Start of a new Tantillus ABS.

Posted by zelogik

|

Start of a new Tantillus ABS. August 31, 2014 04:10AM |

Registered: 11 years ago Posts: 225 |

Hello,

Since many years (yes years), I wanted to print a tantillus, but the first part I have printed was really not beautiful in ABS (warp,crack, etc...). And i prefer ABS instead of PLA (easy to glue, easier to extrude when I started in the world of 3D printing , and many in stock)

, and many in stock)

So I decided to design/build/create my own printer, it's was first an HBot printer, printed with my first one (a zentoolwork+mk7 extruder but too slow and too noisy) atfer some year and many hour of printing the second one (hbot) was dying (slop, backlash etc..), so I create a third one, it was a CoreXY printer (you can find info on this forum).

That third printer was perfect, dual head, full enclosure, reliable, really precise, sturdy (in aluminium) etc... the only downside is the noise and the place it take, in a small apartement place is important, even more when that printer is installed in the main room...

So 2 days ago I have thought about build a Tantillus, small, beautiful, possibility to put no fan (or really big one very silent). I have already all electronic, all hardware (only metric here in France but not a problem).

I have ordered a 100x100 heating element for the bed ... but don't know if I will use that, maybe an only PLA printer can be cool in the main room...

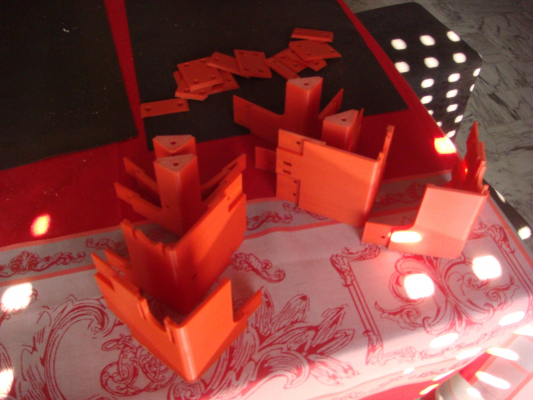

And the pictures of all things I have already printed:

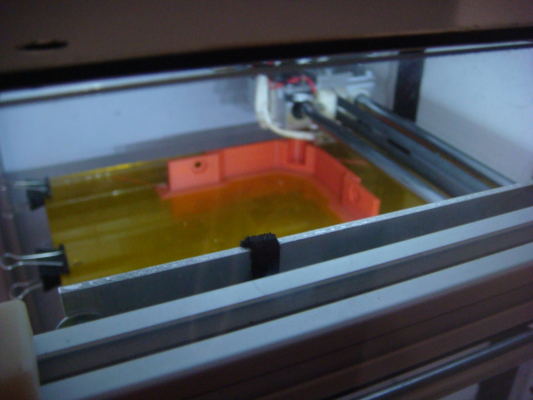

Army of part:

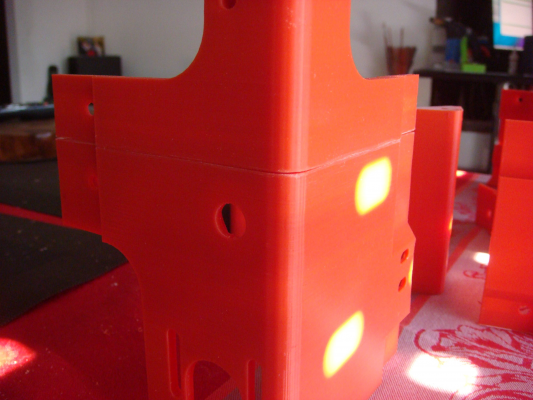

Almost no warping:

No cracking (thanks to heating enclosure):

