Variant of Goopyplastic's Tantillus Variant (Ingentis)

Posted by jimjimma

|

Re: Variant of Goopyplastic's Tantillus Variant August 10, 2013 07:42AM |

Registered: 12 years ago Posts: 95 |

Well, no luck getting holes in the 10mm shafts. Looks like it's induction hardened and the machinist forums I've been trawling all recommend using Tungsten Carbide bits,which should hopefully be here next week.

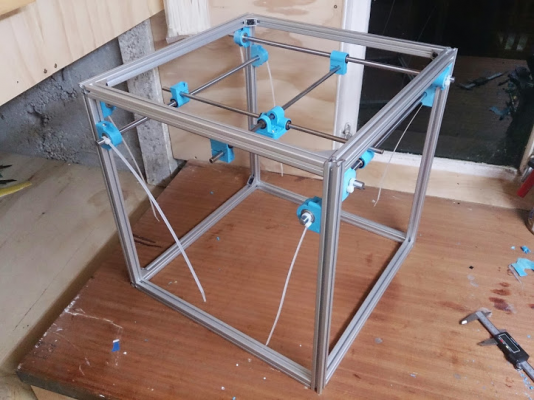

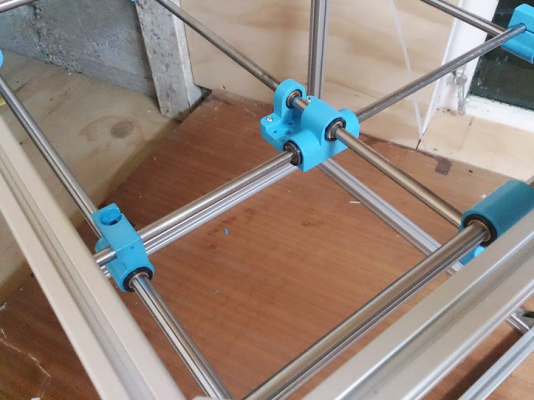

In the mean time - I've been printing parts and putting stuff together, just dry fits of prototype parts but still pleasing :

:

I'm also video blogging the build as I'm not going to get a chance to write stuff up anytime soon.

[www.youtube.com]

Cheers

In the mean time - I've been printing parts and putting stuff together, just dry fits of prototype parts but still pleasing

:

:I'm also video blogging the build as I'm not going to get a chance to write stuff up anytime soon.

[www.youtube.com]

Cheers

|

Re: Variant of Goopyplastic's Tantillus Variant August 10, 2013 09:23AM |

Registered: 10 years ago Posts: 35 |

|

Re: Variant of Goopyplastic's Tantillus Variant August 10, 2013 10:27AM |

Registered: 12 years ago Posts: 95 |

SkyArcher Wrote:

-------------------------------------------------------

> The holes in the shaft are for the cables, right?

> Try printing some shaft collars and use the shaft

> collars to anchor the cables.

Yeah, that's my contingency but the cable needs to run freely between either side of the rod to ensure the spectra is tensioned evenly and a collar means larger rod diameter which then means new x ends to get the cable holes to line up so I'll wait till the TC bits arrive.

-------------------------------------------------------

> The holes in the shaft are for the cables, right?

> Try printing some shaft collars and use the shaft

> collars to anchor the cables.

Yeah, that's my contingency but the cable needs to run freely between either side of the rod to ensure the spectra is tensioned evenly and a collar means larger rod diameter which then means new x ends to get the cable holes to line up so I'll wait till the TC bits arrive.

|

Re: Variant of Goopyplastic's Tantillus Variant August 10, 2013 09:27PM |

Registered: 10 years ago Posts: 180 |

It's looking very nice!

For drilling the holes I made a guide from MDF. Look at this post. It's basically a piece of MDF with an 8mm hole drilled length wise, then cut in half with a saw. The small hole prevents the drill from slipping.

I still think you should be able to do this with the HSS drill bit and cutting fluid on a drill press. Maybe you got some super hard rods or your drill bits are not sharp?

Do you even need the holes? You'll have lots of cable turns on the rod, maybe it work due to friction?

For drilling the holes I made a guide from MDF. Look at this post. It's basically a piece of MDF with an 8mm hole drilled length wise, then cut in half with a saw. The small hole prevents the drill from slipping.

