Calibration contest

Posted by DeuxVis

|

Re: Calibration contest October 13, 2012 05:41PM |

Registered: 11 years ago Posts: 525 |

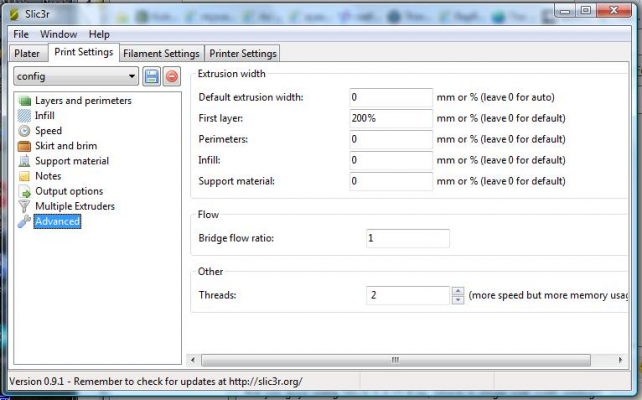

Are you guys using Slic3r 0.9.1? if so, where is single wall width setting?

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Calibration contest October 13, 2012 06:04PM |

Registered: 13 years ago Posts: 2,947 |

@ Wired1

You could set the top one (default) to the width you want and it will use it on any of the other ones with a zero. Or you can change them all individually.

You could set the top one (default) to the width you want and it will use it on any of the other ones with a zero. Or you can change them all individually.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Calibration contest October 14, 2012 01:02AM |

Registered: 13 years ago Posts: 2,947 |

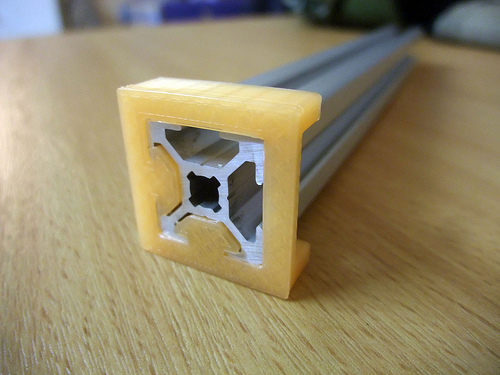

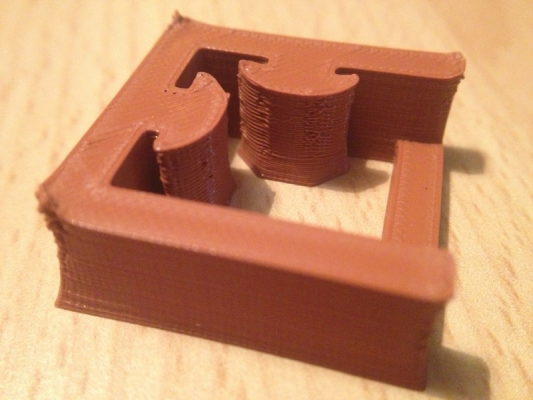

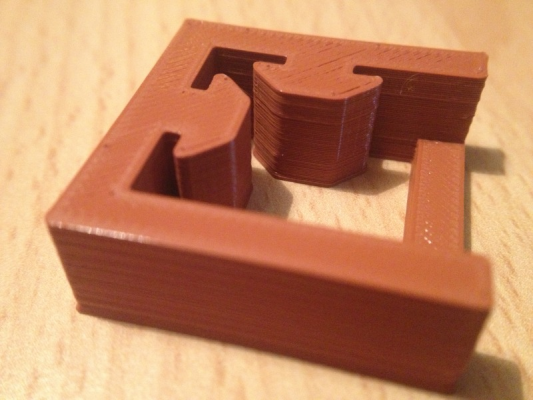

I decided to print this on Tantillus and it turned out well.

The flow is a little low, I may increase the flow by 5-10 steps per mm.

I used the standard coarse 0.5mm Tantillus Slic3r 0.7.2b profile available [github.com]

Edited 1 time(s). Last edit at 10/14/2012 01:05AM by Sublime.

The flow is a little low, I may increase the flow by 5-10 steps per mm.

