip ties was getting it as close to the the bearing as possible.

Had to notch the underside of the plywood to clear the rod holders so I could get full travel.

Then the PCB is bolted directly to that with a small space just enough for the clips to hold the glass on the PCB.

Was going for as much height as i can get out of the Z, I am close to 80 mm at a 195mm x 195mm working area.

I do have a 120mm fan siting at the back of the printer blowing across the table to help cool the parts as they are printed.

It is on a rheostat to slow it down if I can't get enough heat.

|

Re: Is there any one here? July 17, 2012 10:43AM |

Registered: 12 years ago Posts: 53 |

I have only used ABS from the start, and I think it is harder to work with, and there are lots of little tricks to learn, like the right use of fans.

I have a 75-mm 12V fan sitting 50-mm off of the bench blowing up on the electronics board. Without it the FET running the bed gets too hot and shuts down the microcontroller after about two hours. With this fan in place the electronics will run all day.

Heat from the hot-end at 230 deg C softened the X Carriage and the base of my old extruder, so I added a 40-mm fan mounted on my X carriage blowing on the carriage top and the extruder base as part of my upgrade. It seems to keep the carriage and extruder base cool enough.

I had never tried using a fan blowing across the bed, until I had the problem with the small gear, but using it really solved the problem. Issue now is should I always use it after the first few layers? Not sure what problems that could cause.

Leveling the Bed Glass is another issue. One turn of a 6-32 screw is 0.79375-mm, so 1/3rd turn is one layer thick at 0.25-mm/layer. I think finer threaded screw are needed. I will look for some.

I was told to tweak your layer thickness so that it is an exact number of Z-axis motor steps. I'm using 28 TPI threaded rods so I ended up with 0.277-mm for a layer thickness in place of 0.25-mm as per the extruder parts build instructions.

I have a 75-mm 12V fan sitting 50-mm off of the bench blowing up on the electronics board. Without it the FET running the bed gets too hot and shuts down the microcontroller after about two hours. With this fan in place the electronics will run all day.

Heat from the hot-end at 230 deg C softened the X Carriage and the base of my old extruder, so I added a 40-mm fan mounted on my X carriage blowing on the carriage top and the extruder base as part of my upgrade. It seems to keep the carriage and extruder base cool enough.

I had never tried using a fan blowing across the bed, until I had the problem with the small gear, but using it really solved the problem. Issue now is should I always use it after the first few layers? Not sure what problems that could cause.

Leveling the Bed Glass is another issue. One turn of a 6-32 screw is 0.79375-mm, so 1/3rd turn is one layer thick at 0.25-mm/layer. I think finer threaded screw are needed. I will look for some.

I was told to tweak your layer thickness so that it is an exact number of Z-axis motor steps. I'm using 28 TPI threaded rods so I ended up with 0.277-mm for a layer thickness in place of 0.25-mm as per the extruder parts build instructions.

|

Re: Is there any one here? July 17, 2012 09:52PM |

Registered: 12 years ago Posts: 27 |

Had to rethink why I chose .25mm but I believe I am correct for my machine.

200 steps/rev * 16 = 3200 steps per rev.

I am using a 8 x 1.25 mm screw (looked better than the 5/16" all thread they had)

or 0.000390625mm per step

.25 / 0.000390625 = 640 so a even amount of steps goes into getting a .25 mm step height.

Or am I thinking wrong?

200 steps/rev * 16 = 3200 steps per rev.

I am using a 8 x 1.25 mm screw (looked better than the 5/16" all thread they had)

or 0.000390625mm per step

.25 / 0.000390625 = 640 so a even amount of steps goes into getting a .25 mm step height.

Or am I thinking wrong?

|

Re: Is there any one here? July 18, 2012 05:20AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you want to tune out any microstepping inaccuracy then you want to be a multiple of whole motor steps. I.e. 200 per rev.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Is there any one here? July 18, 2012 01:25PM |

Registered: 12 years ago Posts: 27 |

nophead thank you , I have read most of your blog. I really appreciate your hard work.

.25/.0063=40 So should be good, but you knew that already.

I haven't actually checked to see if the screws are a true 1.25 pitch but they appear to be correct I am getting decent results in the Z for my prints.

John

I did print with ABS last night. After a while the print looked pretty good. Took quite a while to get all of the PLA out of the nozzle.

