Game / Competition: Part Manufacturing

Posted by RepRapBCN

|

Re: Game / Competition: Part Manufacturing May 31, 2012 01:56PM |

Registered: 13 years ago Posts: 818 |

billyzelsnack Wrote:

-------------------------------------------------------

> > "Maybe I just need a much bigger fan" - That'll

> do it

>

> That's my question. Would that allow me to print

> this model faster? I'm not so sure.

My print was 1h 1min @ 55mm/sec and I had a minimum layer time of 6 seconds (I think, I'll check the config)

Bigger fan for general cooling of layers, but sometimes a small spot directional fan for doing small stuff.

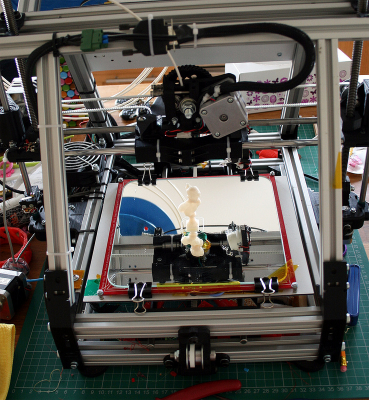

I'm printing a thing at the moment, it has hundreds of holes it it, so the extruder is jumping 0.5mm - to 3mm for each tiny section, and it's about 20mm in diameter, so without cooling it would take forever and be messy and just not print. it needs spot cooling and that makes it a 1h 45min print about 100mm high. I very much doubt an Ultimaker could print it (there's a challenge!), as it's thousands of extruder reversals and Z hops, you could just move really quickly and not do any extruder reverse but I'm not sure how that would come out.

You don't need a minimum layer time on all layers, just the ones that would be too fast without cooling. Or have virtually no layer delay and cool it all down quickly.

[richrap.blogspot.com]

-------------------------------------------------------

> > "Maybe I just need a much bigger fan" - That'll

> do it

>

> That's my question. Would that allow me to print

> this model faster? I'm not so sure.

My print was 1h 1min @ 55mm/sec and I had a minimum layer time of 6 seconds (I think, I'll check the config)

Bigger fan for general cooling of layers, but sometimes a small spot directional fan for doing small stuff.

I'm printing a thing at the moment, it has hundreds of holes it it, so the extruder is jumping 0.5mm - to 3mm for each tiny section, and it's about 20mm in diameter, so without cooling it would take forever and be messy and just not print. it needs spot cooling and that makes it a 1h 45min print about 100mm high. I very much doubt an Ultimaker could print it (there's a challenge!), as it's thousands of extruder reversals and Z hops, you could just move really quickly and not do any extruder reverse but I'm not sure how that would come out.

You don't need a minimum layer time on all layers, just the ones that would be too fast without cooling. Or have virtually no layer delay and cool it all down quickly.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing May 31, 2012 08:06PM |

Registered: 11 years ago Posts: 939 |

Here's my entry, in Pink!

This is repraper.com pink PLA (I ordered the purple). Seems to have a lot less die swell than the 4043D green I was using, I need to print some calibration parts, I'm seeing gaps in my solid layers.

This is off my SeemeCNC- H1

Slic3r 0.82

0.5mm Nozzle

0.2mm Layer height

2 perimeters

0% infill

Fan on for all layers

First layer @200

Rest @185

Bed @50

This is repraper.com pink PLA (I ordered the purple). Seems to have a lot less die swell than the 4043D green I was using, I need to print some calibration parts, I'm seeing gaps in my solid layers.

This is off my SeemeCNC- H1

Slic3r 0.82

0.5mm Nozzle

0.2mm Layer height

2 perimeters

0% infill

Fan on for all layers

First layer @200

Rest @185

Bed @50

|

Re: Game / Competition: Part Manufacturing June 01, 2012 07:43AM |

Registered: 12 years ago Posts: 313 |

billyzelsnack Wrote:

-------------------------------------------------------

> > "Maybe I just need a much bigger fan" - That'll

> do it

>

> That's my question. Would that allow me to print

> this model faster? I'm not so sure.

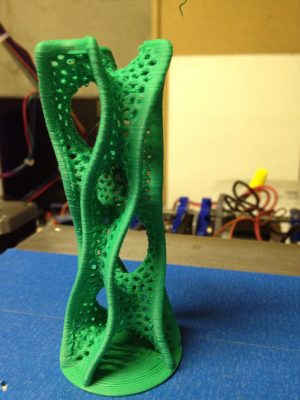

Here's an example: without and with a fan

Left thing was printed at 30 s/layer without fan, right thing at 10 s/layer with fan.

edit: This was the fan, it has a 60x60mm fan and a really cool directed nozzle.

Edited 1 time(s). Last edit at 06/01/2012 07:46AM by ttsalo.

