Alas printing, well sorta

Posted by flemming

|

Alas printing, well sorta January 04, 2014 06:35PM |

Registered: 10 years ago Posts: 21 |

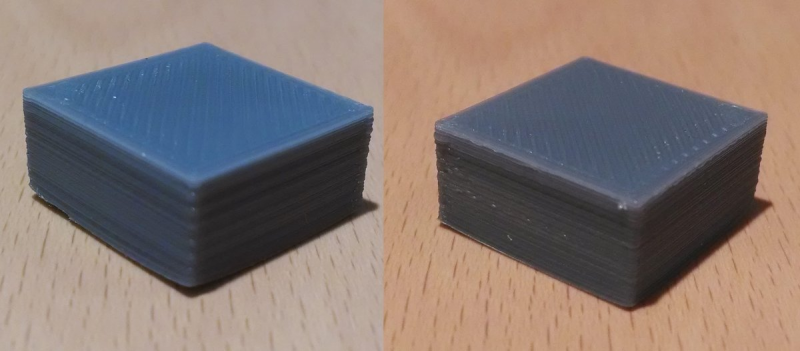

It seems that my extruder problems from here are more or less resolved.I was finally able to print a pretty good calibration cube using a Positive Z-offset of 1.0 and a flow of 400:

I moved on to attempting a pyramid since I think my retraction speed may need a little work (getting a bit of ooze), and while the base starts out okay once it starts to try and do the posts I had a dramatic shift in the Y axis. This happened around the same spot on two different attempts:

A big jump like that seems like a bigger issue than just a couple skipped steps, and since the cube printed cleanly I'm at a bit of a loss. Could this just be a KISSlicer issue?

Robert

I moved on to attempting a pyramid since I think my retraction speed may need a little work (getting a bit of ooze), and while the base starts out okay once it starts to try and do the posts I had a dramatic shift in the Y axis. This happened around the same spot on two different attempts:

A big jump like that seems like a bigger issue than just a couple skipped steps, and since the cube printed cleanly I'm at a bit of a loss. Could this just be a KISSlicer issue?

Robert

|

Re: Alas printing, well sorta January 04, 2014 07:04PM |

Registered: 13 years ago Posts: 2,947 |

Between this and the last problem with skipped steps I think you should reduce your travel speed in Kisslicer and see if it helps. Default 150 and I would try 120. If that fixes the skipped steps you can move on until things are broken in a little more before trying faster again.

A 1 mm positive offset is kind of a lot. The reason I say it is a lot is because the positive offset tells the machine the nozzle is 1mm above the bed and then the bed moves up to take up said distance. But since the end stop switch only has a little bit of travel the 1mm may actually be pushing the switch up which will change the offset if it moves. I would move the switch up a little and then redo the offset calibration.

For the cube prints I see a few things. The Z axis may be a little sticky or the Z lift bracket is too tight in the Z arms so you are getting wobble. The flow looks good for really solid parts but I think you could lower it by 5-20 for more precision. I say that because the photo looks a little like the top surface has small ridges between paths but that may just be the lighting.

A 1 mm positive offset is kind of a lot. The reason I say it is a lot is because the positive offset tells the machine the nozzle is 1mm above the bed and then the bed moves up to take up said distance. But since the end stop switch only has a little bit of travel the 1mm may actually be pushing the switch up which will change the offset if it moves. I would move the switch up a little and then redo the offset calibration.

For the cube prints I see a few things. The Z axis may be a little sticky or the Z lift bracket is too tight in the Z arms so you are getting wobble. The flow looks good for really solid parts but I think you could lower it by 5-20 for more precision. I say that because the photo looks a little like the top surface has small ridges between paths but that may just be the lighting.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Alas printing, well sorta January 05, 2014 01:47AM |

Registered: 10 years ago Posts: 21 |

Quote

Sublime

Between this and the last problem with skipped steps I think you should reduce your travel speed in Kisslicer and see if it helps. Default 150 and I would try 120. If that fixes the skipped steps you can move on until things are broken in a little more before trying faster again.

