Game / Competition: Part Manufacturing

Posted by RepRapBCN

|

Game / Competition: Part Manufacturing May 26, 2012 05:09AM |

Registered: 12 years ago Posts: 145 |

Hello to everyone!

In the group "Reprap en Español" we are playing a game that we believe can be extended to the entire community.

It's simple: each week someone proposes a 3D model to produce and others try their best. Furthermore, if we explain the configuration used, everyone learns.

The proposed rules are as follows:

1. The model is proposed on Saturday (thinginverse, dropbox ...). It is very important to indicate the scale and the minimum layer height allowed.

2. During the week people make models, post photographs of the finish part and explain the settings used.

3. Only DIY machines can be used. Anyway, if anyone wants to make them with other machines (SLA, SLS, Objet, Stratasys...) just to compare can be fine!

4. On Friday at 23:59 GMT 0 the game is over.

5. During saturday the person who won last week chooses the new winner.

6. The new winner repeat step 1 in the same thread.

If anyone thing we could modify the rules to make it better, please tell me!

You can see the original spanish post here:

[forums.reprap.org]

[forums.reprap.org]

To begin, I would like to propose the following model at 100% scale and with a minimum layer height of 0,10mm. (Rich Rap scaled)

[www.thingiverse.com]

Good weekend!!

Edited 3 time(s). Last edit at 05/26/2012 03:46PM by RepRapBCN.

RepRapBCN - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

In the group "Reprap en Español" we are playing a game that we believe can be extended to the entire community.

It's simple: each week someone proposes a 3D model to produce and others try their best. Furthermore, if we explain the configuration used, everyone learns.

The proposed rules are as follows:

1. The model is proposed on Saturday (thinginverse, dropbox ...). It is very important to indicate the scale and the minimum layer height allowed.

2. During the week people make models, post photographs of the finish part and explain the settings used.

3. Only DIY machines can be used. Anyway, if anyone wants to make them with other machines (SLA, SLS, Objet, Stratasys...) just to compare can be fine!

4. On Friday at 23:59 GMT 0 the game is over.

5. During saturday the person who won last week chooses the new winner.

6. The new winner repeat step 1 in the same thread.

If anyone thing we could modify the rules to make it better, please tell me!

You can see the original spanish post here:

[forums.reprap.org]

[forums.reprap.org]

To begin, I would like to propose the following model at 100% scale and with a minimum layer height of 0,10mm. (Rich Rap scaled)

[www.thingiverse.com]

Good weekend!!

Edited 3 time(s). Last edit at 05/26/2012 03:46PM by RepRapBCN.

RepRapBCN - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

|

Re: Game / Competition: Part Manufacturing May 26, 2012 09:48AM |

Registered: 13 years ago Posts: 818 |

Sounds fun

So are you allowed to modify the model selected in any way? before printing? after printing?

What about support structure?

Just also checking "minimum layer height of 0,15mm." so 0.2mm or higher is OK, but 0.1mm is not, correct?

How do you want people to prove it's been printed at 50% size?

It would be good to pick models that can be sliced with many different programs, so you get the most variation of settings and machines.

I don't think the above model works in Slic3r yet

You should also ask the judge describe why the winner is selected. Quality, speed v Quality, material used, machine type, settings, etc.

Edited 1 time(s). Last edit at 05/26/2012 10:00AM by richrap.

[richrap.blogspot.com]

So are you allowed to modify the model selected in any way? before printing? after printing?

What about support structure?

Just also checking "minimum layer height of 0,15mm." so 0.2mm or higher is OK, but 0.1mm is not, correct?

How do you want people to prove it's been printed at 50% size?

It would be good to pick models that can be sliced with many different programs, so you get the most variation of settings and machines.

I don't think the above model works in Slic3r yet

You should also ask the judge describe why the winner is selected. Quality, speed v Quality, material used, machine type, settings, etc.

Edited 1 time(s). Last edit at 05/26/2012 10:00AM by richrap.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 26, 2012 11:26AM |

Registered: 12 years ago Posts: 539 |

|

Re: Game / Competition: Part Manufacturing May 26, 2012 11:29AM |

Registered: 13 years ago Posts: 301 |

A couple of thoughts..

1. To be more clear I think model height should be spelled out and not model scale.

2. Why require a minimum layer height? If someone pulls off a better looking print at a larger layer height then even better.