-------------------------------------------------------

> > "Maybe I just need a much bigger fan" - That'll

> do it

>

> That's my question. Would that allow me to print

> this model faster? I'm not so sure.

Here's an example: without and with a fan

Left thing was printed at 30 s/layer without fan, right thing at 10 s/layer with fan.

edit: This was the fan, it has a 60x60mm fan and a really cool directed nozzle.

Edited 1 time(s). Last edit at 06/01/2012 07:46AM by ttsalo.

|

Re: Game / Competition: Part Manufacturing June 01, 2012 11:06AM |

Registered: 13 years ago Posts: 301 |

ttsalo Wrote:

> Here's an example: without and with a fan

> Left thing was printed at 30 s/layer without fan,

> right thing at 10 s/layer with fan.

That's a really good example. Running the numbers at 0.15mm layers and 55mm/s.

8m21s for 0s min layer time.

40m23s for 10s min layer time.

1h59m for 30s min layer time.

Print time is completely dominated by cooling. Even with a huge directed fan and 10s min layer time I would say that part needs an even larger layer time and/or more cooling. Was it printed with orbit or slow down?

I guess I'm just not convinced that bigger fans are more than a temporary solution. I'm wondering if the real solution, maybe in conjunction with a fan, is in smarter software than takes plastic cooling based upon geometry under consideration.

> Here's an example: without and with a fan

> Left thing was printed at 30 s/layer without fan,

> right thing at 10 s/layer with fan.

That's a really good example. Running the numbers at 0.15mm layers and 55mm/s.

8m21s for 0s min layer time.

40m23s for 10s min layer time.

1h59m for 30s min layer time.

Print time is completely dominated by cooling. Even with a huge directed fan and 10s min layer time I would say that part needs an even larger layer time and/or more cooling. Was it printed with orbit or slow down?

I guess I'm just not convinced that bigger fans are more than a temporary solution. I'm wondering if the real solution, maybe in conjunction with a fan, is in smarter software than takes plastic cooling based upon geometry under consideration.

|

Re: Game / Competition: Part Manufacturing June 01, 2012 11:41AM |

Registered: 12 years ago Posts: 216 |

Ooooh, good one! You mean looking at sharper corners vs. large radii etc...?

Another idea similar I had was to print at whatever speed you can, but lift Z, then position the nozzle outside the parts walls and dwell for x number of seconds to allow cooling, then move over the part, lower Z and "wipe" over to the starting point of the next layer (to remove fuzzies).

Another idea similar I had was to print at whatever speed you can, but lift Z, then position the nozzle outside the parts walls and dwell for x number of seconds to allow cooling, then move over the part, lower Z and "wipe" over to the starting point of the next layer (to remove fuzzies).

|

Re: Game / Competition: Part Manufacturing June 01, 2012 12:18PM |

Registered: 11 years ago Posts: 939 |

You have to be really careful with varying speed within a layer, There is a certain amount of hysteresis in changing the pressure in the hotzone/nozzle, so I think significant extruder speed changes in layer would result in uneven plastic deposition, blobs and voids.

I guess you could try and model that in the slicing software, but it would be very hotend dependent.

A simple win IMO would be when I've just put down a small part next to a big part, don't try and minimize the head travel and immediately do the next layer of the same small part, go do the big one first. Funnily enough up until 0.7.2 at least this was something Slic3r did better than Skeinforge.

I guess you could try and model that in the slicing software, but it would be very hotend dependent.

A simple win IMO would be when I've just put down a small part next to a big part, don't try and minimize the head travel and immediately do the next layer of the same small part, go do the big one first. Funnily enough up until 0.7.2 at least this was something Slic3r did better than Skeinforge.

|

Re: Game / Competition: Part Manufacturing June 01, 2012 02:03PM |

Registered: 13 years ago Posts: 818 |

Polygonhell Wrote:

-------------------------------------------------------

> You have to be really careful with varying speed

> within a layer, There is a certain amount of

> hysteresis in changing the pressure in the

> hotzone/nozzle, so I think significant extruder

> speed changes in layer would result in uneven

> plastic deposition, blobs and voids.

> I guess you could try and model that in the

> slicing software, but it would be very hotend

> dependent.

For the best print quality I always set the infill and perimeter to the same speeds for exactly this reason, also helps reduce curling / warp of parts.

Otherwise for normal printing infill can be faster but I try to stick to a ratio where infill is less or equal to 130% of the perimeter speed.

[richrap.blogspot.com]

-------------------------------------------------------

> You have to be really careful with varying speed

> within a layer, There is a certain amount of

> hysteresis in changing the pressure in the

> hotzone/nozzle, so I think significant extruder

> speed changes in layer would result in uneven

> plastic deposition, blobs and voids.

> I guess you could try and model that in the

> slicing software, but it would be very hotend

> dependent.

