Variant of Goopyplastic's Tantillus Variant (Ingentis)

Posted by jimjimma

|

Re: Variant of Goopyplastic's Tantillus Variant August 29, 2013 01:06PM |

Registered: 13 years ago Posts: 485 |

jimjimma Wrote:

-------------------------------------------------------

> Took me a while to work out those diagrams but I

> get you and it's not too dissimilar than an

> approach I was considering. The problem with

> separating the belts to either side of the chassis

> the that I’m only using a 5mm shaft between the

> pulleys and at a 450mm span, I suspect it might

> have too much flex without further supports.

> Additionally, when I move things around in Rhino

> to see how this looks, it still looks like it

> would bind-up because of the lack of equilibrium

> of forces on eithe side of the bearings when the

> belt moves the bed.

> I think I’ll mock it up in it's current formover

> the next few days and then see what it feels like.

> I take some hope that it might work given that the

> same approach has been taken with this rather

> overly engineered creation (IMO):

> [url=http://kuehlingkuehling.de/kuhlingkuhling-rep

> rap-industrial/]Kühling&Kühling[/url]

Oh, the forum sucked out the extra spaces and I failed to notice. Sorry about that.

No doubt things would need to be resized to deal with the different proportions. I'm not sure which equilibrium forces would be missing, but we can discuss that if the simpler cantilever doesn't work out. The K&K machine has some pretty beefy brackets and bearings. It probably works fine.

-------------------------------------------------------

> Took me a while to work out those diagrams but I

> get you and it's not too dissimilar than an

> approach I was considering. The problem with

> separating the belts to either side of the chassis

> the that I’m only using a 5mm shaft between the

> pulleys and at a 450mm span, I suspect it might

> have too much flex without further supports.

> Additionally, when I move things around in Rhino

> to see how this looks, it still looks like it

> would bind-up because of the lack of equilibrium

> of forces on eithe side of the bearings when the

> belt moves the bed.

> I think I’ll mock it up in it's current formover

> the next few days and then see what it feels like.

> I take some hope that it might work given that the

> same approach has been taken with this rather

> overly engineered creation (IMO):

> [url=http://kuehlingkuehling.de/kuhlingkuhling-rep

> rap-industrial/]Kühling&Kühling[/url]

Oh, the forum sucked out the extra spaces and I failed to notice. Sorry about that.

No doubt things would need to be resized to deal with the different proportions. I'm not sure which equilibrium forces would be missing, but we can discuss that if the simpler cantilever doesn't work out. The K&K machine has some pretty beefy brackets and bearings. It probably works fine.

|

Re: Variant of Goopyplastic's Tantillus Variant August 29, 2013 01:32PM |

Registered: 13 years ago Posts: 485 |

I just read about a new design in another post with a Z axis similar to what I was proposing. The ProtoForge uses screws instead of belts, but the idea is very similar. He links to a video with a demonstration of the Z axis, and it looks quite solid.

|

Re: Variant of Goopyplastic's Tantillus Variant August 30, 2013 07:19AM |

Registered: 12 years ago Posts: 95 |

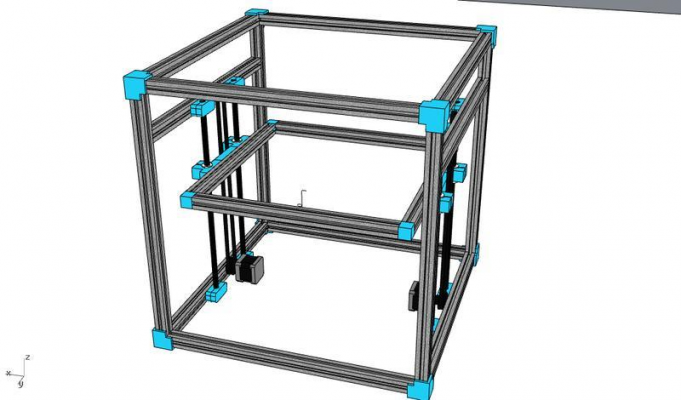

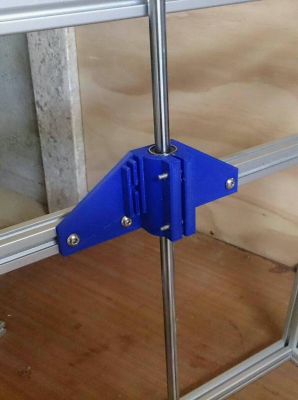

Ok, so what do you think of this?

I had a look at the ProtoForge, and it looks like he's using 12mm shafts and the lead screws will act as a stabilizers to some degree so I was a bit hesitant to mimic the concept exactly. It then occurred to me that I've got these 10mm shafts spare so I started fiddling with how they could be used and this is my first cut.

-I've kept the shafts reasonably close together to reduce the chances of binding.

-1 x LM10UU on each shaft.

-The motor and belt are offset so the belt can be clamped in the exact centre between the shafts.

