Taulman nylon

Posted by Eric Young

|

Taulman nylon December 13, 2012 03:06AM |

Registered: 11 years ago Posts: 149 |

Has anyone tried printing the Taulman Nylon 618 filament with a Tantillus yet? I really want to give it a go.

[taulman3d.com]

Sublime do you have any thoughts about this - namely is it a bad idea for any reason you can think of? Melt temp is around 240-250 Celsius, I guess retraction has to be changed a bit compared to ABS, ilder tension needs adjustment. Other than those things it sounds like all else is the same from the FAQ section.

[taulman3d.com]

Sublime do you have any thoughts about this - namely is it a bad idea for any reason you can think of? Melt temp is around 240-250 Celsius, I guess retraction has to be changed a bit compared to ABS, ilder tension needs adjustment. Other than those things it sounds like all else is the same from the FAQ section.

|

Re: Taulman nylon December 13, 2012 05:11PM |

Registered: 11 years ago Posts: 112 |

|

Re: Taulman nylon December 13, 2012 05:52PM |

Registered: 13 years ago Posts: 2,947 |

I was thinking about trying some as well. Maybe search to see if anyone has used it with a J-head yet. Also if your carriage is PLA I would highly suggest getting a 25mm fan to attach to the thermal barrier of the J-head so the carriage can not go above the glass transition temperature of the carriage at those temperatures. You may even find you need to disable the fans so adding the 25mm fan would be a good idea for an ABS carriage as well.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Taulman nylon December 14, 2012 02:10AM |

Registered: 11 years ago Posts: 111 |

|

Re: Taulman nylon December 27, 2012 04:13PM |

Registered: 11 years ago Posts: 149 |

Thanks for the input on this everyone. I've yet to try the nylon and probably won't get around to it any time soon as I don't want to mess with my machine, but this last week I've been printing a number of parts with the white Impact Modified PLA or IMPLA from Diamond Age (I bought mine from Printbl.com - the US distributor) and it seems to have some unique properties that I've tried to describe below:

1. The biggest plus for me is that the layer adhesion seems superior to normal PLA, which has proven really useful for thin walled areas that are subject to stress/strain.

2. It's less brittle than normal PLA, so it could be good for certain mechanical features like 'live hinges', deformable snaps, or any other feature that requires the plastic to bend more than normal PLA would allow before fracturing.

3. It does seem to undergo plastic deformation more easily than normal PLA, so basically it won't bend back into it's original shape if it's deformed too much.

And here's a little info on my Tantillus settings for the IMPLA:

1. Seems to print best with a lower temp - I'm currently using a temperature of 190 on the first layer and 180 on the rest of the print. Ambient temp has been about 55-70 F recently.

2. Idler tension should be adjusted so it's not quite as tight - on mine the ends of each screw are flush with the flat surface of the nuts.

3. Flow rate I've been using is 364.

I'd definitely recommend the IMPLA plastic if you want/like the properties I described above.

I also bought a spool of the Diamond Age High Impact PLA or HIPLA (the black one), but it seems to have some layer adhesion issues (At temps from 180 up to 200 - I didn't adjust any other variables besides temp and flow) and I would not recommend it unless you want to futz around with it and see if you can get it to perform better. They even say on the website that it's an experimental filament, and recommend it be printed at 5 deg C higher temp and thin layers.

Edited 2 time(s). Last edit at 12/27/2012 04:27PM by Eric Young.

1. The biggest plus for me is that the layer adhesion seems superior to normal PLA, which has proven really useful for thin walled areas that are subject to stress/strain.

2. It's less brittle than normal PLA, so it could be good for certain mechanical features like 'live hinges', deformable snaps, or any other feature that requires the plastic to bend more than normal PLA would allow before fracturing.

3. It does seem to undergo plastic deformation more easily than normal PLA, so basically it won't bend back into it's original shape if it's deformed too much.

And here's a little info on my Tantillus settings for the IMPLA:

1. Seems to print best with a lower temp - I'm currently using a temperature of 190 on the first layer and 180 on the rest of the print. Ambient temp has been about 55-70 F recently.

2. Idler tension should be adjusted so it's not quite as tight - on mine the ends of each screw are flush with the flat surface of the nuts.

3. Flow rate I've been using is 364.

I'd definitely recommend the IMPLA plastic if you want/like the properties I described above.

I also bought a spool of the Diamond Age High Impact PLA or HIPLA (the black one), but it seems to have some layer adhesion issues (At temps from 180 up to 200 - I didn't adjust any other variables besides temp and flow) and I would not recommend it unless you want to futz around with it and see if you can get it to perform better. They even say on the website that it's an experimental filament, and recommend it be printed at 5 deg C higher temp and thin layers.

