It's Alive! ...sort of

Posted by Lisa M

|

It's Alive! ...sort of August 16, 2012 06:56AM |

Registered: 11 years ago Posts: 116 |

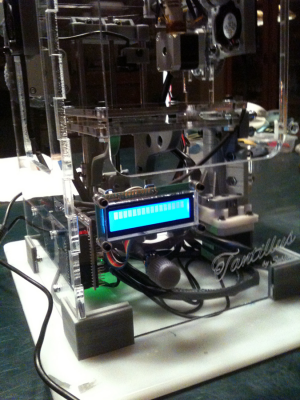

Just working through getting the firmware installed... but construction is complete ...I think.

I've got the computer to recognize the arduino board but it won't upload the Marlin Firmware. I keep getting this compile error:

core.a(main.cpp.o): In function `main':

C:\Documents and Settings\lmulzet\Desktop\3DPrintSoftware-Tantillus\arduino-0023\hardware\arduino\cores\arduino/main.cpp:7: undefined reference to `setup'

C:\Documents and Settings\lmulzet\Desktop\3DPrintSoftware-Tantillus\arduino-0023\hardware\arduino\cores\arduino/main.cpp:10: undefined reference to `loop'

Edited 1 time(s). Last edit at 08/16/2012 06:59AM by Lisa M.

I've got the computer to recognize the arduino board but it won't upload the Marlin Firmware. I keep getting this compile error:

core.a(main.cpp.o): In function `main':

C:\Documents and Settings\lmulzet\Desktop\3DPrintSoftware-Tantillus\arduino-0023\hardware\arduino\cores\arduino/main.cpp:7: undefined reference to `setup'

C:\Documents and Settings\lmulzet\Desktop\3DPrintSoftware-Tantillus\arduino-0023\hardware\arduino\cores\arduino/main.cpp:10: undefined reference to `loop'

Edited 1 time(s). Last edit at 08/16/2012 06:59AM by Lisa M.

|

Re: It's Alive! ...sort of August 16, 2012 11:48AM |

Registered: 12 years ago Posts: 195 |

Nice build!

It sounds like you haven't selected the right project file in the IDE. You should have loaded the file "Marlin.pde" in the Marlin subdirectory. That should open a bunch of tabs, the leftmost one being "Marlin". From there, select Tools->Board->Arduino Mega 2560, then click the build button. It should churn for a minute or so and then say "Done compiling" on the status line. Then choose the right COM port in Tools->Serial Port and click upload.

It sounds like you haven't selected the right project file in the IDE. You should have loaded the file "Marlin.pde" in the Marlin subdirectory. That should open a bunch of tabs, the leftmost one being "Marlin". From there, select Tools->Board->Arduino Mega 2560, then click the build button. It should churn for a minute or so and then say "Done compiling" on the status line. Then choose the right COM port in Tools->Serial Port and click upload.

|

Re: It's Alive! ...sort of August 16, 2012 08:00PM |

Registered: 11 years ago Posts: 116 |

|

Re: It's Alive! ...sort of August 16, 2012 11:14PM |

Registered: 11 years ago Posts: 116 |

Hmm... I was trying to line up the bed ...when I realized something is wrong with this picture. I can't get the upper bed close enough to the hot end. It won't go any higher.

Is the endstop bracket to big?

Is the z-axis top too thick?

Are the holes in the case that the z-axis assembly mounts to in the wrong place?

Is it something else?

I can't figure it out.

My assembly of the z-axis matches the one pictured on Sublime's site from what I can see.

So glad we are having the build day. Looks like I'll have to put this project on hold until I can get some "in person" help.

Edited 1 time(s). Last edit at 08/16/2012 11:15PM by Lisa M.

Is the endstop bracket to big?

Is the z-axis top too thick?

Are the holes in the case that the z-axis assembly mounts to in the wrong place?

Is it something else?

I can't figure it out.

My assembly of the z-axis matches the one pictured on Sublime's site from what I can see.

So glad we are having the build day. Looks like I'll have to put this project on hold until I can get some "in person" help.