For the best print quality I always set the infill and perimeter to the same speeds for exactly this reason, also helps reduce curling / warp of parts.

Otherwise for normal printing infill can be faster but I try to stick to a ratio where infill is less or equal to 130% of the perimeter speed.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 01, 2012 02:41PM |

Registered: 13 years ago Posts: 818 |

faberdasher Wrote:

-------------------------------------------------------

> Loving the prints - and competition!

>

> 3d printing challenges rock!

> If the organizers are happy, we would love to give

> the winner a £40 coupon for use at

> faberdashery.co.uk ...

>

> Let us know if that's ok.

>

> Cheers,

> Andrew

Hi Andrew,

Thanks for supporting this, I'm sure RepRapBCN would be most please to have a prize for this game, and there's still plenty of time for more entries, come on everyone get printing! even more reason now with £40 worth of Faberdashery magic plastic to play for! It's Awesome stuff.

[richrap.blogspot.com]

-------------------------------------------------------

> Loving the prints - and competition!

>

> 3d printing challenges rock!

> If the organizers are happy, we would love to give

> the winner a £40 coupon for use at

> faberdashery.co.uk ...

>

> Let us know if that's ok.

>

> Cheers,

> Andrew

Hi Andrew,

Thanks for supporting this, I'm sure RepRapBCN would be most please to have a prize for this game, and there's still plenty of time for more entries, come on everyone get printing! even more reason now with £40 worth of Faberdashery magic plastic to play for! It's Awesome stuff.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 01, 2012 05:14PM |

Registered: 12 years ago Posts: 344 |

These are my prints at 50% size and 100% size:

DSC_4729 por electroPluma, en Flickr

This photo is a closeup of the 100% size piece:

DSC_4731 por electroPluma, en Flickr

Both were printed at 0.15mm layer height, Green ABS at 235ºC for the first layer and 225ºC after that.

The 50% piece was printed without supports. The 100% was printed with supports.

0.5mm extruder, 3.1mm filament diameter

65ºC bed temp. (PCB heater, glass and kapton on top)

60% Fan after 10 layers to the end.

DSC_4729 por electroPluma, en Flickr

This photo is a closeup of the 100% size piece:

DSC_4731 por electroPluma, en Flickr

Both were printed at 0.15mm layer height, Green ABS at 235ºC for the first layer and 225ºC after that.

The 50% piece was printed without supports. The 100% was printed with supports.

0.5mm extruder, 3.1mm filament diameter

65ºC bed temp. (PCB heater, glass and kapton on top)

60% Fan after 10 layers to the end.

|

Re: Game / Competition: Part Manufacturing June 01, 2012 07:01PM |

Registered: 13 years ago Posts: 248 |

Hi all,

I logged my entry on the Thingiverse page earlier. I've posted full detail on my blog page: [numbersixreprap.blogspot.ie]

Here's a pict of my entry;

and the technical detail...

; generated by Slic3r 0.7.1 on 2012-05-29 at 22:59:22

; layer_height = 0.25

; perimeters = 2

; solid_layers = 2

; fill_density = .15

; nozzle_diameter = 0.35

; filament_diameter = 1.74

; extrusion_multiplier = 1

; perimeter_speed = 15

; infill_speed = 30

; travel_speed = 130

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.39mm

full detail on my blog. Questions and comments welcome.

Tks,

NumberSix

Edited 1 time(s). Last edit at 06/01/2012 07:47PM by NumberSix.

[numbersixreprap.blogspot.com]

I logged my entry on the Thingiverse page earlier. I've posted full detail on my blog page: [numbersixreprap.blogspot.ie]

Here's a pict of my entry;

and the technical detail...

; generated by Slic3r 0.7.1 on 2012-05-29 at 22:59:22

; layer_height = 0.25

; perimeters = 2

; solid_layers = 2

; fill_density = .15

; nozzle_diameter = 0.35

; filament_diameter = 1.74

; extrusion_multiplier = 1

; perimeter_speed = 15

; infill_speed = 30

; travel_speed = 130

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.39mm

full detail on my blog. Questions and comments welcome.

Tks,

NumberSix

Edited 1 time(s). Last edit at 06/01/2012 07:47PM by NumberSix.

[numbersixreprap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 02, 2012 01:03AM |

Registered: 11 years ago Posts: 1 |

I am almost definitely immediately disqualified, since I'm using a Replicator (and maybe too late), but I should get some brownie (tear-drop?) points for using my own, hacked accelerated firmware, right?

In any case, this was a fun print, and it's been great reading through all of the posts and seeing other people's results.

0.1mm layer height, 0.4mm path width

Printed at 80mm/s 1% infill with 1 extra shell (skeinforge, at 1%, basically does the perimeter plus two shells with these settings).