Edited 2 time(s). Last edit at 12/27/2012 04:27PM by Eric Young.

|

Re: Taulman nylon January 06, 2013 10:39PM |

Registered: 11 years ago Posts: 112 |

|

Re: Taulman nylon January 29, 2013 05:06PM |

Registered: 13 years ago Posts: 818 |

I'm printing with Taulman 618 Nylon on Tantillus, it doing really well with the first few prints I have tried.

I'm printing in exactly the same way as PLA - onto Blue 3M tape, I am getting a little lift with things about 40mm+ wide in size so other tapes could do better.

Makealot suggested using Tufnol as the ideal print surface for Nylon, I'm waiting for some to arrive to try that out.

I have used exactly the same settings as PLA, (even the same print speeds) just changed the first layer to be 240 Degrees and all other layers at 235. The layer bonding is amazing, and the finish is even better than ABS, looks many times cleaner than PLA.

I'm using a J-head MKV and 1.75mm Nylon filament, 40mm fan just cooling the PEEK and no other fans onto the build area.

If anything it could do with a tiny little more retraction than PLA, I'm going to increase that by 0.5mm next time.

I'll upload some photos as soon as I get a chance.

[richrap.blogspot.com]

I'm printing in exactly the same way as PLA - onto Blue 3M tape, I am getting a little lift with things about 40mm+ wide in size so other tapes could do better.

Makealot suggested using Tufnol as the ideal print surface for Nylon, I'm waiting for some to arrive to try that out.

I have used exactly the same settings as PLA, (even the same print speeds) just changed the first layer to be 240 Degrees and all other layers at 235. The layer bonding is amazing, and the finish is even better than ABS, looks many times cleaner than PLA.

I'm using a J-head MKV and 1.75mm Nylon filament, 40mm fan just cooling the PEEK and no other fans onto the build area.

If anything it could do with a tiny little more retraction than PLA, I'm going to increase that by 0.5mm next time.

I'll upload some photos as soon as I get a chance.

[richrap.blogspot.com]

|

Re: Taulman nylon January 30, 2013 05:22AM |

Registered: 13 years ago Posts: 818 |

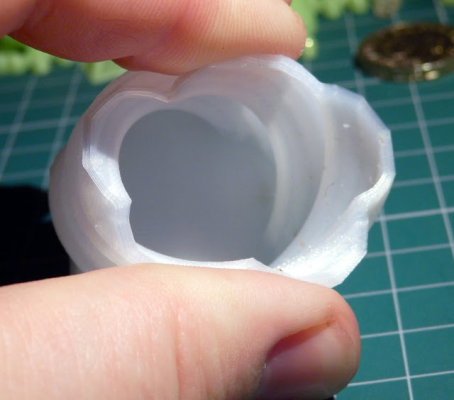

Taulman 618 Nylon first print on Tantillus -

Even with a very thick wall (this is 4 perimeters and about 1.8mm thick) it squashes and feels very strong indeed.

Layer bonding is stunning even at lower temperatures ~220 degrees C

It feels like you could hit the parts with a hammer and they would just bounce it off. - Maybe I'll try that

[richrap.blogspot.com]

Even with a very thick wall (this is 4 perimeters and about 1.8mm thick) it squashes and feels very strong indeed.

Layer bonding is stunning even at lower temperatures ~220 degrees C

It feels like you could hit the parts with a hammer and they would just bounce it off. - Maybe I'll try that

[richrap.blogspot.com]

|

Re: Taulman nylon January 30, 2013 04:55PM |

Registered: 11 years ago Posts: 149 |

|

Re: Taulman nylon January 31, 2013 02:10PM |

Registered: 11 years ago Posts: 10 |

Sublime Wrote:

-------------------------------------------------------

> Maybe

> search to see if anyone has used it with a J-head

> yet.

I have.

3mm Taulman with a Jhead MK IV 0.35mm @ 245C @ 30mm/s and 0.2mm layers.

It worked great!!! Except for the warp.

=)

As Richrap indicated, the layer bonding is amazing. I can twist and bend the part as much as I like and it sticks together.

The finishing is also great.

-------------------------------------------------------

> Maybe

> search to see if anyone has used it with a J-head

> yet.

I have.

3mm Taulman with a Jhead MK IV 0.35mm @ 245C @ 30mm/s and 0.2mm layers.

It worked great!!! Except for the warp.

=)

As Richrap indicated, the layer bonding is amazing. I can twist and bend the part as much as I like and it sticks together.

The finishing is also great.

Sorry, only registered users may post in this forum.