Edited 1 time(s). Last edit at 08/16/2012 11:15PM by Lisa M.

|

Re: It's Alive! ...sort of August 17, 2012 12:39AM |

Registered: 11 years ago Posts: 116 |

|

Re: It's Alive! ...sort of August 17, 2012 11:23AM |

Registered: 12 years ago Posts: 195 |

I finished putting together my Z axis last night, and there doesn't seem to be as much room for adjustment with the #8-32 x 1" bolts as the pictures on the build guide show. Mine looks a lot like yours: with the plates separated as far as they will go, there's only a few mm between the inner nuts. I'll let Sublime chime in, but I suspect that we'll need a longer bolt for the bed corners.

Perhaps 1" bolts were fine before the design switched to using the shorter J-Head MkV.

Perhaps 1" bolts were fine before the design switched to using the shorter J-Head MkV.

|

Re: It's Alive! ...sort of August 17, 2012 11:54AM |

Registered: 13 years ago Posts: 2,947 |

You guys are both correct and someone else emailed me about it last night. I had all the #8 x 1" bolts as #8 x 1-1/4" at first and found them too long for the fans and to hold the extruder on so I changed them to the #8 x 1" which worked fine with the J-head mk-4b and then I upgraded all the machines to mk-5b which are shorter. I had tested the mk-5b but it was on a machine that had the original 1-1/4" bolts. This does mean that the bolts you have are a little to short to raise the bed up enough. I will be sending everyone the missing bolts along with the missing allen keys. But that will not happen until next week when I am back (7000 miles form home right now). For those of you in a hurry you could get some #8 x 1-1/4" bolts from the local hardware store (does not need to be allen head) and replace them with the ones I send you. I apologize for the mistake.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: It's Alive! ...sort of August 17, 2012 12:05PM |

Registered: 11 years ago Posts: 116 |

|

Re: It's Alive! ...sort of August 17, 2012 04:54PM |

Registered: 11 years ago Posts: 149 |

|

Re: It's Alive! ...sort of August 17, 2012 06:36PM |

Registered: 11 years ago Posts: 95 |

Yeeehaa!

Lisa - it looks like you and I are both on TEAM SILVER!!! (go team!)

I just finished my build - although I've yet to heat shrink my heat shrinks - any creative ideas on alternatives when I don't have a hair dryer or heat gun?

- and I'm going to go out and grab those longer bed bolts as well. - So I also won't need you to send me anything Brad.

I'd also like to say that you certainly put the RAD in Brad, Brad. Really impressive seeing the thinking that went into this while assembling. And also thanks for including the little things like the tape, and the mysterious extra nuts and washers

Once again, Yeeehaa!!

Lisa - it looks like you and I are both on TEAM SILVER!!! (go team!)

I just finished my build - although I've yet to heat shrink my heat shrinks - any creative ideas on alternatives when I don't have a hair dryer or heat gun?

- and I'm going to go out and grab those longer bed bolts as well. - So I also won't need you to send me anything Brad.

I'd also like to say that you certainly put the RAD in Brad, Brad. Really impressive seeing the thinking that went into this while assembling. And also thanks for including the little things like the tape, and the mysterious extra nuts and washers

Once again, Yeeehaa!!

|

Re: It's Alive! ...sort of August 17, 2012 07:32PM |

Registered: 11 years ago Posts: 116 |

I went to Canadian Tire and Home Depot but they don't have the bolts. If anyone finds them, please let me know. I'd love to finish this. I'm going to a local build day on Aug 30 so I'll probably get my bolts then if I can't find them sooner.

I've heard Pacific Fasteners in Burnaby might carry them but I won't have time until later next week to go check them out.

I agree with you ernchesto. It was an amazing process assembling this and realizing that a person actually thought up how all this goes together and designed it. It has been a great experience.

I've heard Pacific Fasteners in Burnaby might carry them but I won't have time until later next week to go check them out.

I agree with you ernchesto. It was an amazing process assembling this and realizing that a person actually thought up how all this goes together and designed it. It has been a great experience.

|

Re: It's Alive! ...sort of August 18, 2012 04:10AM |

Registered: 11 years ago Posts: 149 |

Lisa M Wrote:

-------------------------------------------------------

> I went to Canadian Tire and Home Depot but they

> don't have the bolts. If anyone finds them,

> please let me know. I'd love to finish this. I'm

> going to a local build day on Aug 30 so I'll

> probably get my bolts then if I can't find them

> sooner.

