|

Re: Game / Competition: Part Manufacturing June 06, 2012 08:35PM |

Registered: 12 years ago Posts: 5 |

Hi,

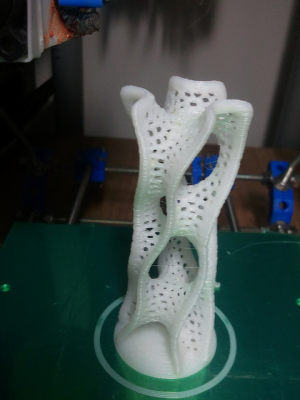

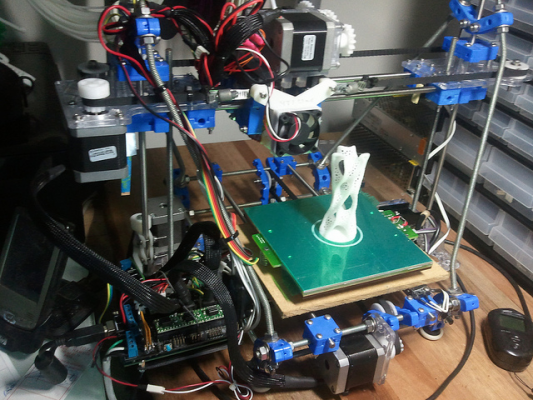

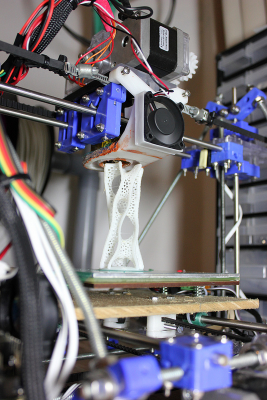

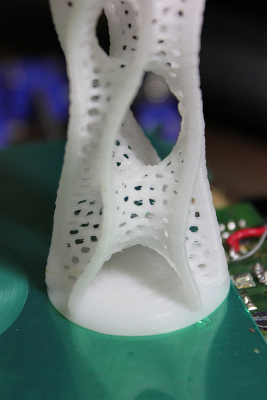

This is my first try for this competition using my modded SeeMeCNC H-1 :

My first print was using those parameters :

Printed in 1h45min next try : 0.1mm layer height

This is my first try for this competition using my modded SeeMeCNC H-1 :

- Budaschnozzle 1.1 with adapter for the original Steve's Extruder

- Custom fan duct

- Huxley PCB heated bed

- RAMPS 1.4

- And some more hacks

My first print was using those parameters :

- 0.3mm layer height

- 20/40/60mm/s for small perimeters/perimeters/infill

- 1mm retraction length at 7mm/s with 0.3mm z-lift

- 70% line infill

- 2 perimeters, 3 solid layers

Printed in 1h45min next try : 0.1mm layer height

|

Re: Game / Competition: Part Manufacturing June 06, 2012 09:06PM |

Registered: 12 years ago Posts: 216 |

|

Re: Game / Competition: Part Manufacturing June 07, 2012 12:00AM |

Registered: 12 years ago Posts: 5 |

Nice improvements john  however, I must honestly admit that I will not find the courage to unscrew all the x-axis... I already spent SO MUCH time on the H-1, I need to get to real life some time

however, I must honestly admit that I will not find the courage to unscrew all the x-axis... I already spent SO MUCH time on the H-1, I need to get to real life some time

Concerning the linear bushing, I'm actually using my seft printed PLA linear bushing for my y-carriage and I'm very happy with it ! You can get a good preview of my progress on my G+ blog. Maybe I'll get the inspiration from your work if I plan sometimes to upgrade my x-axis but if I start to follow this path what I really want to do is to implement a bowden extruder using the nice (but heavy!) Steve's Extruder ! Stay tuned and thank you for having created the H1 !

however, I must honestly admit that I will not find the courage to unscrew all the x-axis... I already spent SO MUCH time on the H-1, I need to get to real life some time

however, I must honestly admit that I will not find the courage to unscrew all the x-axis... I already spent SO MUCH time on the H-1, I need to get to real life some time

Concerning the linear bushing, I'm actually using my seft printed PLA linear bushing for my y-carriage and I'm very happy with it ! You can get a good preview of my progress on my G+ blog. Maybe I'll get the inspiration from your work if I plan sometimes to upgrade my x-axis but if I start to follow this path what I really want to do is to implement a bowden extruder using the nice (but heavy!) Steve's Extruder ! Stay tuned and thank you for having created the H1 !

|

Re: Game / Competition: Part Manufacturing June 07, 2012 12:18AM |

Registered: 11 years ago Posts: 2 |

Here is my entry for this weeks contest. Using my SeeMeCNC H-1.0 kit with Repetier Host/Firmware, Sanguinololu 1.3a and Slic3r.

