Z-Axis Layer Problem

Posted by Robots-Dreams

|

Z-Axis Layer Problem August 20, 2012 11:43AM |

Registered: 11 years ago Posts: 59 |

I'm running into a strange problem with layers along the z-axis.

If a part is relatively short - say under 30 mm tall, then the part surface is very smooth and the layers are almost indistinguishable. But, when I print a tall part, the taller the part the more distinguishable the layers become.

A good (or bad) example is this Bag Handle part:

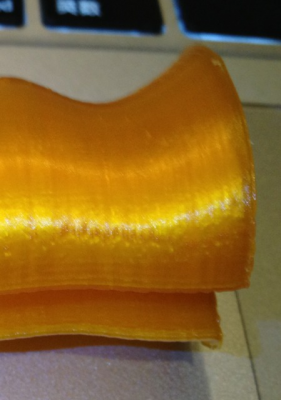

It's 82 mm tall. I laid it down to photograph with Z0 to the right of the part in the image and the top of the part to the left. The first 30 mm along the z-axis are quite smooth:

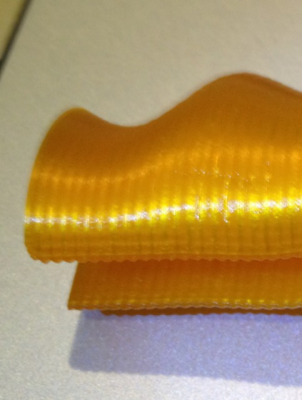

As you move up along the z-axis the layers become more and more pronounced. Near the very top of the part - say 70mm to 82 mm - they are so noticeable that they feel like teeth on a file:

This part was printed with 150 micron layers and sliced with Slic3r 0.7.2. I've examined the gcode in Replieter and can't find any differences that would account for this problem. I've run into the same problem with other tall parts that I've printed. So I'm wondering if it is a mechanical adjustment/alignment issue with my machine.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

If a part is relatively short - say under 30 mm tall, then the part surface is very smooth and the layers are almost indistinguishable. But, when I print a tall part, the taller the part the more distinguishable the layers become.

A good (or bad) example is this Bag Handle part:

It's 82 mm tall. I laid it down to photograph with Z0 to the right of the part in the image and the top of the part to the left. The first 30 mm along the z-axis are quite smooth:

As you move up along the z-axis the layers become more and more pronounced. Near the very top of the part - say 70mm to 82 mm - they are so noticeable that they feel like teeth on a file:

This part was printed with 150 micron layers and sliced with Slic3r 0.7.2. I've examined the gcode in Replieter and can't find any differences that would account for this problem. I've run into the same problem with other tall parts that I've printed. So I'm wondering if it is a mechanical adjustment/alignment issue with my machine.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

|

Re: Z-Axis Layer Problem August 20, 2012 01:03PM |

Admin Registered: 17 years ago Posts: 7,879 |

At a guess it's a bent Z lead screw causing more wobble as it the nut gets closer to the motor. What sort of machine and what sort of Z coupler are you using?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Z-Axis Layer Problem August 20, 2012 01:24PM |

Registered: 11 years ago Posts: 59 |

nophead Wrote:

-------------------------------------------------------

> At a guess it's a bent Z lead screw causing more

> wobble as it the nut gets closer to the motor.

> What sort of machine and what sort of Z coupler

> are you using?

Tantillus. It's a prototype unit, but essentially the same as those that are shipping now.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

-------------------------------------------------------

> At a guess it's a bent Z lead screw causing more

> wobble as it the nut gets closer to the motor.

> What sort of machine and what sort of Z coupler

> are you using?

Tantillus. It's a prototype unit, but essentially the same as those that are shipping now.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

|

Re: Z-Axis Layer Problem August 20, 2012 01:30PM |

Registered: 12 years ago Posts: 195 |

In another thread Sublime mentioned that the Z lift (the part with the leadscrew nut trap) is supposed to have some give between the Z arms, presumably to avoid constraining the leadscrew. The tendons on the lift (from the .stl) are 10x4mm, and the holes 10x4.75mm, so the fit is too tight to allow for the lateral movement. In fact, I had to x-acto the bottom of the holes to get the lift to fit at all.

|

Re: Z-Axis Layer Problem August 20, 2012 01:48PM |

Registered: 11 years ago Posts: 149 |

I think the idea behind the design is to constrain the Z-lift bracket tightly in the Z and Y directions, while providing loose constraint in the X direction. The loose X direction constraint compensates, to some degree, for a bent lead screw by allowing the bracket to move from side to side relative to the Z-arms, which are stationary in the X-direction. Ideally the Y direction would be loosely constrained as well, but this is difficult if not impossible to do without causing other problems or adding parts, at least from what I understand. So anyways I believe it's a good thing that the holes had to be exacto-d in the Z direction for a perfect fit.

|

Re: Z-Axis Layer Problem August 20, 2012 05:31PM |

Registered: 13 years ago Posts: 2,947 |

It is most likey caused by the item having a small base and it starts to get pushed around as it prints because of the drag you get when printing at low layer heights. To eliminate it you can add some support struts to hold the item more securely while printing and then remove them after. You could also try adding a wider base. One other thought is it possibly the glass moving from the drag of the low layer height.