I still think you should be able to do this with the HSS drill bit and cutting fluid on a drill press. Maybe you got some super hard rods or your drill bits are not sharp?

Do you even need the holes? You'll have lots of cable turns on the rod, maybe it work due to friction?

|

Re: Variant of Goopyplastic's Tantillus Variant August 10, 2013 11:21PM |

Registered: 12 years ago Posts: 95 |

lajos Wrote:

-------------------------------------------------------

> It's looking very nice!

>

> For drilling the holes I made a guide from MDF.

> Look at

> [url=http://forums.reprap.org/read.php?279,211553,

> 211802#msg-211802]this post[/url]. It's basically

> a piece of MDF with an 8mm hole drilled length

> wise, then cut in half with a saw. The small hole

> prevents the drill from slipping.

Yeah, I made printed jig with piece of aluminium inserted in the top to act as guide for the drill, that and a good divot in the rod made by a dremel meant that the bit wasn't slipping.

> I still think you should be able to do this with

> the HSS drill bit and cutting fluid on a drill

> press. Maybe you got some super hard rods or your

> drill bits are not sharp?

>

Brand new Colbalt bits and no joy - the rods are just 'really' hard it seems.

> Do you even need the holes? You'll have lots of

> cable turns on the rod, maybe it work due to

> friction?

Maybe but I'd be more comfortable with holes drilled. I'll try it out with some spectra anyway.

-------------------------------------------------------

> It's looking very nice!

>

> For drilling the holes I made a guide from MDF.

> Look at

> [url=http://forums.reprap.org/read.php?279,211553,

> 211802#msg-211802]this post[/url]. It's basically

> a piece of MDF with an 8mm hole drilled length

> wise, then cut in half with a saw. The small hole

> prevents the drill from slipping.

Yeah, I made printed jig with piece of aluminium inserted in the top to act as guide for the drill, that and a good divot in the rod made by a dremel meant that the bit wasn't slipping.

> I still think you should be able to do this with

> the HSS drill bit and cutting fluid on a drill

> press. Maybe you got some super hard rods or your

> drill bits are not sharp?

>

Brand new Colbalt bits and no joy - the rods are just 'really' hard it seems.

> Do you even need the holes? You'll have lots of

> cable turns on the rod, maybe it work due to

> friction?

Maybe but I'd be more comfortable with holes drilled. I'll try it out with some spectra anyway.

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 07:44AM |

Registered: 12 years ago Posts: 95 |

Bugger. Guess what I spotted while I was playing around with spectra line on undrilled rails today:

[www.youtube.com]

Yep, those Uber hard shafts are actually slightly bent - all of them about 0.5mm off axis at the halfway mark :|. The supplier is sending me some more which I will test in the same way. The joys of buying stuff from China. Still they were 1/4 the price of buying them in NZ and most of the stuff I've bought over the years is good quality so can't really complain too much..

[www.youtube.com]

Yep, those Uber hard shafts are actually slightly bent - all of them about 0.5mm off axis at the halfway mark :|. The supplier is sending me some more which I will test in the same way. The joys of buying stuff from China. Still they were 1/4 the price of buying them in NZ and most of the stuff I've bought over the years is good quality so can't really complain too much..

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 01:40PM |

Registered: 11 years ago Posts: 78 |

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 02:18PM |

Registered: 13 years ago Posts: 2,947 |

The only thing I have running without the hole is the cable Z axis and it has not slipped yet.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 03:47PM |

Registered: 12 years ago Posts: 95 |

I tried no holes in the shafts and the carriage holds firmly enough but I'm going to have the TC bits before having straight shafts now anyway so I'll have an experiment with the bent rods and take it from there.

Incidentally, looks like Tantus as a name may not be a goer after all, turns out it's a 'famous' brand of dildo

Edited 1 time(s). Last edit at 08/12/2013 06:07PM by jimjimma.

Incidentally, looks like Tantus as a name may not be a goer after all, turns out it's a 'famous' brand of dildo

Edited 1 time(s). Last edit at 08/12/2013 06:07PM by jimjimma.

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 05:47PM |

Registered: 13 years ago Posts: 2,947 |

That's funny. I guess they make large items!