I printed a funnel in the ABS, just grabbed one from Thingaverse and the first go around had a hard time getting it to stick. It also might have been because it was still extruding some PLA along with the ABS. I triple coated the glass with the titebond II at 8 to 1 then had to wait until the table got below 80c to get it off. The glass is very opaque now so maybe you need more coats of the PVA glue on your mirror.

.25/.0063=40 So should be good, but you knew that already.

I haven't actually checked to see if the screws are a true 1.25 pitch but they appear to be correct I am getting decent results in the Z for my prints.

John

I did print with ABS last night. After a while the print looked pretty good. Took quite a while to get all of the PLA out of the nozzle.

I printed a funnel in the ABS, just grabbed one from Thingaverse and the first go around had a hard time getting it to stick. It also might have been because it was still extruding some PLA along with the ABS. I triple coated the glass with the titebond II at 8 to 1 then had to wait until the table got below 80c to get it off. The glass is very opaque now so maybe you need more coats of the PVA glue on your mirror.

|

Re: Is there any one here? July 18, 2012 06:20PM |

Registered: 12 years ago Posts: 53 |

Taking advice from the maker of my frame plastic, I used SAE threaded rod and 8-mm smooth rod; however in my wisdom (?) I chose to use 28TPI 5/16" threaded rod. 28TPI = 0357142" = 0.9071406-mm per turn. Taking nophead's point about using an integer number of fullsteps rather than microsteps, for 0.25-mm layer height 55 fullsteps = 0.2494635-mm. Close enough for government work.

I'm using a nominal 0.25-mm layer height, because that is what Jonas Kuehling used to make the extruder parts I am working on.

Printing ABS on glass, for me, works great with the sugar-water solution. (One tablespoon sugar to one cup water). I use a flat 1" artists brush. and paint one coat over the print area when the bed gets to 200 deg C, and a second coat after the hot end has reached 230 deg C.

I get good first layer adhesion if the bed is level to better than one 12-mil (I use loose feeler gauges). You have to wait for the bed to cool, but the the part just lifts off. Clean up is real easy. Use the same brush wet and the residue just washes off.

John

I'm using a nominal 0.25-mm layer height, because that is what Jonas Kuehling used to make the extruder parts I am working on.

Printing ABS on glass, for me, works great with the sugar-water solution. (One tablespoon sugar to one cup water). I use a flat 1" artists brush. and paint one coat over the print area when the bed gets to 200 deg C, and a second coat after the hot end has reached 230 deg C.

I get good first layer adhesion if the bed is level to better than one 12-mil (I use loose feeler gauges). You have to wait for the bed to cool, but the the part just lifts off. Clean up is real easy. Use the same brush wet and the residue just washes off.

John

|

Re: Is there any one here? July 18, 2012 06:28PM |

Registered: 12 years ago Posts: 27 |

Yep i would call that close enough as well.

For some reason I was thinking you were using the PVA glue solution. When i look back you did say sugar.

I really like printing with the PLA better but thought it worth while trying the ABS. I had planned on making a new X carriage and ABS would seem better because it can take higher heat.

For some reason I was thinking you were using the PVA glue solution. When i look back you did say sugar.

I really like printing with the PLA better but thought it worth while trying the ABS. I had planned on making a new X carriage and ABS would seem better because it can take higher heat.

|

Re: Is there any one here? July 18, 2012 06:47PM |

Registered: 12 years ago Posts: 53 |

Take a look at this X Carriage Jonas's Carriage I have made one and it is sitting on the bench waiting to be installed. looks great!

|

Re: Is there any one here? July 19, 2012 11:17AM |

Registered: 12 years ago Posts: 53 |

New X Carriage installed.

Going to mount indicator for 'Bed Leveling', as per nophead, before installing extruder

Going to mount indicator for 'Bed Leveling', as per nophead, before installing extruder

|

Re: Is there any one here? July 19, 2012 01:37PM |

Registered: 12 years ago Posts: 27 |

Looks nice..

I was looking at richrap's quick change X carriage.

Edited 1 time(s). Last edit at 07/19/2012 01:38PM by gadman58.

I was looking at richrap's quick change X carriage.

Edited 1 time(s). Last edit at 07/19/2012 01:38PM by gadman58.

|

Re: Is there any one here? November 13, 2012 10:22AM |

Registered: 12 years ago Posts: 53 |

I have finally found a cure for my ABS Corner Curling problem Slic3r has added a feature called 'Brim' that kills the curling problem cold. There is a good write up of this feature at Brim

I have replaced my Z-axis SAE threaded shafts with metric (8-1.25mm) and these shafts, that are noticeably straighter, run much more smoother.