-The square t-slot frame the shafts support will also allow me to directly mount a 4mm aluminum build plate on top (silicone heat pad underneath it) and the 4 blue corner pieces can be used to mount the leveling mechanism (bolt and spring).

-No step down gearing off the motors yet.

I've not bothered with a motor or idler mount design yet as I'd like to get some feedback on the mechanics first.

I'm not super happy with this as I've got 2 more shafts and 1 more motor on the BOM now but I'd prefer it over a weak and unreliable Z stage.

On the up side this design increases the Z build height (about 250mm)

I had a look at the ProtoForge, and it looks like he's using 12mm shafts and the lead screws will act as a stabilizers to some degree so I was a bit hesitant to mimic the concept exactly. It then occurred to me that I've got these 10mm shafts spare so I started fiddling with how they could be used and this is my first cut.

-I've kept the shafts reasonably close together to reduce the chances of binding.

-1 x LM10UU on each shaft.

-The motor and belt are offset so the belt can be clamped in the exact centre between the shafts.

-The square t-slot frame the shafts support will also allow me to directly mount a 4mm aluminum build plate on top (silicone heat pad underneath it) and the 4 blue corner pieces can be used to mount the leveling mechanism (bolt and spring).

-No step down gearing off the motors yet.

I've not bothered with a motor or idler mount design yet as I'd like to get some feedback on the mechanics first.

I'm not super happy with this as I've got 2 more shafts and 1 more motor on the BOM now but I'd prefer it over a weak and unreliable Z stage.

On the up side this design increases the Z build height (about 250mm)

|

Re: Variant of Goopyplastic's Tantillus Variant August 30, 2013 10:26AM |

Registered: 13 years ago Posts: 485 |

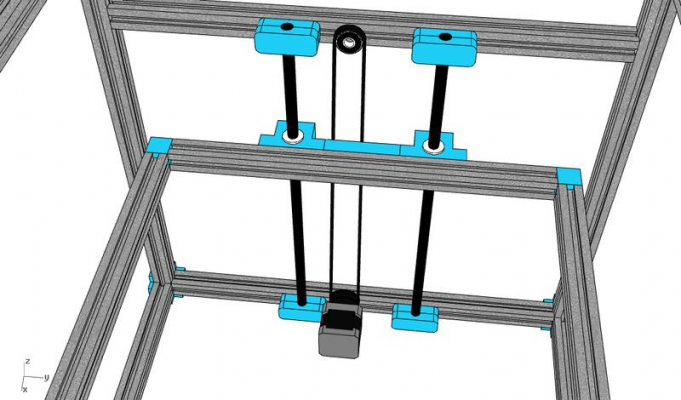

Well, that certainly gets rid of the cantilever loads on the bearings. I don't trust a single bearing per shaft to keep the platform level though. I think it would work better with 2 rods and 2 bearings per rod, separated some to help them resist the forces of offset loads on the platform. If you think about a moment load on a single LM10, the forces on the shaft are sort of focussed* on the balls at either end of the bearing, maybe 40 mm apart. With two bearings per shaft, the forces on the shaft are spread more evenly through all the balls in each bearing, and separated by spacing of the 2 bearings. So, with 2 bearings, all the balls are in play, and carrying lower forces. Pairing the bearings will have similar benefits to stability if there is any clearance between the bearings and shafts.

I don't think you need to add the second motor. My preference would be adapt your geared design from the cantilevered bed. I have a Prusa Mendel, and I can tell you that while the separate Z motors design is simpler to build and does work, it does also get out of sync when things go wrong. Then you have to level your bed again. It happens often enough to be annoying. I think which way you go is a matter of preference though. Either way works, but what you do depends on prioritising either a simpler build or fewer motors and a more robust system.

*Theoretically, the outermost balls would have the highest loads, with forces on the inner ball being progressively less with zero load on the balls in the center of the bearing's length.

I don't think you need to add the second motor. My preference would be adapt your geared design from the cantilevered bed. I have a Prusa Mendel, and I can tell you that while the separate Z motors design is simpler to build and does work, it does also get out of sync when things go wrong. Then you have to level your bed again. It happens often enough to be annoying. I think which way you go is a matter of preference though. Either way works, but what you do depends on prioritising either a simpler build or fewer motors and a more robust system.

*Theoretically, the outermost balls would have the highest loads, with forces on the inner ball being progressively less with zero load on the balls in the center of the bearing's length.

|

Re: Variant of Goopyplastic's Tantillus Variant August 30, 2013 06:59PM |

Registered: 12 years ago Posts: 95 |

I was worried about the single bearing per rod problem and I had a feeling I wouldn't be alone so I started on this too:

I'm still worried about flex and I know that the further I space the bearings (along the z axis) the better the resistance to bending moments will be but it also eats into Z build space which is lagging behind x/y already. I think in version 2 I'm going to flip the hot end carriage over to try to win back some Z height...

The orientation of the bracket that holds the LM10UU is the way it is as it maximizes the Z build..