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 06:45PM |

Registered: 12 years ago Posts: 95 |

Sublime Wrote:

-------------------------------------------------------

> That's funny. I guess they make large items!

One might imagine so . I should have googled it beyond a translate search.

. I should have googled it beyond a translate search.

I'm back to being stumped for names now... Thinking maybe something TST3 as it's a TSlot Tantillus and 3 times bigger. I did say I wasn't any good with names :|

-------------------------------------------------------

> That's funny. I guess they make large items!

One might imagine so

. I should have googled it beyond a translate search.

. I should have googled it beyond a translate search.I'm back to being stumped for names now... Thinking maybe something TST3 as it's a TSlot Tantillus and 3 times bigger. I did say I wasn't any good with names :|

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 07:22PM |

Registered: 14 years ago Posts: 47 |

Instead of drilling the rods, it should be possible to use a printed spool for the cable connection, similar to what some versions of the Kossel or RichRap's 3DR use:

[www.flickr.com]

[www.flickr.com]

|

Re: Variant of Goopyplastic's Tantillus Variant August 12, 2013 07:37PM |

Registered: 12 years ago Posts: 95 |

Nyarlathotep Wrote:

-------------------------------------------------------

> Instead of drilling the rods, it should be

> possible to use a printed spool for the cable

> connection, similar to what some versions of the

> Kossel or RichRap's 3DR use:

>

> [www.flickr.com]

Yeah, I've got that up my sleeve if I can't get the holes drilled. It will mean increasing the vertical dimension of the xy ends and a gear ratio change too so I'll avoid it if I can.

-------------------------------------------------------

> Instead of drilling the rods, it should be

> possible to use a printed spool for the cable

> connection, similar to what some versions of the

> Kossel or RichRap's 3DR use:

>

> [www.flickr.com]

Yeah, I've got that up my sleeve if I can't get the holes drilled. It will mean increasing the vertical dimension of the xy ends and a gear ratio change too so I'll avoid it if I can.

|

Re: Variant of Goopyplastic's Tantillus Variant August 13, 2013 12:51AM |

Registered: 10 years ago Posts: 22 |

Hi,

I've done some work with hardened steel and the trick is to up the flute count on your tool to get things started. Try using a couple of small carbide deburring bits at the lowest RPM possible with Castrol Moly Dee taping fluid (expensive but worth it). You have to be really careful about the work hardening here so light pressureand lots of Molly Dee. The key is to find a deburring bit whose profile somewhat matches the tip of the drill-bit your going to be using, as you will likely be using a very small drill bit you may have to resort to 2 bits, one ball nose or "tree" shaped, the other cylindrical. The ball nose will start much easier especially with your printed guide, once your through the first bit of the rod switch to the cylindrical burr to square off the bottom of the hole, that way the outside tips of the face of the drill bit will not get sheared off by the roundness of the bottom of the hole. Believe me once those break off the drill bit is useless. The rod is likely oil quenched or case hardened in some manner, so the hardest part of the rod is the first 2 to 10 thousands of an inch depending on the treatment method. One your through that hardened layer your home free, just keep the pressure on that drill bit, and if it does work harden on you just hit it with the burr, and a fresh drill bit.

Hope that helps, I'm really excited to see it finished! That carriage is awesomely small!

BTW LMFAO about the Tantus dildos!

I've done some work with hardened steel and the trick is to up the flute count on your tool to get things started. Try using a couple of small carbide deburring bits at the lowest RPM possible with Castrol Moly Dee taping fluid (expensive but worth it). You have to be really careful about the work hardening here so light pressureand lots of Molly Dee. The key is to find a deburring bit whose profile somewhat matches the tip of the drill-bit your going to be using, as you will likely be using a very small drill bit you may have to resort to 2 bits, one ball nose or "tree" shaped, the other cylindrical. The ball nose will start much easier especially with your printed guide, once your through the first bit of the rod switch to the cylindrical burr to square off the bottom of the hole, that way the outside tips of the face of the drill bit will not get sheared off by the roundness of the bottom of the hole. Believe me once those break off the drill bit is useless. The rod is likely oil quenched or case hardened in some manner, so the hardest part of the rod is the first 2 to 10 thousands of an inch depending on the treatment method. One your through that hardened layer your home free, just keep the pressure on that drill bit, and if it does work harden on you just hit it with the burr, and a fresh drill bit.