I can put some in the mail tomorrow, but being in San Diego I don't know that it's worth the wait.

The name of the screw, if you want to call around to your local fastener/hardware stores, is a ' #8-32 by 1.25 inch long socket head cap screw'. Instead of socket head cap screws you can also use pan head, button head, round head, fillister head... pretty much any screw with a flat bottomed head. As long as it's #8-32 by 1.25 inch long then you're fine. I'd imagine a 1.5 inch length would be okay too, if the 1.25 is difficult to find for some reason.

> I agree with you ernchesto. It was an amazing

> process assembling this and realizing that a

> person actually thought up how all this goes

> together and designed it. It has been a great

> experience.

I'm right there with the two of you, it's been a lot of fun doing this build and the thoughtfulness behind the design really shines as it's put together.

-------------------------------------------------------

> I went to Canadian Tire and Home Depot but they

> don't have the bolts. If anyone finds them,

> please let me know. I'd love to finish this. I'm

> going to a local build day on Aug 30 so I'll

> probably get my bolts then if I can't find them

> sooner.

I can put some in the mail tomorrow, but being in San Diego I don't know that it's worth the wait.

The name of the screw, if you want to call around to your local fastener/hardware stores, is a ' #8-32 by 1.25 inch long socket head cap screw'. Instead of socket head cap screws you can also use pan head, button head, round head, fillister head... pretty much any screw with a flat bottomed head. As long as it's #8-32 by 1.25 inch long then you're fine. I'd imagine a 1.5 inch length would be okay too, if the 1.25 is difficult to find for some reason.

> I agree with you ernchesto. It was an amazing

> process assembling this and realizing that a

> person actually thought up how all this goes

> together and designed it. It has been a great

> experience.

I'm right there with the two of you, it's been a lot of fun doing this build and the thoughtfulness behind the design really shines as it's put together.

|

Re: It's Alive! ...sort of August 18, 2012 08:47AM |

Registered: 13 years ago Posts: 2,947 |

Hey Lisa, you can get #8 machine screws from home depot and Canadian tire in the bubble packs on the wall that say any package 1.99 . Home depot also says they have 8-32 x 1-1/2 [www.homedepot.ca] and individual [www.homedepot.ca]

Thank you everyone for your compliments, I have tried my hardest to put myself in your shoes to make assembly as easy as possible. I obviously dropped the ball on these bolts and the missing Allen keys but if that's the extent of the problems I am very happy. I would to thank everyone assembling Tantillus's right now for the feed back and help to improve what I already have done.

Thank you everyone for your compliments, I have tried my hardest to put myself in your shoes to make assembly as easy as possible. I obviously dropped the ball on these bolts and the missing Allen keys but if that's the extent of the problems I am very happy. I would to thank everyone assembling Tantillus's right now for the feed back and help to improve what I already have done.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: It's Alive! ...sort of August 18, 2012 02:36PM |

Registered: 11 years ago Posts: 149 |

|

Re: It's Alive! ...sort of August 18, 2012 07:44PM |

Registered: 11 years ago Posts: 116 |

@Sublime

Home depot, nearest my house did not have them. The smallest they carried was 10-32

I'll wait for the build day.

I'm worried about the electronics in my build. I think the power connector is faulty or not connected properly. The motors and fans and heater worked once briefly. Prior to that I could only connect to the board and the LCD had a very limited display. When the fans, motors, and heater stopped working, I could no longer connect to the tantillus at all with Pronterface. I got gobbledygook in the right hand panel after a longer than normal attempt to connect. Rather than make anything worse I've decided to wait for Aug 30

List of parts needed

Allen Keys

8-32 1.25 bed bolts

Fan mounts

Xy ends

I also cracked the original glass plate. It was too snug between the bolt heads on the top bed in the X dimension.I went to a glass place and they mad me two more ...but the glass somehow isnt quite as thick as the original.

