Variant of Goopyplastic's Tantillus Variant (Ingentis)

Posted by jimjimma

|

Re: Variant of Goopyplastic's Tantillus Variant October 20, 2013 11:48PM |

Registered: 12 years ago Posts: 95 |

acrux Wrote:

-------------------------------------------------------

> Jim how are you getting on with your Z stage?

> Because I didn't model the whole thing I'm having

> issues with solids where I need holes for cables

> to fit through. Never mind just a bit more wasted

> plastic :-)

If you mean the belt driven version of my original design, it's working but the design is a bit clunky. I haven't done any work on a version using the single belt concept yet. All efforts focused on getting it printing right now

-------------------------------------------------------

> Jim how are you getting on with your Z stage?

> Because I didn't model the whole thing I'm having

> issues with solids where I need holes for cables

> to fit through. Never mind just a bit more wasted

> plastic :-)

If you mean the belt driven version of my original design, it's working but the design is a bit clunky. I haven't done any work on a version using the single belt concept yet. All efforts focused on getting it printing right now

|

Re: Variant of Goopyplastic's Tantillus Variant October 21, 2013 03:34PM |

Registered: 12 years ago Posts: 95 |

|

Re: Variant of Goopyplastic's Tantillus Variant October 22, 2013 04:31AM |

Registered: 13 years ago Posts: 818 |

jimjimma Wrote:

-------------------------------------------------------

> I've published the first stages of a build guide.

> Any feedback appreciated.

> [url=http://ingentistst.blogspot.co.nz/2013/10/lar

> ge-form-factor-t-slot-tantillus.html?m=1]Build

> Guide[/url]

Fantastic! - great job, that's going to help get a lot more people started.

[url]http://richrap.blogspot.com/[/url]

-------------------------------------------------------

> I've published the first stages of a build guide.

> Any feedback appreciated.

> [url=http://ingentistst.blogspot.co.nz/2013/10/lar

> ge-form-factor-t-slot-tantillus.html?m=1]Build

> Guide[/url]

Fantastic! - great job, that's going to help get a lot more people started.

[url]http://richrap.blogspot.com/[/url]

|

Re: Variant of Goopyplastic's Tantillus Variant November 03, 2013 05:52PM |

Registered: 12 years ago Posts: 95 |

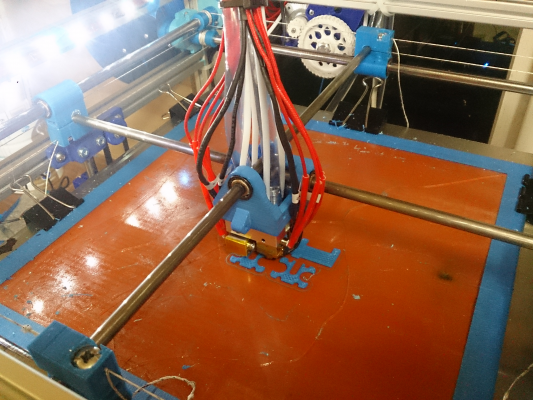

So, yesterday I got the Ingentis printing.

This was the second thing I printed (first was a claibration cube)- very happy that it just worked. Printed at 70mm/s perimeters, 0.14mm layers, 15% infill.

Video here

You may see the bottom of the print looks a bit munted (kiwi term for f*cked), Y axis skipped due to current being too low before I adjusted it. Z axis belt drive works well although I need to put some really deep divots in the drive shaft to prevent the big cog from slipping.

Edited 1 time(s). Last edit at 11/03/2013 09:13PM by jimjimma.

This was the second thing I printed (first was a claibration cube)- very happy that it just worked. Printed at 70mm/s perimeters, 0.14mm layers, 15% infill.

Video here

You may see the bottom of the print looks a bit munted (kiwi term for f*cked), Y axis skipped due to current being too low before I adjusted it. Z axis belt drive works well although I need to put some really deep divots in the drive shaft to prevent the big cog from slipping.