Hope that helps, I'm really excited to see it finished! That carriage is awesomely small!

BTW LMFAO about the Tantus dildos!

|

Re: Variant of Goopyplastic's Tantillus Variant August 13, 2013 05:11AM |

Registered: 12 years ago Posts: 95 |

cns1 Wrote:

-------------------------------------------------------

> Hi,

> I've done some work with hardened steel and the

> trick is to up the flute count on your tool to get

> things started. Try using a couple of small

> carbide deburring bits at the lowest RPM possible

> with Castrol Moly Dee taping fluid (expensive but

> worth it). You have to be really careful about the

> work hardening here so light pressureand lots of

> Molly Dee. The key is to find a deburring bit

> whose profile somewhat matches the tip of the

> drill-bit your going to be using, as you will

> likely be using a very small drill bit you may

> have to resort to 2 bits, one ball nose or "tree"

> shaped, the other cylindrical. The ball nose will

> start much easier especially with your printed

> guide, once your through the first bit of the rod

> switch to the cylindrical burr to square off the

> bottom of the hole, that way the outside tips of

> the face of the drill bit will not get sheared off

> by the roundness of the bottom of the hole.

> Believe me once those break off the drill bit is

> useless. The rod is likely oil quenched or case

> hardened in some manner, so the hardest part of

> the rod is the first 2 to 10 thousands of an inch

> depending on the treatment method. One your

> through that hardened layer your home free, just

> keep the pressure on that drill bit, and if it

> does work harden on you just hit it with the burr,

> and a fresh drill bit.

Thanks for the great advice, do you have good supplier for the deburing bits and tapping fluid?

-------------------------------------------------------

> Hi,

> I've done some work with hardened steel and the

> trick is to up the flute count on your tool to get

> things started. Try using a couple of small

> carbide deburring bits at the lowest RPM possible

> with Castrol Moly Dee taping fluid (expensive but

> worth it). You have to be really careful about the

> work hardening here so light pressureand lots of

> Molly Dee. The key is to find a deburring bit

> whose profile somewhat matches the tip of the

> drill-bit your going to be using, as you will

> likely be using a very small drill bit you may

> have to resort to 2 bits, one ball nose or "tree"

> shaped, the other cylindrical. The ball nose will

> start much easier especially with your printed

> guide, once your through the first bit of the rod

> switch to the cylindrical burr to square off the

> bottom of the hole, that way the outside tips of

> the face of the drill bit will not get sheared off

> by the roundness of the bottom of the hole.

> Believe me once those break off the drill bit is

> useless. The rod is likely oil quenched or case

> hardened in some manner, so the hardest part of

> the rod is the first 2 to 10 thousands of an inch

> depending on the treatment method. One your

> through that hardened layer your home free, just

> keep the pressure on that drill bit, and if it

> does work harden on you just hit it with the burr,

> and a fresh drill bit.

Thanks for the great advice, do you have good supplier for the deburing bits and tapping fluid?

|

Re: Variant of Goopyplastic's Tantillus Variant August 13, 2013 05:14AM |

Registered: 12 years ago Posts: 95 |

|

Re: Variant of Goopyplastic's Tantillus Variant August 13, 2013 11:53AM |

Registered: 13 years ago Posts: 2,947 |

The main issue I see with anything that has Titan in the title it that Daid (Writer of Cura) has a machine called Titan . The ironic part is Daid's Titan is smaller than Tantillus both in outer dimensions as well as build area.

I quickly looked through the Latin word list again and found:

ingens : of immoderate size, vast, huge, monstrous, remarkable.

Its genitive singular inflection is Ingentis which I think sounds pretty good for a machine and does not get any related hits on google (or sex toys).

I quickly looked through the Latin word list again and found:

ingens : of immoderate size, vast, huge, monstrous, remarkable.

Its genitive singular inflection is Ingentis which I think sounds pretty good for a machine and does not get any related hits on google (or sex toys).