I'm worried the power issue has done something to the board. I don't know if you have spares power connectors or boards but if you do can you bring to build day? I'll pay for them if it's through my impatience or lack of knowledge that they may be damaged/fried.

Home depot, nearest my house did not have them. The smallest they carried was 10-32

I'll wait for the build day.

I'm worried about the electronics in my build. I think the power connector is faulty or not connected properly. The motors and fans and heater worked once briefly. Prior to that I could only connect to the board and the LCD had a very limited display. When the fans, motors, and heater stopped working, I could no longer connect to the tantillus at all with Pronterface. I got gobbledygook in the right hand panel after a longer than normal attempt to connect. Rather than make anything worse I've decided to wait for Aug 30

List of parts needed

Allen Keys

8-32 1.25 bed bolts

Fan mounts

Xy ends

I also cracked the original glass plate. It was too snug between the bolt heads on the top bed in the X dimension.I went to a glass place and they mad me two more ...but the glass somehow isnt quite as thick as the original.

I'm worried the power issue has done something to the board. I don't know if you have spares power connectors or boards but if you do can you bring to build day? I'll pay for them if it's through my impatience or lack of knowledge that they may be damaged/fried.

|

Re: It's Alive! ...sort of August 18, 2012 08:19PM |

Registered: 11 years ago Posts: 95 |

I just returned from the Home Depot on Terminal and they didn't have the allen-head units. I grabbed a pack of socket head ones that I'll file down and see how it goes. I don't think I'll be able to get the glass-locating capabilities of the cap-screws, however.

Brad, if you have a load of these, I'll retract my previous comment saying that I wouldn't need them. I'd like 4 if you wouldn't mind. I may be able to make the 22nd meeting, and could grab them then.

Thanks!

Brad, if you have a load of these, I'll retract my previous comment saying that I wouldn't need them. I'd like 4 if you wouldn't mind. I may be able to make the 22nd meeting, and could grab them then.

Thanks!

|

Re: It's Alive! ...sort of August 18, 2012 10:46PM |

Registered: 13 years ago Posts: 2,947 |

No problem. I may or may not make it back for the meeting on Wednesday.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: It's Alive! ...sort of August 18, 2012 10:47PM |

Registered: 13 years ago Posts: 2,947 |

Lisa M Wrote:

-------------------------------------------------------

> List of parts needed

> Allen Keys

> 8-32 1.25 bed bolts

> Fan mounts

> Xy ends

>

> I also cracked the original glass plate. It was

> too snug between the bolt heads on the top bed in

> the X dimension.I went to a glass place and they

> mad me two more ...but the glass somehow isnt

> quite as thick as the original.

>

> I'm worried the power issue has done something to

> the board. I don't know if you have spares power

> connectors or boards but if you do can you bring

> to build day? I'll pay for them if it's through

> my impatience or lack of knowledge that they may

> be damaged/fried.

No worries we will get it all fixed up for you.

-------------------------------------------------------

> List of parts needed

> Allen Keys

> 8-32 1.25 bed bolts

> Fan mounts

> Xy ends

>

> I also cracked the original glass plate. It was

> too snug between the bolt heads on the top bed in

> the X dimension.I went to a glass place and they

> mad me two more ...but the glass somehow isnt

> quite as thick as the original.

>

> I'm worried the power issue has done something to

> the board. I don't know if you have spares power

> connectors or boards but if you do can you bring

> to build day? I'll pay for them if it's through

> my impatience or lack of knowledge that they may

> be damaged/fried.

No worries we will get it all fixed up for you.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: It's Alive! ...sort of August 18, 2012 10:59PM |

Registered: 11 years ago Posts: 95 |

Sublime Wrote:

-------------------------------------------------------

> No problem. I may or may not make it back for the

> meeting on Wednesday.

Excellent. No big rush - I set it up with the 1.25" bolts - but questions have arisen!!