The perimeter was slowed to 20mm/s.

No support. (Tomorrow I'll try a print with PLA supporting the ABS.)

It took 1hr (+- 5 minutes, I was out of the room) to print, but took 45 minutes to slice in Skeinforge 47.

I handed this to my wife, who has gotten used to seeing 0.2mm layer height prints, and she asked me, "did you print this, just now, on your printer?" :-)

In any case, this was a fun print, and it's been great reading through all of the posts and seeing other people's results.

0.1mm layer height, 0.4mm path width

Printed at 80mm/s 1% infill with 1 extra shell (skeinforge, at 1%, basically does the perimeter plus two shells with these settings).

The perimeter was slowed to 20mm/s.

No support. (Tomorrow I'll try a print with PLA supporting the ABS.)

It took 1hr (+- 5 minutes, I was out of the room) to print, but took 45 minutes to slice in Skeinforge 47.

I handed this to my wife, who has gotten used to seeing 0.2mm layer height prints, and she asked me, "did you print this, just now, on your printer?" :-)

|

Re: Game / Competition: Part Manufacturing June 02, 2012 01:51AM |

Registered: 13 years ago Posts: 486 |

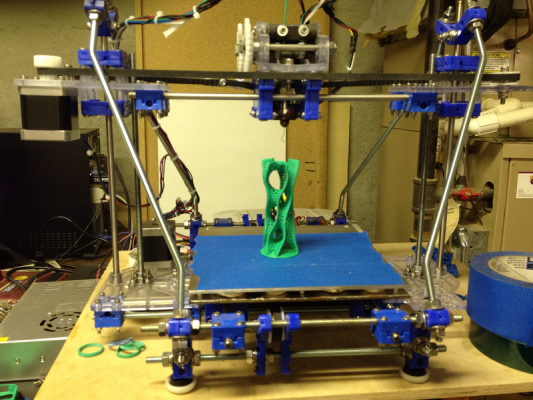

Here's mine:

; generated by Slic3r 0.8.2 on 2012-06-02 at 14:12:12

; layer_height = 0.3

; perimeters = 3

; solid_layers = 3

; fill_density = 0.1

; nozzle_diameter = 0.4

; filament_diameter = 2.87

; extrusion_multiplier = 1

; perimeter_speed = 30

; infill_speed = 60

; travel_speed = 80

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.42mm

Print time 00:51:30

Edited 1 time(s). Last edit at 06/02/2012 01:52AM by Greg Frost.

; generated by Slic3r 0.8.2 on 2012-06-02 at 14:12:12

; layer_height = 0.3

; perimeters = 3

; solid_layers = 3

; fill_density = 0.1

; nozzle_diameter = 0.4

; filament_diameter = 2.87

; extrusion_multiplier = 1

; perimeter_speed = 30

; infill_speed = 60

; travel_speed = 80

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.42mm

Print time 00:51:30

Edited 1 time(s). Last edit at 06/02/2012 01:52AM by Greg Frost.

|

Re: Game / Competition: Part Manufacturing June 02, 2012 04:56AM |

Registered: 12 years ago Posts: 145 |

Hi!

First of all I would like to say that I am very happy with so many people doing great job and sharing knowledge.

After reading carefully all the post, I announce that the first winner of the challenge is..... RICHRAP!!

Now Richrap should propose a new model

Congratulations to all of you !!!!

Edited 1 time(s). Last edit at 06/02/2012 06:45AM by RepRapBCN.

RepRapBCN - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

First of all I would like to say that I am very happy with so many people doing great job and sharing knowledge.

After reading carefully all the post, I announce that the first winner of the challenge is..... RICHRAP!!

Now Richrap should propose a new model

Congratulations to all of you !!!!

Edited 1 time(s). Last edit at 06/02/2012 06:45AM by RepRapBCN.

RepRapBCN - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

|

Re: Game / Competition: Part Manufacturing June 02, 2012 06:18AM |

Registered: 13 years ago Posts: 248 |

|

Re: Game / Competition: Part Manufacturing June 02, 2012 02:58PM |

Registered: 13 years ago Posts: 818 |

Sorry for the delay in reply, we have a 4 day party here in the UK this weekend for the Queen

Thanks everyone, what a good game this is, I'm seriously impressed with all the amazing prints and great discussion.

I have been thinking about the next challenge and I was going to suggest the Eiffel tower by B9Creations but I had some problems slicing it at a sensible size most people could print, even at 90mm high and 0.1mm layers Slic3r does not know what to make of it. Maybe one for the future.

So my proposed model for this weeks challenge is the rather amazing Voronoi D Tower (Math art) by @Dizingof, I'm rather blown away by his work, and this one has a lot of fine detail and has a number of challenges, but can still be printed without support if you like.