Slowing it down indeed seemed to help. I was able to get further along in the pyramid before it looked like the extruder might have started skipping a step here and there. I'll have to try turning that down just a hair and see what happens.

Quote

A 1 mm positive offset is kind of a lot. The reason I say it is a lot is because the positive offset tells the machine the nozzle is 1mm above the bed and then the bed moves up to take up said distance. But since the end stop switch only has a little bit of travel the 1mm may actually be pushing the switch up which will change the offset if it moves. I would move the switch up a little and then redo the offset calibration.

I redid the Z-axis setup and +0.55 seems to be doing the trick for me now.

Quote

For the cube prints I see a few things. The Z axis may be a little sticky or the Z lift bracket is too tight in the Z arms so you are getting wobble. The flow looks good for really solid parts but I think you could lower it by 5-20 for more precision. I say that because the photo looks a little like the top surface has small ridges between paths but that may just be the lighting.

I'm quite certain the lift bracket is too tight. I saw your comment in the Z wobble thread about how it should be loose and I recall mine being a fairly snug fit. Slowing down the speed on the Z-axis looks like it might have helped a little as well. I'm guessing the real fix is to disassemble the Z-Axis and file the tabs on the lift down a bit? As for the flow, 394 is what I calculated when measuring the 5mm retractions. That clearly seemed a bit lean. I went up to 400 and I think you're right in that it may be a tad too much. I split the difference to 397 and small gaps re-appeared, so I moved up to 398 and that looks better though I honestly didn't expect such granularity to matter when you said reduce it 5-20

I'll give the pyramid another go tomorrow after fiddling with the extruder stepper. Thanks for all of your help.

Robert

|

Re: Alas printing, well sorta January 05, 2014 03:07AM |

Registered: 10 years ago Posts: 87 |

When you say the extruder was skipping a step, was it a grndy crunchy noise. If yes then you may need more tension on the extruder spirngs or the bowden is not smooth at the ends. If it does crunch you need to clean the hobbed bolt after you fix it.

If the motor is skipping then ther are a couple of things you can check. Make sure the gears are not pressed too hard together. You should be able to turn the gears easily with no tight spots. The other is turn up the current on the E axis motor board. I set mine by turning it up until it is just a little too hot for me to keep my finger on it. I run it as high as possible wihout it risking burning out and cutting out. Too high and it will thernally cut out(slow skip) or destroy itself.

The temperature too low can cause the extruder to make a bounce sound every so often as it spings the motor back.

If the motor is skipping then ther are a couple of things you can check. Make sure the gears are not pressed too hard together. You should be able to turn the gears easily with no tight spots. The other is turn up the current on the E axis motor board. I set mine by turning it up until it is just a little too hot for me to keep my finger on it. I run it as high as possible wihout it risking burning out and cutting out. Too high and it will thernally cut out(slow skip) or destroy itself.

The temperature too low can cause the extruder to make a bounce sound every so often as it spings the motor back.

|

Re: Alas printing, well sorta January 06, 2014 12:28AM |

Registered: 10 years ago Posts: 21 |

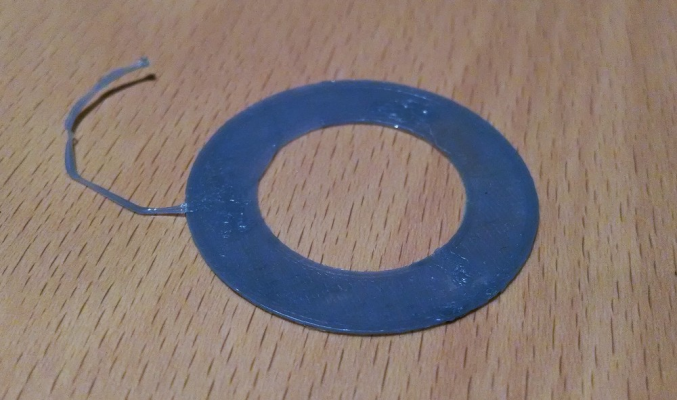

The extruder skipping (looked like kickback) was fixed by upping the current a bit. The extruder seems to be working fine though it is a tad noisy when retracting and advancing back:

[www.youtube.com]

Is this normal? I don't think the hobbed bolt is grinding the filament. The springs are pretty much bottomed out so if this is the sound of it slipping then I'll need to double up the springs like the original kits.