This design will easily accommodate for an single drive shaft between the bottom pulleys. I just need to make a call on what I'm going to do with the base plate. I had been considering a sheet of Alu or acrylic. I think I'll go for Alu, that way I can make some retaining brackets for the shaft that joins the pulleys and repurpose the original gearing for a single motor drive. All of which can be mounted straight onto the ALu plate.

Greatly appreciate the feedback btw, thanks!

Edited 1 time(s). Last edit at 08/30/2013 07:00PM by jimjimma.

I'm still worried about flex and I know that the further I space the bearings (along the z axis) the better the resistance to bending moments will be but it also eats into Z build space which is lagging behind x/y already. I think in version 2 I'm going to flip the hot end carriage over to try to win back some Z height...

The orientation of the bracket that holds the LM10UU is the way it is as it maximizes the Z build..

This design will easily accommodate for an single drive shaft between the bottom pulleys. I just need to make a call on what I'm going to do with the base plate. I had been considering a sheet of Alu or acrylic. I think I'll go for Alu, that way I can make some retaining brackets for the shaft that joins the pulleys and repurpose the original gearing for a single motor drive. All of which can be mounted straight onto the ALu plate.

Greatly appreciate the feedback btw, thanks!

Edited 1 time(s). Last edit at 08/30/2013 07:00PM by jimjimma.

|

Re: Variant of Goopyplastic's Tantillus Variant August 31, 2013 10:53AM |

Registered: 13 years ago Posts: 485 |

jimjimma Wrote:

-------------------------------------------------------

...

> Greatly appreciate the feedback btw, thanks!

You're very welcome. Until I get the time to do this myself, I can only indulge in armchair engineering and telling other people what I think they should do! I'm envious of you, actually getting it done.

This arrangement of bearings looks pretty good. Short of some expensive FEA, the only way to know if it is rigid enough will be to built it and see.

Is it too late to make the machine taller to recover build height? Like maybe you have a limited supply of aluminum? Some earlier remarks lead me to believe you're building this from materials you have on hand.

-------------------------------------------------------

...

> Greatly appreciate the feedback btw, thanks!

You're very welcome. Until I get the time to do this myself, I can only indulge in armchair engineering and telling other people what I think they should do! I'm envious of you, actually getting it done.

This arrangement of bearings looks pretty good. Short of some expensive FEA, the only way to know if it is rigid enough will be to built it and see.

Is it too late to make the machine taller to recover build height? Like maybe you have a limited supply of aluminum? Some earlier remarks lead me to believe you're building this from materials you have on hand.

|

Re: Variant of Goopyplastic's Tantillus Variant August 31, 2013 09:30PM |

Registered: 12 years ago Posts: 95 |

Dale Dunn Wrote:

-------------------------------------------------------

> jimjimma Wrote:

> --------------------------------------------------

> -----

> ...

> > Greatly appreciate the feedback btw, thanks!

>

> You're very welcome. Until I get the time to do

> this myself, I can only indulge in armchair

> engineering and telling other people what I think

> they should do! I'm envious of you, actually

> getting it done.

Well, your Armchair engineering is appreciated. One of the things that makes this process so gratifying is the input form others, I wonder if there's enough impetus out there to do a big collaborative project, I have aspirations to one day build a concrete printer big enough to print a house.....

> This arrangement of bearings looks pretty good.

> Short of some expensive FEA, the only way to know

> if it is rigid enough will be to built it and

> see.

Yeah, I'm just going to build it now and see how it goes - I've got 4 LM10UUS in the post and all the other hardware to hand so I should be able to confirm the solutions efficacy over the next week or so - stuck in bed with a cold right now though. Wife tells me if I'm too sick to do the washing I'm too sick to tinker with printers apparently!

If it's too flexy, I have some 12mm shafts supporting the y axis on my Mendelmax and some beefy 12UUs in block housings (too heavy for y axis) that should work. Im half inclined just to use those in the first place but it goes against my original intent of making the bot reasonably easy to source the parts for.

> Is it too late to make the machine taller to

> recover build height? Like maybe you have a

> limited supply of aluminum? Some earlier remarks

> lead me to believe you're building this from

> materials you have on hand.

It's not too late per se but I'm trying to avoid too much scope creep and it will be easy enough to increase the height later once i've validated the MK1 design as a whole. The lost Z consideration is more about trying to maximize build volume for a given footprint/height really. I have 8 almost imperceptibly bent 500mm long 10mm shafts spare now so I can afford to cut a pair down to fit the current Z design and then put some longer t-slot in on the verts later to increase the Z. I have a crazy thought about going really big with the Z height on the MK2 now - maybe a metre.......

-------------------------------------------------------

> jimjimma Wrote:

> --------------------------------------------------

> -----

> ...

> > Greatly appreciate the feedback btw, thanks!

>

> You're very welcome. Until I get the time to do

> this myself, I can only indulge in armchair

> engineering and telling other people what I think

> they should do! I'm envious of you, actually

> getting it done.

Well, your Armchair engineering is appreciated. One of the things that makes this process so gratifying is the input form others, I wonder if there's enough impetus out there to do a big collaborative project, I have aspirations to one day build a concrete printer big enough to print a house.....