I have made a smaller size file and reduced the size of the model for the competition, but If you want to use the original or print it at a different size to my derivative please feel free, just mention which model you used and how big it's printed.

I have tested it with Slic3r and it works, V0.7.2 throws some errors, but the Gcode is fine, V0.8.2 slices it without any fuss. I'm sure Skeinforge and the others should not be a problem. My first test print is not very good at the moment, so I'm really interested to see what other people can produce and how they did it.

This model may be a good candidate slicing with different settings and mixing the Gcode (info on my blog about mixing Gcode) as it has some tricky sections -

So print whatever size you like, just say how big it is in the print.

And whatever layer height and speed you like.

This should be a really interesting model to learn a few printing tricks from, good luck everyone, and do give it a go, it's not quite as tricky as it looks.

And if you complete the Voronoi D Tower and have some time spare - My favourite model of all time at the moment is Ball of stars by @Dizingof, take a look, it's totally awesome.

Edited 1 time(s). Last edit at 06/02/2012 03:08PM by richrap.

[richrap.blogspot.com]

Thanks everyone, what a good game this is, I'm seriously impressed with all the amazing prints and great discussion.

I have been thinking about the next challenge and I was going to suggest the Eiffel tower by B9Creations but I had some problems slicing it at a sensible size most people could print, even at 90mm high and 0.1mm layers Slic3r does not know what to make of it. Maybe one for the future.

So my proposed model for this weeks challenge is the rather amazing Voronoi D Tower (Math art) by @Dizingof, I'm rather blown away by his work, and this one has a lot of fine detail and has a number of challenges, but can still be printed without support if you like.

I have made a smaller size file and reduced the size of the model for the competition, but If you want to use the original or print it at a different size to my derivative please feel free, just mention which model you used and how big it's printed.

I have tested it with Slic3r and it works, V0.7.2 throws some errors, but the Gcode is fine, V0.8.2 slices it without any fuss. I'm sure Skeinforge and the others should not be a problem. My first test print is not very good at the moment, so I'm really interested to see what other people can produce and how they did it.

This model may be a good candidate slicing with different settings and mixing the Gcode (info on my blog about mixing Gcode) as it has some tricky sections -

- It has a very shallow domed base, that is very hard to get looking good, so that't the first challenge.

- The walls are thin and it has lots of holes in it.

- Sections join together and it has some overhang

- It will really test your extruder calibration and reversal moves.

- You may want to try printing it really fast without any extruder reversal?

So print whatever size you like, just say how big it is in the print.

And whatever layer height and speed you like.

This should be a really interesting model to learn a few printing tricks from, good luck everyone, and do give it a go, it's not quite as tricky as it looks.

And if you complete the Voronoi D Tower and have some time spare - My favourite model of all time at the moment is Ball of stars by @Dizingof, take a look, it's totally awesome.

Edited 1 time(s). Last edit at 06/02/2012 03:08PM by richrap.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 02, 2012 03:22PM |

Registered: 12 years ago Posts: 145 |

|

Re: Game / Competition: Part Manufacturing June 02, 2012 04:11PM |

Registered: 11 years ago Posts: 329 |

i might stand a chance at enterting this week now i got a new decent hotend

will give it a go tommrow.

also why dont we try get a website going for this compo every week ?

seems a bit cluttered in a forum thread.

a website could lead to things like voting on the file etc and even slicer config upload files as well

just a thought as this could really push everyone to get much better results, it did for me

will give it a go tommrow.

also why dont we try get a website going for this compo every week ?

seems a bit cluttered in a forum thread.

a website could lead to things like voting on the file etc and even slicer config upload files as well

just a thought as this could really push everyone to get much better results, it did for me

|

Re: Game / Competition: Part Manufacturing June 02, 2012 06:13PM |

Admin Registered: 17 years ago Posts: 177 |

Congrats on the win, Rich.

Nice to see a challenge based on 3D Voronoi structures. There's a bloke called Adrian Bowyer who is famous principally for a thing called the Bowyer-Watson Algorithm, which is one of the standard ways of computing multidimensional Voronoi diagrams. I wonder what happened to him?

Nice to see a challenge based on 3D Voronoi structures. There's a bloke called Adrian Bowyer who is famous principally for a thing called the Bowyer-Watson Algorithm, which is one of the standard ways of computing multidimensional Voronoi diagrams. I wonder what happened to him?

|

Re: Game / Competition: Part Manufacturing June 02, 2012 07:10PM |

Registered: 12 years ago Posts: 18 |

Not sure what might have become of him, Adrian, but I'm guessing you might know more about that then me.

Congrats on the win, Rich.

I didn't get a chance to print out last weeks, but I have today's printing now. Let you know how it goes.

I agree that there could be a better place to put these than in a forum. That said, a different thread for each weeks attempts might be a way to get the threads into manageable sizes in the mean time.

