RepRap Magazine - Print to improve life quality

Posted by pdesigns

|

RepRap Magazine - Print to improve life quality June 20, 2013 02:49PM |

Registered: 11 years ago Posts: 66 |

With an ever growing number of RepRap based 3D printers out there we decided to challenge the community with our first competition.

We want you to came up with new designs to improve the life quality. You have the freedom to design things as complex as prosthesis or as simple as a anti-snoring device.

Think on how to improve an everyday task, minimize human body handicaps or how to improve your pet life quality.

Prizes are:

1º RepRapPro Huxley hardware kit. Everything that’s needed to build the Huxley 3D printer except the printed parts.

Shipping included.

2º Plastic2Print speciality plastics bundle ( Flame retardant PLA, Crystal clear Natural PET, High temp ABS, Taulman Nylon 618, Flexible polyester and Ultra colored PLA). Diameters and quantities to the preference of the winner (max. of 250€).

Shipping included.

3º RepRapWorld bundle. The bundle includes Lcd, keypad, stepper motors nema17 (set of 4) and a minitronics board.

Shipping included.

4º - 7º Faberdashery £50 voucher.

Each Voucher entitles the bearer up to £50 off a single transaction, excluding P&P, redeemable online during ‘Check-Out’. Voucher is valid from 14th June 2013 - 14th of March 2014 (inclusive). Voucher is not valid in conjunction with any other offer or voucher and may only be used once. Voucher has no cash value. Faberdashery Ltd withhold the right to change or remove this offer at any time, and is not responsible for any voucher that is lost, stolen or otherwise unused by the expiry date.

Requirements:

- Model should be able to be printed in printer with a building envelop of 200x200x200mm.

-It can be printed in sections. Assembly can be done using bolts, snap fit or glue.

- Entries will be selected based on creativity, feasibility, functionality and response to the competition theme.

-Post your entries at RepRap Forum competitions section, on the “RepRap Magazine - Print to improve life quality” topic.

-Name (or team members names).

-Link to the .STL file of the model, and one photo of the printed object.

(use any file hosting site like Thingiverse, Grabcad, RepRap Wiki etc. Tag the model with RepRap Magazine).

Entries will be judged based on:

-Functionality (how complicated it is to use / assemble / how well does it solves the problem).

-Instructions and documentation on it’s use and assembled.

-Proof that it works!

The rules and requirements are in pag. 31 on the issue 2 of the RepRap Magazine: [reprapmagazine.com]

Have Fun!

We want you to came up with new designs to improve the life quality. You have the freedom to design things as complex as prosthesis or as simple as a anti-snoring device.

Think on how to improve an everyday task, minimize human body handicaps or how to improve your pet life quality.

Prizes are:

1º RepRapPro Huxley hardware kit. Everything that’s needed to build the Huxley 3D printer except the printed parts.

Shipping included.

2º Plastic2Print speciality plastics bundle ( Flame retardant PLA, Crystal clear Natural PET, High temp ABS, Taulman Nylon 618, Flexible polyester and Ultra colored PLA). Diameters and quantities to the preference of the winner (max. of 250€).

Shipping included.

3º RepRapWorld bundle. The bundle includes Lcd, keypad, stepper motors nema17 (set of 4) and a minitronics board.

Shipping included.

4º - 7º Faberdashery £50 voucher.

Each Voucher entitles the bearer up to £50 off a single transaction, excluding P&P, redeemable online during ‘Check-Out’. Voucher is valid from 14th June 2013 - 14th of March 2014 (inclusive). Voucher is not valid in conjunction with any other offer or voucher and may only be used once. Voucher has no cash value. Faberdashery Ltd withhold the right to change or remove this offer at any time, and is not responsible for any voucher that is lost, stolen or otherwise unused by the expiry date.

Requirements:

- Model should be able to be printed in printer with a building envelop of 200x200x200mm.

-It can be printed in sections. Assembly can be done using bolts, snap fit or glue.

- Entries will be selected based on creativity, feasibility, functionality and response to the competition theme.

-Post your entries at RepRap Forum competitions section, on the “RepRap Magazine - Print to improve life quality” topic.

-Name (or team members names).

-Link to the .STL file of the model, and one photo of the printed object.

(use any file hosting site like Thingiverse, Grabcad, RepRap Wiki etc. Tag the model with RepRap Magazine).

