Printing Taulman 618 Nylon on Tantillus

Posted by willworkforplastic

|

Printing Taulman 618 Nylon on Tantillus September 01, 2013 02:36AM |

Registered: 11 years ago Posts: 111 |

So I have been AWL, for a bit however over the last few months in my very limited spare time I have been playing around with Taulmans Nylon 618, and I thought I post up some things I learned with it for anybody interested. You can view all the photo's here: [www.flickr.com]

The plan was to print a Tantillus gear set in Nylon so I set about first trying bed materials to stick to.

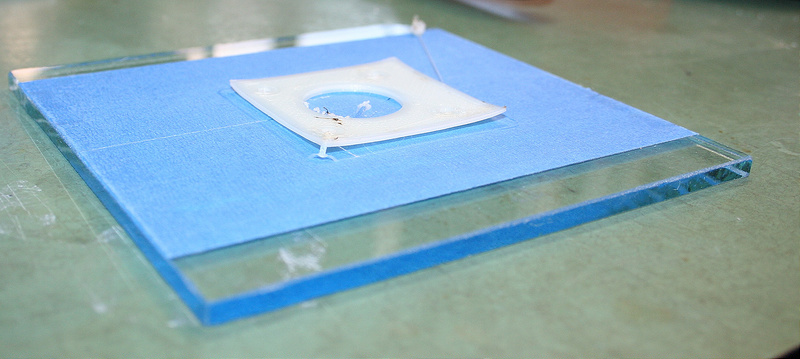

First was blue tape (all these done with fans off and the heated bed at 100oC):

That was a quick fail, so I did my homework and found the Taulman Nylon loves to stick to Cellulose. So I mixed up some wallpaper paste (cellulose paste), in twice the recommended concentration. Spread that on glass, let it dry and tried printing on that:

Again a quick fail. So then I tried printing on a piece of 5mm MDF laser cut out to the same shape as the glass:

That worked really well, however so well it was a real struggle to get it off the MDF. The other annoying things as well was the wood is not as flat as glass, and not the same thickness as glass + blue painters tape so you have to remember to get the correct offsets. That said if you where post machining the part this would be a really good option as it gives you a good clamping base.

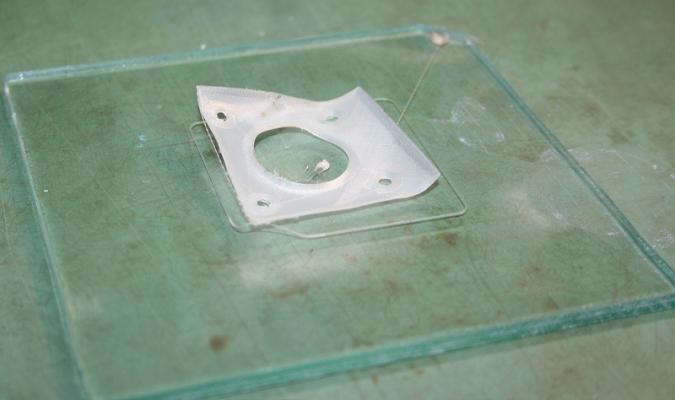

Then I had a brain fart and went hold on a minute, paper = wood = cellulose. What would happen if I wallpapered a piece of glass with paper, sanded it slightly and then printed on it. The result was:

Much better however I still got corner lift and the paper appeared to rip apart. My thinking was that is was due to the short fibers in the paper and a friend told me that A4 white paper has a high clay content to make it shinny. So I went and got a roll of brown craft paper from the stationary store and tried that. Also I added a 0.15mm brim (sombrero mode was the coined name for it in another thread) The result was:

So I tried a motor gear with a 0.3mm sombrero and got:

Then upped the the sombrero to 0.6mm and then started getting really flat prints:

The great thing is one you get them off the glass, you just wash them under water with a scrubbing brush to get the excess paper/paste off.