All the prints looked great on the last one. It had obvious issue areas.

Congrats on the win, Rich.

I didn't get a chance to print out last weeks, but I have today's printing now. Let you know how it goes.

I agree that there could be a better place to put these than in a forum. That said, a different thread for each weeks attempts might be a way to get the threads into manageable sizes in the mean time.

All the prints looked great on the last one. It had obvious issue areas.

|

Re: Game / Competition: Part Manufacturing June 03, 2012 12:35AM |

Registered: 13 years ago Posts: 301 |

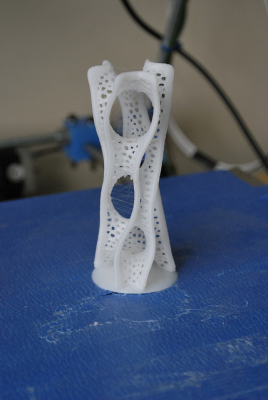

Printxel. KISSlicer 0.33 layers. Overhead 40mm fan. 20mm/s. 2mm retract. 25mm/s retract speed. 10mm wipe. 1h18m estimate. 1h57m actual.

Print time is completely dominated by retraction.

[www.thingiverse.com]

Edited 6 time(s). Last edit at 06/03/2012 12:48AM by billyzelsnack.

Print time is completely dominated by retraction.

[www.thingiverse.com]

Edited 6 time(s). Last edit at 06/03/2012 12:48AM by billyzelsnack.

|

Re: Game / Competition: Part Manufacturing June 03, 2012 04:34AM |

Registered: 13 years ago Posts: 818 |

Adrian Bowyer Wrote:

-------------------------------------------------------

> Congrats on the win, Rich.

>

> Nice to see a challenge based on 3D Voronoi

> structures. There's a bloke called Adrian Bowyer

> who is famous principally for a thing called the

> Bowyer-Watson Algorithm, which is one of the

> standard ways of computing multidimensional

> Voronoi diagrams. I wonder what happened to him?

Thanks Adrian, how perfectly fitting for a RepRap challenge! I'm thinking you may know a really good way to print it

More on Wikipedia about the Bowyer–Watson algorithm and Voronoi diagrams, I can now appreciate their beauty even more.

A quick search on Thingiverse reveals some other great Voronoi models, Dizingof has done some more in recent days, I really like the ball we just need a good dual extruder setup for RepRap to print it now

[richrap.blogspot.com]

-------------------------------------------------------

> Congrats on the win, Rich.

>

> Nice to see a challenge based on 3D Voronoi

> structures. There's a bloke called Adrian Bowyer

> who is famous principally for a thing called the

> Bowyer-Watson Algorithm, which is one of the

> standard ways of computing multidimensional

> Voronoi diagrams. I wonder what happened to him?

Thanks Adrian, how perfectly fitting for a RepRap challenge! I'm thinking you may know a really good way to print it

More on Wikipedia about the Bowyer–Watson algorithm and Voronoi diagrams, I can now appreciate their beauty even more.

A quick search on Thingiverse reveals some other great Voronoi models, Dizingof has done some more in recent days, I really like the ball we just need a good dual extruder setup for RepRap to print it now

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 04, 2012 07:22AM |

Registered: 13 years ago Posts: 818 |

I'm still not having much luck with Slic3r and this model, it's defiantly removing tiny sections of the outer perimeter when it processes the model into Gcode - could be a bug.

Also it's not easy to get a good looking base with Slic3r -

Lots of bases in Slic3r with different infill settings and layer heights.

The black print is with Slic3r, it has issues with this model.

Glow in the dark and Orange both sliced with Skeinforge V46.

90mm high - Skeinforge V46 - 0.5mm nozzle 0.3mm layers / 80mm sec infill / 65mm sec perimeter & 190mm/sec travel speed - the white print on the left is printed with normal Extruder retraction (1.2mm) and the Orange print on the right was done with no retraction at all.

Printed with Black, Orange and Glow in the dark PLA plastic from Faberdashery.

300 layers - 1Hour 17mins to print.

Glow in the dark with Extruder Retraction.

Orange without any extruder retraction - note the tiny little blobs in a few areas, can be rubbed off quite easily.

Apart from a few tiny blobs, the Orange print came out just a little better and printed 9mins faster.

[richrap.blogspot.com]

Also it's not easy to get a good looking base with Slic3r -

Lots of bases in Slic3r with different infill settings and layer heights.

The black print is with Slic3r, it has issues with this model.

Glow in the dark and Orange both sliced with Skeinforge V46.

90mm high - Skeinforge V46 - 0.5mm nozzle 0.3mm layers / 80mm sec infill / 65mm sec perimeter & 190mm/sec travel speed - the white print on the left is printed with normal Extruder retraction (1.2mm) and the Orange print on the right was done with no retraction at all.