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant August 14, 2013 01:35AM |

Registered: 10 years ago Posts: 22 |

I get mine from local suppliers, they are generally sold anywhere you can find machining supplies, so if there is a shop near you that sells end mills, step-clamps, dials, gauges and such that's the place you'll find deburring bits (also known as burrs), as well as the tapping fluid. Usually I have to have the smaller stuff special ordered, they're generally made down to 1/16". I think you mentioned in your video that you get the self centering bushings from McMaster-Carr, they are an excelent source for such an item Burrs. As for the Moly Dee it shouldn't be too hard to get a hold of you can find it on Amazon for example. When ordering the cylindrical deburring bit to make sure it's "end cut" the face of the bit is what you are going to use to finish the bottom of the hole. Also if you have the option the "double cut" burr will be a better for starting and the "single cut" burr will be better for finishing Once you have a flat smooth even surface your drill bit will start nicely and the shallow hole will aid your printed guide to keep the drill bit strait. Just be careful with those TC drill bits when you finally get them in because when they go they shatter, their very brittle so safety glasses is a must.

Ingentis has a nice ring to it sort of sounds like ingenious... can't help but read between the lines there Sublime LOL!

Ingentis has a nice ring to it sort of sounds like ingenious... can't help but read between the lines there Sublime LOL!

|

Re: Variant of Goopyplastic's Tantillus Variant August 18, 2013 07:17AM |

Registered: 12 years ago Posts: 95 |

Ok, so Ingentis it is. Thanks Sublime!

I've got a couple of burs on order from China - Sadly McMaster-Carr don't ship overseas (the bastards). Many thanks for the advice CNS1 , fingers crossed for hoel drilling success.

, fingers crossed for hoel drilling success.

While I'm waiting for bits to turn up, I've done a few more videos - they are only on google plus at present, should still be accessible though:

Link

Aside from that - my extremely simple Mk1 motor mounts are't going to cut it so I'm working on some that fit to both planes of the t-slot with some ridges for stiffness - the mk1s were flexing.

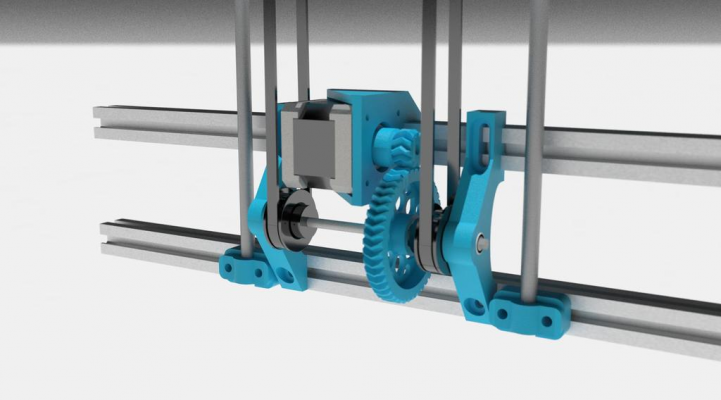

I've also mainly finished the design for the twin belt z drive, I'll post some renders tomorrow. I'm also looking for some help with Open SCAD and herringbone gears. I can't get the damn clunky thing to produce 11/44 gears with 40mm combined pitch diameters without it spitting out a 'non-manifold' error. Anyone got any skill here? I have neither the time nor motivation to learn how to make shapes with code and the only time I'm going to need it is to make these gears.

I've got a couple of burs on order from China - Sadly McMaster-Carr don't ship overseas (the bastards). Many thanks for the advice CNS1

, fingers crossed for hoel drilling success.

, fingers crossed for hoel drilling success.While I'm waiting for bits to turn up, I've done a few more videos - they are only on google plus at present, should still be accessible though:

Link

Aside from that - my extremely simple Mk1 motor mounts are't going to cut it so I'm working on some that fit to both planes of the t-slot with some ridges for stiffness - the mk1s were flexing.