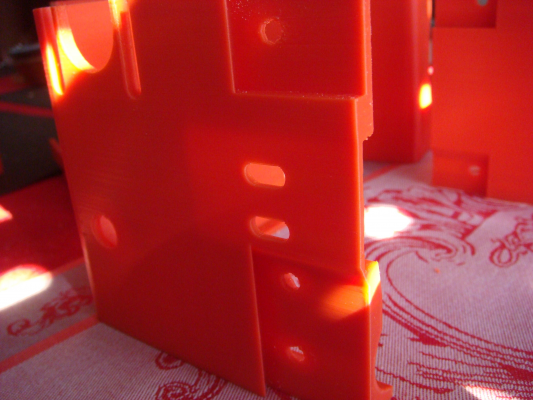

Difficult to see but quality is wonderful

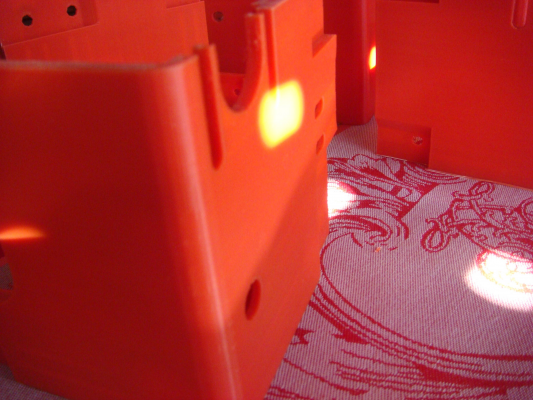

Base part printing now:

The parameters are:

Cura last git.

ABS Red (maybe not enougth for last base part grrrrr...)(another red spool here, but not from the same supplier... (it's why I have printed the top before the base ))

))

Slow speed 70mm/s

Low density 20%-25%

Perimeter 1.6mm

Nozzle size: 0.4mm

layer height: 0.16 (is the perfect compromise between speed/strength/layer height)

Time to building part, between 3 and 5hours each.

Edit: And yes, I haven't printed special ABS part, because I prefer the 'full' enclosure of the normal printed case. I don't like all that hole is ABS parts.

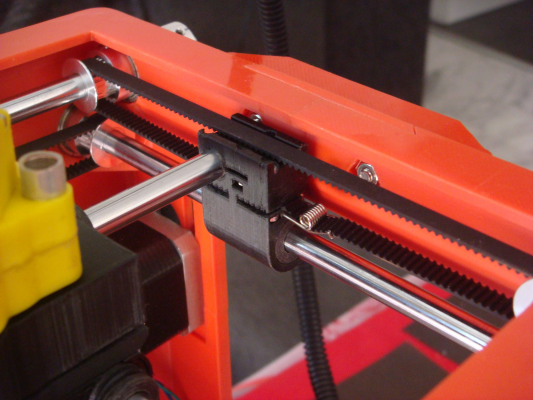

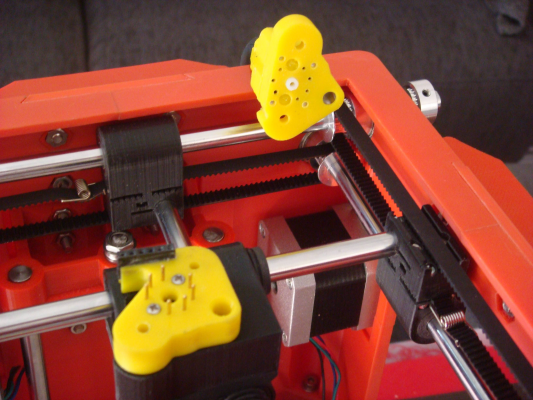

For X and Y axis, transmission will be with GT2 belt, even for motor to shaft. (I have small closed belts available)

For the Zaxis I hesiting between 3 choices:

- 8m Z threaded (I have already a M8 anti-backlash nut in brass.

- Dyneema Zaxis (I have already plenty of this rope but don't really like it, with the winding shift)

- Design my own gt2 Z axis... (just take some time but not so difficult as I have already the base concept with the excellent Zaxis with dyneema).

If anybody have any other suggestion for the Zaxis?

ie: Thanks to have been read my post

Regards!

Edited 3 time(s). Last edit at 08/31/2014 04:34AM by zelogik.

Since many years (yes years), I wanted to print a tantillus, but the first part I have printed was really not beautiful in ABS (warp,crack, etc...). And i prefer ABS instead of PLA (easy to glue, easier to extrude when I started in the world of 3D printing

, and many in stock)

, and many in stock)So I decided to design/build/create my own printer, it's was first an HBot printer, printed with my first one (a zentoolwork+mk7 extruder but too slow and too noisy) atfer some year and many hour of printing the second one (hbot) was dying (slop, backlash etc..), so I create a third one, it was a CoreXY printer (you can find info on this forum).

