Tantillus sized h-bot

Posted by oz9ny

|

Tantillus sized h-bot February 19, 2013 09:03AM |

Registered: 11 years ago Posts: 25 |

Hi

I gave up fiddling with the fishing line setup on my Tantillus sized 3D-printer :-) OK, it worked but I wasn't really happy with it.

About the same time I learned about the Tantillus I saw some experiments with a H-Bot setup using fishing line but again I don't like fishing line.

After having tried several other designs (Huxley, Wallace, Huxley-sized Mendel90). Printed, build and discarded again of many reasons I went back to the Tantillus case and decided to implement the H-Bot movement.

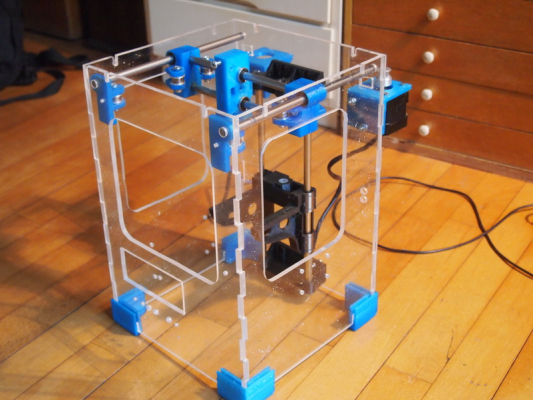

Attached a photo of my first implementation. The printed parts is taken from the Doboz-2 (http://www.thingiverse.com/thing:27202). The bearings is sized down from LM8UU to LM6UU.

A short video of one of the first tests can be seen here [www.youtube.com]

The next step will be a little redesign of the moving parts. They have a few weak points. The two steppers will also be moved to the back of tke printer so the printhead can come closer to the Z-axis. The extruder, controller and powersupply will also be mounted on the backplate.

The belt I use is a t2.5 split in half because I only could find six of the small bearings.

Have fun

Niels

I gave up fiddling with the fishing line setup on my Tantillus sized 3D-printer :-) OK, it worked but I wasn't really happy with it.

About the same time I learned about the Tantillus I saw some experiments with a H-Bot setup using fishing line but again I don't like fishing line.

After having tried several other designs (Huxley, Wallace, Huxley-sized Mendel90). Printed, build and discarded again of many reasons I went back to the Tantillus case and decided to implement the H-Bot movement.

Attached a photo of my first implementation. The printed parts is taken from the Doboz-2 (http://www.thingiverse.com/thing:27202). The bearings is sized down from LM8UU to LM6UU.

A short video of one of the first tests can be seen here [www.youtube.com]

The next step will be a little redesign of the moving parts. They have a few weak points. The two steppers will also be moved to the back of tke printer so the printhead can come closer to the Z-axis. The extruder, controller and powersupply will also be mounted on the backplate.

The belt I use is a t2.5 split in half because I only could find six of the small bearings.

Have fun

Niels

|

Re: Tantillus sized h-bot February 19, 2013 12:56PM |

Registered: 13 years ago Posts: 2,947 |

Looks good. How much movement do you get in X and Y?

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus sized h-bot February 19, 2013 02:29PM |

Registered: 11 years ago Posts: 25 |

Well, my box is a little larger than the original Tantillus so I expect a build area of 150mm*150mm after having redesigned the y-bearings.

Inside X=250mm*Y=225, intention was to have a square box, but measure once and cut twice :-)

X-axis is 150mm after the motors is moved to the backside of the box and the bearings opposite to the motors is moved a little closer to the front. There was no need for large tension adjustment of the belt.

A H-bot design with a build area of 100mm*100mm can easily be designed to fit into the original Tantillus box or scaled up to the TantillusPlus or even a TantillusPlusPlus!

A job for someone with greater skills using Blender or OpenScad than I have.

Have fun

Niels

Inside X=250mm*Y=225, intention was to have a square box, but measure once and cut twice :-)

X-axis is 150mm after the motors is moved to the backside of the box and the bearings opposite to the motors is moved a little closer to the front. There was no need for large tension adjustment of the belt.

A H-bot design with a build area of 100mm*100mm can easily be designed to fit into the original Tantillus box or scaled up to the TantillusPlus or even a TantillusPlusPlus!

A job for someone with greater skills using Blender or OpenScad than I have.

Have fun

Niels

|

Re: Tantillus sized h-bot February 26, 2013 09:36AM |

Registered: 11 years ago Posts: 25 |

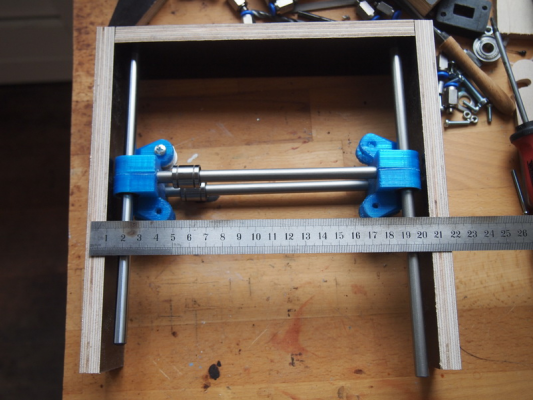

More proof of concept!

I have spent some hours with Sketchup designing the Tantillus H-Bot.

The greatest problem was getting enough travel in the Y-direction. In X-direction there is lots of space because I have the steppers placed on the backside of the box. The bearings for the hot-end mount is LM8SUU, but LM8UU can be used too. Perspective in the photo is a little misleading, distance between the bearing holders is 122mm. Nema-14 steppers can give about 7mm in Y-direction.

The platform for the hot-end is being printed on the old printer when I write this.

Next to be redesigned is the corners and the panels. I had to be sure everything fits before cutting the panels because I don't have access to a laser-cutter so cutting the panels is done with a scrollsaw :-)

Have fun

Niels

I have spent some hours with Sketchup designing the Tantillus H-Bot.

The greatest problem was getting enough travel in the Y-direction. In X-direction there is lots of space because I have the steppers placed on the backside of the box. The bearings for the hot-end mount is LM8SUU, but LM8UU can be used too. Perspective in the photo is a little misleading, distance between the bearing holders is 122mm. Nema-14 steppers can give about 7mm in Y-direction.

The platform for the hot-end is being printed on the old printer when I write this.

Next to be redesigned is the corners and the panels. I had to be sure everything fits before cutting the panels because I don't have access to a laser-cutter so cutting the panels is done with a scrollsaw :-)

Have fun

Niels

|

Re: Tantillus sized h-bot March 08, 2013 11:27AM |

Registered: 11 years ago Posts: 25 |

]The four panels done using a drillpress, small tablesaw and a scrollsaw. Material is 5mm plexiglass.

Next week i'll make the upper corners and assemble the whole machine.

Next week i'll make the upper corners and assemble the whole machine.

|

Re: Tantillus sized h-bot March 08, 2013 12:41PM |

Registered: 11 years ago Posts: 78 |

|

Re: Tantillus sized h-bot March 08, 2013 12:58PM |

Registered: 13 years ago Posts: 2,947 |

Sorry, only registered users may post in this forum.