Material used is ABS, heated bed was on at ~110C and nozzle running ~210C. Almost no to little cleanup.

Slic3r settings:

; layer_height = .20

; perimeters = 2

; solid_layers = 4

; fill_density = .25

; nozzle_diameter = 0.50

; filament_diameter = 1.8

; extrusion_multiplier = 1

; perimeter_speed = 20

; infill_speed = 20

; travel_speed = 120

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.70mm

Print time: 1h:25m

Thanks for making this weeks challenge interesting. Looking forward to future challenges.

Material used is ABS, heated bed was on at ~110C and nozzle running ~210C. Almost no to little cleanup.

Slic3r settings:

; layer_height = .20

; perimeters = 2

; solid_layers = 4

; fill_density = .25

; nozzle_diameter = 0.50

; filament_diameter = 1.8

; extrusion_multiplier = 1

; perimeter_speed = 20

; infill_speed = 20

; travel_speed = 120

; extrusion_width_ratio = 0

; scale = 1

; single wall width = 0.70mm

Print time: 1h:25m

Thanks for making this weeks challenge interesting. Looking forward to future challenges.

|

Re: Game / Competition: Part Manufacturing June 07, 2012 01:40AM |

Registered: 11 years ago Posts: 8 |

Printed on an orca 0.40 in PLA.

No cleanup.

Took 2.5 hours to print.

; layer_height = 0.2

; perimeters = 3

; solid_layers = 4

; fill_density = 0.125

; nozzle_diameter = 0.35

; filament_diameter = 1.7

; extrusion_multiplier = 1

; perimeter_speed = 20

; infill_speed = 75

; travel_speed = 500

; extrusion_width_ratio = 1.535

; scale = 1

; single wall width = 0.31mm

It looks like RichRap was right with slic3r, outer perimeters seem to be missing bits...

A very interesting model though, I thought that my filament would strip from all the retractions.

No cleanup.

Took 2.5 hours to print.

; layer_height = 0.2

; perimeters = 3

; solid_layers = 4

; fill_density = 0.125

; nozzle_diameter = 0.35

; filament_diameter = 1.7

; extrusion_multiplier = 1

; perimeter_speed = 20

; infill_speed = 75

; travel_speed = 500

; extrusion_width_ratio = 1.535

; scale = 1

; single wall width = 0.31mm

It looks like RichRap was right with slic3r, outer perimeters seem to be missing bits...

A very interesting model though, I thought that my filament would strip from all the retractions.

|

Re: Game / Competition: Part Manufacturing June 07, 2012 03:26AM |

Registered: 13 years ago Posts: 818 |

It's so great looking at all these fantastic prints and wonderful machines, It's going to be very hard to pick a winner this week, keep the entries coming, we have a few more days.

Great stuff everyone

[richrap.blogspot.com]