I used the standard coarse 0.5mm Tantillus Slic3r 0.7.2b profile available [github.com]

Edited 1 time(s). Last edit at 10/14/2012 01:05AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Calibration contest October 14, 2012 04:24AM |

Registered: 13 years ago Posts: 818 |

richgain Wrote:

-------------------------------------------------------

> @richrap - Yes, still using the original

> resin-cast pulleys on X and Y on the Huxley.

> What's your experience of them?

> No, I'm planning to try on the Mendel90 some time

> today. Will update when it's ready.

> For quality and tolerance, I've always found the

> Huxley more accurate, probably because of the

> finer nozzle and lightweight Bowden-fed

> printhead.

> This should be an interesting test.

The cast ones worked well for a while, I'm not sure if they changed shape or wore down, but over time I noticed a difference in the Y axis and switched to metal ones. I use metal on all my machines now. I do tend to have my belts very tight.

Nice compare against the Mendel90, this contest is getting very interesting.

[richrap.blogspot.com]

-------------------------------------------------------

> @richrap - Yes, still using the original

> resin-cast pulleys on X and Y on the Huxley.

> What's your experience of them?

> No, I'm planning to try on the Mendel90 some time

> today. Will update when it's ready.

> For quality and tolerance, I've always found the

> Huxley more accurate, probably because of the

> finer nozzle and lightweight Bowden-fed

> printhead.

> This should be an interesting test.

The cast ones worked well for a while, I'm not sure if they changed shape or wore down, but over time I noticed a difference in the Y axis and switched to metal ones. I use metal on all my machines now. I do tend to have my belts very tight.

Nice compare against the Mendel90, this contest is getting very interesting.

[richrap.blogspot.com]

|

Re: Calibration contest October 14, 2012 09:05AM |

Registered: 13 years ago Posts: 615 |

I'm also still using the cast pulleys on my huxleys

eMaker Huxley 2 with slic3r 0.9.3 :

27,73 - 27,98 mm

19,85 - 20,05 mm

1,38 - 1,44 mm

With almost the default Slic3r settings

; Marlin

; absolute X Y Z E

; 884.5 E-step-mm

; 199°C / 60°C

; layer_height = 0.3

; perimeters = 1

; solid_layers = 2

; fill_density = 0.25

; perimeter_speed = 30

; infill_speed = 30

; travel_speed = 200

; scale = 1

; nozzle_diameter = 0.5

; filament_diameter = 1.70

; extrusion_multiplier = 1

; single wall width = 0.70mm

I also tried with a layer width of 160-165% to have thinner strands (0,48mm) but then went back to the default extrusion width.

eMaker Huxley 1 with Skeinforge 47 :

27,98 - 28,15 mm

19,96 - 20,04 mm

1,49 - 1,56 mm

layer : 0,3

perimeter width over thickness : 1,6

infill width over thickness : 1,63

filament diameter : 1,75

I've not yet managed tweak Slic3r to match the results I have with Skeinforge, but things are improving...

I'll try to see if I can invert the profiles between the machines, since they are supposed to be the same (except a little different gear ratio).

Edited 2 time(s). Last edit at 10/14/2012 09:20AM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

eMaker Huxley 2 with slic3r 0.9.3 :

27,73 - 27,98 mm

19,85 - 20,05 mm

1,38 - 1,44 mm

With almost the default Slic3r settings

; Marlin

; absolute X Y Z E

; 884.5 E-step-mm

; 199°C / 60°C

; layer_height = 0.3

; perimeters = 1

; solid_layers = 2

; fill_density = 0.25

; perimeter_speed = 30

; infill_speed = 30

; travel_speed = 200

; scale = 1

; nozzle_diameter = 0.5

; filament_diameter = 1.70

; extrusion_multiplier = 1

; single wall width = 0.70mm

I also tried with a layer width of 160-165% to have thinner strands (0,48mm) but then went back to the default extrusion width.

eMaker Huxley 1 with Skeinforge 47 :

27,98 - 28,15 mm

19,96 - 20,04 mm

1,49 - 1,56 mm

layer : 0,3

perimeter width over thickness : 1,6

infill width over thickness : 1,63

filament diameter : 1,75

I've not yet managed tweak Slic3r to match the results I have with Skeinforge, but things are improving...