I've also mainly finished the design for the twin belt z drive, I'll post some renders tomorrow. I'm also looking for some help with Open SCAD and herringbone gears. I can't get the damn clunky thing to produce 11/44 gears with 40mm combined pitch diameters without it spitting out a 'non-manifold' error. Anyone got any skill here? I have neither the time nor motivation to learn how to make shapes with code and the only time I'm going to need it is to make these gears.

|

Re: Variant of Goopyplastic's Tantillus Variant August 27, 2013 07:22AM |

Registered: 12 years ago Posts: 95 |

Quick update to tell you that even with TC bits, those damn rods just don't want to be drilled, the drill press was flexing with the pressure I was exerting but it barely made a dent with brand new TC bits So, I'm working on a printed bobbin that can go over the shaft to secure the spectra, I'll post some pics in the next few days. Apart from that, I'm mainly waiting on parts - second set of linear shafts turned up, they were bent too! looks like they had a bad batch so they're now making me a custom set with a 5micron/100mm tolerance. I've also bought the electronics for the bot: a Rumba board, LCD controller and 4 x 0.9 degree Wantai steppers. Second E3d hot-end to follow soon with a 300x300 silicone heat pad for the bed.

Renders of z twin belt stage coming shortly!

Renders of z twin belt stage coming shortly!

|

Re: Variant of Goopyplastic's Tantillus Variant August 28, 2013 07:14AM |

Registered: 12 years ago Posts: 95 |

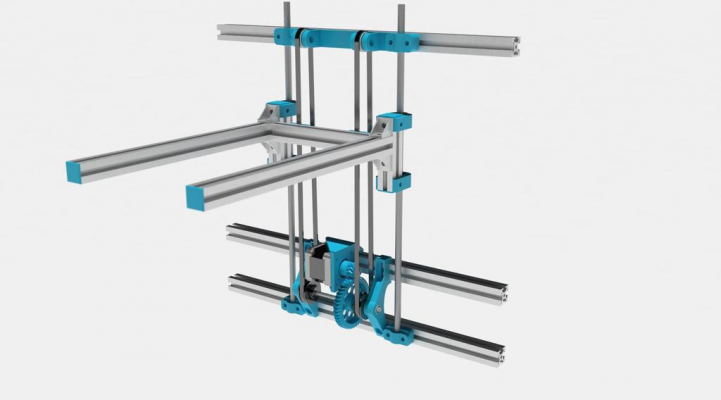

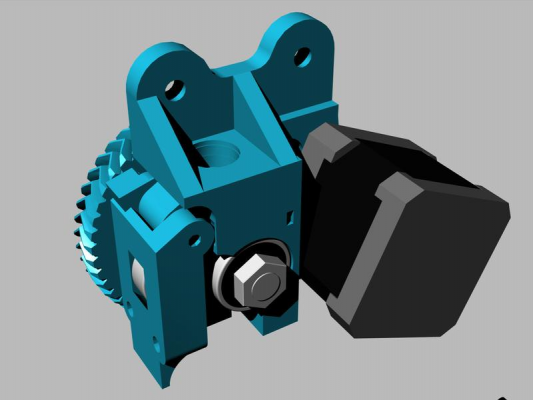

Here's a couple of renders of the Z stage. As far as I can tell it looks feasible. Sublime, please sing out if you can see something wrong with it. I'm printing the parts over the next few days.

Edited 1 time(s). Last edit at 08/28/2013 07:18AM by jimjimma.

Edited 1 time(s). Last edit at 08/28/2013 07:18AM by jimjimma.

|

Re: Variant of Goopyplastic's Tantillus Variant August 28, 2013 12:12PM |

Registered: 13 years ago Posts: 2,947 |

Looks good. My only concern is with the original Z stage cantilever. It looks a little too long for the size of the vertical bearing section. Also on my design the Z arms float on the center section to prevent possible bearing binding. I do not know if it is 100% required as I never built one without it. I just know over constrained linear bearings do not work well.

Edited 1 time(s). Last edit at 08/28/2013 10:07PM by Sublime.

Edited 1 time(s). Last edit at 08/28/2013 10:07PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant August 28, 2013 04:55PM |

Registered: 12 years ago Posts: 95 |

Sublime Wrote:

--------------------------------------i-----------------

> Looks good. My only concern is with the original Z

> stage cantilever. It looks a little too long for

> the size of the vertical bearing section. Also on

> my design the Z arms float on the center section

> to prevent possible bearing binding. I do not no

> if it is 100% required as I never built one

> without it. I just know over constrained linear

> bearings do not work well.

Yeah. I'm mildly concerned about too much weight and bearings binding up. I'd prefer not to go for a third linear shaft on the other side of the frame but I may have to go there to keep things stable. You are right about those vertical bits of tslot that the linear bearings are mounted on. I'm going to have to sacrifice some build height and make them longer. As the two belts are positioned close to the bearings, I hope this will reduce any binding issues.