The Z wobble is quite pronounced as previously noted. The parts were a very snug fit so I guess I need to take it apart and file things down. How much play should be between the Z-lift and the arms? Should they wiggle freely in both the side to side and up and down directions?

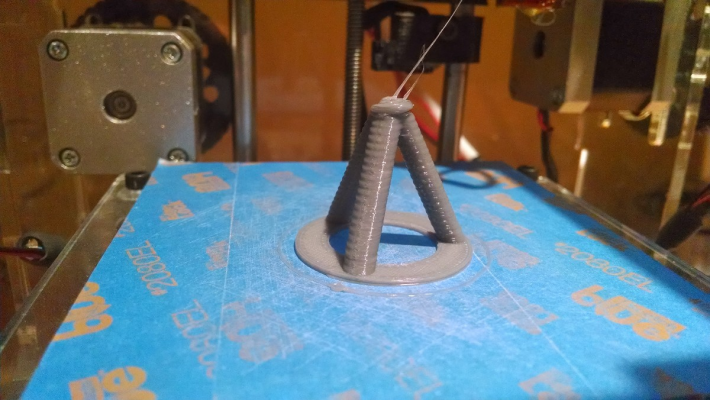

My last attempt at the pyramid got further, but it looked like the Z axis stopped moving for a bit right near the end:

There wasn't any motor noise and visible sticking, it just didn't seem like it was moving at all. I ran through manually moving the Z axis up and down and it does appear to skip every now and then. I've turned the pot in pretty much every direction, but I've been unable to eliminate the occasional hiccup.

[www.youtube.com]

I'm not sure if I just haven't found the sweet spot or if there just isn't one. Any thoughts?

Robert

[www.youtube.com]

Is this normal? I don't think the hobbed bolt is grinding the filament. The springs are pretty much bottomed out so if this is the sound of it slipping then I'll need to double up the springs like the original kits.

The Z wobble is quite pronounced as previously noted. The parts were a very snug fit so I guess I need to take it apart and file things down. How much play should be between the Z-lift and the arms? Should they wiggle freely in both the side to side and up and down directions?

My last attempt at the pyramid got further, but it looked like the Z axis stopped moving for a bit right near the end:

There wasn't any motor noise and visible sticking, it just didn't seem like it was moving at all. I ran through manually moving the Z axis up and down and it does appear to skip every now and then. I've turned the pot in pretty much every direction, but I've been unable to eliminate the occasional hiccup.

[www.youtube.com]

I'm not sure if I just haven't found the sweet spot or if there just isn't one. Any thoughts?

Robert

|

Re: Alas printing, well sorta January 06, 2014 01:02AM |

Registered: 13 years ago Posts: 2,947 |

First question is what voltage are you running the machine on?

The extruder noise may be it trying to go faster then it can actually turn. In the firmware try reducing the speed until it stops making the noise and report the speed back here.

The z-lift bracket should only move in the arms in X and Y, Not in Z.

The wobble is most likely a product of your aluminium coupler not being centered. The reason the default one has the rubber tubing in it is to absorb some of the wobble that your aluminium one is transferring to the rod. You could also try loosening your Z motor bolts just enough that the motor can move around instead of the lead screw.

The skipped steps on Z and E could be a result running the machine off of 12v instead of 15v. The speeds that are set for Tantillus in the firmware and Kisslicer are all designed around a 15v system which allows slightly faster steps without loosing torque.

Edited 1 time(s). Last edit at 01/06/2014 01:26AM by Sublime.

The extruder noise may be it trying to go faster then it can actually turn. In the firmware try reducing the speed until it stops making the noise and report the speed back here.

The z-lift bracket should only move in the arms in X and Y, Not in Z.

The wobble is most likely a product of your aluminium coupler not being centered. The reason the default one has the rubber tubing in it is to absorb some of the wobble that your aluminium one is transferring to the rod. You could also try loosening your Z motor bolts just enough that the motor can move around instead of the lead screw.