Great stuff everyone

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 07, 2012 06:02AM |

Registered: 12 years ago Posts: 5 |

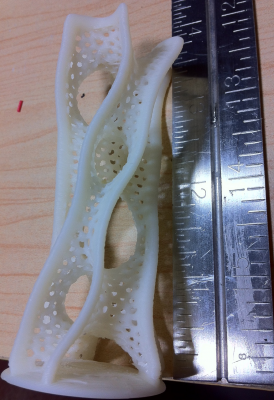

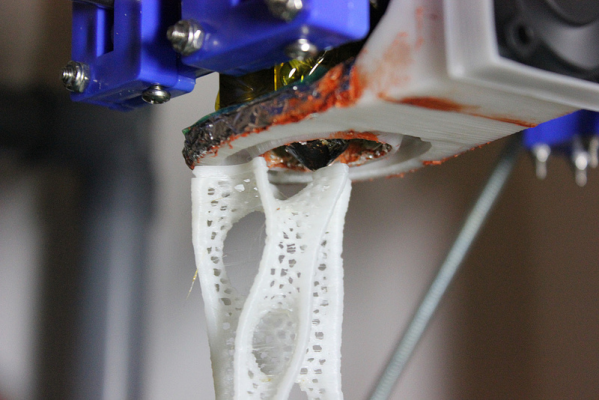

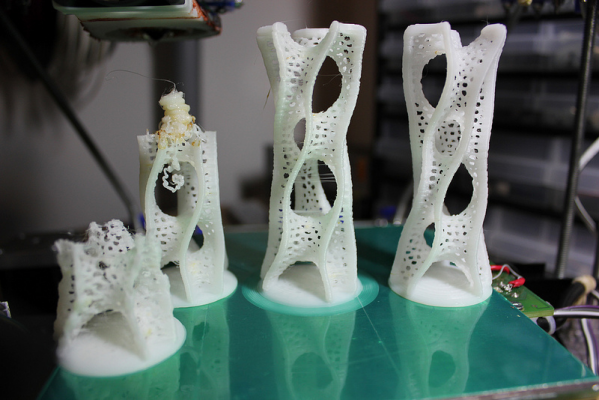

Here's my second (and most likely my last) try with the same parameters as my previous print except that I set the layer height at 0.18mm, the Z-lift retraction at 0.2mm, the infill at 40% (honeycomb) : I get much more - tiny - strings

My first try at 0.3mm layer height close ups :

And last, all my tries from right to left, my first try (0.3mm layer height), my second successfull try (0.18mm layer height), a failed try at 0.1mm layer height (objects unstuck from the bed) and an epic failed try at 0.1mm (too much retraction and too high Z-lift).

from right to left, my first try (0.3mm layer height), my second successfull try (0.18mm layer height), a failed try at 0.1mm layer height (objects unstuck from the bed) and an epic failed try at 0.1mm (too much retraction and too high Z-lift).

Happy voting !

My first try at 0.3mm layer height close ups :

And last, all my tries

from right to left, my first try (0.3mm layer height), my second successfull try (0.18mm layer height), a failed try at 0.1mm layer height (objects unstuck from the bed) and an epic failed try at 0.1mm (too much retraction and too high Z-lift).

from right to left, my first try (0.3mm layer height), my second successfull try (0.18mm layer height), a failed try at 0.1mm layer height (objects unstuck from the bed) and an epic failed try at 0.1mm (too much retraction and too high Z-lift).Happy voting !

|

Re: Game / Competition: Part Manufacturing June 08, 2012 08:20AM |

Registered: 11 years ago Posts: 2 |

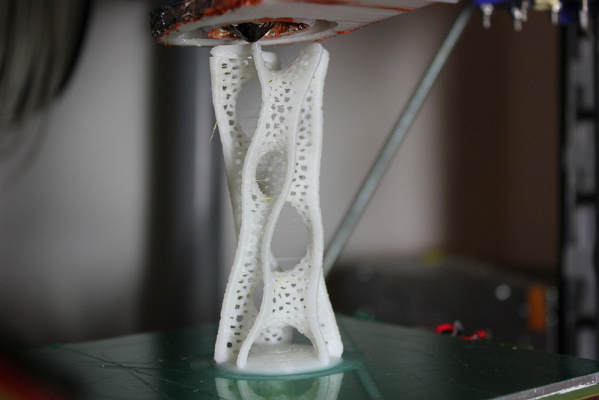

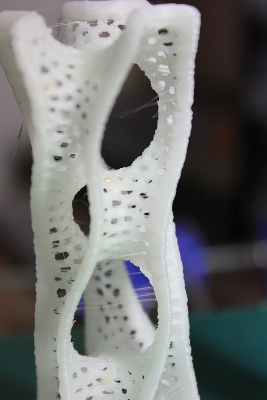

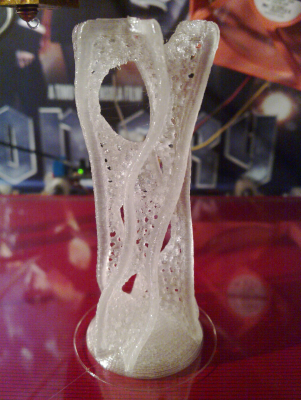

Hello everybody at the forum. I am from RepRapBcn team and this is our Voronoi towers.

It is sliced on Slic3er 0.8.2.

We choose an accuracy of 0.2mm layer height as slic3r had problems slicing at 0.15mm.

For the construction we put two towers side by side in order to enable each layer to cool easily.

The temperature for the estruder was 222ºC on the first layer and 220ºC for the rest, and 80ºC for the hot bed during all the construction.

The print speed have been quite slow, by 20mm/s on the perimeters, slowing it down on the small ones to 15 and 30mm/s on the infill.