3. Judge only quality with speed being the tie breaker. Everyone should list actual build time along with other settings.

4. Have minimum set of settings to list. Layer height, filament swell, slicer, material, show a picture of your setup including fans. Maybe the photos should be taken before the model is popped off the machine too.

5. A new post for each contest.

1. To be more clear I think model height should be spelled out and not model scale.

2. Why require a minimum layer height? If someone pulls off a better looking print at a larger layer height then even better.

3. Judge only quality with speed being the tie breaker. Everyone should list actual build time along with other settings.

4. Have minimum set of settings to list. Layer height, filament swell, slicer, material, show a picture of your setup including fans. Maybe the photos should be taken before the model is popped off the machine too.

5. A new post for each contest.

|

Re: Game / Competition: Part Manufacturing May 26, 2012 11:43AM |

Registered: 13 years ago Posts: 818 |

I can get the model to slice perfectly in Slic3r now, but only by changing it, the original Thingiverse model will not slice in Slic3r, so see my above questions relating to model changes.

And if you tilt the model back 5 degrees, it should print much better with less overhangs, is that going to be cheating?

I could just upload my modified version of the model, what do you think? at least Slic3r people could then also compete?

[richrap.blogspot.com]

And if you tilt the model back 5 degrees, it should print much better with less overhangs, is that going to be cheating?

I could just upload my modified version of the model, what do you think? at least Slic3r people could then also compete?

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 26, 2012 12:25PM |

Registered: 13 years ago Posts: 818 |

I uploaded my modified model as a derivative, and it's already half size - [www.thingiverse.com]

[richrap.blogspot.com]

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 26, 2012 02:02PM |

Registered: 12 years ago Posts: 411 |

|

Re: Game / Competition: Part Manufacturing May 26, 2012 02:07PM |

Registered: 13 years ago Posts: 2,947 |

richrap Wrote:

-------------------------------------------------------

> I can get the model to slice perfectly in Slic3r

> now, but only by changing it, the original

> Thingiverse model will not slice in Slic3r, so see

> my above questions relating to model changes.

>

> And if you tilt the model back 5 degrees, it

> should print much better with less overhangs, is

> that going to be cheating?

>

> I could just upload my modified version of the

> model, what do you think? at least Slic3r people

> could then also compete?

I printed this a few days ago (@ 0.1mm) and did not need to modify it and I only use slic3r.

-------------------------------------------------------

> I can get the model to slice perfectly in Slic3r

> now, but only by changing it, the original

> Thingiverse model will not slice in Slic3r, so see

> my above questions relating to model changes.

>

> And if you tilt the model back 5 degrees, it

> should print much better with less overhangs, is

> that going to be cheating?

>

> I could just upload my modified version of the

> model, what do you think? at least Slic3r people

> could then also compete?

I printed this a few days ago (@ 0.1mm) and did not need to modify it and I only use slic3r.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Game / Competition: Part Manufacturing May 26, 2012 03:18PM |

Registered: 12 years ago Posts: 145 |

I have changed the file. Now the file is Rich Rap's.

I think it is important to fix the scale so everyone make the same part.

We can improve the quality by reducing layer height up to 0,05mm but it also affect to the time... This is the reason to fix the minimum layer.

Edited 1 time(s). Last edit at 05/26/2012 03:44PM by RepRapBCN.

I think it is important to fix the scale so everyone make the same part.

We can improve the quality by reducing layer height up to 0,05mm but it also affect to the time... This is the reason to fix the minimum layer.

Edited 1 time(s). Last edit at 05/26/2012 03:44PM by RepRapBCN.

|

Re: Game / Competition: Part Manufacturing May 26, 2012 03:46PM |

Registered: 12 years ago Posts: 145 |

richrap Wrote:

-------------------------------------------------------

> Sounds fun

>

> So are you allowed to modify the model selected in

> any way? before printing? after printing?

> What about support structure?

>

> Just also checking "minimum layer height of

> 0,15mm." so 0.2mm or higher is OK, but 0.1mm is

> not, correct?

>

> How do you want people to prove it's been printed

> at 50% size?

>

> It would be good to pick models that can be sliced

> with many different programs, so you get the most

> variation of settings and machines.

> I don't think the above model works in Slic3r yet

>

>

> You should also ask the judge describe why the

> winner is selected. Quality, speed v Quality,

> material used, machine type, settings, etc.