So I managed to get a full set of gears off my tantillus and I have run 1.5Kg of PLA through the machine with no problems so far, fingers crossed. The other things I found are:

The basic method I have now for setting a piece of glass is:

1. Clean it

2. Spread wall paper paste over it

3. Put a piece of brown craft paper on it

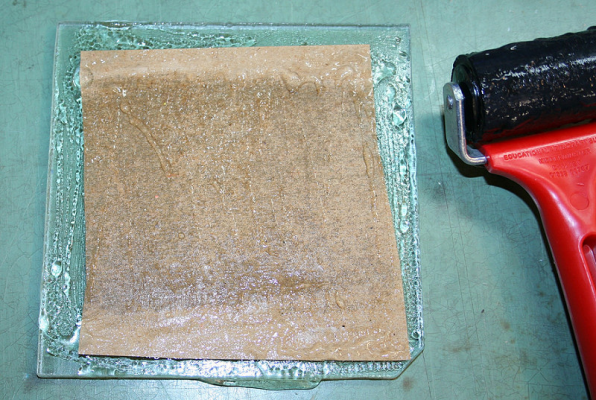

4. Roll it with a hard roller so glue wets paper out:

5. Let it dry then sand it with >180 grit sand paper, till dust coming off it is brown

If you want really flat prints you have to add a sombrero also (I just do in it CAD), wider the better and I found 0.6mm thick is good.

Edited 2 time(s). Last edit at 09/01/2013 02:49AM by willworkforplastic.

The plan was to print a Tantillus gear set in Nylon so I set about first trying bed materials to stick to.

First was blue tape (all these done with fans off and the heated bed at 100oC):

That was a quick fail, so I did my homework and found the Taulman Nylon loves to stick to Cellulose. So I mixed up some wallpaper paste (cellulose paste), in twice the recommended concentration. Spread that on glass, let it dry and tried printing on that:

Again a quick fail. So then I tried printing on a piece of 5mm MDF laser cut out to the same shape as the glass:

That worked really well, however so well it was a real struggle to get it off the MDF. The other annoying things as well was the wood is not as flat as glass, and not the same thickness as glass + blue painters tape so you have to remember to get the correct offsets. That said if you where post machining the part this would be a really good option as it gives you a good clamping base.

Then I had a brain fart and went hold on a minute, paper = wood = cellulose. What would happen if I wallpapered a piece of glass with paper, sanded it slightly and then printed on it. The result was:

Much better however I still got corner lift and the paper appeared to rip apart. My thinking was that is was due to the short fibers in the paper and a friend told me that A4 white paper has a high clay content to make it shinny. So I went and got a roll of brown craft paper from the stationary store and tried that. Also I added a 0.15mm brim (sombrero mode was the coined name for it in another thread) The result was:

So I tried a motor gear with a 0.3mm sombrero and got:

Then upped the the sombrero to 0.6mm and then started getting really flat prints:

The great thing is one you get them off the glass, you just wash them under water with a scrubbing brush to get the excess paper/paste off.

So I managed to get a full set of gears off my tantillus and I have run 1.5Kg of PLA through the machine with no problems so far, fingers crossed. The other things I found are:

- With a 0.35mm nozzle at 240oC i had to take the printer speed down to 25mm/s to get good prints

The Nylon has to be bone dry for good prints (bubbles and massive shrinkage will cause you nightmares). My keep it dry had a leak I did not notice so my stock of Nylon was really wet. I dried it out in a small pizza oven at 60oC with desiccant and a fan for 20hrs. Also I hacked my tantillus to have a dry box feeder as well. I'll post that hack up in the SW thread.

Nylon is tough but not ridged, I found the original gear design is very flexible in Nylon. They run way quieter but they wobble/run out of center. Has not caused me an issue yet.

The basic method I have now for setting a piece of glass is:

1. Clean it

2. Spread wall paper paste over it

3. Put a piece of brown craft paper on it

4. Roll it with a hard roller so glue wets paper out:

5. Let it dry then sand it with >180 grit sand paper, till dust coming off it is brown

If you want really flat prints you have to add a sombrero also (I just do in it CAD), wider the better and I found 0.6mm thick is good.

Edited 2 time(s). Last edit at 09/01/2013 02:49AM by willworkforplastic.

|

Re: Printing Taulman 618 Nylon on Tantillus September 01, 2013 09:43PM |

Registered: 10 years ago Posts: 35 |

|

Re: Printing Taulman 618 Nylon on Tantillus September 02, 2013 02:46AM |

Registered: 11 years ago Posts: 111 |

SkyArcher Wrote:

> What do you have for a heated bed?

Custom CNC aluminium platter with silicone heating wire in it, have a look at: [forums.reprap.org]

> What do you have for a heated bed?

Custom CNC aluminium platter with silicone heating wire in it, have a look at: [forums.reprap.org]

Sorry, only registered users may post in this forum.