Printing 50 Micron or Smaller Layers

Posted by Robots-Dreams

|

Printing 50 Micron or Smaller Layers February 20, 2013 06:34AM |

Registered: 11 years ago Posts: 59 |

I've had pretty good luck printing down to 50 microns and am tempted to go even lower.

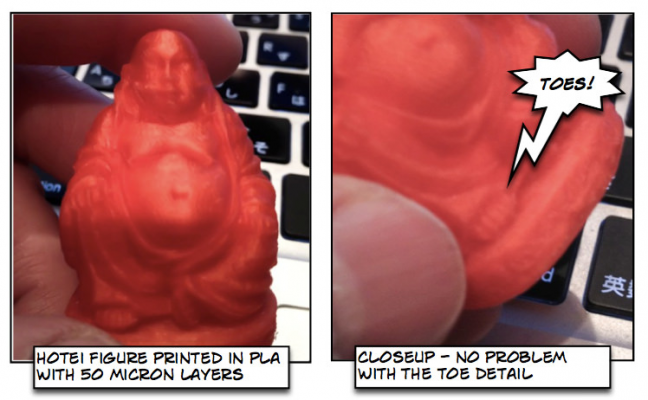

This Hotei figure was printed with 50 micron layers at 190 degrees:

It looks much better in person than in the photo because I couldn't get the camera to pickup all the detail. The detail in the toes and embossed surface patterns is great - much better than I expected. The plastic surface does a bit granulated - perhaps due to water content boiling. This was PLA filament that I purchased last autumn from Repraper, so it's been sitting around for quite a while. Decreasing the temperature doesn't seem to help. I have some new filament from Diamond Age in New Zealand that I will try next.

Strange thing is that I used the default M106/M107 fan codes right out of Kisslicer without replacing them. If I change the fan codes to the recommended settings, then the print looks very bad with protrusions/crystallization.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

This Hotei figure was printed with 50 micron layers at 190 degrees:

It looks much better in person than in the photo because I couldn't get the camera to pickup all the detail. The detail in the toes and embossed surface patterns is great - much better than I expected. The plastic surface does a bit granulated - perhaps due to water content boiling. This was PLA filament that I purchased last autumn from Repraper, so it's been sitting around for quite a while. Decreasing the temperature doesn't seem to help. I have some new filament from Diamond Age in New Zealand that I will try next.

Strange thing is that I used the default M106/M107 fan codes right out of Kisslicer without replacing them. If I change the fan codes to the recommended settings, then the print looks very bad with protrusions/crystallization.

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

|

Re: Printing 50 Micron or Smaller Layers February 20, 2013 12:56PM |

Registered: 13 years ago Posts: 2,947 |

looks really good.

I have updated the instructions and default Kisslicer profiles on Tantillus.org if you would like to try out the newest profiles for Kisslicer 1.1.0 Beta.

For layers below 100 micron I may have a few tips you can try.

1) Increase the speed because we need to keep the extrusion rate up.

2) Play with the fan speeds as you found

3) Play with the temperature. The effect you saw with the crystallisation is usually a sign it has been over heated or sat in the heat for too long and you may need to go way down as low as 155c. I find when making a large drop in temp I may need to purge the filament while lowering the temp to make sure the molten plastic does no harden higher up in the extruder if it had been on for a while already.

4) Some models print better a low layers. Start with a cube and see how low you can go before trying complex models with thousands of faces.

I have updated the instructions and default Kisslicer profiles on Tantillus.org if you would like to try out the newest profiles for Kisslicer 1.1.0 Beta.

For layers below 100 micron I may have a few tips you can try.

1) Increase the speed because we need to keep the extrusion rate up.

2) Play with the fan speeds as you found

3) Play with the temperature. The effect you saw with the crystallisation is usually a sign it has been over heated or sat in the heat for too long and you may need to go way down as low as 155c. I find when making a large drop in temp I may need to purge the filament while lowering the temp to make sure the molten plastic does no harden higher up in the extruder if it had been on for a while already.

4) Some models print better a low layers. Start with a cube and see how low you can go before trying complex models with thousands of faces.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Printing 50 Micron or Smaller Layers February 21, 2013 12:46AM |

Registered: 11 years ago Posts: 59 |

Thanks! That's really helpful.

I haven't tried the latest Beta yet - probably because of my frustrating experiences with Slic3r. I'll give it a try over the weekend.