Edited 1 time(s). Last edit at 11/03/2013 09:13PM by jimjimma.

|

Re: Variant of Goopyplastic's Tantillus Variant November 03, 2013 09:41PM |

Registered: 11 years ago Posts: 290 |

|

Re: Variant of Goopyplastic's Tantillus Variant November 04, 2013 04:01PM |

Registered: 10 years ago Posts: 4 |

|

Re: Variant of Goopyplastic's Tantillus Variant November 05, 2013 03:23AM |

Registered: 10 years ago Posts: 22 |

|

Re: Variant of Goopyplastic's Tantillus Variant November 05, 2013 03:09PM |

Registered: 13 years ago Posts: 2,947 |

Quote

jimjimma

So, yesterday I got the Ingentis printing.

This was the second thing I printed (first was a claibration cube)- very happy that it just worked. Printed at 70mm/s perimeters, 0.14mm layers, 15% infill.

Video here

You may see the bottom of the print looks a bit munted (kiwi term for f*cked), Y axis skipped due to current being too low before I adjusted it. Z axis belt drive works well although I need to put some really deep divots in the drive shaft to prevent the big cog from slipping.

Looks good. Are you using any of the Tantillus software? Tantillus Marlin? Kisslicer and Tantillus profiles? Tantillus Calculator?

Have you done anymore printing with it? Would love to see more pics.

Also the build guide is looking good. One thing that may need attention is I looked at the page a few times before even noticing the drop down at the top to the other pages so I only saw the first page.

Edited 1 time(s). Last edit at 11/07/2013 03:03AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant November 06, 2013 04:49PM |

Registered: 12 years ago Posts: 95 |

Quote

Sublime

Looks good. Are you using any of the Tantillus software? Tantillus Marlin? Kisslicer and Tantillus profiles? Tantillus Calculator?

Have you done anymore printing with it? Would love to see more pics.

Also the build guide is looking good. One thing that may need attention is I looked at the page a few times before even noticing the drop down at the top to the other pages so I only saw the first page.

I've been using the Tantillus calculator for ages - useful for all printers in my experience. I didn't bother with Tantillus Marlin as I'm not usign a J-head, and there are enough differences to make a vanilla marlin build appropriate. My usual Kisslicer profiles seemed to work well - need to fiddle the max/min flow rates though

I'ts been out of action for the past day or 2 as I've been dealing with a minor extruder related issue. Then I got half way through a print last night (using repetier to push the g-code) and repetier crashed. Will stick it on the SD card and try again tonight. The half finished print was very nice though, the belt z drive works very nicely (apart from when it drops like a lead weight).

Duly noted regarding the build guide - I'm still tweeking the design so I've put the guide on hold until I've locked it down.

Thanks again for all you help here Sublime.

Finally, here's a little teeser of what I've got lined up in the near future:

|

Re: Variant of Goopyplastic's Tantillus Variant November 06, 2013 11:07PM |

Registered: 13 years ago Posts: 2,947 |

Quote

jimjimma

I've been using the Tantillus calculator for ages - useful for all printers in my experience.

Glad to here it works for you with other printers. Are you finding the defaults ok for other printers or have you gone through and entered all your data into the calculator?

Quote

jimjimma

I didn't bother with Tantillus Marlin as I'm not usign a J-head, and there are enough differences to make a vanilla marlin build appropriate.

Be sure to have a look at the acceleration, jerk and speed settings in the Tantillus Marlin. Maybe give them a try and report back it they improve or diminish the print quality.