Printed with Black, Orange and Glow in the dark PLA plastic from Faberdashery.

300 layers - 1Hour 17mins to print.

Glow in the dark with Extruder Retraction.

Orange without any extruder retraction - note the tiny little blobs in a few areas, can be rubbed off quite easily.

Apart from a few tiny blobs, the Orange print came out just a little better and printed 9mins faster.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 04, 2012 08:39AM |

Registered: 12 years ago Posts: 18 |

Looks good, Rich.

I did try a couple yesterday.

My results.

This is gold PLA. No heat on the bed. Regular 3M blue tape. Prusa Mendel linear bearings and Gen 6 board.

Sliced with Slic3r 0-8-2.

Temp. 180 C

Speed was too fast on the first print for several settings.

I reduced speed to 30 from 70 for retraction, slowed down to around 50 on everything else including bridging.

That is basically the differences between the first and second prints. Just slowed everything. My machine sits in front of an AC unit, so it is always cooled during these two prints. I also have a steel heat bed base, and when I set it too fast, it overshoots a bit as can be seen in the first print.

After changing the settings, I ran a calibration cube that turned out good. The only issue I have with it are the bumps on corners for direction change.

Other settings are .2 layer height

3 perimeters and solid fills @45%.

I have to say these look better to the eye than under a flash. There seem to be flaws under flash that really don't see by eye.

This also reminds me of both a sea sponge and corals I have seen. Nice choice for this challenge.

First image is starting first print.

Second is first print complete.

Third is a compare photo.

Last is final.

Lee

I did try a couple yesterday.

My results.

This is gold PLA. No heat on the bed. Regular 3M blue tape. Prusa Mendel linear bearings and Gen 6 board.

Sliced with Slic3r 0-8-2.

Temp. 180 C

Speed was too fast on the first print for several settings.

I reduced speed to 30 from 70 for retraction, slowed down to around 50 on everything else including bridging.

That is basically the differences between the first and second prints. Just slowed everything. My machine sits in front of an AC unit, so it is always cooled during these two prints. I also have a steel heat bed base, and when I set it too fast, it overshoots a bit as can be seen in the first print.

After changing the settings, I ran a calibration cube that turned out good. The only issue I have with it are the bumps on corners for direction change.

Other settings are .2 layer height

3 perimeters and solid fills @45%.

I have to say these look better to the eye than under a flash. There seem to be flaws under flash that really don't see by eye.

This also reminds me of both a sea sponge and corals I have seen. Nice choice for this challenge.

First image is starting first print.

Second is first print complete.

Third is a compare photo.

Last is final.

Lee

|

Re: Game / Competition: Part Manufacturing June 04, 2012 10:37AM |

Registered: 13 years ago Posts: 17 |

Congratulations Richard on your win!

I'm emailing you details for your £40 voucher.

Love this design, but quite a challenging print...

Again, we'd be honored to sponsor another £40 voucher for this printing competition. Let's see your best!

- Andrew

Faberdashery

I'm emailing you details for your £40 voucher.

Love this design, but quite a challenging print...

Again, we'd be honored to sponsor another £40 voucher for this printing competition. Let's see your best!

- Andrew

Faberdashery

|

Re: Game / Competition: Part Manufacturing June 05, 2012 03:44AM |

Registered: 13 years ago Posts: 818 |

faberdasher Wrote:

-------------------------------------------------------

> Congratulations Richard on your win!

> I'm emailing you details for your £40 voucher.

>

> Love this design, but quite a challenging

> print...

> Again, we'd be honored to sponsor another £40

> voucher for this printing competition. Let's see

> your best!

>

> - Andrew

Thanks Andrew, I have a cunning plan for using the Prize PLA to help the community, more info soon. I'm loving the new summer Neon colours, they look so great, Anyone not already seen them, put on some sunglasses and then click this link!

and then click this link!

Thanks for sponsoring another week, we are already seeing some great prints, and I'm sure we will get many more entries, it's going to be very tricky to choose a winner.

Keep the competition entries flowing everyone.

Cheers,

Rich.

[richrap.blogspot.com]

-------------------------------------------------------

> Congratulations Richard on your win!

> I'm emailing you details for your £40 voucher.

>

> Love this design, but quite a challenging

> print...

> Again, we'd be honored to sponsor another £40

> voucher for this printing competition. Let's see

> your best!

>

> - Andrew

Thanks Andrew, I have a cunning plan for using the Prize PLA to help the community, more info soon. I'm loving the new summer Neon colours, they look so great, Anyone not already seen them, put on some sunglasses

and then click this link!

and then click this link!Thanks for sponsoring another week, we are already seeing some great prints, and I'm sure we will get many more entries, it's going to be very tricky to choose a winner.

Keep the competition entries flowing everyone.

