New build extruder troubles

Posted by flemming

|

New build extruder troubles December 31, 2013 08:11PM |

Registered: 10 years ago Posts: 21 |

I'm working through a build and unfortunately my extruder is preventing my from actually making my first print. I've been tinkering with the stepper pots, tightening and loosening the idler screws, but nothing seems to be helping. I took a couple videos to hopefully illustrate the problem and ideally get some advice:

First a video of extruder turning while empty:

[www.youtube.com]

You can hear an occasional grating sound, but it's turning and doesn't seem to be skipping steps or anything else obvious. The noise I suspect is the idler bearing on the hobbed bolt (more on that later).

Next is a video with a small piece of PLA loaded:

[www.youtube.com]

Since it's not skipping and it's not slipping my first guess would be that the springs are too tight. In the video when it starts to move again that's because I was pushing it fairly hard with my hand. As is sometimes it feeds and other times it stalls. When I loosen the springs, sometimes it feeds and sometimes it looks to be grinding. This lead me to consider looking a bit closer at the hobbed bolt:

[www.youtube.com]

There is a fair amount of irregularity in the channel, could it be that the problem is that when the channel narrows the motor is stalling because the springs are thus too tight, but when the channel opens up again the filament is able to feed normally? I'm just guessing here.

I bought the bolt from Sublime himself so I'm reluctant to blame the bolt, but I've been tinkering with this on and off for many days now and nothing seems to be helping. Any advice is appreciated. Thanks

Robert

First a video of extruder turning while empty:

[www.youtube.com]

You can hear an occasional grating sound, but it's turning and doesn't seem to be skipping steps or anything else obvious. The noise I suspect is the idler bearing on the hobbed bolt (more on that later).

Next is a video with a small piece of PLA loaded:

[www.youtube.com]

Since it's not skipping and it's not slipping my first guess would be that the springs are too tight. In the video when it starts to move again that's because I was pushing it fairly hard with my hand. As is sometimes it feeds and other times it stalls. When I loosen the springs, sometimes it feeds and sometimes it looks to be grinding. This lead me to consider looking a bit closer at the hobbed bolt:

[www.youtube.com]

There is a fair amount of irregularity in the channel, could it be that the problem is that when the channel narrows the motor is stalling because the springs are thus too tight, but when the channel opens up again the filament is able to feed normally? I'm just guessing here.

I bought the bolt from Sublime himself so I'm reluctant to blame the bolt, but I've been tinkering with this on and off for many days now and nothing seems to be helping. Any advice is appreciated. Thanks

Robert

|

Re: New build extruder troubles December 31, 2013 08:38PM |

Registered: 10 years ago Posts: 80 |

|

Re: New build extruder troubles December 31, 2013 10:12PM |

Registered: 13 years ago Posts: 2,947 |

I would agree with what Wingnut said about the gears possibly catching each other. You may want to lower the gear on the motor a little bit so the teeth of the larger gear do not hit the hub of the motor gear.

But my first impression is the speed is too high. Are you using the LCD to advance the extruder in the videos? Do you have the drivers set to 1/16th stepping (little jumpers under the drivers on a RAMPS board)? If they are set to 1/16th are they actually working in 1/16th? Are you using my version of Marlin for Tantillus? You can try running it slower from a host program like pronterface. If the speed is the issue we can then figure out why and how to fix it. Once it works in partially check your E steps per mm and fix them. Once they are correct it should run at a different speed. Be sure the filament goes through the extruder without any obstruction other then the hobbed bolt. If it does not run a drill through the holes into the start of the bowden tube.

But my first impression is the speed is too high. Are you using the LCD to advance the extruder in the videos? Do you have the drivers set to 1/16th stepping (little jumpers under the drivers on a RAMPS board)? If they are set to 1/16th are they actually working in 1/16th? Are you using my version of Marlin for Tantillus? You can try running it slower from a host program like pronterface. If the speed is the issue we can then figure out why and how to fix it. Once it works in partially check your E steps per mm and fix them. Once they are correct it should run at a different speed. Be sure the filament goes through the extruder without any obstruction other then the hobbed bolt. If it does not run a drill through the holes into the start of the bowden tube.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: New build extruder troubles January 03, 2014 01:02AM |

Registered: 10 years ago Posts: 21 |

Quote

Sublime

I would agree with what Wingnut said about the gears possibly catching each other. You may want to lower the gear on the motor a little bit so the teeth of the larger gear do not hit the hub of the motor gear.

Done, and I also added a washer between the bearing and the extruder gear. I think both of these helped. I was finally able to attempt a print (more below).