I'll try to see if I can invert the profiles between the machines, since they are supposed to be the same (except a little different gear ratio).

Edited 2 time(s). Last edit at 10/14/2012 09:20AM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Calibration contest October 14, 2012 05:49PM |

Registered: 11 years ago Posts: 525 |

Nice print - that's going to be tough to beat.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Calibration contest October 14, 2012 06:08PM |

Registered: 12 years ago Posts: 122 |

I thought I'd try printing with PLA on the Mendel90 using the same file as I generated for the previous ABS print.

Unfortunately, I forgot that PLA really needs a cooling fan. The result wasn't usable but as well as being warped from over-heating, I could see that I was still over-extruding plastic.

I repeated the print with the ducted fan switched onto a low setting. I also reduced the feed-rate to 80% (printing more slowly to allow time for the layers to cool) and the flow-rate to 85% (a figure that seems to work best for me) in Repetier Host, based on the apparent over-heating and over-extrusion in the first print.

This one came out much better: 28.06/28.08; 19.90/20.01; 1.49/1.49/1.49/1.48.

; generated by Slic3r 0.9.3 on 2012-10-13 at 16:10:39

; layer_height = 0.2

; perimeters = 2

; solid_layers = 4

; fill_density = 0.5

; perimeter_speed = 30

; infill_speed = 30

; travel_speed = 150

; scale = 1

; nozzle_diameter = 0.4

; filament_diameter = 2.8

; extrusion_multiplier = 0.85

; single wall width = 0.30mm

I'm very pleased with the way that Slic3r finally seems to be stabilising again, even if it does still need the nozzle diameter tweak (thanks Sublime).

Unfortunately, I forgot that PLA really needs a cooling fan. The result wasn't usable but as well as being warped from over-heating, I could see that I was still over-extruding plastic.

I repeated the print with the ducted fan switched onto a low setting. I also reduced the feed-rate to 80% (printing more slowly to allow time for the layers to cool) and the flow-rate to 85% (a figure that seems to work best for me) in Repetier Host, based on the apparent over-heating and over-extrusion in the first print.

This one came out much better: 28.06/28.08; 19.90/20.01; 1.49/1.49/1.49/1.48.

; generated by Slic3r 0.9.3 on 2012-10-13 at 16:10:39

; layer_height = 0.2

; perimeters = 2

; solid_layers = 4

; fill_density = 0.5

; perimeter_speed = 30

; infill_speed = 30

; travel_speed = 150

; scale = 1

; nozzle_diameter = 0.4

; filament_diameter = 2.8

; extrusion_multiplier = 0.85

; single wall width = 0.30mm

I'm very pleased with the way that Slic3r finally seems to be stabilising again, even if it does still need the nozzle diameter tweak (thanks Sublime).

|

Re: Calibration contest October 15, 2012 04:36AM |

Registered: 13 years ago Posts: 818 |

@Emmanuel & richgain - Are you both happy with Slic3r 0.9.3? I have only been using 0.9.1 and not yet made the jump to 0.9.3, do you see any problems?

@sublime - Are you happy with any newer versions above 0.7.2b for Tantillus yet? I hope to be commissioning it soon.

[richrap.blogspot.com]

@sublime - Are you happy with any newer versions above 0.7.2b for Tantillus yet? I hope to be commissioning it soon.

[richrap.blogspot.com]

|

Re: Calibration contest October 15, 2012 04:46AM |

Registered: 13 years ago Posts: 2,947 |

richrap Wrote:

-------------------------------------------------------

> @sublime - Are you happy with any newer versions

> above 0.7.2b for Tantillus yet? I hope to be

> commissioning it soon.

No they have far to many bugs, geometry errors and the path planning is horrible which makes for to many retracts. Version 0.7.2b only has two small bugs I know of and they are easy to work around. I have altered Slic3r 0.7.2b to have a bunch of special retract settings brought out called it Slic3T. It works well but I have introduced a bug that will not let 0.1 and lower layers. So far though the testing with 0.15 and 0.2 have been promising.

-------------------------------------------------------

> @sublime - Are you happy with any newer versions

> above 0.7.2b for Tantillus yet? I hope to be

> commissioning it soon.