Entries will be judged based on:

-Functionality (how complicated it is to use / assemble / how well does it solves the problem).

-Instructions and documentation on it’s use and assembled.

-Proof that it works!

The rules and requirements are in pag. 31 on the issue 2 of the RepRap Magazine: [reprapmagazine.com]

Have Fun!

|

Re: RepRap Magazine - Print to improve life quality June 26, 2013 05:35PM |

Registered: 11 years ago Posts: 66 |

Hi everyone,

One of the requirements we included on the rules of the competition asked for a photo of the printed object:

" -Link to the .STL file of the model, and one photo of the printed object."

This would make it very hard for those who don´t have a 3D printer or easy access to one to participate on the competition.

So we decided to remove the part asking for a photo of the printed object with:

-Link to the .STL file of the model.

Remember that you are still required to present a proof that the design works!

This way we hope to make the competition open to everyone!

Cheers,

Paulo Gonçalves

One of the requirements we included on the rules of the competition asked for a photo of the printed object:

" -Link to the .STL file of the model, and one photo of the printed object."

This would make it very hard for those who don´t have a 3D printer or easy access to one to participate on the competition.

So we decided to remove the part asking for a photo of the printed object with:

-Link to the .STL file of the model.

Remember that you are still required to present a proof that the design works!

This way we hope to make the competition open to everyone!

Cheers,

Paulo Gonçalves

|

Kitchen chopper add-on - Print to improve life quality August 05, 2013 01:19PM |

Registered: 10 years ago Posts: 14 |

This is my entry for the competition. I invented it a few weeks ago while cooking the diner.

Those kitchen robots have everything but not this handy piece to keep it clean.

That is why I created my add-on for this chopper. It is a guider for the downstream, not left or right, from the machine.

Pictures, proof and tag @ thingiverse + STL file

Those kitchen robots have everything but not this handy piece to keep it clean.

That is why I created my add-on for this chopper. It is a guider for the downstream, not left or right, from the machine.

Pictures, proof and tag @ thingiverse + STL file

|

Re: RepRap Magazine - Print to improve life quality August 15, 2013 05:24PM |

Registered: 10 years ago Posts: 4 |

HuPo Take-Off

Customizable hand crank device.

Details, pictures, video, OpenSCAD files:

[www.thingiverse.com]

Sorry, I forgot to say "Hi"

But page 33 of RepRapMagazine_Issue_2.pdf, which is the good one ?

middle left: "This competition is open until 15 August 2013"

bottom right: "This competition is open until 25 August 2013"

Thanks.

Benjamin.

Edited 1 time(s). Last edit at 08/15/2013 05:30PM by proto.user.

Customizable hand crank device.

Details, pictures, video, OpenSCAD files:

[www.thingiverse.com]

Sorry, I forgot to say "Hi"

But page 33 of RepRapMagazine_Issue_2.pdf, which is the good one ?

middle left: "This competition is open until 15 August 2013"

bottom right: "This competition is open until 25 August 2013"

Thanks.

Benjamin.

Edited 1 time(s). Last edit at 08/15/2013 05:30PM by proto.user.

|

Re: RepRap Magazine - Print to improve life quality August 15, 2013 05:35PM |

Registered: 10 years ago Posts: 2 |

Hello,

I hope that i'm still in time...

A couple of years ago I started to study Electrical Engineering. Since then I always wanted an automatic window opening robot. The reason for this is that I live in the Netherlands where it often rains. Normally it is not a real problem to open or close the window that is a few meters away. However, it often starts raining at night when you are nice and cozy in your bed. A solution for this first world problem is to shut the window when rain falls onto a sensor or when a button is pressed.

A few years ago I tried making it from wood and metal, but this failed due to improper mechanical construction and the lack of mechanical engineering skills at that time to make a shaft coupler strong enough to push a window open without slipping. Being annoyed with the mechanical problems I set the project away for some time... I recently finished a mendel which can print parts reasonable good and I needed an idea for which I could use a 3D printer. This contest brought me to the original idea and so I teamed up with my brother to tackle this design problem.

First lets go over the requirements:

-The system should fit within the limits of the frame depth (about 50mm in this case).

-The moving arm is not allowed to move out of the frame at the room side. This is nescessary to let the window mosquito screen in place. So basically this rules out the use of a double armed system.

-Electronics should fit in the enclosure that also hold the motor and angular position potmeter.