The skipped steps on Z and E could be a result running the machine off of 12v instead of 15v. The speeds that are set for Tantillus in the firmware and Kisslicer are all designed around a 15v system which allows slightly faster steps without loosing torque.

Edited 1 time(s). Last edit at 01/06/2014 01:26AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Alas printing, well sorta January 06, 2014 01:05AM |

Registered: 10 years ago Posts: 87 |

Its great that you have taken a video. The z coupler is wobbling pretty badly. You should not really be able to see it wobbling "much". Sublimes printed coupler is actually hard to beat. I tried a fancy alloy coupler similar to yours and never got good results. But that is only the "main" cause of your horzontal banding.

It looks like you have too much flow coming out of the extruder. This print will blob on top if you get too much flow. Turn it down until you can see gaps between the lines during a print and then turn it back up a tad (5 to 25)

Your extruder sounds like an oinking pig! haha. It should not sound like that. It sounds like grinding from the gears so check for interfernce there. It also looks like it is running too fast, so start by turning down the speed and acceleration before you pull it apart. Here are my extruder settings

; Set extruder flow to nnn mm/min

M92 E465

; maximum feedrate that your machine can sustain (M203 X200 Y200 Z300 E10000) in mm/sec

M203 E60

; set max acceleration mm/s^2 for z axis and exruder

M201 Z100 E70

;retract_acceleration mm/s^2 filament pull-pack

M204 T70

Your z axis needs to be as smooth as silk. You can loosen off your z coupler and slide it up and down by hand. It should be effortless in sliding. Missing z steps is hard to do as there is so much torque on a worm drive, so prolly not the problem. Set your z stepper drive to where you can just keep your finger on it without burning you.

If your machine is metric make sure you

; Set STEPS_PER_UNIT Z

M92 Z3200

It looks like you have too much flow coming out of the extruder. This print will blob on top if you get too much flow. Turn it down until you can see gaps between the lines during a print and then turn it back up a tad (5 to 25)

Your extruder sounds like an oinking pig! haha. It should not sound like that. It sounds like grinding from the gears so check for interfernce there. It also looks like it is running too fast, so start by turning down the speed and acceleration before you pull it apart. Here are my extruder settings

; Set extruder flow to nnn mm/min

M92 E465

; maximum feedrate that your machine can sustain (M203 X200 Y200 Z300 E10000) in mm/sec

M203 E60

; set max acceleration mm/s^2 for z axis and exruder

M201 Z100 E70

;retract_acceleration mm/s^2 filament pull-pack

M204 T70

Your z axis needs to be as smooth as silk. You can loosen off your z coupler and slide it up and down by hand. It should be effortless in sliding. Missing z steps is hard to do as there is so much torque on a worm drive, so prolly not the problem. Set your z stepper drive to where you can just keep your finger on it without burning you.

If your machine is metric make sure you

; Set STEPS_PER_UNIT Z

M92 Z3200

|

Re: Alas printing, well sorta January 06, 2014 01:12AM |

Registered: 10 years ago Posts: 87 |

|

Re: Alas printing, well sorta January 06, 2014 01:24AM |

Registered: 13 years ago Posts: 2,947 |

Quote

Robonz

; Set extruder flow to nnn mm/min

M92 E465

; maximum feedrate that your machine can sustain (M203 X200 Y200 Z300 E10000) in mm/sec

M203 E60

; set max acceleration mm/s^2 for z axis and exruder

M201 Z100 E70

;retract_acceleration mm/s^2 filament pull-pack

M204 T70

By default Marlin for Tantillus has EEprom disabled so using M codes to change the settings they do not stay after a power reset.

E60 is really high and I would place a bet and say your machine can not actually reach 60mm/s and the only reason you can have it set that high is because you have the E acceleration settings so low. I would also guess and say the reason you are having issue with blobbing on Z-lift is because of those low settings as well. I run all of my machine with the default settings in Marlin for Tantillus. So for E max speed I use 40-45 which is the max step pulse Marlin will produce at my E steps per mm, E acceleration is set at 10,000 default and 10,000 max so your 70 is incredibly slow and will cause blobs while it sits and retracts.

