Why I Love Tantillus

Posted by Robots-Dreams

Why I Love Tantillus  September 11, 2012 12:06PM |

Registered: 11 years ago Posts: 59 |

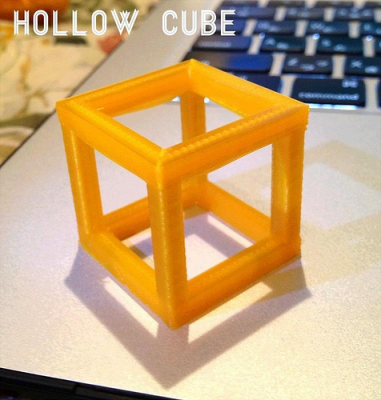

Printed with 150 micron layers in PLA with 100% infill and absolutely no support:

The cube is 30mm x 30mm x 30mm. The STL file is here: http://www.thingiverse.com/thing:30171

It took some fine tuning, but was well worth the time and effort.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

The cube is 30mm x 30mm x 30mm. The STL file is here: http://www.thingiverse.com/thing:30171

It took some fine tuning, but was well worth the time and effort.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

Re: Why I Love Tantillus  September 11, 2012 12:15PM |

Registered: 11 years ago Posts: 95 |

Re: Why I Love Tantillus  September 12, 2012 12:45AM |

Registered: 11 years ago Posts: 59 |

Here's some video footage of the print:

https://www.youtube.com/watch?v=YJPYtoZHp9Q

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

https://www.youtube.com/watch?v=YJPYtoZHp9Q

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

Re: Why I Love Tantillus  September 12, 2012 03:56AM |

Registered: 11 years ago Posts: 111 |

Re: Why I Love Tantillus  September 12, 2012 11:58AM |

Registered: 11 years ago Posts: 149 |

Re: Why I Love Tantillus  September 13, 2012 02:46PM |

Registered: 11 years ago Posts: 95 |

Being inspired by this, I went and made and printed a hollow box myself. I was doing it as a bit of a small test piece after re-tightening and loc-tite-ing the hobbed bolt nut.

I'm impressed with the results I got, but you've set the bar pretty friggin' high Lem!

I'm wondering if anyone can tell me a good means of reducing the 'strings' that occur when the head jumps across gaps (see images). I had set the print to standard>fine, 150micron steps, 100%infill.

To refine my question I guess, would it be increasing the speed setting for Bridges (mm/s) from 25 - up to, say, 200? Or would it be increasing the "Other speed settings">Travel (mm/s) from 150 up to 11 000 000? Or is this more a flow rate/temperature thing?

I'm just trying to save plastic here

I'm impressed with the results I got, but you've set the bar pretty friggin' high Lem!

I'm wondering if anyone can tell me a good means of reducing the 'strings' that occur when the head jumps across gaps (see images). I had set the print to standard>fine, 150micron steps, 100%infill.

To refine my question I guess, would it be increasing the speed setting for Bridges (mm/s) from 25 - up to, say, 200? Or would it be increasing the "Other speed settings">Travel (mm/s) from 150 up to 11 000 000? Or is this more a flow rate/temperature thing?

I'm just trying to save plastic here

Re: Why I Love Tantillus  September 13, 2012 02:56PM |

Registered: 13 years ago Posts: 2,947 |

Have you followed the retraction calibration yet? [www.tantillus.org]

The next thing would be to reduce the temperature so the plastic is not as liquid. The default is 190c and depending on the plastic it can be as low as 160c. To test you can print a cube or similar object over and over and each time reduce the temperature 5c. At a certain point the extruder will stop working and the motor will skip steps. Or you will start to notice that the layers do not adhere to themselves correctly and you can peel them apart. When you find either failing point you can increase the temperature 10c and you should be good for most prints at the current speed.

The max speed for all moves is currently limited to 150mm/s by the firmware so if you do want to increase the travel speed you would have to increase the limit in the firmware. But this will increase the chance of a skipped step which is why I have it limited. I wanted to be sure the machine printed reliably.

The next thing would be to reduce the temperature so the plastic is not as liquid. The default is 190c and depending on the plastic it can be as low as 160c. To test you can print a cube or similar object over and over and each time reduce the temperature 5c. At a certain point the extruder will stop working and the motor will skip steps. Or you will start to notice that the layers do not adhere to themselves correctly and you can peel them apart. When you find either failing point you can increase the temperature 10c and you should be good for most prints at the current speed.

The max speed for all moves is currently limited to 150mm/s by the firmware so if you do want to increase the travel speed you would have to increase the limit in the firmware. But this will increase the chance of a skipped step which is why I have it limited. I wanted to be sure the machine printed reliably.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Re: Why I Love Tantillus  September 13, 2012 03:09PM |

Registered: 11 years ago Posts: 95 |

Sorry, only registered users may post in this forum.