-The system should be able to detach completely from the window with a few screws to allow frame cleaning and painting.

-The mechanical construction should preferably contain parts that are used in most reprap projects so they are easy to source.

The window opener consists of a bar attached to the window, a bearing holder connected to an arm that makes the rotational motion pushing the window out or pulling it in. The bar is held to the window with some bar clamps(similar to those in 3d printers but a bit more lower profile). The hardest part is the 3-way shaft coupler, which is pushfit on the shaft and held in place with some bolts through the shaft(this proved to be necessary because the torque is quite high). The enclosure is quite simple and holds the motor and the potentiometer in place. The potentiometer is used to know the absolute position of the arm. The entire enclosure can be bolted to the window frame using self tapping wood screws. Cable connections are fed through the channels at the back of the enclosure and are held in place by the frame.

Electronics consists of a PIC18f14k50 microcontroller in combination with the L298N motor driver, and is driven at 5V through a 7805 regulator. The controller is at this moment a simple proportional controller but has still room for improvement. At this moment the window can be controlled by a pushbutton that is a away from the window. The idea is to replace it eventually with a rain sensor but is not yet implemented. Eventually the system could be used to integrate in a home automation system.

I will upload a video of the working system soon.

Check the thingiverse for the files!

[Thingiverse]

I hope that i'm still in time...

A couple of years ago I started to study Electrical Engineering. Since then I always wanted an automatic window opening robot. The reason for this is that I live in the Netherlands where it often rains. Normally it is not a real problem to open or close the window that is a few meters away. However, it often starts raining at night when you are nice and cozy in your bed. A solution for this first world problem is to shut the window when rain falls onto a sensor or when a button is pressed.

A few years ago I tried making it from wood and metal, but this failed due to improper mechanical construction and the lack of mechanical engineering skills at that time to make a shaft coupler strong enough to push a window open without slipping. Being annoyed with the mechanical problems I set the project away for some time... I recently finished a mendel which can print parts reasonable good and I needed an idea for which I could use a 3D printer. This contest brought me to the original idea and so I teamed up with my brother to tackle this design problem.

First lets go over the requirements:

-The system should fit within the limits of the frame depth (about 50mm in this case).

-The moving arm is not allowed to move out of the frame at the room side. This is nescessary to let the window mosquito screen in place. So basically this rules out the use of a double armed system.

-Electronics should fit in the enclosure that also hold the motor and angular position potmeter.

-The system should be able to detach completely from the window with a few screws to allow frame cleaning and painting.

-The mechanical construction should preferably contain parts that are used in most reprap projects so they are easy to source.

The window opener consists of a bar attached to the window, a bearing holder connected to an arm that makes the rotational motion pushing the window out or pulling it in. The bar is held to the window with some bar clamps(similar to those in 3d printers but a bit more lower profile). The hardest part is the 3-way shaft coupler, which is pushfit on the shaft and held in place with some bolts through the shaft(this proved to be necessary because the torque is quite high). The enclosure is quite simple and holds the motor and the potentiometer in place. The potentiometer is used to know the absolute position of the arm. The entire enclosure can be bolted to the window frame using self tapping wood screws. Cable connections are fed through the channels at the back of the enclosure and are held in place by the frame.

Electronics consists of a PIC18f14k50 microcontroller in combination with the L298N motor driver, and is driven at 5V through a 7805 regulator. The controller is at this moment a simple proportional controller but has still room for improvement. At this moment the window can be controlled by a pushbutton that is a away from the window. The idea is to replace it eventually with a rain sensor but is not yet implemented. Eventually the system could be used to integrate in a home automation system.

I will upload a video of the working system soon.

Check the thingiverse for the files!

[Thingiverse]

|

Re: RepRap Magazine - Print to improve life quality August 15, 2013 06:09PM |

Registered: 11 years ago Posts: 10 |

Haha, more people here on the edge of a deadthline (or is the 25th?) but I hope I'm in time as well. I just finished my design for a coinclip. I always come home after shopping to find I still got the deposit ticket in my pocket. They tend to stick on the fridge with a magnet for mostly a year. So this combines a shopping-trolley coin (euro size) and a clip to hold those tickets and your shoppinglist. It's to late to print it out now but I will do tomorrow.

The design and .stl you can find here: 123 design

Edited 1 time(s). Last edit at 08/15/2013 06:24PM by Wavetracer.