Here's a macro shot of the figure with extreme flash to bring out the detail:

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

I haven't tried the latest Beta yet - probably because of my frustrating experiences with Slic3r. I'll give it a try over the weekend.

Here's a macro shot of the figure with extreme flash to bring out the detail:

----------------

Lem Fugitt

3D Printing Dreams

Robots Dreams

"The map is not the territory."

|

Re: Printing 50 Micron or Smaller Layers February 25, 2013 04:34AM |

Registered: 11 years ago Posts: 111 |

OH SWEET 50µm layers! If you do get a generic KISSLICER config for this please do share. The Diamond Age filament is really good as well, I went round and had a chat to Vik, who owns the place and he had about 8 repraps setup, so he definitely knows his stuff.

Have you got the model for this, I might give it a go once I clear the queue of parts I have to do. Only thing is I seem to be getting about a 30µm error in layer thickness with my current setup (overall height of parts however I always seem to be off by 50µm), but at least giving this a go will force me to fix it.

Have you got the model for this, I might give it a go once I clear the queue of parts I have to do. Only thing is I seem to be getting about a 30µm error in layer thickness with my current setup (overall height of parts however I always seem to be off by 50µm), but at least giving this a go will force me to fix it.

|

Re: Printing 50 Micron or Smaller Layers February 25, 2013 01:29PM |

Registered: 13 years ago Posts: 2,947 |

willworkforplastic Wrote:

-------------------------------------------------------

> OH SWEET 50µm layers! If you do get a generic

> KISSLICER config for this please do share.

The reason I have not released a generic config for layers below 50um is because I always found it was a per model situation. But with that said I only tried with Slic3r to create the config and Kisslicer may be easier to create one that works in more situations.

> Only thing is I seem to be getting about a 30µm

> error in layer thickness with my current setup

> (overall height of parts however I always seem to

> be off by 50µm), but at least giving this a go

> will force me to fix it.

I would check for rounding errors with your layer height verse steps per mm. Then check for friction. Then check if you glass is lifting at the back. Then check if the hotend is moving up and down a little.

-------------------------------------------------------

> OH SWEET 50µm layers! If you do get a generic

> KISSLICER config for this please do share.

The reason I have not released a generic config for layers below 50um is because I always found it was a per model situation. But with that said I only tried with Slic3r to create the config and Kisslicer may be easier to create one that works in more situations.

> Only thing is I seem to be getting about a 30µm

> error in layer thickness with my current setup

> (overall height of parts however I always seem to

> be off by 50µm), but at least giving this a go

> will force me to fix it.

I would check for rounding errors with your layer height verse steps per mm. Then check for friction. Then check if you glass is lifting at the back. Then check if the hotend is moving up and down a little.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Printing 50 Micron or Smaller Layers February 26, 2013 03:03AM |

Registered: 11 years ago Posts: 111 |

|

Re: Printing 50 Micron or Smaller Layers February 26, 2013 03:56AM |

Registered: 13 years ago Posts: 2,947 |

By the spacing I would say its a lead screw issue.

Is the Z-lift bracket in the middle of the two Z-arms able to move side to side and absorb possible wobble of the lead screw?

Have you tried running a die over the threaded rod to make sure the threads are a consistent pitch?

I just uploaded a cable driven Z axis to my Github repo that I will be posting about soon. It completely eliminates the possibility of lead screw wobble.

Is the Z-lift bracket in the middle of the two Z-arms able to move side to side and absorb possible wobble of the lead screw?

Have you tried running a die over the threaded rod to make sure the threads are a consistent pitch?

I just uploaded a cable driven Z axis to my Github repo that I will be posting about soon. It completely eliminates the possibility of lead screw wobble.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Printing 50 Micron or Smaller Layers February 27, 2013 10:14AM |

Registered: 11 years ago Posts: 23 |

I have the same, slightly wavey, z axis on Tantillus.

The wire based z-lift looks mighty interesting. Any photos of a working installation?

Also the GT2 3mm pulleys for X&Y is a great addition. My tantillus runs on these, though with HTD pulleys, already and with very good results and less much less noise.

The wire based z-lift looks mighty interesting. Any photos of a working installation?

Also the GT2 3mm pulleys for X&Y is a great addition. My tantillus runs on these, though with HTD pulleys, already and with very good results and less much less noise.

Sorry, only registered users may post in this forum.