If 0,15mm is the minimum layer, 0,20, 0,25... is ok. 0,10 mm would not be ok.

Anyway, I think 0,10mm could be also ok so I have changed the original post.

-------------------------------------------------------

> Sounds fun

>

> So are you allowed to modify the model selected in

> any way? before printing? after printing?

> What about support structure?

>

> Just also checking "minimum layer height of

> 0,15mm." so 0.2mm or higher is OK, but 0.1mm is

> not, correct?

>

> How do you want people to prove it's been printed

> at 50% size?

>

> It would be good to pick models that can be sliced

> with many different programs, so you get the most

> variation of settings and machines.

> I don't think the above model works in Slic3r yet

>

>

> You should also ask the judge describe why the

> winner is selected. Quality, speed v Quality,

> material used, machine type, settings, etc.

If 0,15mm is the minimum layer, 0,20, 0,25... is ok. 0,10 mm would not be ok.

Anyway, I think 0,10mm could be also ok so I have changed the original post.

|

Re: Game / Competition: Part Manufacturing May 26, 2012 04:36PM |

Registered: 12 years ago Posts: 127 |

I also have printed the above model using slicer on my very un-finetuned printer, only 42 mm tall too. Granted it wasnt as good as some others ive seen but it still did decent.

Ryan

Quality Engineer & Hobbyist

thingsandtrains.blogspot.com

Ryan

Quality Engineer & Hobbyist

thingsandtrains.blogspot.com

|

Re: Game / Competition: Part Manufacturing May 27, 2012 01:54AM |

Registered: 13 years ago Posts: 301 |

I added a "I MADE ONE!" to your thingiverse item.

[www.thingiverse.com]

Printxel. PLA. KISSlicer. 0.4mm layers. 0.6mm thread width. 80deg supports. Retraction on. 2 perimeters. 25% fill.

I'm in the process of figuring out a new fan setup so no fan during the print and I had a ridiculous 30 second minimum layer time so it took forever.

The print came out pretty well minus the supports scars. The little one between the shoulder and the hair was really wedged in there. I'll print another one at 0.1mm when I get my new fan setup working.

Here are more photos: [docs.google.com]

Edited 2 time(s). Last edit at 05/27/2012 02:13AM by billyzelsnack.

[www.thingiverse.com]

Printxel. PLA. KISSlicer. 0.4mm layers. 0.6mm thread width. 80deg supports. Retraction on. 2 perimeters. 25% fill.

I'm in the process of figuring out a new fan setup so no fan during the print and I had a ridiculous 30 second minimum layer time so it took forever.

The print came out pretty well minus the supports scars. The little one between the shoulder and the hair was really wedged in there. I'll print another one at 0.1mm when I get my new fan setup working.

Here are more photos: [docs.google.com]

Edited 2 time(s). Last edit at 05/27/2012 02:13AM by billyzelsnack.

|

Re: Game / Competition: Part Manufacturing May 27, 2012 04:43AM |

Registered: 12 years ago Posts: 145 |

|

Re: Game / Competition: Part Manufacturing May 27, 2012 05:46AM |

Registered: 13 years ago Posts: 301 |

Here you go.

Attachments:

open | download - IMG_20120527_001704.jpg (551 KB)

open | download - IMG_20120527_002346.jpg (520.2 KB)

open | download - IMG_20120527_002354.jpg (541.3 KB)

open | download - IMG_20120527_002401.jpg (501.8 KB)

open | download - IMG_20120527_002415.jpg (513.1 KB)

open | download - IMG_20120527_002433.jpg (524 KB)

open | download - IMG_20120527_001704.jpg (551 KB)

open | download - IMG_20120527_002346.jpg (520.2 KB)

open | download - IMG_20120527_002354.jpg (541.3 KB)

open | download - IMG_20120527_002401.jpg (501.8 KB)

open | download - IMG_20120527_002415.jpg (513.1 KB)

open | download - IMG_20120527_002433.jpg (524 KB)

|

Re: Game / Competition: Part Manufacturing May 29, 2012 10:18AM |

Registered: 11 years ago Posts: 2 |

Sorry, my English is very bad, I will use the google translator.

Even that took some time with my reprap I would like to participate in the game.

This is my sample in PLA.

slic3r configuration, diameter 0.5, 3 perimeter, fill 0, layer 0.2

Edited 3 time(s). Last edit at 05/29/2012 10:41AM by marcosmunoz.