No they have far to many bugs, geometry errors and the path planning is horrible which makes for to many retracts. Version 0.7.2b only has two small bugs I know of and they are easy to work around. I have altered Slic3r 0.7.2b to have a bunch of special retract settings brought out called it Slic3T. It works well but I have introduced a bug that will not let 0.1 and lower layers. So far though the testing with 0.15 and 0.2 have been promising.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Calibration contest October 18, 2012 11:05AM |

Registered: 12 years ago Posts: 122 |

richrap Wrote:

-------------------------------------------------------

> @Emmanuel & richgain - Are you both happy with

> Slic3r 0.9.3? I have only been using 0.9.1 and not

> yet made the jump to 0.9.3, do you see any

> problems?

@richrap

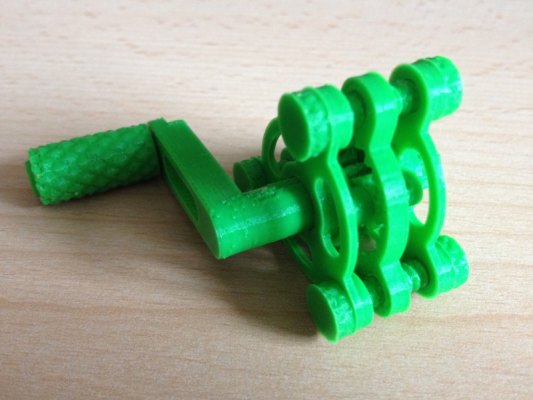

I'm much happier with 0.9.3 than any of the other recent versions of Slic3r, so much so that I decided to have another go at the 'Tiny planetary gears' which I failed to print before. It's not the best copy in the world but it definitely works.

richgain

-------------------------------------------------------

> @Emmanuel & richgain - Are you both happy with

> Slic3r 0.9.3? I have only been using 0.9.1 and not

> yet made the jump to 0.9.3, do you see any

> problems?

@richrap

I'm much happier with 0.9.3 than any of the other recent versions of Slic3r, so much so that I decided to have another go at the 'Tiny planetary gears' which I failed to print before. It's not the best copy in the world but it definitely works.

richgain

|

Re: Calibration contest October 18, 2012 01:36PM |

Registered: 13 years ago Posts: 818 |

Thanks richgain, that looks promising, are the bolts still very loose (I think the design was like that) your first layer also looks a little too squished. I'm going to make the switch to 0.9.3 then.

I have a few standard test parts (one is a herringbone gear set) that should tell me if it's as accurate as 0.9.1

And thanks Sublime, I will experiment when the Tantillus is alive - Really love the extruder BTW, the tiny Fish-bone gears are a nice print to see come out of my machine!

[richrap.blogspot.com]

I have a few standard test parts (one is a herringbone gear set) that should tell me if it's as accurate as 0.9.1

And thanks Sublime, I will experiment when the Tantillus is alive - Really love the extruder BTW, the tiny Fish-bone gears are a nice print to see come out of my machine!

[richrap.blogspot.com]

|

Re: Calibration contest October 18, 2012 02:24PM |

Registered: 11 years ago Posts: 939 |

I think this competition has been very interesting, I have 3 of the pieces printed, none in any danger of winning, so I'll skip posting them.

I ran the test piece through Slic3r 0.91 and Kisslicer with as close to similar settings as possible and what's apparent is the flowrate calculations don't match, Slic3r seems to over extrude at the same settings as Kisslic3r, Kisslic3r also produces a better surface finish, which I think is likely due to the expected overlap between the solid infil and the perimeters.

My experience with Slic3r 0.91 is it's OK, though I've gone back to using Kisslic3r for anything but the simplest of prints. I only use Slic3r for those because it's integrated into repetier host and it's quicker.

I ran the test piece through Slic3r 0.91 and Kisslicer with as close to similar settings as possible and what's apparent is the flowrate calculations don't match, Slic3r seems to over extrude at the same settings as Kisslic3r, Kisslic3r also produces a better surface finish, which I think is likely due to the expected overlap between the solid infil and the perimeters.