Quote

jimjimma

My usual Kisslicer profiles seemed to work well - need to fiddle the max/min flow rates though

One thing I played with in Kisslicer is having it automatically calculate the speed for you based on flow rate. To do this you just set the min and max flow to the same number and set the min and max speeds to the actual min and max the machine can go. Then when you change the layer height or extrusion width it will automatically adjust the speed to keep the flow rate the same. The default for the Tantillus Calculator is 3mm^3/s and I often print at 6mm^3/s

Quote

jimjimma

I'ts been out of action for the past day or 2 as I've been dealing with a minor extruder related issue. Then I got half way through a print last night (using repetier to push the g-code) and repetier crashed. Will stick it on the SD card and try again tonight. The half finished print was very nice though, the belt z drive works very nicely (apart from when it drops like a lead weight).

Yeah you could always just add a G1 Znnn F1200 where nnn is the max height of the machine to the postfix (end gcode) so it moves the bed to the bottom at the end of the print instead of dropping.

Quote

jimjimma

Thanks again for all you help here Sublime.

No problem, I like seeing what others do with Tantillus and its evolution.

I do not like this new quoting system it makes answering questions a pain in the ass. Sure it looks pretty but the functionality is crap.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant November 07, 2013 04:22PM |

Registered: 12 years ago Posts: 95 |

Damn, just realised that image I posted wasn't publicly accesible. Try again.

|

Re: Variant of Goopyplastic's Tantillus Variant November 07, 2013 05:35PM |

Registered: 14 years ago Posts: 51 |

|

Re: Variant of Goopyplastic's Tantillus Variant November 07, 2013 06:30PM |

Registered: 10 years ago Posts: 14 |

|

Re: Variant of Goopyplastic's Tantillus Variant November 07, 2013 08:22PM |

Registered: 10 years ago Posts: 14 |

Re the Tantillus calculator, I have seen it and wondered if it could be of use on my current Prusa i3. However can someone point me to postings that go into some detail of all the settings like XJ jerk etc and talk about a systematic way to get values that are appropriate for your hardware? I think I am getting good prints from good luck rather than good management. It is confusing as there seems to be settings in Marlin, Kisslicer and the start g-code I have in kisslicer that all fight each other.

|

Re: Variant of Goopyplastic's Tantillus Variant November 07, 2013 10:21PM |

Registered: 13 years ago Posts: 2,947 |

Quote

acrux

Re the Tantillus calculator, I have seen it and wondered if it could be of use on my current Prusa i3. However can someone point me to postings that go into some detail of all the settings like XJ jerk etc and talk about a systematic way to get values that are appropriate for your hardware? I think I am getting good prints from good luck rather than good management. It is confusing as there seems to be settings in Marlin, Kisslicer and the start g-code I have in kisslicer that all fight each other.

The settings that the calculator creates are those for the slicer. Be it Kisslicer, Cura, SF, SFact, Repsnapper or Slic3r. Extrusion width, speed and temperature for a given layer height and object size based on your hardware. Just input the nozzle size, filament size and the E and Z steps per mm and it will calculate the settings best suited for your machine to give the best finish and dimensionally accurate prints. ( All of the above mentioned slicers do things differently but none of them seem to get those settings correct by default )

If you want to know more about the calculator and how and why it determines these settings you can read here [forums.reprap.org] and here [kisslicer.com] or start a new thread and we can discuss it further.

The settings for the machine in Marlin are a bit harder. You want the acceleration and jerk as high as you can have them reliably. This is because the more instantaneously you can get up to speed the higher the definition you get. But they are hard to figure out because one kind of overrides the other so it just takes a lot of trial and error to find a good set of numbers. This higher is better applies to all machines but with them too high on a Mendel variant you end up with "ringing" or "ghost" patterns near corners because of the high rate of direction change and the large moving mass of the bed and extruder carriage.

You also want the firmwares max speeds all set to the actual reliable maximum speed your machine can handle for all types of prints. This will allow you to have the shortest non-printing moves. Then set the speeds for travel and Z speed in the slicer to these same max speeds. With the max set in the firmware you can always travel at the max reliable speed even if you increase the print speed via an LCD controller.