That third printer was perfect, dual head, full enclosure, reliable, really precise, sturdy (in aluminium) etc... the only downside is the noise and the place it take, in a small apartement place is important, even more when that printer is installed in the main room...

So 2 days ago I have thought about build a Tantillus, small, beautiful, possibility to put no fan (or really big one very silent). I have already all electronic, all hardware (only metric here in France but not a problem).

I have ordered a 100x100 heating element for the bed ... but don't know if I will use that, maybe an only PLA printer can be cool in the main room...

And the pictures of all things I have already printed:

Army of part:

Almost no warping:

No cracking (thanks to heating enclosure):

Difficult to see but quality is wonderful

Base part printing now:

The parameters are:

Cura last git.

ABS Red (maybe not enougth for last base part grrrrr...)(another red spool here, but not from the same supplier... (it's why I have printed the top before the base

))

))Slow speed 70mm/s

Low density 20%-25%

Perimeter 1.6mm

Nozzle size: 0.4mm

layer height: 0.16 (is the perfect compromise between speed/strength/layer height)

Time to building part, between 3 and 5hours each.

Edit: And yes, I haven't printed special ABS part, because I prefer the 'full' enclosure of the normal printed case. I don't like all that hole is ABS parts.

For X and Y axis, transmission will be with GT2 belt, even for motor to shaft. (I have small closed belts available)

For the Zaxis I hesiting between 3 choices:

- 8m Z threaded (I have already a M8 anti-backlash nut in brass.

- Dyneema Zaxis (I have already plenty of this rope but don't really like it, with the winding shift)

- Design my own gt2 Z axis... (just take some time but not so difficult as I have already the base concept with the excellent Zaxis with dyneema).

If anybody have any other suggestion for the Zaxis?

ie: Thanks to have been read my post

Regards!

Edited 3 time(s). Last edit at 08/31/2014 04:34AM by zelogik.

|

Re: Start of a new Tantillus ABS. September 01, 2014 10:09AM |

Registered: 10 years ago Posts: 24 |

|

Re: Start of a new Tantillus ABS. September 01, 2014 10:50AM |

Registered: 11 years ago Posts: 225 |

Deception yesterday ... I have finished the ABS red spool at the 9/12 parts... I have printed the 3 others parts this night/today but not exactly the same red color .... grrr

@Leonal: Yes just need to design the file for the Zaxis with gt2 belt.... I already have all pulley/belt instead of gears.

@Sublime: I you read me. I have found many glitch/bug on the printed case... do you want correct that ?

Edited 1 time(s). Last edit at 09/01/2014 10:52AM by zelogik.

@Leonal: Yes just need to design the file for the Zaxis with gt2 belt.... I already have all pulley/belt instead of gears.

@Sublime: I you read me. I have found many glitch/bug on the printed case... do you want correct that ?

Edited 1 time(s). Last edit at 09/01/2014 10:52AM by zelogik.

|

Re: Start of a new Tantillus ABS. September 01, 2014 01:51PM |

Registered: 10 years ago Posts: 208 |

Gears could be useful in preventing the bed falling too fast (or even at all) when shutting motors off.

Moreover, they will improve resolution on the Z axis, with positive impact on positioning precision (at least useful when leveling the bed).

On the other hand, how much noise is Z axis really producing? It's perhaps only about starting and finishing the print.

I'm also interested on opinions about noise, since this week I have to build such a mechanism. It will however use T2.5 hence yet another reason for a geared reduction, to obtain a "nice" resolution value.

And though, well, it's not a Tantillus, it is very much inspired from some of the mechanics of Tantillus and its derivates (e.g. Ingentis).

Moreover, they will improve resolution on the Z axis, with positive impact on positioning precision (at least useful when leveling the bed).

On the other hand, how much noise is Z axis really producing? It's perhaps only about starting and finishing the print.