Both were printed with ABS in a Prusa Mendel

Edited 3 time(s). Last edit at 06/08/2012 09:48AM by Guillem Tena.

Guillem Tena

RepRapBCN Team - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

It is sliced on Slic3er 0.8.2.

We choose an accuracy of 0.2mm layer height as slic3r had problems slicing at 0.15mm.

For the construction we put two towers side by side in order to enable each layer to cool easily.

The temperature for the estruder was 222ºC on the first layer and 220ºC for the rest, and 80ºC for the hot bed during all the construction.

The print speed have been quite slow, by 20mm/s on the perimeters, slowing it down on the small ones to 15 and 30mm/s on the infill.

Both were printed with ABS in a Prusa Mendel

Edited 3 time(s). Last edit at 06/08/2012 09:48AM by Guillem Tena.

Guillem Tena

RepRapBCN Team - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

|

Re: Game / Competition: Part Manufacturing June 08, 2012 08:55AM |

Registered: 12 years ago Posts: 145 |

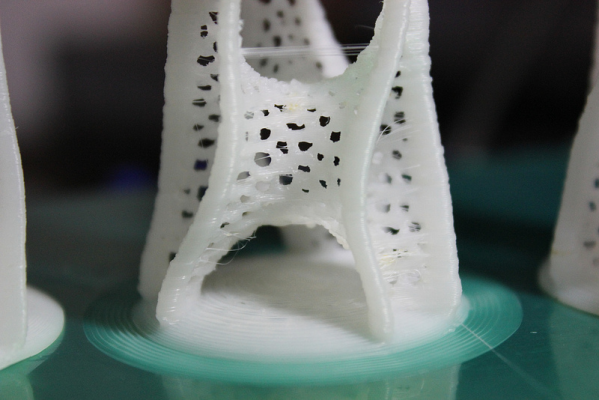

Here some pics of a what SLS can do...

Part made in our Vanguard 2500. 0,1mm/layer and horizontal oriented.

You can see the larger pics in flickr.

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Edited 2 time(s). Last edit at 06/08/2012 09:01AM by RepRapBCN.

RepRapBCN - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

Part made in our Vanguard 2500. 0,1mm/layer and horizontal oriented.

You can see the larger pics in flickr.

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Voronoi D Tower por Reprapbcn, en Flickr

Edited 2 time(s). Last edit at 06/08/2012 09:01AM by RepRapBCN.

RepRapBCN - Barcelona Tech - Universitat Politècnica de Catalunya

Visit our Webstore - Blog - Facebook

|

Re: Game / Competition: Part Manufacturing June 08, 2012 10:33AM |

Registered: 11 years ago Posts: 1 |

Unmodified STL from "Print competition Voronoi D Tower 1/4 res 1/2 size by @Dizingof"

Slic3r + Prusa Mendel + Marlin

0.25 layers, 25mm/s, 3 perimeters, 0.5 infill, on glass, bed temps first layer 60, next ones 50

Print time was 1:52:04

Edited 1 time(s). Last edit at 06/08/2012 10:35AM by juslem.

Slic3r + Prusa Mendel + Marlin

0.25 layers, 25mm/s, 3 perimeters, 0.5 infill, on glass, bed temps first layer 60, next ones 50

Print time was 1:52:04

Edited 1 time(s). Last edit at 06/08/2012 10:35AM by juslem.

|

Re: Game / Competition: Part Manufacturing June 08, 2012 06:15PM |

Registered: 13 years ago Posts: 818 |

I did a summary blog post of this 3D printing competition, to help collect the entries and view them side-by-side.

Amazing printing everyone! - http://richrap.blogspot.co.uk/2012/06/reprap-printing-competition-30doc-day-8.html?spref=tw

[richrap.blogspot.com]

Amazing printing everyone! - http://richrap.blogspot.co.uk/2012/06/reprap-printing-competition-30doc-day-8.html?spref=tw

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 09, 2012 04:36AM |

Registered: 13 years ago Posts: 818 |

It was a very close competition this week and a difficult decision, but after reviewing all the entries I'm going to select billyzelsnack as this week's winner.

Billy's entry made me think and really stuck in my mind - it was printed with the Printxel, one of the lowest cost RepRap printers currently available. And the fact is was done with quite thick layers (0.33) and all the holes came out so well is a great achievement, the base is very good and it made me checkout the Kisslicer very impressive.