> This arrangement of bearings looks pretty good.

> Short of some expensive FEA, the only way to know

> if it is rigid enough will be to built it and

> see.

Yeah, I'm just going to build it now and see how it goes - I've got 4 LM10UUS in the post and all the other hardware to hand so I should be able to confirm the solutions efficacy over the next week or so - stuck in bed with a cold right now though. Wife tells me if I'm too sick to do the washing I'm too sick to tinker with printers apparently!

If it's too flexy, I have some 12mm shafts supporting the y axis on my Mendelmax and some beefy 12UUs in block housings (too heavy for y axis) that should work. Im half inclined just to use those in the first place but it goes against my original intent of making the bot reasonably easy to source the parts for.

> Is it too late to make the machine taller to

> recover build height? Like maybe you have a

> limited supply of aluminum? Some earlier remarks

> lead me to believe you're building this from

> materials you have on hand.

It's not too late per se but I'm trying to avoid too much scope creep and it will be easy enough to increase the height later once i've validated the MK1 design as a whole. The lost Z consideration is more about trying to maximize build volume for a given footprint/height really. I have 8 almost imperceptibly bent 500mm long 10mm shafts spare now so I can afford to cut a pair down to fit the current Z design and then put some longer t-slot in on the verts later to increase the Z. I have a crazy thought about going really big with the Z height on the MK2 now - maybe a metre.......

|

Re: Variant of Goopyplastic's Tantillus Variant September 04, 2013 07:29AM |

Registered: 12 years ago Posts: 95 |

So turns out I shouldn't have been worried about flex

There is no apparent flex when I apply a bending moment to the end of the tslot

Top and bottom brackets for the shafts are designed and are printing so i should be able to get the z stage built this week.

In other news I finally have straight 10mm shafts! With a prevailing wind, ill be able to do some movement tests over the weekend.

There is no apparent flex when I apply a bending moment to the end of the tslot

Top and bottom brackets for the shafts are designed and are printing so i should be able to get the z stage built this week.

In other news I finally have straight 10mm shafts! With a prevailing wind, ill be able to do some movement tests over the weekend.

|

Re: Variant of Goopyplastic's Tantillus Variant September 04, 2013 01:14PM |

Registered: 13 years ago Posts: 485 |

|

Re: Variant of Goopyplastic's Tantillus Variant September 13, 2013 08:04PM |

Registered: 13 years ago Posts: 2,947 |

Looking good.

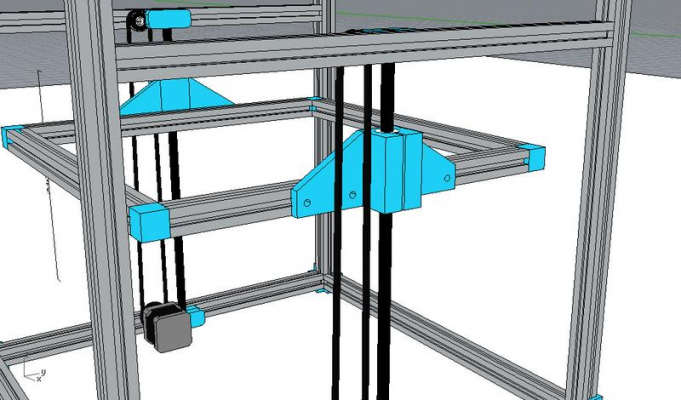

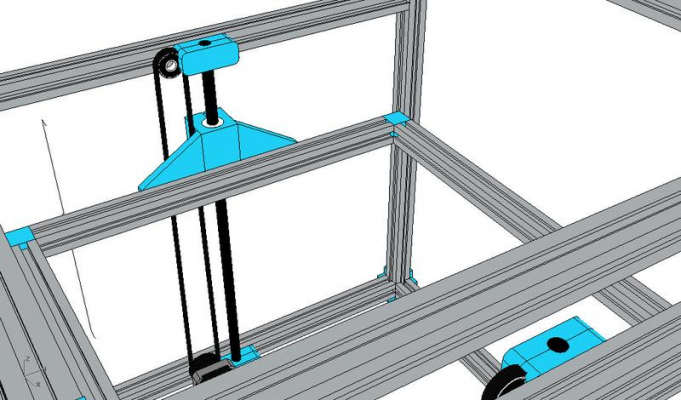

I like the third Z axis and the first. I would completely stay away from the second with the four smooth rods.

On the third I would use a shaft and a single motor not two motors that is just asking for misalignment issues in my opinion.

I like the third Z axis and the first. I would completely stay away from the second with the four smooth rods.

On the third I would use a shaft and a single motor not two motors that is just asking for misalignment issues in my opinion.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant September 14, 2013 05:38AM |

Registered: 12 years ago Posts: 95 |

Sublime Wrote:

-------------------------------------------------------

> Looking good.

>

> I like the third Z axis and the first. I would

> completely stay away from the second with the four

> smooth rods.