--------------------------------------i-----------------

> Looks good. My only concern is with the original Z

> stage cantilever. It looks a little too long for

> the size of the vertical bearing section. Also on

> my design the Z arms float on the center section

> to prevent possible bearing binding. I do not no

> if it is 100% required as I never built one

> without it. I just know over constrained linear

> bearings do not work well.

Yeah. I'm mildly concerned about too much weight and bearings binding up. I'd prefer not to go for a third linear shaft on the other side of the frame but I may have to go there to keep things stable. You are right about those vertical bits of tslot that the linear bearings are mounted on. I'm going to have to sacrifice some build height and make them longer. As the two belts are positioned close to the bearings, I hope this will reduce any binding issues.

|

Re: Variant of Goopyplastic's Tantillus Variant August 28, 2013 08:23PM |

Registered: 13 years ago Posts: 485 |

What if the Z belts and rods were moved to opposite sides of the platform? Instead of being at the back edge of the platform, they could be 1/4 or 1/3 of the platform depth away from the rear. The weight of the platform should still keep it hanging on the same side of the rods, but the bending moment on the rods would be immensely reduced.

Attempted ASCII art follows. Belts are ":", and rods are "*".

_________

:| |:

*| |*

| |

|________|

Instead of:

__*:__:*__

| |

| |

| |

|________|

The Z rods would have to be outboard of the Y axis rods, of course.

Attempted ASCII art follows. Belts are ":", and rods are "*".

_________

:| |:

*| |*

| |

|________|

Instead of:

__*:__:*__

| |

| |

| |

|________|

The Z rods would have to be outboard of the Y axis rods, of course.

|

Re: Variant of Goopyplastic's Tantillus Variant August 28, 2013 09:58PM |

Registered: 12 years ago Posts: 95 |

Dale Dunn Wrote:

-------------------------------------------------------

> What if the Z belts and rods were moved to

> opposite sides of the platform? Instead of being

> at the back edge of the platform, they could be

> 1/4 or 1/3 of the platform depth away from the

> rear. The weight of the platform should still keep

> it hanging on the same side of the rods, but the

> bending moment on the rods would be immensely

> reduced.

>

> Attempted ASCII art follows. Belts are ":", and

> rods are "*".

>

> _________

> :| |:

> *| |*

> | |

> |________|

>

> Instead of:

>

> __*:__:*__

> | |

> | |

> | |

> |________|

>

> The Z rods would have to be outboard of the Y axis

> rods, of course.

Took me a while to work out those diagrams but I get you and it's not too dissimilar than an approach I was considering. The problem with separating the belts to either side of the chassis the that I’m only using a 5mm shaft between the pulleys and at a 450mm span, I suspect it might have too much flex without further supports. Additionally, when I move things around in Rhino to see how this looks, it still looks like it would bind-up because of the lack of equilibrium of forces on eithe side of the bearings when the belt moves the bed.

I think I’ll mock it up in it's current formover the next few days and then see what it feels like. I take some hope that it might work given that the same approach has been taken with this rather overly engineered creation (IMO): Kühling&Kühling

-------------------------------------------------------

> What if the Z belts and rods were moved to

> opposite sides of the platform? Instead of being

> at the back edge of the platform, they could be

> 1/4 or 1/3 of the platform depth away from the

> rear. The weight of the platform should still keep

> it hanging on the same side of the rods, but the

> bending moment on the rods would be immensely

> reduced.

>

> Attempted ASCII art follows. Belts are ":", and

> rods are "*".

>

> _________

> :| |:

> *| |*

> | |

> |________|

>

> Instead of:

>

> __*:__:*__

> | |

> | |

> | |

> |________|

>

> The Z rods would have to be outboard of the Y axis

> rods, of course.

Took me a while to work out those diagrams but I get you and it's not too dissimilar than an approach I was considering. The problem with separating the belts to either side of the chassis the that I’m only using a 5mm shaft between the pulleys and at a 450mm span, I suspect it might have too much flex without further supports. Additionally, when I move things around in Rhino to see how this looks, it still looks like it would bind-up because of the lack of equilibrium of forces on eithe side of the bearings when the belt moves the bed.