I'm also interested on opinions about noise, since this week I have to build such a mechanism. It will however use T2.5 hence yet another reason for a geared reduction, to obtain a "nice" resolution value.

And though, well, it's not a Tantillus, it is very much inspired from some of the mechanics of Tantillus and its derivates (e.g. Ingentis).

|

Re: Start of a new Tantillus ABS. September 01, 2014 02:07PM |

Registered: 11 years ago Posts: 225 |

@3Dmaker4U: Yes Z thread don't produce so much noise. And the bed don't fall when you stop the motor.

But M8 don't have easy layer height (almost always rounded). On my other printer I have a F8 (8mm x 8 by turn instead of M8x1.25), so with 400 or 800 step/mm you always have the right layer height.

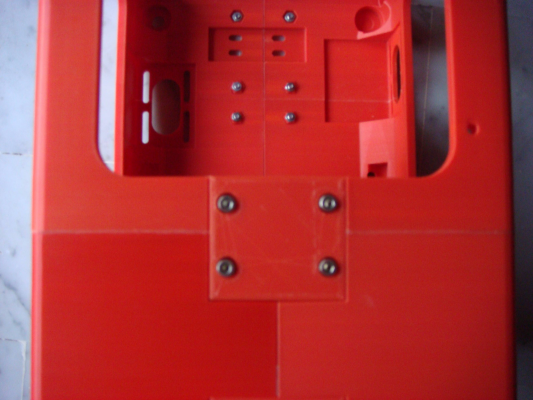

Sorry for bad picture quality:

Yes maybe I will reprint Base_4 ....

Who see any warping ? :-D

But M8 don't have easy layer height (almost always rounded). On my other printer I have a F8 (8mm x 8 by turn instead of M8x1.25), so with 400 or 800 step/mm you always have the right layer height.

Sorry for bad picture quality:

Yes maybe I will reprint Base_4 ....

Who see any warping ? :-D

|

Re: Start of a new Tantillus ABS. September 02, 2014 06:46PM |

Registered: 10 years ago Posts: 35 |

|

Re: Start of a new Tantillus ABS. September 05, 2014 04:11PM |

Registered: 12 years ago Posts: 195 |

|

Re: Start of a new Tantillus ABS. September 18, 2014 02:05AM |

Registered: 11 years ago Posts: 364 |

|

Re: Start of a new Tantillus ABS. September 18, 2014 05:37AM |

Registered: 11 years ago Posts: 225 |

I make a big thread for the corexy printer on Repraper forum with many pictures:

http://forums.reprap.org/read.php?4,297740

Conclusion: enclosure with polycarbonate + dibond is an excellent sound box.

This week I have family at home, so no many work on the tantillus.

But: GT2 belt carriage is finish, Z axis is on going. I just waiting for: power supply, Aluhotend nozzle.

Need to design X an Y endstop (yes i want it )

)

I will put pictures of that the next week.

http://forums.reprap.org/read.php?4,297740

Conclusion: enclosure with polycarbonate + dibond is an excellent sound box.

This week I have family at home, so no many work on the tantillus.

But: GT2 belt carriage is finish, Z axis is on going. I just waiting for: power supply, Aluhotend nozzle.

Need to design X an Y endstop (yes i want it

)

) I will put pictures of that the next week.

|

Re: Start of a new Tantillus ABS. September 28, 2014 04:47AM |

Registered: 11 years ago Posts: 225 |

So, news of my build.