The design and .stl you can find here: 123 design

Edited 1 time(s). Last edit at 08/15/2013 06:24PM by Wavetracer.

|

Re: RepRap Magazine - Print to improve life quality August 15, 2013 06:52PM |

Registered: 10 years ago Posts: 28 |

I havnt finished my models to enter

Logic would dictate that the competition ends on the 25th a sunday and not the 15th a thursday. Plus ending on the 25 would mean they get exactly 1 month to judge the competition and print objects for the show maybe.

Also we have not had 7 entries yet for the seven seperate competition prizes so it would be a bad idea to end the competition now.

One last thing, Isnt the use of all those metal rods, metal ball bearings and electronics against the rules to make it out of plastic but be held togetther with bolts, snap fit or glue? ggaljoen is the only one who seems to be doing that as its all plastic and snapfits to the device.

I had an idea turned down because it contained a sheet of clear plastic and water so just sayin.

Edited 1 time(s). Last edit at 08/15/2013 06:54PM by stonefisher.

Logic would dictate that the competition ends on the 25th a sunday and not the 15th a thursday. Plus ending on the 25 would mean they get exactly 1 month to judge the competition and print objects for the show maybe.

Also we have not had 7 entries yet for the seven seperate competition prizes so it would be a bad idea to end the competition now.

One last thing, Isnt the use of all those metal rods, metal ball bearings and electronics against the rules to make it out of plastic but be held togetther with bolts, snap fit or glue? ggaljoen is the only one who seems to be doing that as its all plastic and snapfits to the device.

I had an idea turned down because it contained a sheet of clear plastic and water so just sayin.

Edited 1 time(s). Last edit at 08/15/2013 06:54PM by stonefisher.

|

Re: RepRap Magazine - Print to improve life quality August 15, 2013 08:03PM |

Registered: 10 years ago Posts: 4 |

|

Re: RepRap Magazine - Print to improve life quality August 17, 2013 07:19AM |

Registered: 11 years ago Posts: 66 |

|

Re: RepRap Magazine - Print to improve life quality August 25, 2013 10:42AM |

Registered: 10 years ago Posts: 7 |

So, this is my contribution.

Description:

A Clip to hold the overlap of a trouser belt in place.

For overlap belt thickness of 9.5mm

and a width of 35mm.

Instruction:

Just Print and wear

Links:

Link to Thingiveerse

Link to STL download

Nothin special.

But i didn't found a clip just for this specific purpose.

Edited 1 time(s). Last edit at 08/25/2013 10:44AM by UnasOne.

Cheers!

David

First 3D Printer: Velleman K8200/3Drag

Second 3D Printer: RRPro Huxley

Description:

A Clip to hold the overlap of a trouser belt in place.

For overlap belt thickness of 9.5mm

and a width of 35mm.

Instruction:

Just Print and wear

Links:

Link to Thingiveerse

Link to STL download

Nothin special.

But i didn't found a clip just for this specific purpose.

Edited 1 time(s). Last edit at 08/25/2013 10:44AM by UnasOne.

Cheers!

David

First 3D Printer: Velleman K8200/3Drag

Second 3D Printer: RRPro Huxley

|

Re: RepRap Magazine - Print to improve life quality August 25, 2013 03:32PM |

Registered: 11 years ago Posts: 10 |

Ok, since the death-line is today and not the 15th I've improved the design and uploaded it to Thingiverse. I'm still not completely pleased with the result so it's stays a work in progress but I think it is enough to show the idea. My post earlier can be neglected.

Description:

I always come home from the supermarket to find out I still got the deposit ticket from the empty bottles in my pocket. They have thereafter the tendency to stick on the fridge with a magnet for mostly a year and then bleached out to much in the sun. No money for me then.

So this combines a shopping-trolley coin (euro size) and a clip to hold those tickets and your shopping-list. As an extra it will hold a Airmiles card, a customer card from the supermarket where I usually buy groceries.

This design still needs a bit of work because some parts are to thin and I'm not pleased yet with the coin, which has to flip out, is attached to the clip. I will adapt the design later.

I've printed this prototype on a Printrbot LC with a resolution of 0.15 (the clip) and 0.10 (the coin).

Thingiverse

Stl part 1coinclip1.stl

stl part 2coinclip2.stl

Edited 1 time(s). Last edit at 08/25/2013 03:42PM by Wavetracer.