Eric is correct the idea is to have the Z lift constrained in Y and Z while letting it move along X

Eric is correct the idea is to have the Z lift constrained in Y and Z while letting it move along X

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-Axis Layer Problem August 20, 2012 08:22PM |

Registered: 11 years ago Posts: 59 |

Sublime Wrote:

-------------------------------------------------------

> It is most likey caused by the item having a small

> base and it starts to get pushed around as it

> prints because of the drag you get when printing

> at low layer heights. To eliminate it you can add

> some support struts to hold the item more securely

> while printing and then remove them after. You

> could also try adding a wider base. One other

> thought is it possibly the glass moving from the

> drag of the low layer height.

Makes sense. Going back and examining all the parts I've printed over the past month or so, the effect is most pronounced on tall thin objects. For example, the cemetery statue really shows it, while on the Amazing Box pieces it's less noticeable. The Amazing Box parts are tall but only have thin walls so there is almost zero drag.

Do you think increasing the hotend temperature would lower the drag and improve the print? Printing at 150 microns seems to be the best trade-off between good surface finish and print time.

>Eric is correct the idea is to have the Z lift constrained in Y and Z while letting it move along X

This particular effect seems to be evenly distributed rather than being more visible along x.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

-------------------------------------------------------

> It is most likey caused by the item having a small

> base and it starts to get pushed around as it

> prints because of the drag you get when printing

> at low layer heights. To eliminate it you can add

> some support struts to hold the item more securely

> while printing and then remove them after. You

> could also try adding a wider base. One other

> thought is it possibly the glass moving from the

> drag of the low layer height.

Makes sense. Going back and examining all the parts I've printed over the past month or so, the effect is most pronounced on tall thin objects. For example, the cemetery statue really shows it, while on the Amazing Box pieces it's less noticeable. The Amazing Box parts are tall but only have thin walls so there is almost zero drag.

Do you think increasing the hotend temperature would lower the drag and improve the print? Printing at 150 microns seems to be the best trade-off between good surface finish and print time.

>Eric is correct the idea is to have the Z lift constrained in Y and Z while letting it move along X

This particular effect seems to be evenly distributed rather than being more visible along x.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

|

Re: Z-Axis Layer Problem August 20, 2012 09:13PM |

Registered: 13 years ago Posts: 2,947 |

Robots-Dreams Wrote:

-------------------------------------------------------

> Makes sense. Going back and examining all the

> parts I've printed over the past month or so, the

> effect is most pronounced on tall thin objects.

> For example, the cemetery statue really shows it,

> while on the Amazing Box pieces it's less

> noticeable. The Amazing Box parts are tall but

> only have thin walls so there is almost zero

> drag.

Yeah I found it the most noticeable on the Maker beam. You could see it get worse as the print got higher and some would even come off the bed as the force push and pulled it around near the top.

>

> Do you think increasing the hotend temperature

> would lower the drag and improve the print?

> Printing at 150 microns seems to be the best

> trade-off between good surface finish and print

> time.

Its hard to say, it should lower the viscosity but could also start to crystallize the plastic if you raise it too much. If you want a setting that will reduce I would say lower the print speed. But instead of lowering the whole prints speed just reduce it near the top by adding M220 S50 to the gcode file where it starts to show the problem. You could een lower it gradually with M220 S90 and then a M220 S80 and Then M220 S70 etc etc etc (S70 = 70% the speed of slic3rs set speed).

-------------------------------------------------------

> Makes sense. Going back and examining all the

> parts I've printed over the past month or so, the

> effect is most pronounced on tall thin objects.

> For example, the cemetery statue really shows it,

> while on the Amazing Box pieces it's less

> noticeable. The Amazing Box parts are tall but

> only have thin walls so there is almost zero

> drag.

Yeah I found it the most noticeable on the Maker beam. You could see it get worse as the print got higher and some would even come off the bed as the force push and pulled it around near the top.

>

> Do you think increasing the hotend temperature

> would lower the drag and improve the print?

> Printing at 150 microns seems to be the best

> trade-off between good surface finish and print

> time.

Its hard to say, it should lower the viscosity but could also start to crystallize the plastic if you raise it too much. If you want a setting that will reduce I would say lower the print speed. But instead of lowering the whole prints speed just reduce it near the top by adding M220 S50 to the gcode file where it starts to show the problem. You could een lower it gradually with M220 S90 and then a M220 S80 and Then M220 S70 etc etc etc (S70 = 70% the speed of slic3rs set speed).