>

> On the third I would use a shaft and a single

> motor not two motors that is just asking for

> misalignment issues in my opinion.

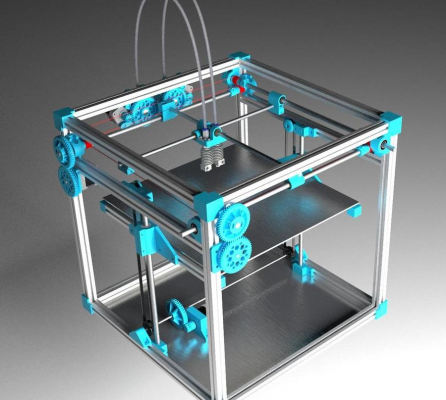

Yeah, don't know what I was thinking with the 4 rod idea. I'm not making much build progress at the moment because my Mendelmax is having a spasm and a small human requires wrangling but here's a pretty render instead. Note the single Z motor and shaft . Once I've got the thing working, I'm considering printing a normal size Tantillus as a single piece - has that been done before?

. Once I've got the thing working, I'm considering printing a normal size Tantillus as a single piece - has that been done before?

-------------------------------------------------------

> Looking good.

>

> I like the third Z axis and the first. I would

> completely stay away from the second with the four

> smooth rods.

>

> On the third I would use a shaft and a single

> motor not two motors that is just asking for

> misalignment issues in my opinion.

Yeah, don't know what I was thinking with the 4 rod idea. I'm not making much build progress at the moment because my Mendelmax is having a spasm and a small human requires wrangling but here's a pretty render instead. Note the single Z motor and shaft

. Once I've got the thing working, I'm considering printing a normal size Tantillus as a single piece - has that been done before?

. Once I've got the thing working, I'm considering printing a normal size Tantillus as a single piece - has that been done before?|

Re: Variant of Goopyplastic's Tantillus Variant September 14, 2013 01:34PM |

Registered: 13 years ago Posts: 2,947 |

I tried printing the original case on my prusa in three parts (200 x 200 x 100) but they warped to much. There is a one piece file in my repo for anyone wanting to try. With a heated bed you may get past the trouble spot where it wants to tear the part off the bed and then may run into problems with it cracking in the middle at which point you would need a heated chamber.

Have you moved the cables to the outside of the X/Y ends? Or does the rendering just look backwards?

Have you moved the cables to the outside of the X/Y ends? Or does the rendering just look backwards?

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant September 14, 2013 03:29PM |

Registered: 12 years ago Posts: 95 |

Sublime Wrote:

-------------------------------------------------------

> I tried printing the original case on my prusa in

> three parts (200 x 200 x 100) but they warped to

> much. There is a one piece file in my repo for

> anyone wanting to try. With a heated bed you may

> get past the trouble spot where it wants to tear

> the part off the bed and then may run into

> problems with it cracking in the middle at which

> point you would need a heated chamber.

I fully intend to enclose this thing and I'm looking at 12v heaters to get the ambient temp up to 50/60 degrees to reduce the thermal contraction issues. The rumba board I'm using has spare ports for a chamber heater.

> Have you moved the cables to the outside of the

> X/Y ends? Or does the rendering just look

> backwards?

Good spotting. Must have flipped them along the horizontal plane by accident.

-------------------------------------------------------

> I tried printing the original case on my prusa in

> three parts (200 x 200 x 100) but they warped to

> much. There is a one piece file in my repo for

> anyone wanting to try. With a heated bed you may

> get past the trouble spot where it wants to tear

> the part off the bed and then may run into

> problems with it cracking in the middle at which

> point you would need a heated chamber.

I fully intend to enclose this thing and I'm looking at 12v heaters to get the ambient temp up to 50/60 degrees to reduce the thermal contraction issues. The rumba board I'm using has spare ports for a chamber heater.

> Have you moved the cables to the outside of the

> X/Y ends? Or does the rendering just look

> backwards?

Good spotting. Must have flipped them along the horizontal plane by accident.

|

Re: Variant of Goopyplastic's Tantillus Variant September 14, 2013 07:46PM |

Registered: 11 years ago Posts: 78 |

|

Re: Variant of Goopyplastic's Tantillus Variant September 21, 2013 04:29AM |

Registered: 10 years ago Posts: 22 |

jimjimma Wrote:

-------------------------------------------------------

>

> I fully intend to enclose this thing and I'm

> looking at 12v heaters to get the ambient temp up

> to 50/60 degrees to reduce the thermal contraction

> issues. The rumba board I'm using has spare ports

> for a chamber heater.

The power supply to run a heater pad that size in 12 volt is rediculous, like 350 Watts+! I know I'll catch some heat for this but why not just run a 110 VAC heater pad. You'll have to put in a relay anyway reguaress of the voltage.

-------------------------------------------------------

>

> I fully intend to enclose this thing and I'm

> looking at 12v heaters to get the ambient temp up

> to 50/60 degrees to reduce the thermal contraction

> issues. The rumba board I'm using has spare ports

> for a chamber heater.