Description:

I always come home from the supermarket to find out I still got the deposit ticket from the empty bottles in my pocket. They have thereafter the tendency to stick on the fridge with a magnet for mostly a year and then bleached out to much in the sun. No money for me then.

So this combines a shopping-trolley coin (euro size) and a clip to hold those tickets and your shopping-list. As an extra it will hold a Airmiles card, a customer card from the supermarket where I usually buy groceries.

This design still needs a bit of work because some parts are to thin and I'm not pleased yet with the coin, which has to flip out, is attached to the clip. I will adapt the design later.

I've printed this prototype on a Printrbot LC with a resolution of 0.15 (the clip) and 0.10 (the coin).

Thingiverse

Stl part 1coinclip1.stl

stl part 2coinclip2.stl

Edited 1 time(s). Last edit at 08/25/2013 03:42PM by Wavetracer.

|

Re: RepRap Magazine - Print to improve life quality August 25, 2013 06:49PM |

Registered: 10 years ago Posts: 28 |

Heres my model,

Just panic typeing description and taking photoes.

Edit1: [www.thingiverse.com]

Edit2: The photo:

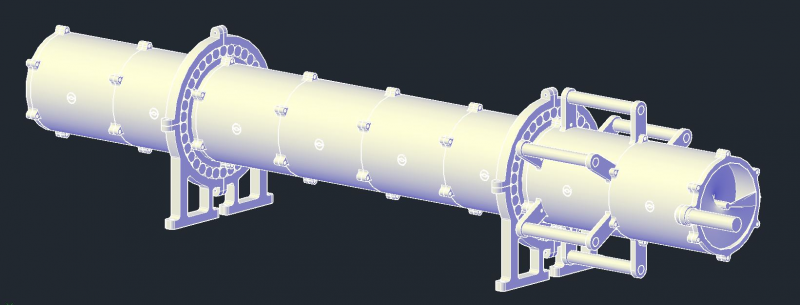

Edit3: Water is the most basic and most important thing for a good quality of life. You need to drink it, grow food with it, cook with it, wash with it, travel on it and there are so many activeties that use it. So idecided to make an all plastic (with some nuts and bolts) water transport device. This device can be used to move water out of rivers onto feilds, empty water out of containers and all sorts of usefull things.

This is a moduler Water Screw based on the Archimedes' screw. It has been changed to be built out of many parts allowing the length and design to be easily altered. The screw has been fixed to the inside of the tube so that water cannot flow backwards between the screw and the tube increasing its efficency. This does mean bearings have to be added to the supports to allow the tube and screw to turn.

This is designed to be built on a 3d printer with a build area of 200x200x200mm. It is recommended that bylon and ABS is used to make the model and isopropynol, M6 nuts and bolts are used to fix it together. A Wood screw is needed to fix the crank handle to the crank. This model can be easily scaled bigger or smaller though the crank and handles will need to be modifyed as they will get way to big or small fast. If you quarter the model reducing the print area needed to 100x100x100mm you can use M3 nuts and bolts to hold it together and it will be alot faster to print. On the negative side only a quature of the water will be moved per revolution.

Further info and files on thingiverse.

Edit4: I have no 3D printer so i cannot make a working model. As for proof of function search Archimedes' screw on youtube.

Edited 4 time(s). Last edit at 08/25/2013 08:29PM by stonefisher.

Just panic typeing description and taking photoes.

Edit1: [www.thingiverse.com]

Edit2: The photo:

Edit3: Water is the most basic and most important thing for a good quality of life. You need to drink it, grow food with it, cook with it, wash with it, travel on it and there are so many activeties that use it. So idecided to make an all plastic (with some nuts and bolts) water transport device. This device can be used to move water out of rivers onto feilds, empty water out of containers and all sorts of usefull things.

This is a moduler Water Screw based on the Archimedes' screw. It has been changed to be built out of many parts allowing the length and design to be easily altered. The screw has been fixed to the inside of the tube so that water cannot flow backwards between the screw and the tube increasing its efficency. This does mean bearings have to be added to the supports to allow the tube and screw to turn.

This is designed to be built on a 3d printer with a build area of 200x200x200mm. It is recommended that bylon and ABS is used to make the model and isopropynol, M6 nuts and bolts are used to fix it together. A Wood screw is needed to fix the crank handle to the crank. This model can be easily scaled bigger or smaller though the crank and handles will need to be modifyed as they will get way to big or small fast. If you quarter the model reducing the print area needed to 100x100x100mm you can use M3 nuts and bolts to hold it together and it will be alot faster to print. On the negative side only a quature of the water will be moved per revolution.