I think I’ll mock it up in it's current formover the next few days and then see what it feels like. I take some hope that it might work given that the same approach has been taken with this rather overly engineered creation (IMO): Kühling&Kühling

|

Re: Variant of Goopyplastic's Tantillus Variant August 28, 2013 10:38PM |

Registered: 11 years ago Posts: 633 |

|

Re: Variant of Goopyplastic's Tantillus Variant August 29, 2013 03:51AM |

Registered: 12 years ago Posts: 95 |

nic0laz Wrote:

-------------------------------------------------------

> guys, what extruder are you planning to use?.

>

> i wanna use 3mm filament but i cant find any

> bowden non direct drive extruder that can be

> mounted on t-slot

I've repurposed a 3mm bowden version of Greg's wade geared extruder. I'll stick it up on github when I get a spare moment.

-------------------------------------------------------

> guys, what extruder are you planning to use?.

>

> i wanna use 3mm filament but i cant find any

> bowden non direct drive extruder that can be

> mounted on t-slot

I've repurposed a 3mm bowden version of Greg's wade geared extruder. I'll stick it up on github when I get a spare moment.

|

Re: Variant of Goopyplastic's Tantillus Variant August 29, 2013 05:11AM |

Registered: 13 years ago Posts: 818 |

nic0laz Wrote:

-------------------------------------------------------

> guys, what extruder are you planning to use?.

>

> i wanna use 3mm filament but i cant find any

> bowden non direct drive extruder that can be

> mounted on t-slot

Woodsmoke did a 3mm remix of my Rostock t-slot mounted geared bowden extruder - Here

[richrap.blogspot.com]

-------------------------------------------------------

> guys, what extruder are you planning to use?.

>

> i wanna use 3mm filament but i cant find any

> bowden non direct drive extruder that can be

> mounted on t-slot

Woodsmoke did a 3mm remix of my Rostock t-slot mounted geared bowden extruder - Here

[richrap.blogspot.com]

|

Re: Variant of Goopyplastic's Tantillus Variant August 29, 2013 05:53AM |

Registered: 12 years ago Posts: 95 |

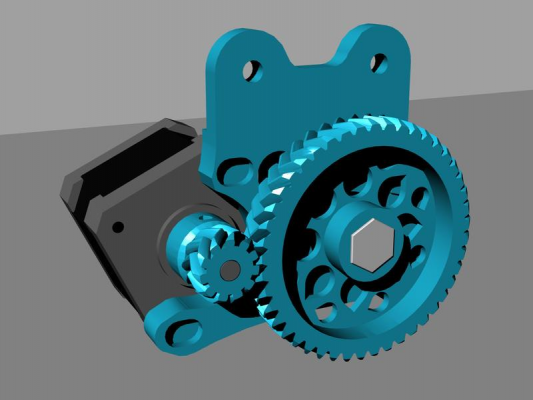

richrap Wrote:

-------------------------------------------------------

> Woodsmoke did a 3mm remix of my Rostock t-slot

> mounted geared bowden extruder -

That's the one I've re-purposed. I've altered the mounts so it's correctly oriented for mounting to a horizontal piece of t-slot with the bowden fitting facing upwards

Google Drive Link:

Link

Please note, the extruder body is untested but I've not changed Rich's/Woodsmoke's design beyond altering the mounts. STLs are manifold.

Edited 3 time(s). Last edit at 08/29/2013 08:42PM by jimjimma.

-------------------------------------------------------

> Woodsmoke did a 3mm remix of my Rostock t-slot

> mounted geared bowden extruder -

That's the one I've re-purposed. I've altered the mounts so it's correctly oriented for mounting to a horizontal piece of t-slot with the bowden fitting facing upwards

Google Drive Link:

Link

Please note, the extruder body is untested but I've not changed Rich's/Woodsmoke's design beyond altering the mounts. STLs are manifold.

Edited 3 time(s). Last edit at 08/29/2013 08:42PM by jimjimma.

|

Re: Variant of Goopyplastic's Tantillus Variant August 29, 2013 07:23AM |

Registered: 11 years ago Posts: 633 |

Sorry, only registered users may post in this forum.