The Auger Chewer

Posted by willworkforplastic

|

The Auger Chewer October 29, 2013 05:18AM |

Registered: 11 years ago Posts: 111 |

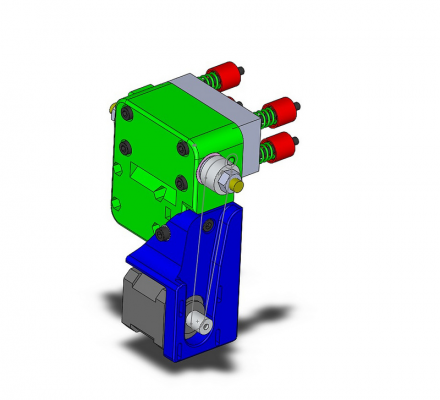

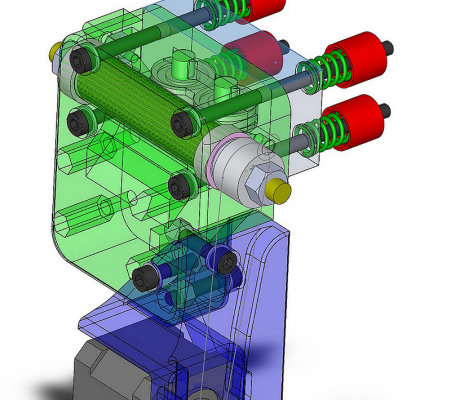

So I have been doing a lot of work with accuracy which I'll cover in another post when I have got a definite result. But as I wait for a few more parts to come in I have come up with this crazy idea for an extruder. Not saying the current extruder is bad, actually is really good considering its simplicity but I seem to have to clean the hobbed bolt out every 1Kg of PLA. So I thought why not an auger system, yeah OK its got a machined auger in it but cleaning would hopefully not be an issue. At the moment it looks like this:

And:

At the moment the auger has a 0.5mm pitch, and belt gearing of 1:2.5, which gives about 600pulse/mm @1/16microstepping. So is this idea too crazy and remain in the land of CAD?

And:

At the moment the auger has a 0.5mm pitch, and belt gearing of 1:2.5, which gives about 600pulse/mm @1/16microstepping. So is this idea too crazy and remain in the land of CAD?

|

Re: The Auger Chewer October 29, 2013 12:27PM |

Registered: 13 years ago Posts: 2,947 |

That is how the original RepRap Darwin extruder worked as well as how the BFB extruders worked until the BFB line was renamed to Cube and CubeX. From what I have gathered they do work but tend to make the filament rotate which lends to inaccurate movement of the filament. They also tend to be slow at retraction. This is not to say that it will not work as they may have had their own design related issues causing these things. But seeing as a large company like 3dsystems spent time and money to change their low end printers (rebranded bfb printers) over to a pinchwheel design I can not imagine it worked well or reliably.

edit: BFB touch triple auger style extruder.

Picture [www.bitsfrombytes.com]

On another note I have never found cleaning my hobbed bolts helped. I have tried a few times in the past but it was never the issue. If I ever have chewed up filament it is a result of dirt in the hotend. To clean the hotend I push filament into the hotend while hot and remove it quickly. I cut off the part with the dirt and repeat this over and over (maybe 10 - 50 times) until the filament comes out clean and I get no more burnt looking plastic on the end of the filament. It can take a few feet of filament to get it all out and clean. Also I find if I try and print black it almost ruins the hotend and causes jams at an unbelievable rate.

Do you have your idler tensioner bolts tight? I run mine so the springs are fully compressed while there is filament loaded in it. This way they are as tight as they can be while still allowing for slightly smaller filament.

Edited 2 time(s). Last edit at 10/30/2013 02:49AM by Sublime.

edit: BFB touch triple auger style extruder.

Picture [www.bitsfrombytes.com]

On another note I have never found cleaning my hobbed bolts helped. I have tried a few times in the past but it was never the issue. If I ever have chewed up filament it is a result of dirt in the hotend. To clean the hotend I push filament into the hotend while hot and remove it quickly. I cut off the part with the dirt and repeat this over and over (maybe 10 - 50 times) until the filament comes out clean and I get no more burnt looking plastic on the end of the filament. It can take a few feet of filament to get it all out and clean. Also I find if I try and print black it almost ruins the hotend and causes jams at an unbelievable rate.

Do you have your idler tensioner bolts tight? I run mine so the springs are fully compressed while there is filament loaded in it. This way they are as tight as they can be while still allowing for slightly smaller filament.

Edited 2 time(s). Last edit at 10/30/2013 02:49AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: The Auger Chewer November 04, 2013 02:46AM |

Registered: 11 years ago Posts: 111 |

Ah thanks sublime, I thought someone must have done this before. I'll shelf this idea as it is one of those good idea's which never work out in practice by the looks of it.