Further info and files on thingiverse.

Edit4: I have no 3D printer so i cannot make a working model. As for proof of function search Archimedes' screw on youtube.

Edited 4 time(s). Last edit at 08/25/2013 08:29PM by stonefisher.

|

Re: RepRap Magazine - Print to improve life quality August 25, 2013 11:21PM |

Registered: 10 years ago Posts: 4 |

Hi,

Hand cranked blower.

Photos, video, STL and OpenSCAD files:

[www.thingiverse.com]

No bearing, no threaded rod. M8 nuts and bolts.

Customisable for other size.

Benjamin.

Edited 1 time(s). Last edit at 08/26/2013 12:54AM by proto.user.

Hand cranked blower.

Photos, video, STL and OpenSCAD files:

[www.thingiverse.com]

No bearing, no threaded rod. M8 nuts and bolts.

Customisable for other size.

Benjamin.

Edited 1 time(s). Last edit at 08/26/2013 12:54AM by proto.user.

|

Re: RepRap Magazine - Print to improve life quality August 26, 2013 03:58PM |

Registered: 10 years ago Posts: 2 |

My entry... if I'm not too late:

A white cane for the blind and visually impared.

Stl's, OpenSCAD source and photos on Thingiverse: [www.thingiverse.com]

By: PuZZleDucK

A white cane for the blind and visually impared.

Stl's, OpenSCAD source and photos on Thingiverse: [www.thingiverse.com]

By: PuZZleDucK

|

Re: RepRap Magazine - Print to improve life quality September 05, 2013 07:44PM |

Registered: 10 years ago Posts: 4 |

Hello,

And sorry for my previous messages, I'm not at all comfortable at writing English, but I'd want to briefly explain the motivations behind my objects, I'm not happy with my first posts on RepRap forums.

Not so long time ago, we were not connected to mains electricity, with only one old solar panel, a regulator and a 12V car battery. It wasn't enough for: light bulb, computer and our first 3d printer, so we have built a basic alternator pedal generator (picture joined).

I know their energy consumption because I have sweated for it!

The documentation to build one came from:

[autonopedia.org]

First missions for our 3d printer were to help in the production of electricity: small water wheel, gears for vertical axis wind turbine (to replace wooden pulley).

The lack of electricity was for us a life quality limiting factor, I approached this contest with that in mind:

Electricity. Replace it, or produce it.

Benjamin.

And sorry for my previous messages, I'm not at all comfortable at writing English, but I'd want to briefly explain the motivations behind my objects, I'm not happy with my first posts on RepRap forums.

Not so long time ago, we were not connected to mains electricity, with only one old solar panel, a regulator and a 12V car battery. It wasn't enough for: light bulb, computer and our first 3d printer, so we have built a basic alternator pedal generator (picture joined).

I know their energy consumption because I have sweated for it!

The documentation to build one came from:

[autonopedia.org]

First missions for our 3d printer were to help in the production of electricity: small water wheel, gears for vertical axis wind turbine (to replace wooden pulley).

The lack of electricity was for us a life quality limiting factor, I approached this contest with that in mind:

Electricity. Replace it, or produce it.

Benjamin.

|

Re: RepRap Magazine - Print to improve life quality October 01, 2013 09:25AM |

Registered: 11 years ago Posts: 10 |

|

Re: RepRap Magazine - Print to improve life quality October 08, 2013 03:51PM |

Registered: 10 years ago Posts: 14 |

|

Re: RepRap Magazine - Print to improve life quality October 08, 2013 04:07PM |

Registered: 11 years ago Posts: 66 |

Hi Guys,

First of all our apologies for this exceptional gap of communication.

We were to announce the winner at the TCT Show, but the organization of the RepRap Community Hub took some very hard work and we decided to postpone the results of the competition to after the show, so we could have time to really look at the entries and make our decision.

So given this we have decided to announce the winners in the next issue of the magazine, and we are close to release.

Again we apologize for this small change of plans and hope everyone can understand the reason why we did it.

Cheers,

First of all our apologies for this exceptional gap of communication.