Cheers,

Rich.

[richrap.blogspot.com]

|

My entry this week June 05, 2012 04:35PM |

Registered: 12 years ago Posts: 116 |

This was printed on a SeeMeCNC H-1 controlled with Mach3. Used Rich's STL at 100% in green ABS 1.69mm filament.

As-printed (no cleanup)

Sliced in Slic3r 0.8.2

Accuracy: .2mm layer height, 1 first layer ratio, infill every 1 layer

Retraction: 2 mm len, .5 mm lift, 25 mm/s speed, 0 extra len, 2 mm travel after retraction

Print Settings: 3 perimeters, 4 solid layers .25 fill density, 45 deg fill, rectilinear fill and solid fill patterns, random starting points

Cooling fan on extruder

Printer: .5mm nozzle, Mach3/EMC gcode

Filament: 1.69mm, 1 multiplier, 205 deg C extruder, 110 deg C hot bed

Print speed: 20 mm/s perimeters, 15 mm/s small perimeters, 60 mm/s infill, 30 mm/s solid infill, 20 mm/s bridges

Other speed settings: 300 mm/s travel, .5 bottom layer ratio

Took 1 hr 58 minutes to print. Not bad for a first attempt. This is a challenging item! Put the printer through its paces!

Cheers,

Michael

Edited 1 time(s). Last edit at 06/05/2012 04:39PM by mhackney.

As-printed (no cleanup)

Sliced in Slic3r 0.8.2

Accuracy: .2mm layer height, 1 first layer ratio, infill every 1 layer

Retraction: 2 mm len, .5 mm lift, 25 mm/s speed, 0 extra len, 2 mm travel after retraction

Print Settings: 3 perimeters, 4 solid layers .25 fill density, 45 deg fill, rectilinear fill and solid fill patterns, random starting points

Cooling fan on extruder

Printer: .5mm nozzle, Mach3/EMC gcode

Filament: 1.69mm, 1 multiplier, 205 deg C extruder, 110 deg C hot bed

Print speed: 20 mm/s perimeters, 15 mm/s small perimeters, 60 mm/s infill, 30 mm/s solid infill, 20 mm/s bridges

Other speed settings: 300 mm/s travel, .5 bottom layer ratio

Took 1 hr 58 minutes to print. Not bad for a first attempt. This is a challenging item! Put the printer through its paces!

Cheers,

Michael

Edited 1 time(s). Last edit at 06/05/2012 04:39PM by mhackney.

|

Re: Game / Competition: Part Manufacturing June 05, 2012 09:01PM |

|

Re: Game / Competition: Part Manufacturing June 05, 2012 10:28PM |

Registered: 13 years ago Posts: 301 |

hmm. I can't edit my other post anymore. Same print as before just a nicer daylight photo.

I also made a little video because I think this is one of those prints that look a lot better in real life than in a photo. Maybe a video can help express how cool it is. Dunno.

[www.youtube.com]

Edited 1 time(s). Last edit at 06/05/2012 10:31PM by billyzelsnack.

I also made a little video because I think this is one of those prints that look a lot better in real life than in a photo. Maybe a video can help express how cool it is. Dunno.

[www.youtube.com]

Edited 1 time(s). Last edit at 06/05/2012 10:31PM by billyzelsnack.

|

Re: Game / Competition: Part Manufacturing June 06, 2012 07:01AM |

Registered: 12 years ago Posts: 145 |

|

Re: Game / Competition: Part Manufacturing June 06, 2012 12:47PM |

Registered: 11 years ago Posts: 10 |

First of all, thank you @richrap - without you preparing @dizingof's awesome model for smaller printers and suggesting it as a test, I would never have even attempted something as complex as this.

It's not a great print, but I am chuffed that it completed it successfully! Printed on a young Mendel (just got round to finishing it off a few weeks ago) and I am still tweaking the settings.

0.25mm layers in natural cream ABS on tape prepped w/ a layer of glue (no hot bed or fan - they are on the cards for future upgrades!)

Larger pic.

Picture set, showing base, errors and inner structures: (flickr)

Thanks again to @richrap and to @dizingof for an inspiring challenge!

Edited 1 time(s). Last edit at 06/06/2012 12:55PM by benosteen.

It's not a great print, but I am chuffed that it completed it successfully! Printed on a young Mendel (just got round to finishing it off a few weeks ago) and I am still tweaking the settings.

0.25mm layers in natural cream ABS on tape prepped w/ a layer of glue (no hot bed or fan - they are on the cards for future upgrades!)

Larger pic.

Picture set, showing base, errors and inner structures: (flickr)

Thanks again to @richrap and to @dizingof for an inspiring challenge!

Edited 1 time(s). Last edit at 06/06/2012 12:55PM by benosteen.

Sorry, only registered users may post in this forum.