Last thing you want is the E settings in the firmware to be the very max they can be reliably. Tantillus has the default and max E acceleration set to 10,000 which is the max before Marlin does something strange and reduces the acceleration back to the minimum. The jerk is also set really high at 100mm/s.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant November 07, 2013 10:21PM |

Registered: 12 years ago Posts: 95 |

Quote

acrux

OMG the four headed monster is almost awakened. I would love to play with one of these. Are there any controller boards that can control four hot ends at once? I think the one I have from gadgets3d can do two.

Sanjay is working on a Ramps modification that will support 4 extruders. My RUMBA will support 5 thermistors and 5 PWM mosfets, it only has space for 3 Extruder stepper drivers at present so I'll have to make a wee sheild to drive a 4th, plenty of spare pins for that purpose.

Marlin also needs to be changed to accomodate for 4 extruders, that's being worked on by the E3D folk.

|

Re: Variant of Goopyplastic's Tantillus Variant November 08, 2013 06:13PM |

Registered: 10 years ago Posts: 22 |

Quote

jimjimma

Damn, just realised that image I posted wasn't publicly accesible. Try again.

Is that a water cooled thermal break?

|

Re: Variant of Goopyplastic's Tantillus Variant November 10, 2013 10:54PM |

Registered: 13 years ago Posts: 485 |

|

Re: Variant of Goopyplastic's Tantillus Variant November 11, 2013 08:27PM |

Registered: 12 years ago Posts: 95 |

Quote

Sublime

The settings for the machine in Marlin are a bit harder. You want the acceleration and jerk as high as you can have them reliably. This is because the more instantaneously you can get up to speed the higher the definition you get. But they are hard to figure out because one kind of overrides the other so it just takes a lot of trial and error to find a good set of numbers. This higher is better applies to all machines but with them too high on a Mendel variant you end up with "ringing" or "ghost" patterns near corners because of the high rate of direction change and the large moving mass of the bed and extruder carriage.

I'm running 20mm/s jerk and 1500 default accel at this stage but I shall push the accel up once I'm happy I've got everything working. I've strated to see Ultimaker 2 prints beign poseted and the quality and dimentional accuracy they are producing is amazing. The 'secretmarlin' repository has all the default Ultimaker2 settings - I see they have jerk at 20 and default accel at 5000.

Quote

Sublime

You also want the firmware's max speeds all set to the actual reliable maximum speed your machine can handle for all types of prints. This will allow you to have the shortest non-printing moves. Then set the speeds for travel and Z speed in the slicer to these same max speeds. With the max set in the firmware you can always travel at the max reliable speed even if you increase the print speed via an LCD controller.

I'm still struggling to establish a way to define a 'reliable' maximum and minumum rate. I assume free air extrusion is not the best way of doign this. Also, maximum flowrate is constrained by the temperature you're printing at too eh? I see that marlin has an autotemp setting in advance.h whereby it calculates extrusion temp based upon buffered gcode as well as a setting dynamically varying altering PID power based upon extrusion speed. Any tips here would be awesome - I'm using E3d so, the numbers will be quite different from a J-Head I think.

Quote

Sublime

Last thing you want is the E settings in the firmware to be the very max they can be reliably. Tantillus has the default and max E acceleration set to 10,000 which is the max before Marlin does something strange and reduces the acceleration back to the minimum. The jerk is also set really high at 100mm/s.

I see that the Ultimaker2 Max accel is 10,000 too but their e-jerk is only 5mm/s. I get the feeling you've proven your settings work well for a Gregs style geared extruder. What retract accel are you using?

I'm playing around with Kisslicer profiles at present. Got your ones loaded in as a starting point and will tweak things from there.

|

Re: Variant of Goopyplastic's Tantillus Variant November 11, 2013 08:41PM |

Registered: 12 years ago Posts: 95 |

Here is another test print - something of a mixed bag as the overhangs on this model are well past 45 degrees and with ABS (no cooling) the surface finish really suffers.