My experience with Slic3r 0.91 is it's OK, though I've gone back to using Kisslic3r for anything but the simplest of prints. I only use Slic3r for those because it's integrated into repetier host and it's quicker.

|

Re: Calibration contest October 18, 2012 03:22PM |

Registered: 12 years ago Posts: 122 |

richrap Wrote:

-------------------------------------------------------

> Thanks richgain, that looks promising, are the

> bolts still very loose (I think the design was

> like that) your first layer also looks a little

> too squished. I'm going to make the switch to

> 0.9.3 then.

I had real trouble getting this Faberdashery green to stick to the bed (all the other colours in the Rainbow pack have been fine). In the end I had to turn the heat up to 80 and lower the nozzle til it was almost touching the glass.

The bolts are just right. Not loose at all but I was able to do them all up without any clean up or using tools. I was amazed at how well the fairly primitive looking threads worked.

-------------------------------------------------------

> Thanks richgain, that looks promising, are the

> bolts still very loose (I think the design was

> like that) your first layer also looks a little

> too squished. I'm going to make the switch to

> 0.9.3 then.

I had real trouble getting this Faberdashery green to stick to the bed (all the other colours in the Rainbow pack have been fine). In the end I had to turn the heat up to 80 and lower the nozzle til it was almost touching the glass.

The bolts are just right. Not loose at all but I was able to do them all up without any clean up or using tools. I was amazed at how well the fairly primitive looking threads worked.

|

Re: Calibration contest October 24, 2012 01:55PM |

Registered: 13 years ago Posts: 615 |

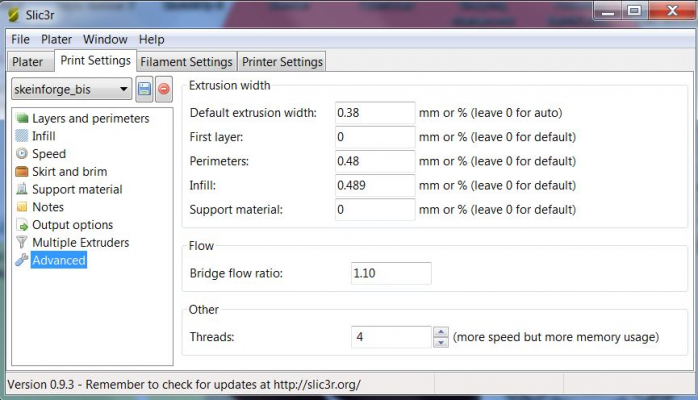

Yes I'm happy with Slic3r 093

Tonight I even managed to get quite close to my Skeinforge results !!! (previously unmatched with any version of Slic3r)

This time I tried to use the same key settings I had in Skeinforge.

A 101% scale, the 0.38 extrusion (even if it's for free extrusion I wanted to try), then the 0.48 pwot and 0.489 iwot (since it's 1.6 and 1.63 in skeinforge ratio's)

; layer_height = 0.3

; perimeters = 1

; solid_layers = 2

; fill_density = 0.30

; perimeter_speed = 35

; infill_speed = 35

; travel_speed = 200

; scale = 1

; nozzle_diameter = 0.50

; filament_diameter = 1.70

; extrusion_multiplier = 1

; single wall width = 0.38mm

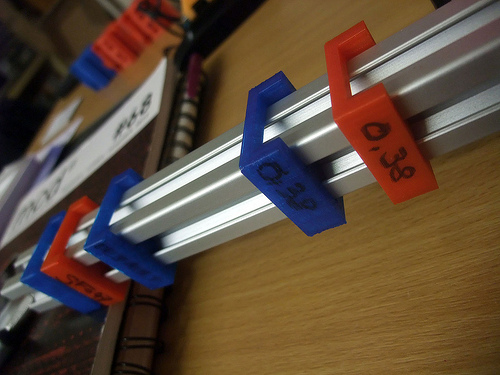

left : SF47

middle : defaut-slic3r

right : slic3r-038

red is with my huxley1, blue with the huxley 2

(huxley1_SF47 : dead on as seen in my previous post)

huxley1_default-slic3r : good but... 19.95-19.96 / 1.48-1.60

huxley1_038.gcode : better ! 19.97-20.05 / 1.46-1.60 it even look like the skeinforge one

huxley2_038.gcode : very good 19.95-20.05 / 1.46-1.55

The results are promising for me in that mean I can use Slic3r more often for the precise parts

about // liberapay // flickr // wiki // thingiverse - github

Tonight I even managed to get quite close to my Skeinforge results !!! (previously unmatched with any version of Slic3r)

This time I tried to use the same key settings I had in Skeinforge.