Quote

Sublime

But my first impression is the speed is too high. Are you using the LCD to advance the extruder in the videos? Do you have the drivers set to 1/16th stepping (little jumpers under the drivers on a RAMPS board)? If they are set to 1/16th are they actually working in 1/16th? Are you using my version of Marlin for Tantillus? You can try running it slower from a host program like pronterface. If the speed is the issue we can then figure out why and how to fix it. Once it works in partially check your E steps per mm and fix them. Once they are correct it should run at a different speed. Be sure the filament goes through the extruder without any obstruction other then the hobbed bolt. If it does not run a drill through the holes into the start of the bowden tube.

I was advancing the extruder via the LCD's "Purge 5mm" option. In the video I was holding the button in. The jumpers on the RAMPS board are indeed set to 1/16th. I'm using your version of Marlin. I did the E axis calibration from the tutorial and ended up reducing the flow to 394.

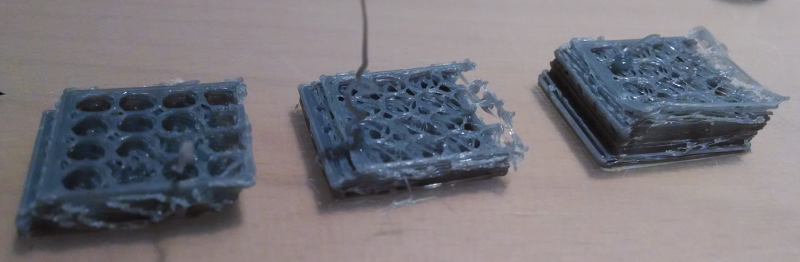

Now back to those first prints... After a bit of tinkering with the endstop I was finally able to get a few prints going:

I never really got a good first layer to stick though eventually something stuck and it was able to build up a little. According to the tutorial I'm guessing I should be increasing the Positive Z-Offset in KISSlicer. I gave that a go and even at 1.0 the results were more or less the same. At that point I moved the printer out into the garage since my wife was tired of hearing it and ever since then I haven't been able to get anything to stick. I'm wondering if the temperature difference in the garage is contributing to the problem. I tried removing the fans, but that didn't seem to really make a difference either. The filament comes out quite stringy and when it doesn't stick it simply curls up and sticks to the print head.

And on a completely unrelated note (or maybe related) I seem to be having odd firmware problems at times. For example if I select Load Filament from the LCD it loads, but then the LCD display become "corrupt" and I need to reset the printer. Also if I print from the SD card menu, then cancel my print, I can't print again without power cycling the printer (even after selecting Home). The print head goes to the front left corner and just starts spewing filament when starting the second print. Good times.

But I'm getting closer

Robert

|

Re: New build extruder troubles January 03, 2014 01:45AM |

Registered: 13 years ago Posts: 2,947 |

To get the plastic to stick your best bet is to wipe the tape with acetone or 99% rubbing alcohol. Also you can scrape or sand the tape lightly.

The first couple of test prints have skipped steps and could be that need to up your stepper current just a little bit. Or maybe your x/y gears are loose. Or maybe your bushings are too tight. It also looks like it is only on one axis.

It also looks like either the flow is too high or maybe the the temperature is too high or maybe just because the fans are off. Either way I would not worry to much until you get past the skipped steps.

The first couple of test prints have skipped steps and could be that need to up your stepper current just a little bit. Or maybe your x/y gears are loose. Or maybe your bushings are too tight. It also looks like it is only on one axis.

It also looks like either the flow is too high or maybe the the temperature is too high or maybe just because the fans are off. Either way I would not worry to much until you get past the skipped steps.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: New build extruder troubles January 04, 2014 06:32PM |

Registered: 10 years ago Posts: 21 |

Quote

Sublime

To get the plastic to stick your best bet is to wipe the tape with acetone or 99% rubbing alcohol. Also you can scrape or sand the tape lightly.

The first couple of test prints have skipped steps and could be that need to up your stepper current just a little bit. Or maybe your x/y gears are loose. Or maybe your bushings are too tight. It also looks like it is only on one axis.

It also looks like either the flow is too high or maybe the the temperature is too high or maybe just because the fans are off. Either way I would not worry to much until you get past the skipped steps.

The missed steps in the X axis seemed to be happening around the same spot so I assumed that my steppers were getting warm right around that time and reducing the current a bit seems to have helped. I did a little sanding and a little wiping down with alcohol and that also improved the situation. Thanks.

Robert

Sorry, only registered users may post in this forum.