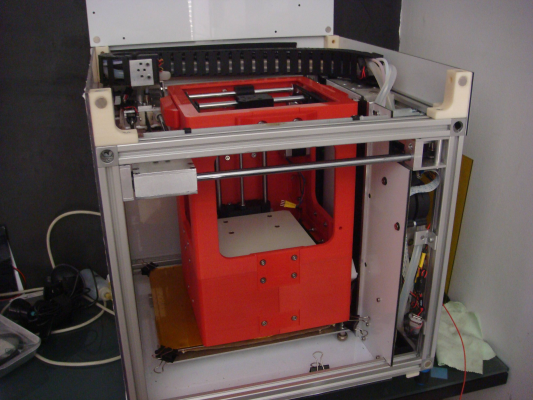

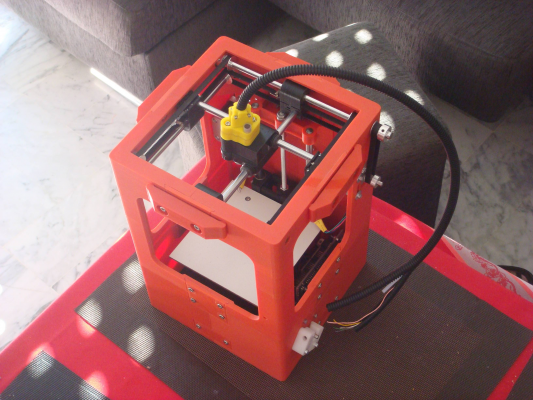

As somebody have asked, photos with the mother:

Photo with direct drive extruder (1.75mm filament): Need to finish: Z, electronic connection, etc...

X & Y carriage part for gt2 belt:

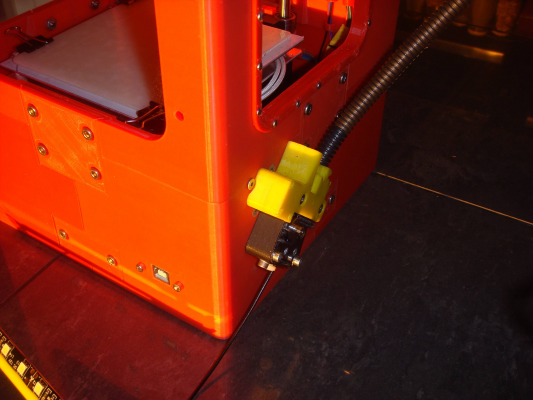

Prototype of a quick&fast multi medium connnector for transportable 3DP, power/filament/air flow:

As somebody have asked, photos with the mother:

Photo with direct drive extruder (1.75mm filament): Need to finish: Z, electronic connection, etc...

X & Y carriage part for gt2 belt:

Prototype of a quick&fast multi medium connnector for transportable 3DP, power/filament/air flow:

|

Re: Start of a new Tantillus ABS. March 07, 2015 02:09AM |

Registered: 11 years ago Posts: 225 |

Been a while since my last post.

And many time without make any modification on this Tantillus GT2, ABS 3D printer.

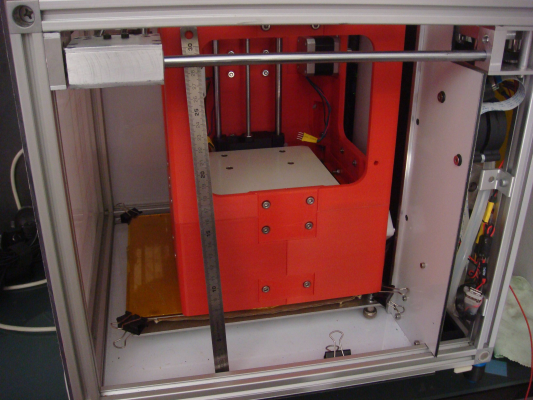

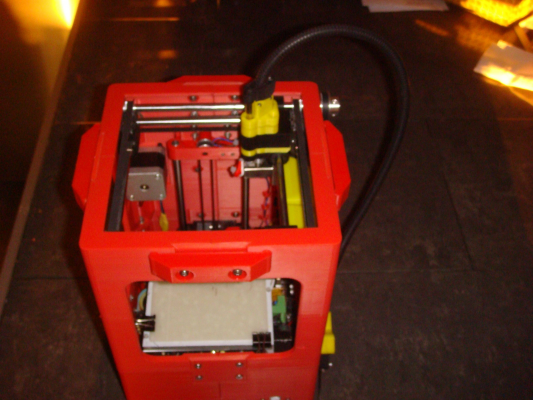

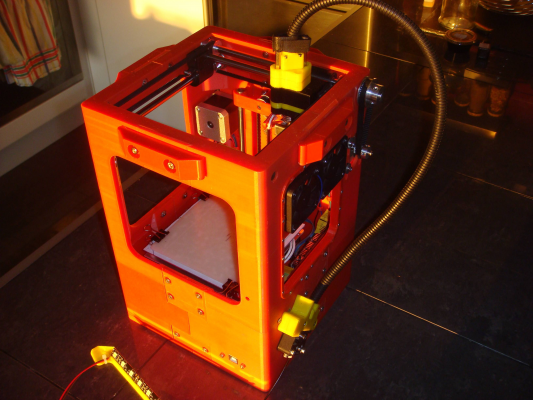

So there somes pictures:

My favorite picture of this newcommer at home

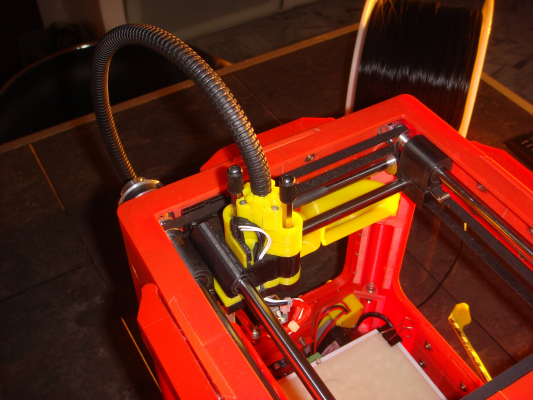

View of the quick and multi medium connector:

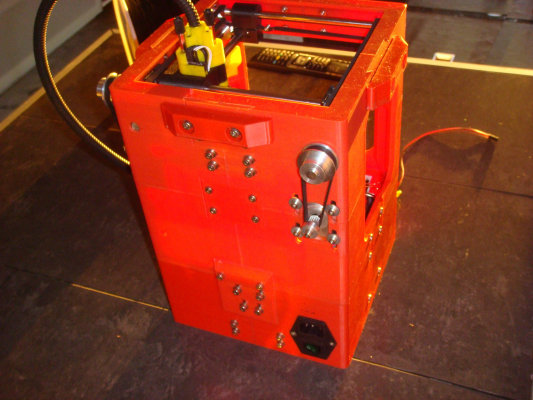

A nice rear, with the power connector:

The extruder + start of the multi medium connector:

A quick look on the inside of the printer:

Sorry I haven't take photo of printed part, I have only printed 4 or 5 parts, but the quality seem really good

And I always with my design, if anybody is interested by gt2 concept and multi medium connector, I can make some github... I just need to finding all files, because the backup of the part I draft is often non-existant...

And many time without make any modification on this Tantillus GT2, ABS 3D printer.

So there somes pictures:

My favorite picture of this newcommer at home

View of the quick and multi medium connector:

A nice rear, with the power connector:

The extruder + start of the multi medium connector:

A quick look on the inside of the printer:

Sorry I haven't take photo of printed part, I have only printed 4 or 5 parts, but the quality seem really good

And I always with my design, if anybody is interested by gt2 concept and multi medium connector, I can make some github... I just need to finding all files, because the backup of the part I draft is often non-existant...

|

Re: Start of a new Tantillus ABS. March 07, 2015 03:49AM |

Registered: 10 years ago Posts: 14 |

|

Re: Start of a new Tantillus ABS. March 24, 2015 02:29PM |

Registered: 10 years ago Posts: 14 |

|

Re: Start of a new Tantillus ABS. April 19, 2015 10:32AM |

Registered: 9 years ago Posts: 245 |

|

Re: Start of a new Tantillus ABS. April 20, 2015 05:34PM |

Registered: 9 years ago Posts: 569 |

|

Re: Start of a new Tantillus ABS. April 23, 2015 10:13AM |

Registered: 9 years ago Posts: 245 |

I actually found the X/Y Pulleys for GT2 on thingiverseQuote

Kurzaa

Quote

dintid

I am very interested in documentation as well. Anyone know if it is available somewhere?

Look for posts on the website going down. People have been linking to some internet archive.

[www.thingiverse.com]

The Tantillus site is available via web.archive.org:

[web.archive.org]

|

Re: Start of a new Tantillus ABS. June 07, 2015 04:04PM |

Registered: 9 years ago Posts: 47 |

Sorry, only registered users may post in this forum.