The power supply to run a heater pad that size in 12 volt is rediculous, like 350 Watts+! I know I'll catch some heat for this but why not just run a 110 VAC heater pad. You'll have to put in a relay anyway reguaress of the voltage.

|

Re: Variant of Goopyplastic's Tantillus Variant September 29, 2013 02:13AM |

Registered: 12 years ago Posts: 95 |

|

Re: Variant of Goopyplastic's Tantillus Variant September 29, 2013 12:57PM |

Registered: 12 years ago Posts: 72 |

|

Re: Variant of Goopyplastic's Tantillus Variant September 29, 2013 05:13PM |

Registered: 12 years ago Posts: 95 |

cns1 Wrote:

-------------------------------------------------------

> jimjimma Wrote:

> --------------------------------------------------

> -----

> >

> > I fully intend to enclose this thing and I'm

> > looking at 12v heaters to get the ambient temp

> up

> > to 50/60 degrees to reduce the thermal

> contraction

> > issues. The rumba board I'm using has spare

> ports

> > for a chamber heater.

>

> The power supply to run a heater pad that size in

> 12 volt is rediculous, like 350 Watts+! I know

> I'll catch some heat for this but why not just run

> a 110 VAC heater pad. You'll have to put in a

> relay anyway reguaress of the voltage.

Ah, yeah sorry. Didn't make myself clear - I'm looking at using 12V portable hairdryers or car heaters. Will use a seperate PSU either way - prefer to steer clear of 230v (we don't use 110V in NZ) beyond input into the PDU. Particulalry as I'm looking at water cooling the hotend.

-------------------------------------------------------

> jimjimma Wrote:

> --------------------------------------------------

> -----

> >

> > I fully intend to enclose this thing and I'm

> > looking at 12v heaters to get the ambient temp

> up

> > to 50/60 degrees to reduce the thermal

> contraction

> > issues. The rumba board I'm using has spare

> ports

> > for a chamber heater.

>

> The power supply to run a heater pad that size in

> 12 volt is rediculous, like 350 Watts+! I know

> I'll catch some heat for this but why not just run

> a 110 VAC heater pad. You'll have to put in a

> relay anyway reguaress of the voltage.

Ah, yeah sorry. Didn't make myself clear - I'm looking at using 12V portable hairdryers or car heaters. Will use a seperate PSU either way - prefer to steer clear of 230v (we don't use 110V in NZ) beyond input into the PDU. Particulalry as I'm looking at water cooling the hotend.

|

Re: Variant of Goopyplastic's Tantillus Variant September 29, 2013 09:09PM |

Registered: 12 years ago Posts: 95 |

kburr Wrote:

-------------------------------------------------------

> That looks absolutely fantastic! What did you end

> up deciding on for your z-axis?

Dual Z Belts as per the drawing above. Going to get onto that this week.

After running a bunch of twiddly gcode through it last night it's moving much more smoothly - everything is bedding in. Put some lithium grease on the gears that helped a lot. Allowed me to turn down the stepper driver pots quite a lot, which is good as the Y driver was going into thermal shut down.

Here's Another Video

-------------------------------------------------------

> That looks absolutely fantastic! What did you end

> up deciding on for your z-axis?

Dual Z Belts as per the drawing above. Going to get onto that this week.

After running a bunch of twiddly gcode through it last night it's moving much more smoothly - everything is bedding in. Put some lithium grease on the gears that helped a lot. Allowed me to turn down the stepper driver pots quite a lot, which is good as the Y driver was going into thermal shut down.

Here's Another Video

|

Re: Variant of Goopyplastic's Tantillus Variant September 30, 2013 01:10AM |

Registered: 10 years ago Posts: 28 |

|

Re: Variant of Goopyplastic's Tantillus Variant October 01, 2013 01:31PM |

Registered: 10 years ago Posts: 4 |

|

Re: Variant of Goopyplastic's Tantillus Variant October 02, 2013 10:04PM |

Registered: 12 years ago Posts: 95 |

|

Re: Variant of Goopyplastic's Tantillus Variant October 02, 2013 11:26PM |

Registered: 12 years ago Posts: 95 |

phil_roberts Wrote:

-------------------------------------------------------

> Jimjimma- I've been following this thread closely.

> Great work and thanks for sharing. I'm building

> a mid-size t-slot tantillus. Any chance you could

> share the x/y spool files?

>

> Thanks!

> Phil

Yep, they still need some tweeking which I should get round to over the next few days, after which I'll stick them on Github. They are for 10mm Shaft BTW.

-------------------------------------------------------

> Jimjimma- I've been following this thread closely.

> Great work and thanks for sharing. I'm building

> a mid-size t-slot tantillus. Any chance you could

> share the x/y spool files?

>

> Thanks!