The surface finish on the rest of it is awesome though, the photos don't do it justice really but you can barely discern the layers either visually or by touch. Clearly, the Z belt drive seems to be reliable. Printed at 0.1mm with 60mm/s perimeters btw.

Full album including the overhang horror shots here.

The surface finish on the rest of it is awesome though, the photos don't do it justice really but you can barely discern the layers either visually or by touch. Clearly, the Z belt drive seems to be reliable. Printed at 0.1mm with 60mm/s perimeters btw.

Full album including the overhang horror shots here.

|

Re: Variant of Goopyplastic's Tantillus Variant November 12, 2013 12:15AM |

Registered: 13 years ago Posts: 2,947 |

Quote

jimjimma

Quote

Sublime

The settings for the machine in Marlin are a bit harder. You want the acceleration and jerk as high as you can have them reliably. This is because the more instantaneously you can get up to speed the higher the definition you get. But they are hard to figure out because one kind of overrides the other so it just takes a lot of trial and error to find a good set of numbers. This higher is better applies to all machines but with them too high on a Mendel variant you end up with "ringing" or "ghost" patterns near corners because of the high rate of direction change and the large moving mass of the bed and extruder carriage.

I'm running 20mm/s jerk and 1500 default accel at this stage but I shall push the accel up once I'm happy I've got everything working. I've strated to see Ultimaker 2 prints beign poseted and the quality and dimentional accuracy they are producing is amazing. The 'secretmarlin' repository has all the default Ultimaker2 settings - I see they have jerk at 20 and default accel at 5000.

Back at the beginning of Tantillus I had these settings.

#define DEFAULT_XYJERK 20.0

#define DEFAULT_MAX_ACCELERATION {9000,9000,300,10000}

#define DEFAULT_ACCELERATION 3000

Which is what you see in the early Tantillus videos. But every couple of large prints I would end up with skipped steps and ruined prints. Then I changed them to:

#define DEFAULT_XYJERK 10.0

#define DEFAULT_MAX_ACCELERATION {8000,8000,300,100000}

Which did not change the prints much but reduced the chance of skipped steps. This may be due to the printed bushings and used motors.

The Ultimaker settings should give nice high definition prints. Is there anything special in SecretMarlin or about the Ultimaker2 that may improve the prints.

Quote

jimjimma

Quote

Sublime

You also want the firmware's max speeds all set to the actual reliable maximum speed your machine can handle for all types of prints. This will allow you to have the shortest non-printing moves. Then set the speeds for travel and Z speed in the slicer to these same max speeds. With the max set in the firmware you can always travel at the max reliable speed even if you increase the print speed via an LCD controller.

I'm still struggling to establish a way to define a 'reliable' maximum and minumum rate. I assume free air extrusion is not the best way of doign this. Also, maximum flowrate is constrained by the temperature you're printing at too eh? I see that marlin has an autotemp setting in advance.h whereby it calculates extrusion temp based upon buffered gcode as well as a setting dynamically varying altering PID power based upon extrusion speed. Any tips here would be awesome - I'm using E3d so, the numbers will be quite different from a J-Head I think.

For the max and min feedrates for X and Y I used my break in code which is similar to the one you used to break in the gears. I then set the max in the config to something way above reality like 1000. Then start your break in code and start to turn up the speed via the LCD or through the host with M220 Snn. Turn it up say 50% each time and let it sit at that speed for a few minutes to look/listen for skipped steps. Repeat until you find the failure point. Set the new max in the firmware to prevent the travel moves in the next step from going above this speed. Then start printing low infill and low perimeter count Yoda heads about 50mm tall at about 50% of the new hypothetical max speed and see if it skips steps when the ears curl up and the nozzle catches the curled up plastic. If not turn it up another 30-50mm/s second and repeat until it skips steps and go back to the last reliable speed. I know this sounds time consuming and crazy but it will give you a good idea of the max speed it can reliably print when having to push through curled up plastic.