Even that took some time with my reprap I would like to participate in the game.

This is my sample in PLA.

slic3r configuration, diameter 0.5, 3 perimeter, fill 0, layer 0.2

Edited 3 time(s). Last edit at 05/29/2012 10:41AM by marcosmunoz.

|

Re: Game / Competition: Part Manufacturing May 29, 2012 11:19AM |

Registered: 13 years ago Posts: 818 |

My first entry in the competition - can we have more than one

This was printed with Slic3r V 0.7.2b, but I'm very tempted to print it again with the new version of Slic3r that's just been released!

I also only used a single outline, so maybe two will help a little more on this print, especially if you look close on the shoulder, a small hole.

Printed with Faberdashery Pearly white PLA at 186 degrees C (that's a calibrated temperature reading from inside the hot-end)

Finished print - Processed with Slic3r and printed with Pronterface - Print time -

Print Started at: 16:22:47

Print ended at: 17:24:14

and took: 01:01:26

; layer_height = 0.15

; perimeters = 1

; solid_layers = 3

; fill_density = 0.15

; nozzle_diameter = 0.53

; filament_diameter = 2.86

; extrusion_multiplier = 1

; perimeter_speed = 55

; infill_speed = 55

; travel_speed = 190

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.74mm

0.53mm nozzle - 0.15mm layers

Machine setup for print -

MendelMAX V1.5 with all printed Y axis - LM8uu Linear bearings

(M10) 2mm ACME Leadscrews

8 x microstepping on Z and E

16 x microstepping on X and Y

Marlin V1 RC2

I'm not going for ultimate quality, but speed v quality for this print.

What else can I tell you?, anyone have any questions?

[richrap.blogspot.com]

This was printed with Slic3r V 0.7.2b, but I'm very tempted to print it again with the new version of Slic3r that's just been released!

I also only used a single outline, so maybe two will help a little more on this print, especially if you look close on the shoulder, a small hole.

Printed with Faberdashery Pearly white PLA at 186 degrees C (that's a calibrated temperature reading from inside the hot-end)

Finished print - Processed with Slic3r and printed with Pronterface - Print time -

Print Started at: 16:22:47

Print ended at: 17:24:14

and took: 01:01:26

; layer_height = 0.15

; perimeters = 1

; solid_layers = 3

; fill_density = 0.15

; nozzle_diameter = 0.53

; filament_diameter = 2.86

; extrusion_multiplier = 1

; perimeter_speed = 55

; infill_speed = 55

; travel_speed = 190

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.74mm

Printing the final section of the head, 15% infill and single outline.

0.53mm nozzle - 0.15mm layers

Slightly odd angle I know, but it's the reflection of the left side overhang in the mirrored printing surface.

Machine setup for print -

MendelMAX V1.5 with all printed Y axis - LM8uu Linear bearings

(M10) 2mm ACME Leadscrews

8 x microstepping on Z and E

16 x microstepping on X and Y

Marlin V1 RC2

I'm not going for ultimate quality, but speed v quality for this print.

What else can I tell you?, anyone have any questions?

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 29, 2012 11:28AM |

Registered: 13 years ago Posts: 301 |

|

Re: Game / Competition: Part Manufacturing May 29, 2012 02:50PM |

Registered: 13 years ago Posts: 818 |

Hi Billy,

I do have a 40mm fan on the hot-end, this is on all of the time. RHS of the X carriage.

I'm using the same speed for the infill as the perimeter, and have low infill (15%) that all seems to help keep down any curling for parts like this. The Faberdashery PLA is also very good and exhibits no warp on almost any print even massive parts like the evil face planter here

[richrap.blogspot.com]

I do have a 40mm fan on the hot-end, this is on all of the time. RHS of the X carriage.

I'm using the same speed for the infill as the perimeter, and have low infill (15%) that all seems to help keep down any curling for parts like this. The Faberdashery PLA is also very good and exhibits no warp on almost any print even massive parts like the evil face planter here

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 29, 2012 03:55PM |

Registered: 13 years ago Posts: 301 |

ha! The fan is perfectly visible in the reflection and I totally missed it.

I'm still undecided on my fan strategy. Sometimes it seems my fan is too powerful. Sometimes not enough. Sometimes I'll print some with the fan off and don't understand why it worked at all. The only real given is to make sure to not have the fan on during the first layers.