We were to announce the winner at the TCT Show, but the organization of the RepRap Community Hub took some very hard work and we decided to postpone the results of the competition to after the show, so we could have time to really look at the entries and make our decision.

So given this we have decided to announce the winners in the next issue of the magazine, and we are close to release.

Again we apologize for this small change of plans and hope everyone can understand the reason why we did it.

Cheers,

|

Re: RepRap Magazine - Print to improve life quality November 02, 2013 02:42AM |

Registered: 10 years ago Posts: 14 |

|

Re: RepRap Magazine - Print to improve life quality November 27, 2013 06:18PM |

Registered: 11 years ago Posts: 66 |

Hi Guys,

Sorry for the long silence and the late competition results, but here are they:

1º Proto.user

2º Roelofg

3º Wavetracer

4º ggaljoen

5º unasone

6º Stonefisher

7º puzzled duck

Know i need ask for each to send an email to editorial@reprapmagazine.com with the following info:

Full Name, Address, Contact Phone number and email.

Cheers, and tanks for the participating in the competition!

Sorry for the long silence and the late competition results, but here are they:

1º Proto.user

2º Roelofg

3º Wavetracer

4º ggaljoen

5º unasone

6º Stonefisher

7º puzzled duck

Know i need ask for each to send an email to editorial@reprapmagazine.com with the following info:

Full Name, Address, Contact Phone number and email.

Cheers, and tanks for the participating in the competition!

|

Re: RepRap Magazine - Print to improve life quality December 09, 2013 01:47PM |

Registered: 11 years ago Posts: 10 |

|

Re: RepRap Magazine - Print to improve life quality January 04, 2014 06:52PM |

Registered: 11 years ago Posts: 10 |

|

Re: RepRap Magazine - Print to improve life quality January 04, 2014 07:05PM |

Registered: 11 years ago Posts: 66 |

Hi,

Wavetracer: i did get your info and send it to the sponsor that confirmed he received the info.

I will try to get in touch to see how the delivery of all prizes is going and try to keep you all posted

The next number is on its close to be finished but some final works on the articles is still being done by some authors so we cannot give a final release date.

Cheers

Wavetracer: i did get your info and send it to the sponsor that confirmed he received the info.

I will try to get in touch to see how the delivery of all prizes is going and try to keep you all posted

The next number is on its close to be finished but some final works on the articles is still being done by some authors so we cannot give a final release date.

Cheers

|

Re: RepRap Magazine - Print to improve life quality January 05, 2014 05:45PM |

Registered: 10 years ago Posts: 2 |

|

Re: RepRap Magazine - Print to improve life quality January 15, 2014 02:50AM |

Registered: 10 years ago Posts: 14 |

|

Re: RepRap Magazine - Print to improve life quality February 03, 2014 07:22AM |

Registered: 11 years ago Posts: 10 |

|

Re: RepRap Magazine - Print to improve life quality February 14, 2014 01:55PM |

Registered: 11 years ago Posts: 10 |

|

Re: RepRap Magazine - Print to improve life quality February 14, 2014 05:43PM |

Registered: 10 years ago Posts: 28 |

Ah, I was wondering if anyone had got there prizes. I have not received a Faberdashery voucher yet. It also expires in less than a months time. It looks like I'm going to have to do a panic purchase.

I was thinking of getting a 100m coil of Aurora and 100m of Glowbug yellow. I couldn't resist there colour changing properties when I saw them.

The only real question is do I buy 1.75 or 3mm as I don't have a 3d printer yet. I want more plastic for my money which makes me want to get the 3mm but I want to be able to do fine prints which makes me want the 1.75mm filament ;(.

I wonder if there will be another chance to win a 3d printer in the new reprapmagazine?

I was thinking of getting a 100m coil of Aurora and 100m of Glowbug yellow. I couldn't resist there colour changing properties when I saw them.

The only real question is do I buy 1.75 or 3mm as I don't have a 3d printer yet. I want more plastic for my money which makes me want to get the 3mm but I want to be able to do fine prints which makes me want the 1.75mm filament ;(.

I wonder if there will be another chance to win a 3d printer in the new reprapmagazine?

|

Re: RepRap Magazine - Print to improve life quality March 17, 2014 08:31PM |

Registered: 10 years ago Posts: 28 |

|

Re: RepRap Magazine - Print to improve life quality April 04, 2014 04:41PM |

Registered: 10 years ago Posts: 14 |

Sorry, only registered users may post in this forum.