Edited 2 time(s). Last edit at 01/06/2014 02:46AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Alas printing, well sorta January 06, 2014 01:58AM |

Registered: 10 years ago Posts: 21 |

Quote

Sublime

First question is what voltage are you running the machine on?

15v or at least that's what my universal power supply is set to, I haven't actually measured it. It can be set from 15v - 24v.

Quote

The extruder noise may be it trying to go faster then it can actually turn. In the firmware try reducing the speed until it stops making the noise and report the speed back here.

Is this something that can be changed via the LCD or when slicing, or is it only in the firmware? What specific option should I be changing?

Quote

The z-lift bracket should only move in the arms in X and Y, Not in Z.

The wobble is most likely a product of your aluminium coupler not being centered. The reason the default one has the rubber tubing in it is to absorb some of the wobble that your aluminium one is transferring to the rod. You could also try loosening your Z motor bolts just enough that the motor can move around instead of the lead screw.

The skipped steps on Z and E could be a result running the machine off of 12v instead of 15v. The speeds that are set for Tantillus in the firmware and Kisslicer are all designed around a 15v system which allows slightly faster steps without loosing torque.

I centered the coupler (I had it shifted down to allow for the full Z height) and the visible wobble is gone. As for the "skipped" steps, I'm only seeing them when moving the Z axis with the knob. If I move the axis in pronterface, it goes way faster and I don't see or hear the skipped steps. Perhaps that's a red herring.

Robert

|

Re: Alas printing, well sorta January 06, 2014 02:08AM |

Registered: 10 years ago Posts: 87 |

Thanks Sublime!

If I can improve my prints some more for free then that's awesome. I set those numbers up right when I got the machine going after reading some stuff about the arduino missing steps if the acceleration was set too fast e.g 10,000 due to the internal scheduler. I cant remember the thread.

But looking at my numbers, yes they do look small! lI will have a play and see if I can get rid of those blobs. Thanks again.

If I can improve my prints some more for free then that's awesome. I set those numbers up right when I got the machine going after reading some stuff about the arduino missing steps if the acceleration was set too fast e.g 10,000 due to the internal scheduler. I cant remember the thread.

But looking at my numbers, yes they do look small! lI will have a play and see if I can get rid of those blobs. Thanks again.

|

Re: Alas printing, well sorta January 06, 2014 02:46AM |

Registered: 13 years ago Posts: 2,947 |

Quote

flemming

Quote

The extruder noise may be it trying to go faster then it can actually turn. In the firmware try reducing the speed until it stops making the noise and report the speed back here.

Is this something that can be changed via the LCD or when slicing, or is it only in the firmware? What specific option should I be changing?

Yes and no. You can change the speed via the LCD (see the retraction calibration section of the tutorials page on Tantillus.org) But since EEPROM is disabled it will not stay for more than one print. You will then have to set it in the firmware and reupload to make it permanent (also in the retraction calibration). You could enable EEPROM but that can lead to troubleshooting issues since they stay even when uploading new firmware.

Quote

Quote

The z-lift bracket should only move in the arms in X and Y, Not in Z.

The wobble is most likely a product of your aluminium coupler not being centered. The reason the default one has the rubber tubing in it is to absorb some of the wobble that your aluminium one is transferring to the rod. You could also try loosening your Z motor bolts just enough that the motor can move around instead of the lead screw.

The skipped steps on Z and E could be a result running the machine off of 12v instead of 15v. The speeds that are set for Tantillus in the firmware and Kisslicer are all designed around a 15v system which allows slightly faster steps without loosing torque.

I centered the coupler (I had it shifted down to allow for the full Z height) and the visible wobble is gone. As for the "skipped" steps, I'm only seeing them when moving the Z axis with the knob. If I move the axis in pronterface, it goes way faster and I don't see or hear the skipped steps. Perhaps that's a red herring.