I'm still undecided on my fan strategy. Sometimes it seems my fan is too powerful. Sometimes not enough. Sometimes I'll print some with the fan off and don't understand why it worked at all. The only real given is to make sure to not have the fan on during the first layers.

|

Re: Game / Competition: Part Manufacturing May 29, 2012 04:23PM |

Registered: 13 years ago Posts: 818 |

marcosmunoz Wrote:

-------------------------------------------------------

> Sorry, my English is very bad, I will use the

> google translator.

>

> Even that took some time with my reprap I would

> like to participate in the game.

> This is my sample in PLA.

> slic3r configuration, diameter 0.5, 3 perimeter,

> fill 0, layer 0.2

>

> [i47.tinypic.com]

Nice print, Did you flip the image? it's reversed, if it printed like that, you have your X axis backwards.

[richrap.blogspot.com]

-------------------------------------------------------

> Sorry, my English is very bad, I will use the

> google translator.

>

> Even that took some time with my reprap I would

> like to participate in the game.

> This is my sample in PLA.

> slic3r configuration, diameter 0.5, 3 perimeter,

> fill 0, layer 0.2

>

> [i47.tinypic.com]

Nice print, Did you flip the image? it's reversed, if it printed like that, you have your X axis backwards.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 30, 2012 10:25AM |

Registered: 11 years ago Posts: 2 |

|

Re: Game / Competition: Part Manufacturing May 30, 2012 05:01PM |

Admin Registered: 12 years ago Posts: 2,569 |

Here's my entry. Fabberdashery PLA, 200°C, 40 mm/s, 0.15 mm/layer, fan on all the time after the third layer.

My machine is a Techzone Huxley, 0.5 mm hotend V5 from mendelparts, printing on cold glass with 2090 blue tape.

Sorry for the blurry pictures, my camera and I are bad at taking close ups

Skeinforge on the left, Slic3r on the right, trying to get the most similar settings. I notice Skeinforge is still a bit less messy, have a look at the back.

Also Slic3r (0.8.2) does a lot of (useless IMO) full infill layers, resulting in nearly twice the amount of plastic used.

The yellowish base for the right one is due to me not purging my hotend perfectly before starting.

Also including for your eyes but out of competition is a previous print I did of the original (full scale) model at 0.1 mm/layer, done on an ultimaker (orange PLA from ultimaker too).

Thanks for that game, like it

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

My machine is a Techzone Huxley, 0.5 mm hotend V5 from mendelparts, printing on cold glass with 2090 blue tape.

Sorry for the blurry pictures, my camera and I are bad at taking close ups

Skeinforge on the left, Slic3r on the right, trying to get the most similar settings. I notice Skeinforge is still a bit less messy, have a look at the back.

Also Slic3r (0.8.2) does a lot of (useless IMO) full infill layers, resulting in nearly twice the amount of plastic used.

The yellowish base for the right one is due to me not purging my hotend perfectly before starting.

Also including for your eyes but out of competition is a previous print I did of the original (full scale) model at 0.1 mm/layer, done on an ultimaker (orange PLA from ultimaker too).

Thanks for that game, like it

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Game / Competition: Part Manufacturing May 30, 2012 09:14PM |

Registered: 12 years ago Posts: 216 |

|

Re: Game / Competition: Part Manufacturing May 30, 2012 09:39PM |

Registered: 11 years ago Posts: 2 |

Here is my entry. First attempt using my SeeMeCNC H-1 kit with Repetier Host/Firmware, Sanguinololu 1.3a and Slic3r.

Material used is ABS, heated bed was on at ~110C and nozzle running ~210C

Slic3r settings:

; layer_height = .20

; perimeters = 2

; solid_layers = 4

; fill_density = .25

; nozzle_diameter = 0.50

; filament_diameter = 1.8

; extrusion_multiplier = 1

; perimeter_speed = 20

; infill_speed = 20

; travel_speed = 120

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.70mm

Printing time: 45m:1s

About 120 layers into the print I noticed that the fan had become disconnected! The armpit became a bit too heated and caused discoloration.

