Rods and Holes

Posted by colpaert

|

Rods and Holes May 23, 2013 06:22PM |

Registered: 10 years ago Posts: 9 |

Are the holes in the axis rods really necessary?

Is their function to prevent the braided line to slip horizontally on the rod (and keep alignment) or to prevent them to slip during the rotation?

I'm asking this because it is somewhat easy to get the rods for a reasonable price down here in Rio, but the costs for having them perforated would make them 3 times more expensive. I also don't have the right tools to make the holes myself (and maybe others don't as well), so I was wondering if there wouldn't be another way to prevent them from slipping (I noticed the opposite rods don't have such holes).

Is their function to prevent the braided line to slip horizontally on the rod (and keep alignment) or to prevent them to slip during the rotation?

I'm asking this because it is somewhat easy to get the rods for a reasonable price down here in Rio, but the costs for having them perforated would make them 3 times more expensive. I also don't have the right tools to make the holes myself (and maybe others don't as well), so I was wondering if there wouldn't be another way to prevent them from slipping (I noticed the opposite rods don't have such holes).

|

Re: Rods and Holes May 23, 2013 09:07PM |

Registered: 13 years ago Posts: 2,947 |

After running a few machines for more then a year I do not think the hole is entirely needed but I have not tested.

The holes in all my rods I drilled with a cordless hand drill and a 1/16" HSS drill bit. It is not that easy but it can be done (drill it quickly otherwise it will work harden the metal). All the ones I sold I drilled with a dill press and were much easier.

The holes in all my rods I drilled with a cordless hand drill and a 1/16" HSS drill bit. It is not that easy but it can be done (drill it quickly otherwise it will work harden the metal). All the ones I sold I drilled with a dill press and were much easier.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Rods and Holes May 24, 2013 02:49PM |

Registered: 10 years ago Posts: 180 |

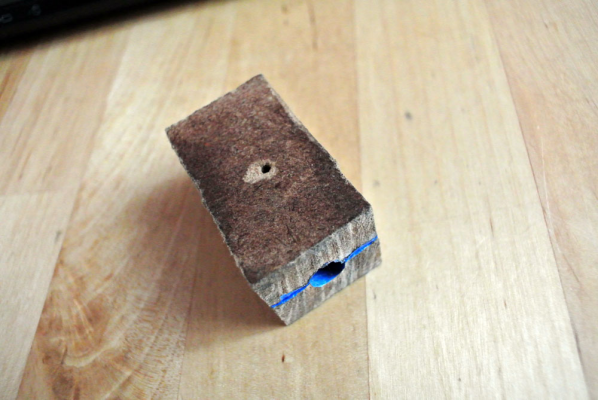

You could make a guide like this to help drilling the rods:

I've used also these to help cutting the rods (hence they are dirty ; ). It's basically a piece of wood with a 5/16" hole drilled through, then cut in half. Then a 1/16" hole is drilled in the middle. Place the rod in the guide, clamp it and drill the small hole through the 1/16" hole.

Or maybe you could go to a car mechanic or some machine shop where they have a drill press and ask them to drill the holes for a beer.

I think I have enough leftover 5/16" rod from my build for two 230mm rods. If all else fails I can give you two drilled rods, if you don't mind paying shipping from US.

I've used also these to help cutting the rods (hence they are dirty ; ). It's basically a piece of wood with a 5/16" hole drilled through, then cut in half. Then a 1/16" hole is drilled in the middle. Place the rod in the guide, clamp it and drill the small hole through the 1/16" hole.

Or maybe you could go to a car mechanic or some machine shop where they have a drill press and ask them to drill the holes for a beer.

I think I have enough leftover 5/16" rod from my build for two 230mm rods. If all else fails I can give you two drilled rods, if you don't mind paying shipping from US.

|

Re: Rods and Holes May 24, 2013 06:24PM |

Registered: 10 years ago Posts: 9 |

|

Re: Rods and Holes May 24, 2013 09:31PM |

Registered: 10 years ago Posts: 180 |

Forgot to suggest to mark the hole on the rod with a center punch. That helps start the drill, otherwise if you use the drill press the drill bit most likely will slip, bend and possibly break. With the drill press you don't need the whole guide from above, just the bottom half to help stabilize the rod.

Also, use some drilling or thread cutting lubricant. It will keep things nice and cool.

With a drill press though, this will be a piece of cake.

Also, use some drilling or thread cutting lubricant. It will keep things nice and cool.

With a drill press though, this will be a piece of cake.

Sorry, only registered users may post in this forum.