With PLA the current extruder is great, just sometimes I have to adjust the flow rate up, but your probably right I am getting partial/blocks in the head, I'll check next time it happens. I have about 600N (60Kg or 132lb calculated) of spring force on my idler which I assume is plenty. I am using die springs commonly used in press tools (IEM5008).

The real issue I have is when I run Nylon I have to go slow (around 20mm/s mark) as the extruder just strips the filament. Probably as the Nylon has a lower shear modulus than PLA, or the pressure in the head has to be massive for a 0.35mm head as Nylon does not flow as well as PLA. So my thoughts where to get more engagement on the filament to prevent stripping. However that will probably blow something out at the head due to the pressure on it if successful.

So my other thoughts where:

1. Increase the diameter of the hobbing to get more teeth engaged on the filament probably easiest as I can easily turn something up, getting the resulting larger gear ratio to fit might be interesting however.

2. Run a dual auger system with left/right threads to prevent torsion on the filament (sounds hard to me though would be fun to try though)

3. Use a friction drive system somehow (again probably hard and loss of traction becomes a concern)

4. F it and run the machine slow, go have a beer in the sun

5. Build another machine with a 0.4-0.5mm head solely for Nylon

With PLA the current extruder is great, just sometimes I have to adjust the flow rate up, but your probably right I am getting partial/blocks in the head, I'll check next time it happens. I have about 600N (60Kg or 132lb calculated) of spring force on my idler which I assume is plenty. I am using die springs commonly used in press tools (IEM5008).

The real issue I have is when I run Nylon I have to go slow (around 20mm/s mark) as the extruder just strips the filament. Probably as the Nylon has a lower shear modulus than PLA, or the pressure in the head has to be massive for a 0.35mm head as Nylon does not flow as well as PLA. So my thoughts where to get more engagement on the filament to prevent stripping. However that will probably blow something out at the head due to the pressure on it if successful.

So my other thoughts where:

1. Increase the diameter of the hobbing to get more teeth engaged on the filament probably easiest as I can easily turn something up, getting the resulting larger gear ratio to fit might be interesting however.

2. Run a dual auger system with left/right threads to prevent torsion on the filament (sounds hard to me though would be fun to try though)

3. Use a friction drive system somehow (again probably hard and loss of traction becomes a concern)

4. F it and run the machine slow, go have a beer in the sun

5. Build another machine with a 0.4-0.5mm head solely for Nylon

|

Re: The Auger Chewer November 04, 2013 04:04AM |

Registered: 13 years ago Posts: 2,947 |

You could use a mini hyena with an 8mm bore over the standard 5/16" (8mm) bolt that is normally hobbed and then all you need to do is make clearance in the extruder body for it and offset the filament entrance/exit holes to compensate for the larger drive diameter. You could then use the original 3.3:1 extruder gears (look through the commits for when I removed it and then click the browse code button at that point to be able to download it). Beyond that I think a double hobbed drive system. Basically two hobbed drives facing each other with the filament in between like steve's extruder from seemecnc [reprap.org] (which I do not think is available any longer for whatever reason).

Another thing is it may be a result of the nylon being too soft for the bowden tube and as it gets compressed it expands outward and increases the force required to push it. The last thing is RichRap prints a lot of nylon with his Tantillus but his machine uses 1.75mm filament so that may be something to test as well.

Another thing is it may be a result of the nylon being too soft for the bowden tube and as it gets compressed it expands outward and increases the force required to push it. The last thing is RichRap prints a lot of nylon with his Tantillus but his machine uses 1.75mm filament so that may be something to test as well.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: The Auger Chewer November 04, 2013 04:38AM |

Registered: 11 years ago Posts: 111 |

Hmm interesting point about the filament swelling in the bowden tube never thought of that. What I might do when I get a chance is try and calculate the force required to shear the filament for various setups then try something based on that. Double hobbed bolts is an interesting idea also.

|

Re: The Auger Chewer November 15, 2013 07:05PM |

Registered: 12 years ago Posts: 95 |

I've got a half baked idea for a twin hobbed solution as Sublime describes if your interested.

Also, I clean my hot end with nylon: push it through at 230 drop the temp to 190 and pull it out. Amazing how much burnt ABS comes out. 5-10 cycles is all it takes. Credit to Whosa whatsis for this method.

Also, I clean my hot end with nylon: push it through at 230 drop the temp to 190 and pull it out. Amazing how much burnt ABS comes out. 5-10 cycles is all it takes. Credit to Whosa whatsis for this method.

Sorry, only registered users may post in this forum.