> Phil

Yep, they still need some tweeking which I should get round to over the next few days, after which I'll stick them on Github. They are for 10mm Shaft BTW.

|

Re: Variant of Goopyplastic's Tantillus Variant October 03, 2013 04:43PM |

Registered: 10 years ago Posts: 4 |

jimjimma Wrote:

> Yep, they still need some tweeking which I should

> get round to over the next few days, after which

> I'll stick them on Github. They are for 10mm Shaft

> BTW.

Hmm- I'm using 8mm shafts. Could I use the spools with Goopy's corner brackets and the stock X/Y ends? The spectra needs to be perfectly level from the rod/spool to the X/Y end, right?

I'll post some pics soon..still debating what to do with the z-axis. I was leaning towards a cantilever bed. I was planning to add an offset weight opposite the bed to equalize the moment on the linear z bearings. But an 8lb basalt bed with an 8lb offset weight doesn't seem like a great idea. A dual belt/cable setup is looking more attractive.

Edited 3 time(s). Last edit at 10/04/2013 03:57PM by phil_roberts.

> Yep, they still need some tweeking which I should

> get round to over the next few days, after which

> I'll stick them on Github. They are for 10mm Shaft

> BTW.

Hmm- I'm using 8mm shafts. Could I use the spools with Goopy's corner brackets and the stock X/Y ends? The spectra needs to be perfectly level from the rod/spool to the X/Y end, right?

I'll post some pics soon..still debating what to do with the z-axis. I was leaning towards a cantilever bed. I was planning to add an offset weight opposite the bed to equalize the moment on the linear z bearings. But an 8lb basalt bed with an 8lb offset weight doesn't seem like a great idea. A dual belt/cable setup is looking more attractive.

Edited 3 time(s). Last edit at 10/04/2013 03:57PM by phil_roberts.

|

Re: Variant of Goopyplastic's Tantillus Variant October 06, 2013 03:43PM |

Registered: 11 years ago Posts: 7 |

|

Re: Variant of Goopyplastic's Tantillus Variant October 07, 2013 04:26AM |

Registered: 12 years ago Posts: 95 |

phil_roberts Wrote:

-------------------------------------------------------

>

> Hmm- I'm using 8mm shafts. Could I use the spools

> with Goopy's corner brackets and the stock X/Y

> ends? The spectra needs to be perfectly level

> from the rod/spool to the X/Y end, right?

Not sure how perfectly level it needs to be, because the cable walks up and down the spool as the rods rotate - the cable is only ever perfectly perpendicular to the shaft (when viewed from above in) in one position across the range of movement. so, if there is a small deviation in height between the cable entering the x/y end and the point it leaves the spool, I'm not sure it will make much difference.

>

> I'll post some pics soon..still debating what to

> do with the z-axis. I was leaning towards a

> cantilever bed. I was planning to add an offset

> weight opposite the bed to equalize the moment on

> the linear z bearings. But an 8lb basalt bed with

> an 8lb offset weight doesn't seem like a great

> idea. A dual belt/cable setup is looking more

> attractive.

Here's a video of me fiddling with the Z stage on the Ingentis - the whole motor cutting out problem is still unsolved, although I have about 5 possible solutions to work through.

[www.youtube.com]

-------------------------------------------------------

>

> Hmm- I'm using 8mm shafts. Could I use the spools

> with Goopy's corner brackets and the stock X/Y

> ends? The spectra needs to be perfectly level

> from the rod/spool to the X/Y end, right?

Not sure how perfectly level it needs to be, because the cable walks up and down the spool as the rods rotate - the cable is only ever perfectly perpendicular to the shaft (when viewed from above in) in one position across the range of movement. so, if there is a small deviation in height between the cable entering the x/y end and the point it leaves the spool, I'm not sure it will make much difference.

>

> I'll post some pics soon..still debating what to

> do with the z-axis. I was leaning towards a

> cantilever bed. I was planning to add an offset

> weight opposite the bed to equalize the moment on

> the linear z bearings. But an 8lb basalt bed with

> an 8lb offset weight doesn't seem like a great

> idea. A dual belt/cable setup is looking more

> attractive.

Here's a video of me fiddling with the Z stage on the Ingentis - the whole motor cutting out problem is still unsolved, although I have about 5 possible solutions to work through.

[www.youtube.com]

|

Re: Variant of Goopyplastic's Tantillus Variant October 07, 2013 08:36AM |

Registered: 10 years ago Posts: 87 |

|

Re: Variant of Goopyplastic's Tantillus Variant October 07, 2013 11:02AM |

Registered: 12 years ago Posts: 95 |

Robonz Wrote:

-------------------------------------------------------

> I mounted my Dremel onto my drill press.30,000 RPM

> works like a charm. At that speed the drill bits

> dont get stuck if they do snap.You can stop and

> start at your leasure. I used tungsten carbide PCB

> drills that only cost 30 cents each. I should take

> a photo of my setup.

Now there's an idea I hadn't come up with. I assume you're in Nz? Im in Welly. Where did you get these drill bits from? Like you rod straightening method too btw

-------------------------------------------------------

> I mounted my Dremel onto my drill press.30,000 RPM

> works like a charm. At that speed the drill bits

> dont get stuck if they do snap.You can stop and

> start at your leasure. I used tungsten carbide PCB

> drills that only cost 30 cents each. I should take

> a photo of my setup.