Regards,

PM

Material used is ABS, heated bed was on at ~110C and nozzle running ~210C

Slic3r settings:

; layer_height = .20

; perimeters = 2

; solid_layers = 4

; fill_density = .25

; nozzle_diameter = 0.50

; filament_diameter = 1.8

; extrusion_multiplier = 1

; perimeter_speed = 20

; infill_speed = 20

; travel_speed = 120

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.70mm

Printing time: 45m:1s

About 120 layers into the print I noticed that the fan had become disconnected! The armpit became a bit too heated and caused discoloration.

Regards,

PM

|

Re: Game / Competition: Part Manufacturing May 31, 2012 03:14AM |

Registered: 13 years ago Posts: 301 |

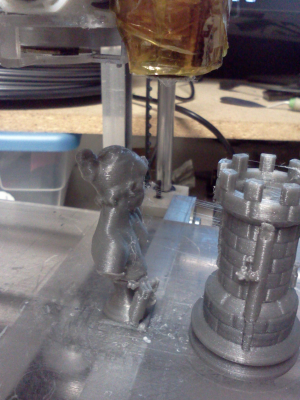

KISSlicer 0.17mm 0.65 threadwidth, 30s min layer time, 2 perimeters, retraction on, 85% supports that broke and were worthless, overhead fan

With the long 30s min layer time I decided to print the rook at the same time. Estimated build time went from 2h40m to 2h45m or something so why not? This configuration was interesting because most of the actual extruding time was in the rook which put the fan directly over the bust most of the time. This meant that the bust layers were always very cooled before the next layer was added. It definitely helped but the shallow grade in some places still were a problem. I think the only real solution is to print proper supports otherwise we are expecting the plastic to not layer, but stick nearly only to the side of an inner perimeter and I don't think that's going to work no matter how much magic fan is applied.

Left to right.

0.4mm KISSlicer, 30s min layer time, no fan

0.2mm KISSlicer, 10s min layer time, overhead fan

0.2mm Slic3r, 10s min layer time, overhead fan

0.17mm from above

[docs.google.com]

With the long 30s min layer time I decided to print the rook at the same time. Estimated build time went from 2h40m to 2h45m or something so why not? This configuration was interesting because most of the actual extruding time was in the rook which put the fan directly over the bust most of the time. This meant that the bust layers were always very cooled before the next layer was added. It definitely helped but the shallow grade in some places still were a problem. I think the only real solution is to print proper supports otherwise we are expecting the plastic to not layer, but stick nearly only to the side of an inner perimeter and I don't think that's going to work no matter how much magic fan is applied.

Left to right.

0.4mm KISSlicer, 30s min layer time, no fan

0.2mm KISSlicer, 10s min layer time, overhead fan

0.2mm Slic3r, 10s min layer time, overhead fan

0.17mm from above

[docs.google.com]

|

Re: Game / Competition: Part Manufacturing May 31, 2012 07:58AM |

Registered: 13 years ago Posts: 818 |

billyzelsnack Wrote:

-------------------------------------------------------

Estimated build

> time went from 2h40m to 2h45m or something so why

What was your actual build time, I'm finding for me it's usually just over half of what Pronterface estimates it's going to be (almost Ultimaker acceleration speeds on my MendelMax).

>

> Left to right.

> 0.4mm KISSlicer, 30s min layer time, no fan

> 0.2mm KISSlicer, 10s min layer time, overhead fan

> 0.2mm Slic3r, 10s min layer time, overhead fan

> 0.17mm from above

>

>

> [docs.google.com]

> MHVuZGkzenM/edit

Loving that last image, great stuff!

[richrap.blogspot.com]

-------------------------------------------------------

Estimated build

> time went from 2h40m to 2h45m or something so why

What was your actual build time, I'm finding for me it's usually just over half of what Pronterface estimates it's going to be (almost Ultimaker acceleration speeds on my MendelMax).

>

> Left to right.

> 0.4mm KISSlicer, 30s min layer time, no fan

> 0.2mm KISSlicer, 10s min layer time, overhead fan

> 0.2mm Slic3r, 10s min layer time, overhead fan

> 0.17mm from above

>

>

> [docs.google.com]

> MHVuZGkzenM/edit

Loving that last image, great stuff!

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 31, 2012 10:41AM |

Registered: 13 years ago Posts: 301 |

> Estimated build

> > time went from 2h40m to 2h45m or something so

> why

>

> What was your actual build time, I'm finding for

> me it's usually just over half of what Pronterface

> estimates it's going to be (almost Ultimaker

> acceleration speeds on my MendelMax).