Robert

If it is just when you turn the knob it may actually be a result of the knob and the timing of the firmware reading it. I have a hard time ever getting any of my machines to move smoothly with the knob unless I am really careful and smooth.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Alas printing, well sorta January 06, 2014 09:32PM |

Registered: 10 years ago Posts: 22 |

Flemming,

Hey, just for the heck of it would you please wait till your hot-end is cooled down to room temp. hold the carrage steady with one hand an grab the nozzel by the heater block and see if you have any play (wiggle) between the J-head groove mount and the piece of plexi in the X-Y carriage. I had what I thought was Z wobble it turned out to be a broken/loose carriage/hot-end mount. If there is significant play, there is a chance to get rid of some of the Z artifact in your prints by simply adding some tape to your hot-end to take up the play in the mount.

Hey, just for the heck of it would you please wait till your hot-end is cooled down to room temp. hold the carrage steady with one hand an grab the nozzel by the heater block and see if you have any play (wiggle) between the J-head groove mount and the piece of plexi in the X-Y carriage. I had what I thought was Z wobble it turned out to be a broken/loose carriage/hot-end mount. If there is significant play, there is a chance to get rid of some of the Z artifact in your prints by simply adding some tape to your hot-end to take up the play in the mount.

|

Re: Alas printing, well sorta January 07, 2014 01:48PM |

Registered: 10 years ago Posts: 21 |

Quote

Sublime

Yes and no. You can change the speed via the LCD (see the retraction calibration section of the tutorials page on Tantillus.org) But since EEPROM is disabled it will not stay for more than one print. You will then have to set it in the firmware and reupload to make it permanent (also in the retraction calibration). You could enable EEPROM but that can lead to troubleshooting issues since they stay even when uploading new firmware.

Changing the retraction speed made things a bit quieter, but I don't think that's the root cause. It sounds like rubbing to me and going slower just made the force less and thus the noise decreased. I don't think it's having an impact on the prints themselves. Here's a video with the speed at 30 and then about half way through changing to 40. The max retraction speed I was able to run at was 44:

[www.youtube.com]

Quote

Sublime

The z-lift bracket should only move in the arms in X and Y, Not in Z.

The wobble is most likely a product of your aluminium coupler not being centered. The reason the default one has the rubber tubing in it is to absorb some of the wobble that your aluminium one is transferring to the rod. You could also try loosening your Z motor bolts just enough that the motor can move around instead of the lead screw.

Adjusting the coupler made a pretty big difference:

Quote

Sublime

If it is just when you turn the knob it may actually be a result of the knob and the timing of the firmware reading it. I have a hard time ever getting any of my machines to move smoothly with the knob unless I am really careful and smooth.

I think you're right, I can't reproduce this via pronterface no matter how much I move the Z axis.

Quote

cns1

Hey, just for the heck of it would you please wait till your hot-end is cooled down to room temp. hold the carrage steady with one hand an grab the nozzel by the heater block and see if you have any play (wiggle) between the J-head groove mount and the piece of plexi in the X-Y carriage.

The J-Head is plenty snug, the Z coupler was the primary culprit.

The pyramid looks a good bit better now:

I needed to print something other than a calibration object to make myself feel better so here is my first "actual" print:

KISSlicer settings are mostly black magic to me so I used the values from Sublime's calculator for a "small" object. The layer height is 0.15, infill was hollow, and printed without support.

Robert

|

Re: Alas printing, well sorta January 07, 2014 02:14PM |

Registered: 13 years ago Posts: 2,947 |

I would just leave the extruder alone for a while unless it causes an issue. If it is just friction somewhere it will wear away the offending area soon enough.

The first print is really good especially for an object that small. Most people (that is non-Tantillus users) have a hard time printing something that small even after months of tuning.

For the Kisslicer settings I assume you started with a Tantillus config and changed it per the Calculator? They do seem a little strange, and some are.

The first print is really good especially for an object that small. Most people (that is non-Tantillus users) have a hard time printing something that small even after months of tuning.

For the Kisslicer settings I assume you started with a Tantillus config and changed it per the Calculator? They do seem a little strange, and some are.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Alas printing, well sorta January 08, 2014 12:44AM |

Registered: 10 years ago Posts: 87 |

Sorry, only registered users may post in this forum.