For the max E speed you want it set at the max speed the extruder can retract at or the max speed Marlin will allow you to run it at. In my branch of Marlin it has some strange (bug maybe) behaviour that once it reaches a certain step rate it reduces it to almost nothing. To see how I set it read the tutorials page on Tantillus.org . We do not need to worry about the max flow rate of the extruder in the firmware since it is tied to the slicer settings (layer height, extrusion width and speed) which is what the calculator is for. The calculator uses a minimum flow rate of 0.25mm^3/s and a maximum of 8.0mm^3/s by default which is about the reliable max for a J-head with PLA. I believe it is higher for ABS. For a different hotend it will be different, but from what I have read most hotends like to stay below 10-15mm^3/s and when above some of them tend to break. Maybe due to the temperature required combined with the pressure and materials used.

For the autotemp in the firmware I have no experience. I tend to like being in control of things and when I did try some of the advanced features in Marlin I did not have much success. Then after finding what I think are good settings I never bothered to play with any of the new features.

Quote

jimjimma

Quote

Sublime

Last thing you want is the E settings in the firmware to be the very max they can be reliably. Tantillus has the default and max E acceleration set to 10,000 which is the max before Marlin does something strange and reduces the acceleration back to the minimum. The jerk is also set really high at 100mm/s.

I see that the Ultimaker2 Max accel is 10,000 too but their e-jerk is only 5mm/s. I get the feeling you've proven your settings work well for a Gregs style geared extruder. What retract accel are you using?

I'm playing around with Kisslicer profiles at present. Got your ones loaded in as a starting point and will tweak things from there.

E is 10000 max, 10000 default, and 100jerk but my extrudes are 3.3:1 and 2.7:1 which may allow the motor to accelerate at those rates. Also the reason you can retract at those speeds with a bowden is the filament is acting like a giant spring trying to turn the motor backwards. I am not even sure if Tantillus needs the jerk so high but I never have issues that I believe would be fixed by lowering it. But it may be an option for anyone that has their filament being chewed up.

I hope I answered everything. If not just let me know.

The new print looks good. Does 0.1mm work well with the belt driven Z steps per mm

Edited 1 time(s). Last edit at 11/12/2013 12:49AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant December 02, 2013 06:36PM |

Registered: 12 years ago Posts: 95 |

Thanks for that very detailed resposne Sublime - I have been playing around with settings and in some cases your values work and in others they cause some prolems, not entirely suprising given the variations from the Tantillus design. I am crazy busy at present but I'll get an update out on the Ingentis over the next week - it is pretty much done now, baring a few minor modifications.

Also, I've been busy getting this thing going

Also, I've been busy getting this thing going

|

Re: Variant of Goopyplastic's Tantillus Variant December 06, 2013 02:21AM |

Registered: 13 years ago Posts: 2,947 |

Yeah sorry for the long post. Sometimes I start typing and when I look up there are paragraphs.

The Kraken looks good. Have you seen Bobc's ext6 board to add up to 6 stepper drivers and temp control circuits?

Are you doing much printing with it yet?

The Kraken looks good. Have you seen Bobc's ext6 board to add up to 6 stepper drivers and temp control circuits?

Are you doing much printing with it yet?

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant December 15, 2013 12:01PM |

Registered: 10 years ago Posts: 1 |

Hello All.

I have decided to build this printer. I started to print parts. I noticed that "Shaft Bearing Mounts" have apertures on the both sides. One is for inserting the bearing, I cant figure out why the bigger on the apposite side is for? On the pictures of the printer there is also only one aperture for bearing. So am a bit confused.

Thanks for answers.

I have decided to build this printer. I started to print parts. I noticed that "Shaft Bearing Mounts" have apertures on the both sides. One is for inserting the bearing, I cant figure out why the bigger on the apposite side is for? On the pictures of the printer there is also only one aperture for bearing. So am a bit confused.

Thanks for answers.

|

Re: Variant of Goopyplastic's Tantillus Variant December 15, 2013 06:25PM |

Registered: 12 years ago Posts: 95 |

Quote

Finch

Hello All.