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-Axis Layer Problem August 20, 2012 09:43PM |

Registered: 11 years ago Posts: 59 |

Sublime Wrote:

-------------------------------------------------------

> Yeah I found it the most noticeable on the Maker

> beam. You could see it get worse as the print got

> higher and some would even come off the bed as

> the force push and pulled it around near the top.

The Maker beam might be a good test/calibration part to experiment with for this. Which one of the maker beam STL files do you use?

Besides the obvious surface finish aspect, one of the reasons I'm quite interested in this is that I want to build a larger bed Tantillus. Most of the parts I design/print will fit within the 100x100x100 envelope, but there are exceptions, like smartphone/iPhone cases, and some robot frames. Some of them I could lay down to print, but a few will need to be printed upright.

> Its hard to say, it should lower the viscosity but

> could also start to crystallize the plastic if you

> raise it too much.

I've seen that on some parts, and backed off. Right now I'm printing consistently at 180 degrees with 150 micron layers without delamination issues.

> If you want a setting that will

> reduce I would say lower the print speed. But

> instead of lowering the whole prints speed just

> reduce it near the top by adding M220 S50 to the

> gcode file where it starts to show the problem.

> You could een lower it gradually with M220 S90

> and then a M220 S80 and Then M220 S70 etc etc etc

> (S70 = 70% the speed of slic3rs set speed).

Excellent!

Assuming that works, then I can write a simple post-processor that scans the gcode, finds the Z moves, and inserts speed commands based on the layer height.

Thanks!

Edited 2 time(s). Last edit at 08/21/2012 12:09AM by Robots-Dreams.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

-------------------------------------------------------

> Yeah I found it the most noticeable on the Maker

> beam. You could see it get worse as the print got

> higher and some would even come off the bed as

> the force push and pulled it around near the top.

The Maker beam might be a good test/calibration part to experiment with for this. Which one of the maker beam STL files do you use?

Besides the obvious surface finish aspect, one of the reasons I'm quite interested in this is that I want to build a larger bed Tantillus. Most of the parts I design/print will fit within the 100x100x100 envelope, but there are exceptions, like smartphone/iPhone cases, and some robot frames. Some of them I could lay down to print, but a few will need to be printed upright.

> Its hard to say, it should lower the viscosity but

> could also start to crystallize the plastic if you

> raise it too much.

I've seen that on some parts, and backed off. Right now I'm printing consistently at 180 degrees with 150 micron layers without delamination issues.

> If you want a setting that will

> reduce I would say lower the print speed. But

> instead of lowering the whole prints speed just

> reduce it near the top by adding M220 S50 to the

> gcode file where it starts to show the problem.

> You could een lower it gradually with M220 S90

> and then a M220 S80 and Then M220 S70 etc etc etc

> (S70 = 70% the speed of slic3rs set speed).

Excellent!

Assuming that works, then I can write a simple post-processor that scans the gcode, finds the Z moves, and inserts speed commands based on the layer height.

Thanks!

Edited 2 time(s). Last edit at 08/21/2012 12:09AM by Robots-Dreams.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

|

Re: Z-Axis Layer Problem August 22, 2012 02:11AM |

Registered: 13 years ago Posts: 2,947 |

Robots-Dreams Wrote:

-------------------------------------------------------

> The Maker beam might be a good test/calibration

> part to experiment with for this. Which one of the

> maker beam STL files do you use?

I use the 100 mm one from thingiverse.

> Besides the obvious surface finish aspect, one of

> the reasons I'm quite interested in this is that I

> want to build a larger bed Tantillus. Most of the

> parts I design/print will fit within the

> 100x100x100 envelope, but there are exceptions,

> like smartphone/iPhone cases, and some robot

> frames. Some of them I could lay down to print,

> but a few will need to be printed upright.

With the larger base it should not be and issue.

> Assuming that works, then I can write a simple

> post-processor that scans the gcode, finds the Z

> moves, and inserts speed commands based on the

> layer height.

If you do, it would nice if it automatically checked the base size vs. the height so it could be left on all the time.

-------------------------------------------------------

> The Maker beam might be a good test/calibration

> part to experiment with for this. Which one of the

> maker beam STL files do you use?

I use the 100 mm one from thingiverse.

> Besides the obvious surface finish aspect, one of

> the reasons I'm quite interested in this is that I

> want to build a larger bed Tantillus. Most of the

> parts I design/print will fit within the

> 100x100x100 envelope, but there are exceptions,

> like smartphone/iPhone cases, and some robot

> frames. Some of them I could lay down to print,

> but a few will need to be printed upright.

With the larger base it should not be and issue.

> Assuming that works, then I can write a simple

> post-processor that scans the gcode, finds the Z

> moves, and inserts speed commands based on the

> layer height.

If you do, it would nice if it automatically checked the base size vs. the height so it could be left on all the time.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.