Now there's an idea I hadn't come up with. I assume you're in Nz? Im in Welly. Where did you get these drill bits from? Like you rod straightening method too btw

|

Re: Variant of Goopyplastic's Tantillus Variant October 07, 2013 11:17AM |

Registered: 10 years ago Posts: 4 |

jimjimma Wrote:

> Not sure how perfectly level it needs to be,

> because the cable walks up and down the spool as

> the rods rotate - the cable is only ever perfectly

> perpendicular to the shaft (when viewed from above

> in) in one position across the range of movement.

> so, if there is a small deviation in height

> between the cable entering the x/y end and the

> point it leaves the spool, I'm not sure it will

> make much difference.

Good point. If the spooling/unspooling has some (small) angular deflection perhaps it's okay if there's a slight z deflection as well. Although I would think you'd want to minimize it to the greatest degree possible.

> Here's a video of me fiddling with the Z stage on

> the Ingentis - the whole motor cutting out problem

> is still unsolved, although I have about 5

> possible solutions to work

> through.[url=https://www.youtube.com/watch?v=20agR

> 5ksUwU][/url]

>

> [url]https://www.youtube.com/watch?v=20agR5ksUwU[/url]

Love the videos- I can also appreciate keeping the volume down while the little ones are sleeping. But hey, that's dads only time to get stuff done Re: motor cutting bed drop issue- second look at the threadless ball screw?

Re: motor cutting bed drop issue- second look at the threadless ball screw?

> Not sure how perfectly level it needs to be,

> because the cable walks up and down the spool as

> the rods rotate - the cable is only ever perfectly

> perpendicular to the shaft (when viewed from above

> in) in one position across the range of movement.

> so, if there is a small deviation in height

> between the cable entering the x/y end and the

> point it leaves the spool, I'm not sure it will

> make much difference.

Good point. If the spooling/unspooling has some (small) angular deflection perhaps it's okay if there's a slight z deflection as well. Although I would think you'd want to minimize it to the greatest degree possible.

> Here's a video of me fiddling with the Z stage on

> the Ingentis - the whole motor cutting out problem

> is still unsolved, although I have about 5

> possible solutions to work

> through.[url=https://www.youtube.com/watch?v=20agR

> 5ksUwU][/url]

>

> [url]https://www.youtube.com/watch?v=20agR5ksUwU[/url]

Love the videos- I can also appreciate keeping the volume down while the little ones are sleeping. But hey, that's dads only time to get stuff done

Re: motor cutting bed drop issue- second look at the threadless ball screw?

Re: motor cutting bed drop issue- second look at the threadless ball screw?

|

Re: Variant of Goopyplastic's Tantillus Variant October 07, 2013 01:54PM |

Registered: 13 years ago Posts: 2,947 |

jimjimma Wrote:

-------------------------------------------------------

> Not sure how perfectly level it needs to be,

> because the cable walks up and down the spool as

> the rods rotate - the cable is only ever perfectly

> perpendicular to the shaft (when viewed from above

> in) in one position across the range of movement.

> so, if there is a small deviation in height

> between the cable entering the x/y end and the

> point it leaves the spool, I'm not sure it will

> make much difference.

Because the cables are supposed to be lined up with the X/Y end when they are at their extremes near the rods there should be no deviation there. The deviation is then a smooth gradual deviation as it crosses to the opposite side. On Tantillus the maximum deviation of the cable from side to side is 1mm since it is equal to 2wraps of 0.5mm diameter cable. With the height deviation of the spools to the X/Y ends I could see it causing the deviation to accelerate as it approaches the rods.

> Here's a video of me fiddling with the Z stage on

> the Ingentis - the whole motor cutting out problem

> is still unsolved, although I have about 5

> possible solutions to work

> through.

If you are talking about it dropping when the power is turned off you could go to a worm drive.

-------------------------------------------------------

> Not sure how perfectly level it needs to be,

> because the cable walks up and down the spool as

> the rods rotate - the cable is only ever perfectly

> perpendicular to the shaft (when viewed from above

> in) in one position across the range of movement.

> so, if there is a small deviation in height

> between the cable entering the x/y end and the

> point it leaves the spool, I'm not sure it will

> make much difference.

Because the cables are supposed to be lined up with the X/Y end when they are at their extremes near the rods there should be no deviation there. The deviation is then a smooth gradual deviation as it crosses to the opposite side. On Tantillus the maximum deviation of the cable from side to side is 1mm since it is equal to 2wraps of 0.5mm diameter cable. With the height deviation of the spools to the X/Y ends I could see it causing the deviation to accelerate as it approaches the rods.

> Here's a video of me fiddling with the Z stage on

> the Ingentis - the whole motor cutting out problem

> is still unsolved, although I have about 5

> possible solutions to work

> through.

If you are talking about it dropping when the power is turned off you could go to a worm drive.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.