A 101% scale, the 0.38 extrusion (even if it's for free extrusion I wanted to try), then the 0.48 pwot and 0.489 iwot (since it's 1.6 and 1.63 in skeinforge ratio's)

; layer_height = 0.3

; perimeters = 1

; solid_layers = 2

; fill_density = 0.30

; perimeter_speed = 35

; infill_speed = 35

; travel_speed = 200

; scale = 1

; nozzle_diameter = 0.50

; filament_diameter = 1.70

; extrusion_multiplier = 1

; single wall width = 0.38mm

left : SF47

middle : defaut-slic3r

right : slic3r-038

red is with my huxley1, blue with the huxley 2

(huxley1_SF47 : dead on as seen in my previous post)

huxley1_default-slic3r : good but... 19.95-19.96 / 1.48-1.60

huxley1_038.gcode : better ! 19.97-20.05 / 1.46-1.60 it even look like the skeinforge one

huxley2_038.gcode : very good 19.95-20.05 / 1.46-1.55

The results are promising for me in that mean I can use Slic3r more often for the precise parts

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Calibration contest November 15, 2012 11:02AM |

Admin Registered: 12 years ago Posts: 2,569 |

Well it seems I didn't have anyone submit his part as an entry, so I'll try again with a simpler competition process next time I have an idea

As for me the only improvement I was able to obtain is by reducing the E_STEPS a bit.

At minus 5 % I have better dimensional accuracy with a good skin, If I go down to 10% the dimensions are still better but the surface infill starts to look bad because of the lack of plastic.

Will post photos later.

Thank you all for showing your prints/sharing your tips.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

As for me the only improvement I was able to obtain is by reducing the E_STEPS a bit.

At minus 5 % I have better dimensional accuracy with a good skin, If I go down to 10% the dimensions are still better but the surface infill starts to look bad because of the lack of plastic.

Will post photos later.

Thank you all for showing your prints/sharing your tips.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Calibration contest November 21, 2012 04:27PM |