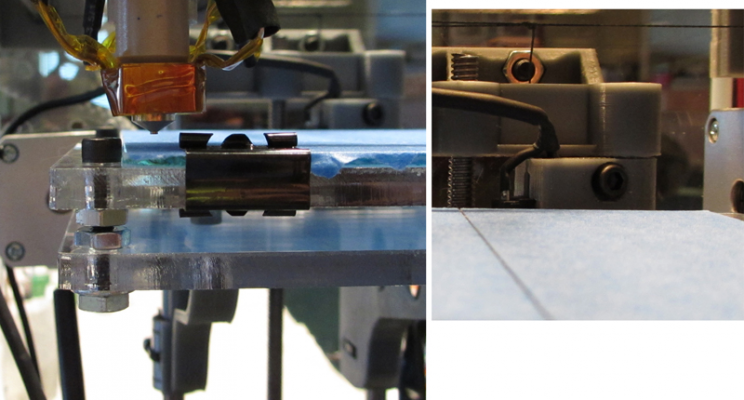

I'm still ~10mm off the bed when I bring it up as high as it will go. I moved the endstop up as high as I could without giving its' wires a hard time, but the motor refuses to push the bed up high enough to engage the switch. The motor shaft and the threaded rod are basically butted up against one another. (see attached image)

I'm still getting this terrible sound out of the motors when I do a move >1. The X is extra nasty where I can feel the motor trying to turn, but it's like it's created its own friction and working against itself. I just unplugged it when it seemed to freeze in position. I know that this is kinda mixing up threads on here because I mentioned this and learned of the pots as being a potential source of this... Not really sure what I can 'safely' do to configure...

All thoughts are ultra-welcome.

-------------------------------------------------------

> No problem. I may or may not make it back for the

> meeting on Wednesday.

Excellent. No big rush - I set it up with the 1.25" bolts - but questions have arisen!!

I'm still ~10mm off the bed when I bring it up as high as it will go. I moved the endstop up as high as I could without giving its' wires a hard time, but the motor refuses to push the bed up high enough to engage the switch. The motor shaft and the threaded rod are basically butted up against one another. (see attached image)

I'm still getting this terrible sound out of the motors when I do a move >1. The X is extra nasty where I can feel the motor trying to turn, but it's like it's created its own friction and working against itself. I just unplugged it when it seemed to freeze in position. I know that this is kinda mixing up threads on here because I mentioned this and learned of the pots as being a potential source of this... Not really sure what I can 'safely' do to configure...

All thoughts are ultra-welcome.

|

Re: It's Alive! ...sort of August 18, 2012 11:39PM |

Registered: 13 years ago Posts: 2,947 |

ernchesto Wrote:

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

> -----

> > No problem. I may or may not make it back for

> the

> > meeting on Wednesday.

>

> Excellent. No big rush - I set it up with the

> 1.25" bolts - but questions have arisen!!

>

> I'm still ~10mm off the bed when I bring it up as

> high as it will go. I moved the endstop up as high

> as I could without giving its' wires a hard time,

> but the motor refuses to push the bed up high

> enough to engage the switch. The motor shaft and

> the threaded rod are basically butted up against

> one another. (see attached image)

This is strange indeed. In this picture you will see the z-lift is off to the right side. This is where it wanted to be, not because I put it there on purpose. The bracket should float from side to side to allow the lead screw to self center. It also allows the sides to move in and out enough that they do not constrain the linear bearings.

>

> I'm still getting this terrible sound out of the

> motors when I do a move >1. The X is extra nasty

> where I can feel the motor trying to turn, but

> it's like it's created its own friction and

> working against itself. I just unplugged it when

> it seemed to freeze in position. I know that this

> is kinda mixing up threads on here because I

> mentioned this and learned of the pots as being a

> potential source of this... Not really sure what I

> can 'safely' do to configure...

See the other thread.

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

> -----

> > No problem. I may or may not make it back for

> the

> > meeting on Wednesday.

>

> Excellent. No big rush - I set it up with the

> 1.25" bolts - but questions have arisen!!

>

> I'm still ~10mm off the bed when I bring it up as

> high as it will go. I moved the endstop up as high

> as I could without giving its' wires a hard time,

> but the motor refuses to push the bed up high

> enough to engage the switch. The motor shaft and

> the threaded rod are basically butted up against

> one another. (see attached image)

This is strange indeed. In this picture you will see the z-lift is off to the right side. This is where it wanted to be, not because I put it there on purpose. The bracket should float from side to side to allow the lead screw to self center. It also allows the sides to move in and out enough that they do not constrain the linear bearings.