I have decided to build this printer. I started to print parts. I noticed that "Shaft Bearing Mounts" have apertures on the both sides. One is for inserting the bearing, I cant figure out why the bigger on the apposite side is for? On the pictures of the printer there is also only one aperture for bearing. So am a bit confused.

Thanks for answers.

Hi Finch, the large hole is for the bearings, the smaller hole on the other side is to allow for some clearance for the spectra bobbins. Please take note of the need to print differnt ones for X and Y shafts, that's explained int eh blog. Any problems, message me via google plus +tim rastall.

|

Re: Variant of Goopyplastic's Tantillus Variant December 15, 2013 07:41PM |

Registered: 13 years ago Posts: 2,947 |

Quote

jimjimma

Any problems, message me via google plus +tim rastall.

Is there any way for anyone to contact you that does not involve handing over all your personal information to big brother (Google +). I for one have stopped using most of Googles services (other than search) because of them trying to force people to use their social networking service. You can't even comment on your own videos in Youtube with handing over your private info.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Variant of Goopyplastic's Tantillus Variant December 15, 2013 07:46PM |

Registered: 10 years ago Posts: 35 |

|

Re: Variant of Goopyplastic's Tantillus Variant December 15, 2013 08:53PM |

Registered: 12 years ago Posts: 95 |

Quote

Sublime

Is there any way for anyone to contact you that does not involve handing over all your personal information to big brother (Google +). I for one have stopped using most of Googles services (other than search) because of them trying to force people to use their social networking service. You can't even comment on your own videos in Youtube with handing over your private info.

Well, you can get me on gmail

. I'm too imbedded in the Google machine already and G+ (for me anyway) is a good compromise between forum and social network - the 3d pritning community in particular is awesome.

. I'm too imbedded in the Google machine already and G+ (for me anyway) is a good compromise between forum and social network - the 3d pritning community in particular is awesome.My gmail address is pretty obvious, dot between first and last name. Or failing that, a PM from this forum will hit my gmail anyway.

Quote

Sublime

Yeah sorry for the long post. Sometimes I start typing and when I look up there are paragraphs.

The Kraken looks good. Have you seen Bobc's ext6 board to add up to 6 stepper drivers and temp control circuits?

Are you doing much printing with it yet? .

I ahve seen Bobc's board. I'm running a RUMBA which means I have 4 x HE Thermistor and 4 x HE PWM already available, will make a little expansion sheild for stepper driver#4 at some point but 3 will do for the time being.

Plenty of printing with Kraken with a single head - have been struggling with 1.75mm filament and my Wades (with a bolt hobbed for 3mm) so I've just chnged to Airtripper direct drives that are behavign better. Have everythign set up for HIPS support printing.

Picture of one of the airtripper housings below - hard to see scale but it's about 30mm high. Printed at 0.2mm, 50mm/s, sliced with Cura (which I am starting to like more than Kiss).

Edited 1 time(s). Last edit at 12/16/2013 08:45PM by jimjimma.

|

Re: Variant of Goopyplastic's Tantillus Variant December 22, 2013 12:29PM |

Registered: 12 years ago Posts: 227 |

Will you place extruders above the box to make bowdens shorter?

like this [www.calumdouglas.ch]

like this [www.calumdouglas.ch]

|

Re: Variant of Goopyplastic's Tantillus Variant December 29, 2013 12:40AM |

Registered: 12 years ago Posts: 95 |

Quote

karabas

Will you place extruders above the box to make bowdens shorter?

like this [www.calumdouglas.ch]

Not sure. At some stage I'll go for enclosing the bot and that will mean accommodating for the Bowden tubes etc with an extra void space at the top of the machine, it may be possible to place the extruders at the top of this space but I really don't want some ugly apparatus mounted above the bot as shown in the link.

Sorry, only registered users may post in this forum.