Had problems with a Hotend bought on Ebay from Poland. There was a bad crimp connection on the thermocouple connector, which after working great for three to four weeks caused overheating to the extend that the PTFE warped and allowed ABS leakage through the joints. I replaced the thermocouple connector with a MTA-100 IDC part and the Hotend maker is sending replacement PTFE parts.

I'm working on a new more rigid cube-like frame, but I'm about a month from finishing it

I have replaced my Z-axis SAE threaded shafts with metric (8-1.25mm) and these shafts, that are noticeably straighter, run much more smoother.

Had problems with a Hotend bought on Ebay from Poland. There was a bad crimp connection on the thermocouple connector, which after working great for three to four weeks caused overheating to the extend that the PTFE warped and allowed ABS leakage through the joints. I replaced the thermocouple connector with a MTA-100 IDC part and the Hotend maker is sending replacement PTFE parts.

I'm working on a new more rigid cube-like frame, but I'm about a month from finishing it

|

Re: Is there any one here? November 16, 2012 09:55AM |

Registered: 12 years ago Posts: 27 |

Between last month and this month I have been home 18 days. So have done nothing.

I had started work on a Rack and Pinion frame that I can print, but have done nothing since May on it.

I want to use the "cubed" heated pad which I think is 12" x 18" and get a full 10" in height. Just because.

I did get some ABS and now need to rebuilt my PLA X carriage it sagged pretty badly. Still prints but messed with table height.

I also got a harbor freight mini lathe (another project paid for it) and got all the way through making a nozzle for my LutzBot Budaschnozzle, except for the .35 mm hole.

Have to get better drills..

I had started work on a Rack and Pinion frame that I can print, but have done nothing since May on it.

I want to use the "cubed" heated pad which I think is 12" x 18" and get a full 10" in height. Just because.

I did get some ABS and now need to rebuilt my PLA X carriage it sagged pretty badly. Still prints but messed with table height.

I also got a harbor freight mini lathe (another project paid for it) and got all the way through making a nozzle for my LutzBot Budaschnozzle, except for the .35 mm hole.

Have to get better drills..

|

Re: Is there any one here? November 16, 2012 11:21AM |

Registered: 12 years ago Posts: 53 |

I have had great success using the 'Brim' feature of Slic3r to prevent corner curling. I was printing on an 8" square of frosted glass, but with the extra adhesion with a 'Brim' I was lifting flakes of of the glass surface when the part cooled to room temperature. I switched back to using the mirror that came free with my Bed Heater PCB but started to have the same problem. I'm now working on the back of the mirror and using very little ABS juice, and the parts are still coming out very flat with no sign of curling. I do not understand how the Brim does it, but it works.

I have had an eye on the Harbor Freight mill, and am hoping Father Christmas will OK it. My idea also was to be able to make Hotends. I have a lot of small drills but nothing under 0.6mm. I will look for some. They make some printed circuit drills that have a thick (3mm) body with a very short drill section at one end. I do not fancy working with 25mm long 0.3mm regular drill bits.

I have finished my cube like frame, and am working on the Z and Y motor mounts. Hoping to move my already updated X and Y assemblies to the new frame in a few weeks. The original idea for the cube frame was to be able to make a heated tent to stop curling by not letting the lower part of tall objects cool, while the upper part is still being printed. Now with Brim the tent idea seems unnecessary. However the cube assembly will allow me to get all three axis truly orthogonal.

I have had an eye on the Harbor Freight mill, and am hoping Father Christmas will OK it. My idea also was to be able to make Hotends. I have a lot of small drills but nothing under 0.6mm. I will look for some. They make some printed circuit drills that have a thick (3mm) body with a very short drill section at one end. I do not fancy working with 25mm long 0.3mm regular drill bits.

I have finished my cube like frame, and am working on the Z and Y motor mounts. Hoping to move my already updated X and Y assemblies to the new frame in a few weeks. The original idea for the cube frame was to be able to make a heated tent to stop curling by not letting the lower part of tall objects cool, while the upper part is still being printed. Now with Brim the tent idea seems unnecessary. However the cube assembly will allow me to get all three axis truly orthogonal.

Sorry, only registered users may post in this forum.