>

> I'm still getting this terrible sound out of the

> motors when I do a move >1. The X is extra nasty

> where I can feel the motor trying to turn, but

> it's like it's created its own friction and

> working against itself. I just unplugged it when

> it seemed to freeze in position. I know that this

> is kinda mixing up threads on here because I

> mentioned this and learned of the pots as being a

> potential source of this... Not really sure what I

> can 'safely' do to configure...

See the other thread.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: It's Alive! ...sort of August 19, 2012 12:07AM |

Registered: 11 years ago Posts: 95 |

Sublime Wrote:

-------------------------------------------------------

> ernchesto Wrote:

> --------------------------------------------------

> -----

> > Sublime Wrote:

> >

> --------------------------------------------------

>

> > -----

> > > No problem. I may or may not make it back for

> > the

> > > meeting on Wednesday.

> >

> > Excellent. No big rush - I set it up with the

> > 1.25" bolts - but questions have arisen!!

> >

> > I'm still ~10mm off the bed when I bring it up

> as

> > high as it will go. I moved the endstop up as

> high

> > as I could without giving its' wires a hard

> time,

> > but the motor refuses to push the bed up high

> > enough to engage the switch. The motor shaft

> and

> > the threaded rod are basically butted up

> against

> > one another. (see attached image)

>

> This is strange indeed. In this picture you will

> see the z-lift is off to the right side. This is

> where it wanted to be, not because I put it there

> on purpose. The bracket should float from side to

> side to allow the lead screw to self center. It

> also allows the sides to move in and out enough

> that they do not constrain the linear bearings.

>

I've managed to get the bed ~5mm from the extruder tip (by homing the Z - strange that it was able to travel further than I was able to nudge it. I'll keep the rod alignment in mind when I troubleshoot.

> >

> > I'm still getting this terrible sound out of

> the

> > motors when I do a move >1. The X is extra

> nasty

> > where I can feel the motor trying to turn, but

> > it's like it's created its own friction and

> > working against itself. I just unplugged it

> when

> > it seemed to freeze in position. I know that

> this

> > is kinda mixing up threads on here because I

> > mentioned this and learned of the pots as being

> a

> > potential source of this... Not really sure what

> I

> > can 'safely' do to configure...

>

> See the other thread.

Done, thanks!

-------------------------------------------------------

> ernchesto Wrote:

> --------------------------------------------------

> -----

> > Sublime Wrote:

> >

> --------------------------------------------------

>

> > -----

> > > No problem. I may or may not make it back for

> > the

> > > meeting on Wednesday.

> >

> > Excellent. No big rush - I set it up with the

> > 1.25" bolts - but questions have arisen!!

> >

> > I'm still ~10mm off the bed when I bring it up

> as

> > high as it will go. I moved the endstop up as

> high

> > as I could without giving its' wires a hard

> time,

> > but the motor refuses to push the bed up high

> > enough to engage the switch. The motor shaft

> and

> > the threaded rod are basically butted up

> against

> > one another. (see attached image)

>

> This is strange indeed. In this picture you will

> see the z-lift is off to the right side. This is

> where it wanted to be, not because I put it there

> on purpose. The bracket should float from side to

> side to allow the lead screw to self center. It

> also allows the sides to move in and out enough

> that they do not constrain the linear bearings.

>

I've managed to get the bed ~5mm from the extruder tip (by homing the Z - strange that it was able to travel further than I was able to nudge it. I'll keep the rod alignment in mind when I troubleshoot.

> >

> > I'm still getting this terrible sound out of

> the

> > motors when I do a move >1. The X is extra

> nasty

> > where I can feel the motor trying to turn, but

> > it's like it's created its own friction and

> > working against itself. I just unplugged it

> when

> > it seemed to freeze in position. I know that

> this

> > is kinda mixing up threads on here because I

> > mentioned this and learned of the pots as being

> a

> > potential source of this... Not really sure what

> I

> > can 'safely' do to configure...

>

> See the other thread.

Done, thanks!

Sorry, only registered users may post in this forum.