Admin Registered: 12 years ago Posts: 2,569 |

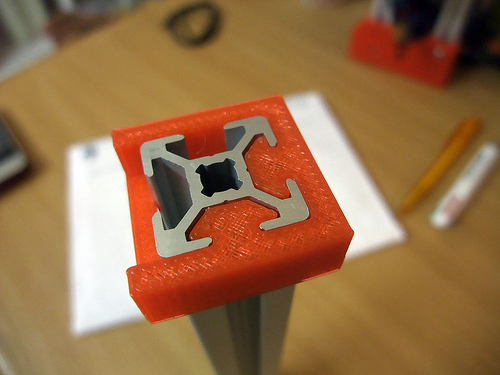

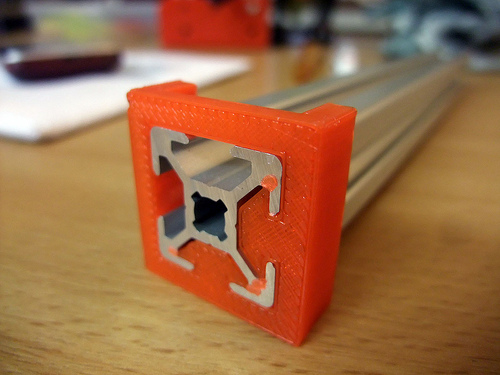

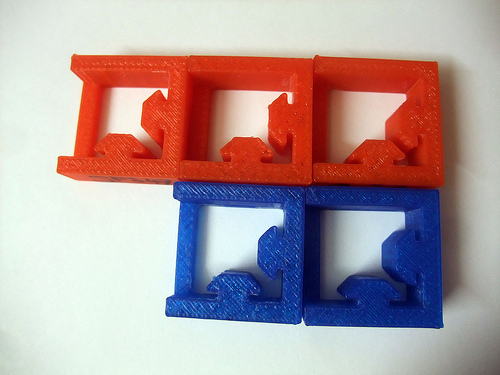

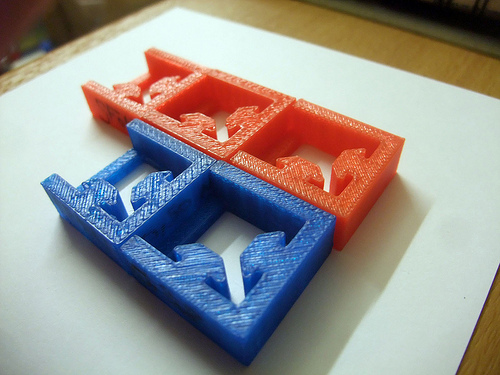

Here are my pictures.

#1 is done with my usual settings. Dimensions : inner 19.80, outer 28.05, gap between 1.38 and 1.51.

#2 is lowering E_Steps by 5%. Dimensions : inner 19.85, outer 28.03, gap 1.41 to 1.53.

#3 (no number drawn on the part) is with lowering E_Steps by 10%. Notice the top full layer starting to be sparse, and the infill not joining the perimeters. Dimensions : inner 19.98, outer 28.01, gap 1.42 to 1.55.

#4 (bonus, shown bent) is printed with normal settings in soft pla. I'm pretty sure it would be easy to slide on the profile, but on the other hand it might not provide a rigid structure... (Thanks to Gregory for lending me a hand - literally - for the picture). Dimensions are variable as the plastic flex..

Note to Emmanuel : still planning to send you those parts asap.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

#1 is done with my usual settings. Dimensions : inner 19.80, outer 28.05, gap between 1.38 and 1.51.

#2 is lowering E_Steps by 5%. Dimensions : inner 19.85, outer 28.03, gap 1.41 to 1.53.

#3 (no number drawn on the part) is with lowering E_Steps by 10%. Notice the top full layer starting to be sparse, and the infill not joining the perimeters. Dimensions : inner 19.98, outer 28.01, gap 1.42 to 1.55.

#4 (bonus, shown bent) is printed with normal settings in soft pla. I'm pretty sure it would be easy to slide on the profile, but on the other hand it might not provide a rigid structure... (Thanks to Gregory for lending me a hand - literally - for the picture). Dimensions are variable as the plastic flex..

Note to Emmanuel : still planning to send you those parts asap.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Calibration contest November 23, 2012 08:14AM |

Registered: 12 years ago Posts: 4,555 |

my print.

Slic3r

; layer_height = 0.2

; perimeters = 2

; solid_layers = 3

; fill_density = 0.25

; perimeter_speed = 30

; infill_speed = 60

; travel_speed = 250

; scale = 1

; nozzle_diameter = 0.35

; filament_diameter = 2.9

; extrusion_multiplier = 1

IeC 3D printer

Slic3r

; layer_height = 0.2

; perimeters = 2

; solid_layers = 3

; fill_density = 0.25

; perimeter_speed = 30

; infill_speed = 60

; travel_speed = 250

; scale = 1

; nozzle_diameter = 0.35

; filament_diameter = 2.9

; extrusion_multiplier = 1

IeC 3D printer

Attachments:

open | download - measure01.jpg (46.1 KB)

open | download - measure02.jpg (44.5 KB)

open | download - measure03.jpg (45.7 KB)

open | download - measure04.jpg (45.3 KB)

open | download - measure05.jpg (40.9 KB)

open | download - contest.jpg (65.4 KB)

open | download - IeC 3D Printer.jpg (170.6 KB)

open | download - measure01.jpg (46.1 KB)

open | download - measure02.jpg (44.5 KB)

open | download - measure03.jpg (45.7 KB)

open | download - measure04.jpg (45.3 KB)

open | download - measure05.jpg (40.9 KB)

open | download - contest.jpg (65.4 KB)

open | download - IeC 3D Printer.jpg (170.6 KB)

|

Re: Calibration contest November 23, 2012 08:38AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: Calibration contest November 23, 2012 09:51AM |

Registered: 12 years ago Posts: 4,555 |

|

Re: Calibration contest December 17, 2012 11:22AM |

Registered: 12 years ago Posts: 4,555 |

Sorry, only registered users may post in this forum.