I'm also highly impressed to see so many excellent ABS prints, especially benosteen done without a heated bed! so that get's a 'highly commended' award and almost pipped Billy's entry to the winning spot.

Over to you Billy - select us a good challenge for next week, and enjoy your great Faberdashery filament.

I would recommend starting a new thread for each week's competition, now that we have a dedicated forum section - thanks Rhys for setting it up.

Cheers,

Rich.

[richrap.blogspot.com]

Billy's entry made me think and really stuck in my mind - it was printed with the Printxel, one of the lowest cost RepRap printers currently available. And the fact is was done with quite thick layers (0.33) and all the holes came out so well is a great achievement, the base is very good and it made me checkout the Kisslicer very impressive.

I'm also highly impressed to see so many excellent ABS prints, especially benosteen done without a heated bed! so that get's a 'highly commended' award and almost pipped Billy's entry to the winning spot.

Over to you Billy - select us a good challenge for next week, and enjoy your great Faberdashery filament.

I would recommend starting a new thread for each week's competition, now that we have a dedicated forum section - thanks Rhys for setting it up.

Cheers,

Rich.

[richrap.blogspot.com]

|

Re: Game / Competition: Part Manufacturing June 09, 2012 05:18AM |

Registered: 11 years ago Posts: 8 |

|

Re: Game / Competition: Part Manufacturing June 09, 2012 06:04AM |

Registered: 12 years ago Posts: 145 |

|

Re: Game / Competition: Part Manufacturing June 09, 2012 06:07AM |

Registered: 12 years ago Posts: 145 |

richrap Wrote:

-------------------------------------------------------

>

> I would recommend starting a new thread for each

> week's competition, now that we have a dedicated

> forum section - thanks Rhys for setting it up.

>

> Cheers,

>

> Rich.

I also think this will be better.

And if someone wants to print an antique piece, can put the picture in the same post.

-------------------------------------------------------

>

> I would recommend starting a new thread for each

> week's competition, now that we have a dedicated

> forum section - thanks Rhys for setting it up.

>

> Cheers,

>

> Rich.

I also think this will be better.

And if someone wants to print an antique piece, can put the picture in the same post.

|

Re: Game / Competition: Part Manufacturing June 09, 2012 06:36AM |

Registered: 11 years ago Posts: 10 |

|

Re: Game / Competition: Part Manufacturing June 09, 2012 07:38AM |

Registered: 13 years ago Posts: 17 |

Another great competition!

Well done to everyone - some great prints, making it a very tough decision for Richard .

.

Congratulations to Billy - it was my personal fave too! I've dropped you a PM to claim your Fab voucher.

We may be setting our own dedicated competition in the coming weeks...

- Andrew

Faberdashery

Well done to everyone - some great prints, making it a very tough decision for Richard

.

.Congratulations to Billy - it was my personal fave too! I've dropped you a PM to claim your Fab voucher.

We may be setting our own dedicated competition in the coming weeks...

- Andrew

Faberdashery

|

Re: Game / Competition: Part Manufacturing June 09, 2012 10:04AM |

Registered: 12 years ago Posts: 18 |

|

Re: Game / Competition: Part Manufacturing June 09, 2012 12:49PM |

Registered: 13 years ago Posts: 248 |

Well done Billy!

I think you’ve sent the community on a trawl to see what interesting machine produced such a neat looking print. I’ve certainly taken a moment to step back and review your work. You have caused me to question some of the sudo-fundamentals I’ve followed, such as “threaded z-axis is better” (you have belt driven Z) or “Nema17s are best” (you appear to have Nema14s all round). Your curious extruder is also showing some trend bucking. You are adding a new corner stone to the mini-3D printer market segment!

Congratulations on the win! There’s no better endorsement of your work. The proof in this game is in the printing. Best of luck!

NumberSix

[numbersixreprap.blogspot.com]

I think you’ve sent the community on a trawl to see what interesting machine produced such a neat looking print. I’ve certainly taken a moment to step back and review your work. You have caused me to question some of the sudo-fundamentals I’ve followed, such as “threaded z-axis is better” (you have belt driven Z) or “Nema17s are best” (you appear to have Nema14s all round). Your curious extruder is also showing some trend bucking. You are adding a new corner stone to the mini-3D printer market segment!

Congratulations on the win! There’s no better endorsement of your work. The proof in this game is in the printing. Best of luck!

NumberSix

[numbersixreprap.blogspot.com]

Sorry, only registered users may post in this forum.