3 hours for bust + rook printed at the same time.

I use RepG and its estimate is usually pretty close to KISSlicer's and ranges from a little low to twice as long. It seems to depend on how much retraction is involved and this print doesn't have much.

I'm wondering how the Ultimaker folks do all those crazy fast thin layer prints because speed seems to be very limited by cooling. Maybe choice of print is a factor. Maybe to go low and go fast requires prints large enough to have 20+ sec min layer times even when moving fast. Maybe I just need a much bigger fan.

> > time went from 2h40m to 2h45m or something so

> why

>

> What was your actual build time, I'm finding for

> me it's usually just over half of what Pronterface

> estimates it's going to be (almost Ultimaker

> acceleration speeds on my MendelMax).

3 hours for bust + rook printed at the same time.

I use RepG and its estimate is usually pretty close to KISSlicer's and ranges from a little low to twice as long. It seems to depend on how much retraction is involved and this print doesn't have much.

I'm wondering how the Ultimaker folks do all those crazy fast thin layer prints because speed seems to be very limited by cooling. Maybe choice of print is a factor. Maybe to go low and go fast requires prints large enough to have 20+ sec min layer times even when moving fast. Maybe I just need a much bigger fan.

|

Re: Game / Competition: Part Manufacturing May 31, 2012 11:27AM |

Registered: 13 years ago Posts: 818 |

billyzelsnack Wrote:

-------------------------------------------------------

"Maybe I just need a much bigger fan" - That'll do it

No heated bed on Ultimaker, so they can freeze the PLA as soon at it's extruded, high-powered nozzle fan blowing straight down onto the object.

[richrap.blogspot.com]

-------------------------------------------------------

"Maybe I just need a much bigger fan" - That'll do it

No heated bed on Ultimaker, so they can freeze the PLA as soon at it's extruded, high-powered nozzle fan blowing straight down onto the object.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 31, 2012 12:24PM |

Registered: 13 years ago Posts: 17 |

Loving the prints - and competition!

3d printing challenges rock!

If the organizers are happy, we would love to give the winner a £40 coupon for use at faberdashery.co.uk ...

Let us know if that's ok.

Cheers,

Andrew

Faberdashery

3d printing challenges rock!

If the organizers are happy, we would love to give the winner a £40 coupon for use at faberdashery.co.uk ...

Let us know if that's ok.

Cheers,

Andrew

Faberdashery

|

Re: Game / Competition: Part Manufacturing May 31, 2012 01:29PM |

Registered: 13 years ago Posts: 301 |

> "Maybe I just need a much bigger fan" - That'll do it

That's my question. Would that allow me to print this model faster? I'm not so sure.

Here's some numbers at 0.15mm layers, 1 perimeter in KISSlicer. btw. KISSlicer will recompute these without having to reslice which is super nice.

20mm/s, 0s min layer time = 30m

20mm/s, 10s min layer time = 1h1m

20mm/s, 20s min layer time = 1h59m

20mm/s, 30s min layer time = 2h59m

50mm/s, 0s min layer time = 14m

50mm/s, 10s min layer time = 1h0m

50mm/s, 20s min layer time = 1h59m

50mm/s, 30s min layer time = 2h59m

So basically print time even with only a 10s min layer time is completely dominated by cooling slow down on this print. Are the Ultimaker folks running with 0 min layer times?

Edited 1 time(s). Last edit at 05/31/2012 01:30PM by billyzelsnack.

That's my question. Would that allow me to print this model faster? I'm not so sure.

Here's some numbers at 0.15mm layers, 1 perimeter in KISSlicer. btw. KISSlicer will recompute these without having to reslice which is super nice.

20mm/s, 0s min layer time = 30m

20mm/s, 10s min layer time = 1h1m

20mm/s, 20s min layer time = 1h59m

20mm/s, 30s min layer time = 2h59m

50mm/s, 0s min layer time = 14m

50mm/s, 10s min layer time = 1h0m

50mm/s, 20s min layer time = 1h59m

50mm/s, 30s min layer time = 2h59m

So basically print time even with only a 10s min layer time is completely dominated by cooling slow down on this print. Are the Ultimaker folks running with 0 min layer times?

Edited 1 time(s). Last edit at 05/31/2012 01:30PM by billyzelsnack.

Sorry, only registered users may post in this forum.